DOI:10.19476/j.ysxb.1004.0609.2018.10.06

时效对固溶+冷轧7075铝合金力学性能和显微组织的影响

李 海1, 2,陈 鹏1,王芝秀1, 2,郑子樵3

(1. 常州大学 材料科学与工程学院,常州 213164;

2. 常州大学 江苏省材料表面科学与技术重点实验室,常州 213164;

3. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用拉伸测试、金相显微镜、XRD及TEM等方法,研究时效处理对经历固溶+冷轧的7075铝合金显微组织和力学性能的影响规律。力学性能测试表明:80、100、120 ℃时效均能显著提高合金强度并保持一定塑性。(475 ℃, 1 h固溶处理)+80%压下量冷轧+(80 ℃, 48 h)时效合金的抗拉强度、屈服强度和伸长率分别为773 MPa、720 MPa和5%。显微组织分析表明:相较于冷轧合金,时效合金强度的提高源于冷轧加工硬化(高的位错密度、高的轧制织构体积分数及细化的晶粒尺寸)和析出强化的共同作用;时效合金伸长率的改善与位错回复程度和析出相特征同时相关。此外,根据时效析出和位错回复特征,分析了时效过程中合金强度和伸长率的变化规律。

关键词:7075铝合金;形变热处理;显微组织;力学性能

文章编号:1004-0609(2018)-10-1999-10 中图分类号:TG146.2 文献标志码:A

时效硬化7000系Al-Zn-Mg-Cu合金具有低密度、高强度、高韧性以及良好的耐蚀性和塑性变形性能,广泛应用于航空航天、轨道交通、军工装备等领域[1-2]。通常情况下,时效硬化铝合金强度主要来源于纳米级析出相的强化作用。因此,增大元素含量能够增加析出相数量,从而提高合金强度[3-5],然而,溶解度极限使得增大合金元素含量只能在有限范围内进行,也就是说,通过析出强化来提高合金强度是有限的。为了进一步提高金属材料强度,采用强塑性变形(Severe plastic deformation, SPD)方法将常规微米级晶粒尺寸细化至亚微米、甚至纳米级,从而大幅度提高合金强度,已经得到广泛研究并开发出多种实施方法[6-11],例如等径角挤(Equal channel angular pressing, ECAP)、高压扭转(High pressure torsion, HPT)、累积轧制(Accumulative roll bonding, ARB)、超低温轧制(Rolling at cryogenic temperature, Cryorolling)等。然而,SPD方法存在样品尺寸小、装备要求高、作业风险大、生产成本高等问题,迄今难以应用于铝合金工业化生产。

为了适应高性能铝合金板材工业化生产,一种基于常规固溶处理、冷轧及时效相结合的形变热处理方法已被开发出来。根据这种方法,李海等[12]研究表明,6061铝合金经(550 ℃, 1 h)固溶处理+(180 ℃, 2 h)欠时效+75%压下量冷轧+(180 ℃, 48 h)再时效,抗拉强度和屈服强度分别为560 MPa和542 MPa,伸长率为7%。顾媛等[13]研究表明,经(560 ℃, 30 min)固溶处理+24 h自然时效+80%压下量冷轧+(180 ℃, 1 h)时效,Al-0.75Mg-0.75Si-0.8Cu合金的抗拉强度为450 MPa,伸长率为7.1%。HUANG等[14]研究表明,2024铝合金经(500 ℃, 1 h)固溶处理+40%压下量冷 轧+(175 ℃, 7 h)时效,抗拉强度和屈服强度分别达到608 MPa和540 MPa,伸长率为7.8%。PANIGRAHI等[15]研究表明,经过(490 ℃, 6 h)固溶处理+应变量为2.3冷轧+(100 ℃, 35 h)时效,7075铝合金抗拉强度、屈服强度和伸长率分别为618 MPa、577 MPa和6%。上述研究结果表明,与SPD方法相比,通过常规固溶处理、冷轧及时效相结合,不仅大幅度提高时效硬化铝合金强度,还能保持一定伸长率;更为重要的是,这种形变热处理方法在现有生产条件下便可实施,具有良好的工业化应用前景。

