文章编号:1004-0609(2015)06-1655-07

铜银合金导线的显微组织与性能

文 姗1,常丽丽1,尚兴军2,李胜利1

(1. 山东大学 材料科学与工程学院,济南 250061;

2. 济南宝世达实业发展有限公司,济南 250061)

摘 要:利用光学显微镜和X射线衍射仪表征TAg0.1铜银合金的显微组织,采用显微硬度计、电子万能试验机、电导率测量仪等设备研究TAg0.1合金的力学性能及电学性能,系统分析铜银合金导线成型工艺过程中挤压、拉拔及退火等工序对TAg0.1合金显微组织、力学性能和电学性能的影响。结果表明:拉拔处理后TAg0.1合金的强度和硬度较挤压态提高,但伸长率和电导率降低。经退火处理后,TAg0.1合金的强度和硬度值均减小,伸长率和电导率均增大。经挤压、拉拔、中间退火、拉拔的工艺后,获得的TAg0.1空心导线硬度值为129.7 HV0.05、抗拉强度为400 MPa、导电率为99.5% IACS。

关键词:铜银合金;显微组织;力学性能;电学性能

中图分类号:TG146.1;TG359;TG379 文献标志码:A

Microstructure and properties of Cu-Ag alloy wire

WEN Shan1, CHANG Li-li1, SHANG Xing-jun2, LI Sheng-li1

(1. School of Material Science and Engineering, Shandong University, Jinan 250061, China;

2. Jinan Baoshida Industrial Development Co., Ltd, Jinan 250061, China)

Abstract: The microstructures of TAg0.1 alloys were characterized by optical microscopy and X-ray diffraction. The mechanical and electrical properties of TAg0.1 alloys were studied by microhardness tester, electronic universal testing machine and conductivity indicator. The influence of producing procedures, such as extraction, drawing and annealing, on the microstructure, mechanical properties and electrical properties of TAg0.1 alloys in the molding process of Cu-Ag alloy wire was analyzed systematically. The results indicate that the strength and hardness of TAg0.1 alloys increase after the drawing process, while the elongation and conductivity decrease. The elongation and conductivity of TAg0.1 alloys increase after annealing process, while the strength and hardness decrease. The TAg0.1 alloys were gotten after extraction, drawing, annealing and drawing processes. The hardness of TAg0.1 alloys is 129.7 HV0.05, the tensile strength is 400 MPa, and the electrical conductivity is 99.5% IACS.

Key words: Cu-Ag alloy; microstructure; mechanical property; electrical property

空心铜导线是制造大型水冷式发电机组定子绕组线的主要材料,具有较高的导电率、良好的力学性能和密封性,并且有一定的水流量[1]。由于纯铜的抗软化温度低、耐热性能差、强度低,特别是高温强度低,其综合性能已不能满足科学技术日益发展对材料的特殊要求。以无氧铜为基体,通过加入微量元素所获得的新型铜合金,在导电率下降很少的情况下硬度、强度和软化温度均大幅提高,因此,该新型铜合金是当前铜合金研究的主要研究方向之一。目前,这一领域的工作主要集中在材料的应用和重点元素含量大于0.1%(质量分数)的铜合金的研究方面,而对于极微量元素(元素含量小于0.1%)对无氧铜性能的影响,仍有许多问题急需深入研究[2-5]。

铜中加入合金元素,溶质原子溶入晶格后会引起铜晶体点阵畸变,形成应力场,该应力场与位错周围的弹性应力场交互作用,使溶质原子移向位错附近,在位错周围形成溶质原子的偏聚,即“科垂尔气团”,结果造成位错运动时,一方面要克服“气团”的钉扎作用,另一方面又要克服溶质原子对位错运动的摩擦阻力,从而产生固溶强化。与此同时,晶体中畸变的晶格点阵对电子的散射作用也相应加剧。因此,固溶强化对铜的导电性和强度的效应是矛盾的。