与2000系和6000系铝合金相比,采用常规固溶处理、冷轧及时效相结合来提高7000系铝合金力学性能的研究仍相对较少[15]。为此,本文作者以7075铝合金为实验材料,研究后续时效处理对经历固溶处理及室温冷轧合金拉伸性能的影响规律,优化出最佳形变热处理工艺参数,并在显微组织分析基础上,进一步探讨合金强化与韧化机制。

1 实验

实验材料为5 mm厚的7075铝合金板材,化学成分为5.8 Zn,2.4 Mg,1.8 Cu,0.3 Mn,0.1 Cr,0.4 Si,0.5 Fe,0.1 Ti,余量Al(质量分数,%)。板材经475 ℃、1 h固溶处理(Solution treating,ST)和室温水淬,多道次冷轧(Cold-rolling,CR)至1 mm厚(总压下量为80%)。随后,冷轧板分别进行80、100、120 ℃人工时效(Artificial ageing,AA)。为了比较力学性能,部分淬火板材直接进行120 ℃、24 h峰值时效(Peak ageing,PA)。

采用电火花线切割技术,沿板材轧向加工出标距长35 mm、宽8 mm的板状试样,在WDT-30型电子试验机上进行拉伸性能测试,拉伸速率为2 mm/min。每种处理状态测试3个平行试样,并以平均值形式给出抗拉强度、屈服强度和伸长率。

截取拉伸试样夹持端,通过机械减薄至约100 μm厚,然后在-30 ℃左右的30% HNO3+70% CH3OH溶液(体积分数)中进行双喷电解减薄,制得透射电镜(Transmission electron microscopy,TEM)薄膜样品,电压约为12 V,电流约为80 mA。利用JEM-2100 型高分辨TEM进行组织观察,操作电压为200 kV。

利用Bruker D8型X射线衍射仪(X-ray radiation, XRD,Cu Kα)分析冷轧和时效试样的织构和位错密度,管电压40 kV,管电流40 mA。按Schulz背反射法扫描出{111}、{200}和{220} 3张不完整极图(χ=0°~80°,Φ=0°~360°),通过Bunge级数展开法获取取向分布函数(Orientation distribution function,ODF),然后,根据分解法估算出织构组分及体积分数[16]。此外,根据XRD峰的宽化程度,采用Williamson-Hall法线性拟合出晶格微应变ε和微晶直径d,按下式估算试样的位错密度 [17]:

[17]:

(1)

(1)

式中:b为纯铝Burgers矢量的大小,约0.286 nm。

2 实验结果

2.1 拉伸性能

7075铝合金经过475 ℃、1 h固溶处理和室温水淬,ST试样抗拉强度、屈服强度和伸长率分别为492 MPa、232 MPa和26.9%。ST试样进一步进行120 ℃、24 h时效,得到PA试样,合金抗拉强度、屈服强度分别大幅度提高到629 MPa和531 MPa,而伸长率降至12.4%。ST试样进行80%压下量冷轧变形,CR试样抗拉强度和屈服强度分别大幅度提高至714 MPa和677 MPa,而伸长率则急剧降至2.5%。