在影响铜导电率的各元素中,银对铜导电率的影响最小。铜银合金是典型的固溶强化型合金,在共晶温度(779 ℃)时,银在铜中的溶解度可达8%。银分布在固溶体中, 产生显著的固溶强化效应,从而提高了铜的强度和硬度。一般来说,在铜中加入合金元素,溶质原子溶入晶格引起晶体点阵畸变,这种畸变的晶格点阵对运动电子的散射作用也相应加剧。因此,固溶强化对铜的导电性和强度的效应是矛盾的。但银与可固溶于铜的其他元素不同,当含银量少时,铜的电导率和热导率的下降幅度较小,银的添加对铜合金塑性的影响也甚微,同时,银的添加能够显著提高铜的再结晶温度、蠕变强度和抗高温热低周疲劳[6]。因此,随着工业的发展和对材料性能要求的不断提高,采用铜银合金代替纯铜空心导线成为当前趋势[7-8]。

然而,在铜银合金中,高强度通常意味着较小的晶粒、大量的晶界、晶体缺陷及夹杂或第二相,而所有这些都会破坏晶格的对称性,从而造成电子的散射,降低铜银合金的电导率[9]。针对上述问题,本文作者以银含量为0.08%~0.12%(质量分数)的TAg0.1铜银合金为研究对象,研究了不同成型工艺过程中TAg0.1合金的显微组织与性能。

1 实验

将阴极铜板(纯度大于99.9935%(质量分数),银含量为0.08%~0.12%)放入1.5 t半连续熔炼炉中进行熔炼。熔炼获得的TAg0.1合金铸锭经挤压、拉拔、退火、拉拔的工艺制备空心导线,其中挤压工序在1800 t卧式双动水封式挤压机上进行,拉拔工艺在液压拉拔机进行,中间退火工艺则在卧式退火炉内进行,在炉内通入氮气作为保护气氛。

TAg0.1铜银合金试样经机械研磨和机械抛光后,以氯化铁盐酸水溶液为金相腐蚀剂进行腐蚀,采用Nikon Epiphot300金相显微镜观察金相显微组织;采用DMAX-2500X射线衍射仪获得试样的XRD谱;在HV-1000型数显显微硬度计上进行显微硬度测量,载荷为0.05 kg,加载时间为10 s,每个试样测量次数不少于4次;在WDW-200E电子万能试验机上进行拉伸试验,除挤压样品外,其他工序均需对沿着拉拔方向(即0°)、垂直于拉拔方向(即90°)以及与拉拔方向呈45°的样品进行拉伸测试;采用JSM-6610LA型扫描电子显微镜观察拉伸断口形貌;在D60K金属电导率测量仪上进行电导率测量,每个试样测量次数不少于3次。