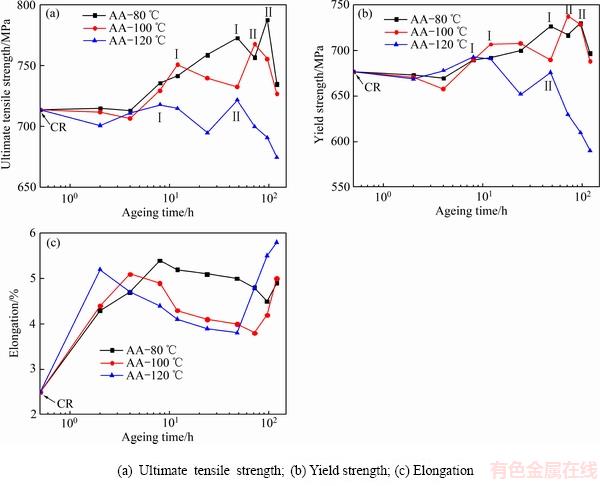

图1(a)和(b)所示分别为CR试样经80、100、120 ℃时效后,AA试样抗拉强度和屈服强度的变化规律。可以看出,3种温度时效过程中AA试样均存在2个强度峰。时效初期,AA试样强度略有降低;随后,随着时效时间的延长,强度先增加至峰值I后逐渐下降至最低值,然后,再次上升至峰值II后再次下降。时效温度的高低不改变强度峰数量,但影响达到强度峰的时间。例如,当CR试样进行100 ℃时效时,即AA试样经(100 ℃, 12 h)处理后达到强度峰Ⅰ,抗拉强度和屈服强度分别为751 MPa和707 MPa;AA试样经(100 ℃, 72 h)处理后达到强度峰Ⅱ,抗拉强度和屈服强度分别为768 MPa和738 MPa。与100 ℃时效相比,80 ℃时效合金峰值时效时间有所延长,120 ℃时效合金峰值时效时间则有所缩短。具体来说,AA试样经(80 ℃, 48 h)处理后达到强度峰Ⅰ,抗拉强度和屈服强度分别为773 MPa和720 MPa,AA试样经(80 ℃, 96 h)处理后达到强度峰Ⅱ,抗拉强度和屈服强度分别为788 MPa和735 MPa;相比之下,AA试样经(120 ℃, 8 h)处理后到达强度峰Ⅰ,抗拉强度和屈服强度分别为718 MPa和692 MPa;AA试样经(120 ℃, 48 h)处理后达到强度峰Ⅱ,抗拉强度和屈服强度分别为722 MPa和676 MPa。

图1(c)所示为CR试样经80、100、120 ℃时效后,AA试样伸长率的变化规律。可以看出,CR试样伸长率为2.5%,经100 ℃时效4 h,AA试样的伸长率增加至5.1%;继续进行时效处理AA试样伸长率逐渐下降;并在时效至72 h时,AA试样伸长率降至最低值3.8%;随后,延长时效时间,AA试样的伸长率再次上升。经80 ℃处理的AA试样和经120 ℃处理的AA试样的伸长率变化规律与经100 ℃处理的AA试样的基本相同。例如,AA试样经(80 ℃, 8 h)处理后伸长率增加至5.4%,而AA试样经(80 ℃, 96 h)处理后的伸长率降到最低值4.5%;AA试样经(120 ℃, 2 h)处理后伸长率增加至5.3%,而AA试样经(120 ℃, 48 h)处理后的伸长率降至最低值3.7%。由此可见,CR试样经80、100、120 ℃时效后,伸长率能够得到改善。总而言之,固溶+冷轧+时效相结合能显著提高7075铝合金强度并保持一定伸长率,例如,AA试样经(80 ℃, 48 h)处理后的抗拉强度、屈服强度和伸长率分别为773 MPa、720 MPa和5%。

2.2 金相组织

图1 固溶+冷轧7075铝合金经80、100和120 ℃时效后的拉伸性能

Fig. 1 Tensile properties of 7075 Al alloy aged at 80, 100 and 120 ℃ after being solution-treated at 475 ℃ for 1 h and cold-rolling by thickness reduction of 80%

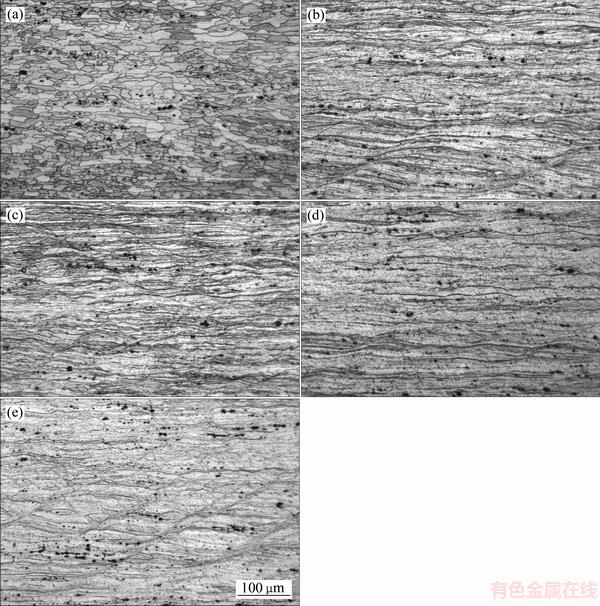

图2 不同处理状态合金的纵截面金相组织

Fig. 2 Optical images of longitudinal sections of 7075 Al alloy in processing conditions of PA(a), CR(b), AA-(80 ℃, 72 h)(c), AA-(100 ℃, 72 h)(d) and AA- (120 ℃, 72 h)(e)

图2所示为几种状态下试样如PA、CR、AA-(80 ℃, 72 h)、AA-(100 ℃, 72 h)和AA-(120 ℃, 72 h)状态试样的纵截面金相照片。从图2(a)可以看出,PA试样晶粒呈扁平状,平均晶粒尺寸约25 μm。此外,还可以观察到一些黑色结晶相颗粒,这些颗粒以Al7Cu2Fe相为主,同时含有少量Al2CuMg相。图2(b)表明,经80%压下量冷轧变形,CR试样晶粒沿轧向拉长,并出现波浪状的变形带;同时,板材厚度方向晶粒尺寸显著减小。此外,与PA相比,CR试样中结晶相颗粒的尺寸和分布没有明显变化。从图2(c)、(d)、(e)可以看出,AA-(80 ℃, 72 h)、AA-(100 ℃, 72 h)和AA- (120 ℃, 72 h)这3种状态试样晶粒形貌与CR试样的基本相同,晶粒仍然沿轧向拉长,变形带依然存在,由此表明,80、100、120 ℃时效过程中,AA试样未发生再结晶。

2.3 晶体织构

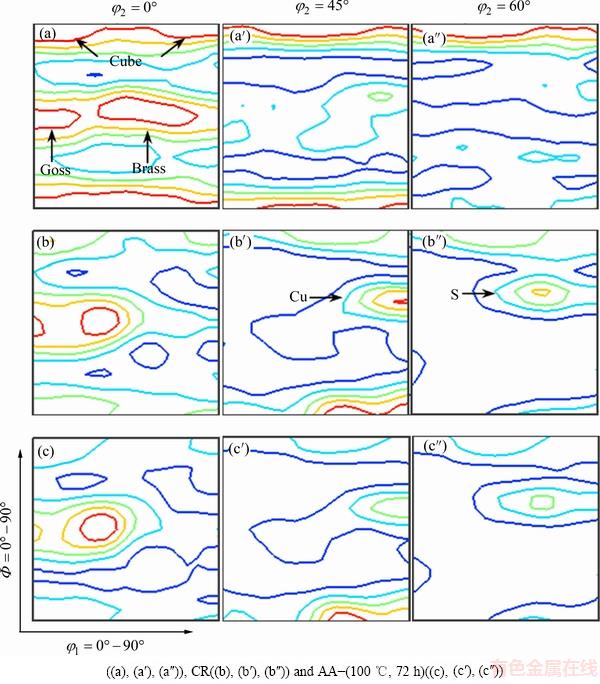

图3所示为ST、CR、AA-(100 ℃, 72 h)这3种状态试样φ2为0°、45°和60°的ODF图。表1所示为试样的织构组分和体积分数。从图3(a)和表1可以看出,ST试样中以Cube{001} 和Goss{011}

和Goss{011} 等再结晶织构为主,总体积分数约65%,此外,还存在一些Brass{011}

等再结晶织构为主,总体积分数约65%,此外,还存在一些Brass{011} 轧制织构,体积分数约31%。对于经过80%压下量冷轧变形的CR试样,再结晶织构的总体积分数大幅降低至约18%,相比之下,Cu{112}