2 结果与讨论

2.1 显微组织结构分析

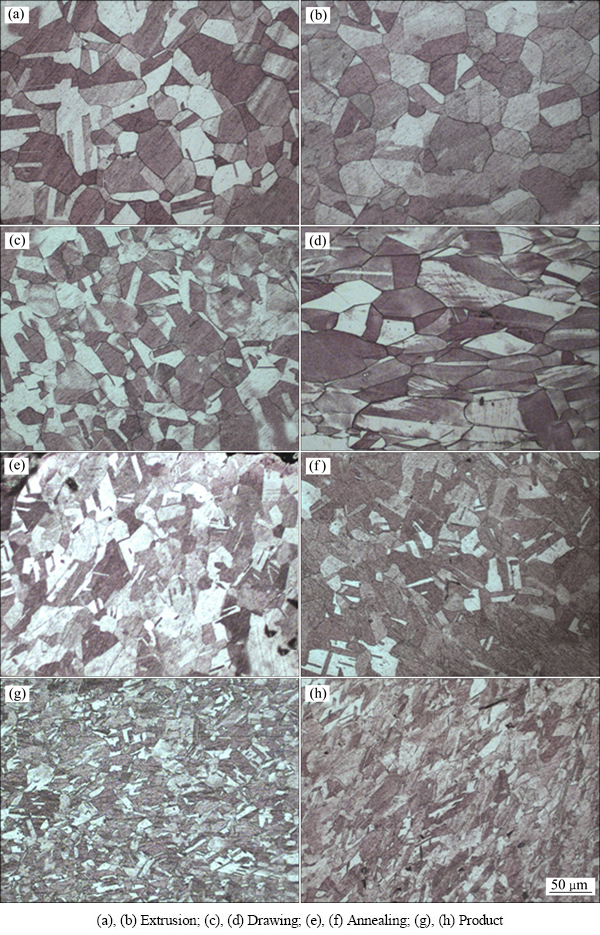

图1所示为经挤压、拉拔、退火等工艺处理后TAg0.1铜银合金横截面和纵剖面的金相显微组织。由图1(a)和(b)可以看出,挤压态TAg0.1合金的显微组织为等轴晶粒,表面与截面的晶粒大小基本相同,平均晶粒尺寸为19.65 μm。经过拉拔变形后,等轴晶粒被拉长(见图1(c)和(d)),呈椭球状,平均晶粒尺寸减小为16.69 μm。拉拔处理后进行再结晶退火,TAg0.1合金内部发生回复和再结晶,形成均匀的等轴晶组织(见图1(f)),平均晶粒尺寸相比形变态的减小,约为14.75 μm。值得注意的是,在退火后的TAg0.1合金内部观察到大量的退火孪晶[10](见图1(e))。退火孪晶的形变过程如下:相邻亚晶以凸出机制逐渐吞并形变孪晶,孪晶板条以合并机制逐渐减少板条数量而使板条扩宽。退火孪晶形成于回复阶段,是大角度界面迁移的结果[11]。退火后经过一道次拉拔得到成品试样(见图1(g)),与退火试样相比,成品样品的平均晶粒尺寸明显减小(见图1(h)),约为12.95 μm。

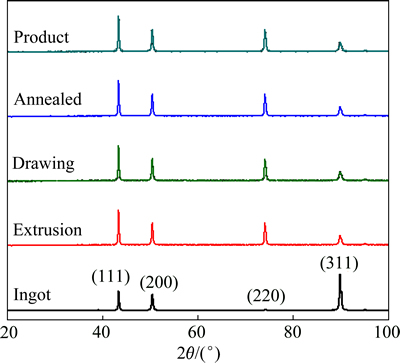

图2所示为熔铸、挤压、拉拔、退火后及成品样品的XRD谱。从图2中可以看出,TAg0.1铜银合金经各道工序处理后,均为单相α-Cu,未检测到其他析出相。在各工序获得的TAg0.1合金样品的XRD谱中检测到衍射峰为铜的(111)、(200)、(220)和(311)晶面衍射峰,但XRD峰的相对强度有所不同。从图2可以看出,铸锭样在经过挤压、拉拔等变形处理后,(220)与(111)晶面的衍射峰强度明显增强,(311)晶面的衍射峰强度减弱。

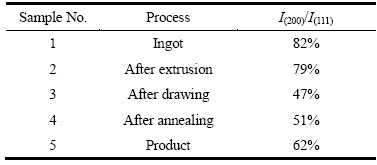

表1所列为晶面(111)与(200)的峰强度比值随各工序的变化情况。由表1可知,熔铸工序中铸锭的强度比值最大,为82%。经过挤压、拉拔变形后,强度比值均不同程度的降低,而TAg0.1合金经过退火与一道次的拉拔后,(200)与(111)晶面的峰强度比值依次增大,但是与铸锭相比,其他工序的峰强度比值均有不同程度的下降。晶面相对强度的变化表明铜银合金经塑性变形后产生弱的纤维织构[12]。

图1 铜银合金各道工序试样横截面和纵剖面显微组织

Fig. 1 Microstructures of longitudinal((a), (c), (e), (g)) and cross((b), (d), (f), (h)) section of Cu-Ag alloys at different processes

图2 各道工序铜银合金的XRD谱

Fig. 2 XRD patterns of Cu-Ag alloy at different processes

表1 不同工序铜银合金的(200)晶面峰强度(I(200))与(111)晶面强度(I(111) )的比值

Table 1 Intensity ratio of (200) crystal plane and (111) crystal plane of Cu-Ag alloys at different processes