轧制织构,体积分数约31%。对于经过80%压下量冷轧变形的CR试样,再结晶织构的总体积分数大幅降低至约18%,相比之下,Cu{112} 和S{123}

和S{123} 等轧制织构增强,总体积分数增加至约80%。图3(c)和表1进一步表明,AA-(100 ℃, 72 h)状态试样的织构类型和织构体积分数均与CR试样类似,这应该与时效温度较低、试样没有发生再结晶有关(见图2(d))。

等轧制织构增强,总体积分数增加至约80%。图3(c)和表1进一步表明,AA-(100 ℃, 72 h)状态试样的织构类型和织构体积分数均与CR试样类似,这应该与时效温度较低、试样没有发生再结晶有关(见图2(d))。

根据不同处理状态试样测得的织构类型、体积分数( )以及Taylor因子值(

)以及Taylor因子值( )(见表1),可以按混合法则估算出试样的平均Taylor因子值(

)(见表1),可以按混合法则估算出试样的平均Taylor因子值( )[18],也列于表1中。

)[18],也列于表1中。

(2)

(2)

由表1可以看出,ST试样的 值为2.7,相比之下,由于轧制织构体积分数增加,CR试样的

值为2.7,相比之下,由于轧制织构体积分数增加,CR试样的 值增大至3.19;此外,因为AA-(80 ℃, 72 h)、AA-(100 ℃,72 h)和AA-(120 ℃, 72 h)这几种状态的试样没有发生再结晶,其织构类型和体积分数均与CR试样的基本相同,因此,MA值也大致相等,分别为3.17、3.17和3.15。

值增大至3.19;此外,因为AA-(80 ℃, 72 h)、AA-(100 ℃,72 h)和AA-(120 ℃, 72 h)这几种状态的试样没有发生再结晶,其织构类型和体积分数均与CR试样的基本相同,因此,MA值也大致相等,分别为3.17、3.17和3.15。

图3 不同处理状态合金的ODF图

Fig. 3 ODF plots of 7075 Al alloy under processing conditions of ST

表1 不同处理状态试样的织构组分、体积分数及平均Taylor因子值

Table 1 Texture components, volume fractions and average Taylor factors (MA) of 7075 Al alloy under different processing conditions

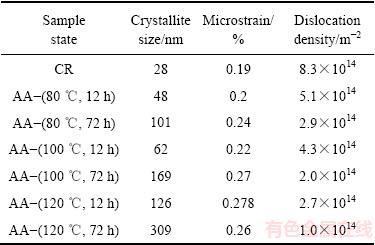

2.4 位错密度

根据不同处理状态试样的XRD峰的宽化程度,采用Williamson-Hall法线性拟合出晶格微应变(ε)和微晶尺寸(d),进而基于式(1)估算出位错密度( )。表2所示为CR试样和不同AA试样的位错密度。由于80%压下量冷轧变形,CR试样含有高位错密度,约8.3×1014 m-2。当CR试样进行80、100、120 ℃时效时,在相同时效温度下,随着时效时间延长,AA试样位错密度逐渐降低;当时效时间相同时,随着时效温度增加,位错密度也相应降低。例如,AA-(80 ℃, 12 h)、AA-(100 ℃, 12 h)和AA-(120 ℃, 12 h)这几种状态试样的位错密度分别为5.1×1014、4.3×1014、2.7×1014 m-2;当进一步时效至72 h,AA-(80 ℃, 72 h)、AA-(100 ℃, 72 h)和AA-(120 ℃, 72 h)这几种状态试样的位错密度分别降至2.9×1014、2.0×1014、1.0× 1014 m-2。

)。表2所示为CR试样和不同AA试样的位错密度。由于80%压下量冷轧变形,CR试样含有高位错密度,约8.3×1014 m-2。当CR试样进行80、100、120 ℃时效时,在相同时效温度下,随着时效时间延长,AA试样位错密度逐渐降低;当时效时间相同时,随着时效温度增加,位错密度也相应降低。例如,AA-(80 ℃, 12 h)、AA-(100 ℃, 12 h)和AA-(120 ℃, 12 h)这几种状态试样的位错密度分别为5.1×1014、4.3×1014、2.7×1014 m-2;当进一步时效至72 h,AA-(80 ℃, 72 h)、AA-(100 ℃, 72 h)和AA-(120 ℃, 72 h)这几种状态试样的位错密度分别降至2.9×1014、2.0×1014、1.0× 1014 m-2。

表2 不同处理状态合金的微晶尺寸、晶格微应变和位错密度

Table 2 Micro-crystallite sizes, micro-strains and estimated dislocation densities of CR and AA samples

2.5 TEM观察

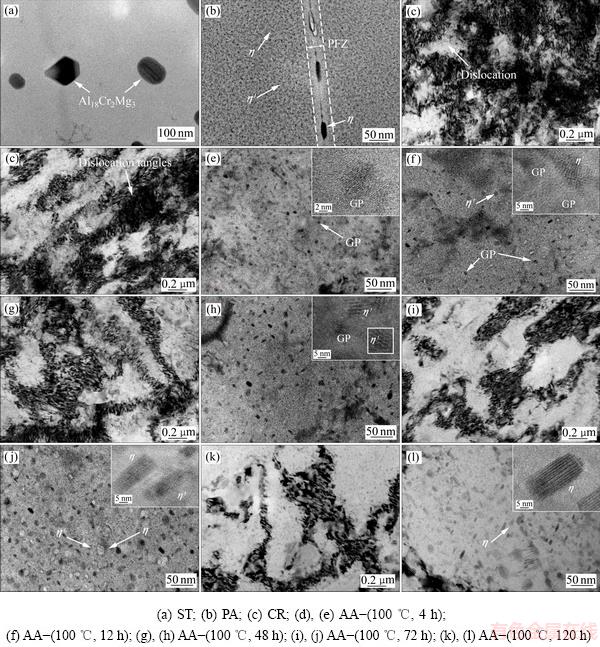

图4所示为不同处理状态试样的TEM像。经475 ℃、1 h固溶处理和室温水淬,ST试样中Zn、Mg、Cu等元素固溶于基体,形成过饱和固溶体。此外,能谱分析表明,ST试样还含有一些尺寸在50~200 nm的Al18Cr2Mg3弥散相(见图4(a))。当ST试样经过120 ℃、24 h时效,PA试样基体析出相以板条状n'相为主,同时含有少量盘状n相;此外,晶界上分布着粗大n相,晶界两侧分布着宽度约50 nm 的无析出区(Precipitation free zone, PFZ)(见图4(b))。ST试样经80%压下量冷轧变形,CR试样中位错密度急剧增加并缠结在一起,形成胞状结构(见图4(c))。此外,CR试样中难以观察到析出相,表明Zn、Mg、Cu等合金元素仍然处于过饱和状态。

当CR试样进行80、100、120 ℃时效时,一方面,AA试样中仍然含有高密度位错,例如AA-(100 ℃,4 h)、AA-(100 ℃, 48 h)、AA-(100 ℃, 72 h)和AA-(100 ℃, 120 h)这几种状态的合金(见图4(d)、(g)、(i)、(k)),但是,位错密度随着时效时间增加而降低(见表2),表明AA试样在时效过程中没有发生再结晶,但发生了回复过程;另一方面,AA试样中开始析出强化相,并且随着时效时间延长,析出相特征不断发生变化[19]。以100 ℃时效为例,AA-(100 ℃, 4 h)状态试样中基体析出相为GP区(见图4(e)),这点可从析出相与基体保持共格关系加以证实(见图4(e)中HRTEM像)。当时效至12 h,AA-(100 ℃, 12 h)状态试样基体析出相仍以GP区为主,但析出少量n'相(见图4(f));继续时效至48 h,AA-(100 ℃, 48 h)状态试样基体析出相主要是n'相和少量GP区(见图4(h));当时效至72 h,AA-(100 ℃, 72 h)状态试样基体析出相以n'相为主,同时含有少量n相(见图4(j));继续时效至120 h时,AA-(100 ℃, 120 h)状态试样基体析出相主要是n相(见图4(l)),并且尺寸大于AA-(100 ℃, 72 h)状态试样的n相(见图4(j)),表明析出相开始发生粗化,析出相间距增加、数密度降低。