2.2 力学性能分析

2.2.1 硬度测试

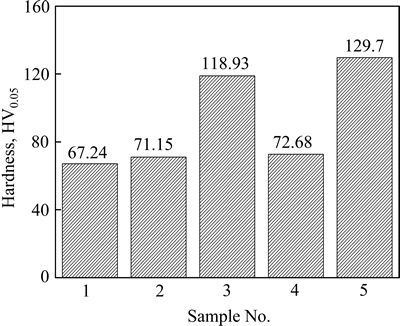

图3所示为不同生产工序TAg0.1铜银合金样品的显微硬度。由图3可知,经过挤压变形后,显微硬度由铸态的67.24 HV0.05变为挤压态的71.15 HV0.05,略有增加;经过两道次的拉拔之后,显微硬度有明显的增大,为118.93 HV0.05,提高幅度约为67%;而在再结晶退火后硬度降低到72.68 HV0.05,成品的硬度值最大,为129.7 HV0.05。从图3可以看出,拉拔后TAg0.1铜银合金的硬度增加较大,这是由于在冷变形过程中,TAg0.1铜银合金以滑移为主要变形方式,随着变形量的增加,出现位错的缠结,位错密度增加,位错运动的阻力增大,从而产生加工硬化,使铜银合金的硬度大幅度提高[13]。合金经退火后硬度和强度均有下降[14-15],是因为在退火过程中发生回复和再结晶,塑性变形产生的加工硬化得以消除。

2.2.2 拉伸试验

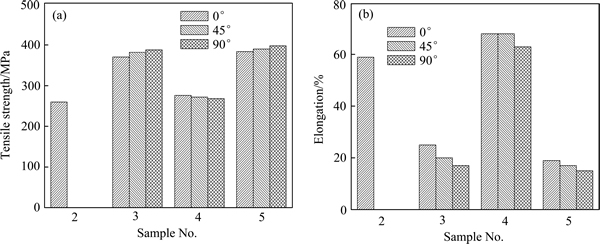

图4所示为TAg0.1铜银合金试样经过挤压、拉拔、退火后,其抗拉强度和伸长率随加工工序的变化情况(挤压样品由于受到挤压模具、挤压成型形状尺寸等限制,只能对0°方向的试样进行拉伸测试)。从图4可以看出,由于塑性变形过程中产生加工硬化,经拉拔处理后,TAg0.1合金的抗拉强度显著增大。经退火处理后,样品的抗拉强度降低,再次拉拔变形后,抗拉强度大幅增加,达到最大值。对于同一工序,拉伸方向不同时抗拉强度也不尽相同,经拉拔处理后的TAg0.1铜银合金试样,沿0°、45°、90°方向试样的抗拉强度依次增大,而处于退火态的合金沿0°、45°、90°方向试样的抗拉强度依次略有降低。由XRD结果分析可知,TAg0.1合金退火后,各向异性减弱,因此,退火态试样沿不同方向的抗拉强度相比其他工序试样的变化微小,即退火后TAg0.1合金各向异性减弱。

图3 不同铜银合金样品的显微硬度

Fig. 3 Microhardness of different Cu-Ag alloy samples

由图4中伸长率的变化可知,TAg0.1铜银合金经挤压变形后,伸长率达到59%,而经拉拔处理后,伸长率降低,这是由于拉拔过程中产生加工硬化,使强度和硬度升高,塑性降低;经再结晶退火后,合金的伸长率达到最大值,为68%,表明退火态的铜银合金塑性优于其他工序的,而成品的最大伸长率为19%,这与强度和硬度的变化结果是相符的。对于同一工序,沿不同方向的伸长率也略有差别,拉拔态的合金伸长率沿0°、45°、90°的方向依次降低,而退火态的合金伸长率沿0°和45°保持不变,只有沿90°方向的伸长率略有下降,这是由于发生退火后晶体的各向异性减弱。材料的各向异性主要源于其晶粒形貌、加工过程中产生的晶体学织构和时效过程中析出片状相等的交互作用。若材料中具有拉长的非等轴晶粒,对于不同方位的试样,外加应力引起的晶内最大切应力的方向与晶界的方向之间的夹角不同,从而在宏观上造成材料沿不同方向的变形程度存在差异,引发各向异性[16-17]。

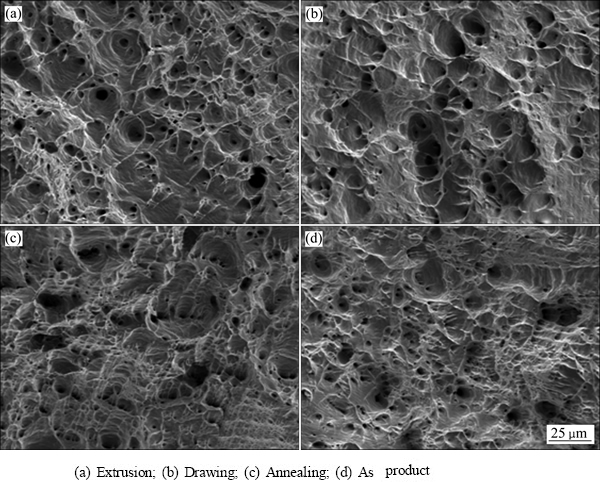

图5所示为TAg0.1铜银合金经挤压、拉拔、退火等工艺处理后试样的断口形貌。从图5中可以看出,拉伸试样断口均为韧性断裂断口,组织为韧窝组织[18-19],在韧窝中没有第二相粒子的存在。挤压样的韧窝较为密集,存在深且大的韧窝和浅而小韧窝;拉拔样相比挤压样的韧窝较为疏散,并且大韧窝所占比例较大;退火样和成品与挤压样和拉拔样相比,韧窝数量略有减少,小、浅韧窝则占主导,且断口较为平整。拉拔样相比挤压样,深韧窝比例增大,而韧窝深浅可以说明材料的塑性大小。韧窝深则基体发生强化,应变强化指数值大、塑性差、伸长率小[20-21],即拉拔处理后的铜银合金相比挤压态的试样,强度增大、塑性变差、伸长率减小。从图5(c)和(d)中可以看出,与挤压样及拉拔样相比,退火样及成品态铜银合金的韧窝较浅,说明铜银合金的退火样及成品试样的塑性较好、伸长率较大。综上所述,拉伸断口形貌特征与铜银合金强度、硬度和伸长率的变化规律相对应,能够准确反映铜银合金的力学性能。

图4 不同工序铜银合金经不同方向拔拉后的抗拉强度和伸长率

Fig. 4 Tensile strength(a) and elongation(b) of Cu-Ag alloys at different processes after drawing along different directions

图5 TAg0.1铜银合金各道工序试样的拉伸断口形貌

Fig. 5 Tensile fracture morphologies of TAg0.1 alloy at different processes

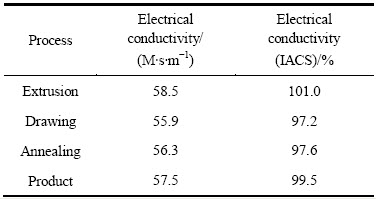

表2所列为TAg0.1铜银合金经挤压、拉拔以及退火处理后的电导率和导电率的变化值。TAg0.1合金的电导率随着挤压、拉拔、退后、拉拔的加工顺序先降低后增加。在经过冷拉拔处理后,TAg0.1合金的电导率和导电率均下降,分别为55.9 M·s/m和97.2%IACS。冷轧态合金中晶体缺陷较多、基体晶格畸变严重、位错密度较大,对电子运动具有阻碍作用,因此电导率下降;而在再结晶退火的条件下,异号位错相互抵消,位错滑移攀移能力增强,材料发生回复再结晶,晶体缺陷密度大大降低,对电子散射的作用减弱,因此,退火后合金的电导率小幅增加。

表2 不同工序铜银合金的电学性能参数

Table 2 Electrical property parameters of Cu-Ag alloys at different processes

3 结论

1) 含银量为0.1%的铜银合金(TAg0.1合金)挤压变形后,显微组织为等轴晶,截面与表面晶粒大小基本相同;挤压态TAg0.1铜银合金经拉拔后,晶粒被沿拉拔方向拉长,晶粒细化;与挤压态相比,拉拔后合金的抗拉强度和硬度均显著增大,而电导率略有下降。

2) 拉拔过程中的中间退火处理使TAg0.1铜银合金拉长晶粒经回复和再结晶过程形成无畸变等轴晶组织,合金的电导率升高,强度和硬度略有下降。TAg0.1铜银合金拉制成型获得的成品样品,晶粒明显细化,平均晶粒尺寸为12.95 μm,硬度值为129.7 HV0.05、抗拉强度为400 MPa、导电率为99.5% IACS,抗拉强度和导电率均较为良好,铜银合金成品具有优良的性能。

REFERENCES

[1] 吕殿泉. 空心导线的拉制技术[J]. 电线电缆, 1989(4): 53-54.

Dian-quan. The control technology of hollow conductor[J]. Electric Wire Eelectric Cable, 1989(4): 53-54.

Dian-quan. The control technology of hollow conductor[J]. Electric Wire Eelectric Cable, 1989(4): 53-54.

[2] 孙向明. 微量Ag对无氧铜性能的影响[J]. 机械工程材料, 2002, 26(2): 31-33.

SUN Xiang-ming. Effect of tract Ag on properties of oxygen free copper[J]. Materials for Mechanical Engineering, 2002, 26(2): 31-33.

[3] 孙向明, 吕松强. 高纯无氧铜银合金的研究[J]. 机械工程材料, 2000, 24(1): 29-31.

SUN Xiang-ming,  Song-qiang. Study on high-purity Cu-Ag alloy of oxygen free[J]. Materials for Mechanical Engineering, 2000, 24(1): 29-31.

Song-qiang. Study on high-purity Cu-Ag alloy of oxygen free[J]. Materials for Mechanical Engineering, 2000, 24(1): 29-31.

[4] 李来军. 连续定向凝固技术制备Cu-Ag、Cu-Cr合金线材及其组织和性能的研究[D]. 兰州: 兰州理工大学, 2004.

LI Lai-jun. Study on the microstructure and the mechanical electrical properties of copper alloy wires prepared by continuous directional solidification process[D]. Lanzhou: Lanzhou University of Technology, 2004.

[5] SAKAI Y, INOUE K, MAEDA H. New high-strength, high-conductivity Cu-Ag alloy sheets[J]. Acta Metal Mater, 1995, 43(4): 1517-1522.

[6] 肖世玲. Cu-Ag-Zr合金组织与性能[D]. 长沙: 中南大学, 2004.

XIAO Shi-ling. Cu-Ag-Zr alloy microstructure and properties[D]. Changsha: Central South University, 2004.

[7] 于朝清, 秦秀芳, 刘安利. 无氧铜的制备及电子铜的发展趋势[J]. 电工材料, 2006, 1: 10-13.

YU Chao-qing, QIN Xiu-fang, LIU An-li. Preparation of oxygen-free copper and developing trend of electron copper[J]. Electric Material, 2006, 1: 10-13.

[8] 程 鸣. 中国高端电子铜带技术发展战略研讨[J]. 中国高新技术企业, 2012, 32: 3-4.

CHENG Ming. Research of Chinese high-end electric copper strip technology development strategy[J]. Chinese High-tech Enterprises, 2012, 32: 3-4.

[9] 王英民, 毛大立. 形变纤维增强高强度高导电率的Cu-Ag合金[J]. 稀有金属材料与工程, 2001, 30(4): 295-298.

WANG Ying-min, MAO Da-li. Deformed fiber strengthened high-strength and high-conductivity alloy[J]. Rare Metal Materials and Engineering, 2001, 30(4): 295-298.

[10] 吴永福, 刘新华, 谢建新. 退火温度对连铸-连轧成形铜包铝复合扁排组织与性能的影响[J]. 中国有色金属学报, 2014, 24(1): 189-192.

WU Yong-fu, LIU Xin-hua, XIE Jian-xin. Effect of annealing temperature on texture and properties of copper cladding aluminum flat bar fabricated by continuous casting and subsequent rolling technology[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 189-192.

[11] 杨 钢, 孙利军, 张丽娜, 王立民, 王 昌. 形变孪晶的消失与退火孪晶的形成机制[J]. 钢铁研究学报, 2009, 21(2): 39-43.

YANG Gang, SUN Li-jun, ZHANG Li-na, WANG Li-min, WANG Chang. Mechanical twin disappear and the formation mechanism of annealing twin[J]. Journal of Iron and Steel Research, 2009, 21(2): 39-43.

[12] 蒋 琼. 两种铸态镁合金的深冷处理研究[D]. 长沙: 湖南大学, 2010.

JIANG Qiong. Effect of cryogenic treatment on two kinds of as-cast magnesium alloys[D]. Changsha: Hunan University, 2010.

[13] 王露娟, 宋克兴, 王 青, 高安江, 张彦敏. 拉拔变形对不同直径纯铜线材组织性能的影响[J]. 河南科技大学学报(自然科学版), 2013, 34(3): 16-17.

WANG Lu-juan, SONG Ke-xing, WANG Qing, GAO An-jiang, ZHANG Yan-min. Effects of drawing on microstructures and properties of pure copper wires with different diameters[J]. Journal of Henan University of Science and Technology (Natural Science), 2013, 34(3): 16-17.

[14] 罗 阳, 田文怀, 石高锋, 成生伟. 退火对高速电铸镍组织和塑性的影响[J]. 材料工程, 2014(4): 41-44.

LUO Yang, TIAN Wen-huai, SHI Gao-feng, CHENG Sheng-wei. Influence of annealing treatment on microstructure and plasticity of high-speed electroformed nickel[J]. Journal of Materials Engineering, 2014(4): 41-44.

[15] 周善佑. 铜合金的热处理[J]. 上海金属1985, 6(2): 51-52.

ZHOU Shan-you. Copper alloy heat treatment[J]. Journal of Shanghai Metal, 1985, 6(2): 51-52.

[16] RIOJA R J. Fabrication methods to manufacture isotropic Al-Li alloys and products for space and aerospace applications[J]. Materials Science and Engineering A, 1998, 257(1): 100-107.

[17] 程 彬, 郑子椎, 范春平, 钟继发, 韩 烨, 孙景峰. 时效制度对新型Al-Cu-Li合金组织与性能的影响[J]. 中国有色金属学报, 2014, 24(4): 926-933.

CHENG Bin, ZHENG Zi-zhui, FAN Chun-ping, ZHONG Ji-fa, HAN Ye, SUN Jing-feng. Effect of aging treatments on microstructures and properties of new Al-Cu-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4): 926-933.

[18] 林高用, 雷玉霞, 郭道强, 许秀芝, 张宗鹏. 变形Al-Si-Cu-Mg合金热处理强化及其组织特征[J]. 中国有色金属学报, 2014, 24(3): 588-590.

LIN Gao-yong, LEI Yu-xia, GUO Dao-qiang, XU Xiu-zhi, ZHANG Zong-peng. Heat treatment strengthening and microstructure characteristics of wrought Al-Si-Cu-Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 588-590.

[19] 崔约贤. 金属断口分析[M]. 哈尔滨: 哈尔滨工业大学出版社, 1998.

CUI Yue-xian. Metal fracture analysis[M]. Harbin: Harbin Industrial University Press, 1998.

[20] 李 杰, 王 丽, 李 志, 张景海, 颜鸣皋. 热处理对Co-Ni超高强度钢冲击断口的影响[J]. 航空材料学报, 2008, 28(1): 36-38.

LI Jie, WANG Li, LI Zhi, ZHANG Jing-hai, YAN Ming-gao. Effect of heat-treatment on impact fracture surface of high Co-Ni UI trahigh strength steel[J]. Journal of Areonautical Materials, 2008, 28(1): 36-38.

[21] 陈玉柏, 范景莲, 刘 涛, 成会朝, 田家敏. 细晶钼铜合金的制备[J]. 中国有色金属学报, 2008, 18(6): 1042-1043.

CHEN Yu-bai, FAN Jing-lian, LIU Tao, CHENG Hui-chao, TIAN Jia-min. Fabrication of fine-grained Mo-Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(6): 1042-1043.

(编辑 王 超)

基金项目:山东省自主创新专项资金支持项目(2013CXB60201);山东省博士基金资助项目(BS2013CL034)

收稿日期:2014-10-20;修订日期:2015-03-13

通信作者:李胜利,教授,博士;电话:0531-88395620;E-mail: lishengli@sdu.edu.cn