图4 不同处理状态7075铝合金的TEM像

Fig. 4 TEM images for 7075 Al alloy under different processing conditions

3 分析与讨论

作为时效硬化型Al-Zn-Mg-Cu合金,7075合金经过475 ℃、1 h固溶处理和室温水淬,Zn、Mg、Cu等合金元素大部分已经固溶于ST试样中,形成过饱和固溶体(见图4(a)),此时合金强化机制主要来自于过饱和溶质原子的固溶强化,此时,阻碍位错滑移的障碍力低、容纳位错的晶格空间大,由此造成ST试样强度低、塑性高(见图1)。当过饱和Al-Zn-Mg-Cu合金进行人工时效时,析出序列通常为过饱和固溶体→GP区→n'→h[20],其中,半共格n'相的强化效果大于共格GP区和非共格n相[21]。图4(b)表明(120 ℃, 24 h)时效的PA试样基体析出大量n'相,强化效果显著,合金抗拉强度和屈服强度分别达到629 MPa和531 MPa。然而,n'相的大量析出同时造成基体中容纳位错的晶格空间减少,并且,低强度晶界PFZ的形成又使得合金易于发生沿晶断裂。因此,与ST试样相比,PA试样伸长率必然降低(12.4%)。当ST试样进行80%压下量冷轧,CR试样显微组织发生如下变化:位错密度大幅度增加并形成胞状结构(见图4(c));轧制织构显著增加、再结晶织构大幅减少(见图3),造成CR试样MA值提高至3.19(见表1);此外,CR试样厚度方向晶粒尺寸得到一定程度细化(见图2)。基于以上组织变化,与ST试样相比,CR试样抗拉强度和屈服强度分别大幅提高至714 MPa和677 MPa、伸长率降至2.5%,这主要源于冷轧变形造成的加工硬化效果。由图4(c)可知,CR试样中Zn、Mg、Cu等合金元素仍然处于过饱和状态。当其进行80、100、120 ℃时效,由于时效温度较低,AA试样发生回复而没有再结晶,因而仍含有高密度位错,同时,织构类型和体积分数几乎不变。不同与CR试样,AA试样基体析出了不同类型强化相。由此得出,AA试样强度来源于冷轧加工硬化和析出强化的共同作用。时效硬化型铝合金屈服强度可以采用下式综合表达[22]:

(3)

(3)

式中: 为晶界强化贡献,取决于晶粒尺寸 [23];MA为平均Taylor因子;

为晶界强化贡献,取决于晶粒尺寸 [23];MA为平均Taylor因子; 为纯Al的临界剪切屈服应力,约为10 MPa[24];

为纯Al的临界剪切屈服应力,约为10 MPa[24]; 为固溶强化贡献,取决于溶质原子种类和数量;

为固溶强化贡献,取决于溶质原子种类和数量; 为位错强化贡献,取决于位错密度;

为位错强化贡献,取决于位错密度; 为析出强化贡献,取决于析出相特征参数。由于AA试样处于时效状态,过饱和溶质原子已经析出,故

为析出强化贡献,取决于析出相特征参数。由于AA试样处于时效状态,过饱和溶质原子已经析出,故 可忽略不计,式(3)进而简化为

可忽略不计,式(3)进而简化为

(4)

(4)

以PA和AA-(100 ℃, 72 h)状态试样为例,加以说明形变时效提高合金强度的机理。AA-(100 ℃, 72 h)状态试样厚度方向晶粒尺寸比PA试样小(见图1),故前者晶界强化贡献( )大于后者;尽管时效发生位错回复,但AA-(100 ℃, 72 h)状态试样仍含有高位错密度(见表2),而PA试样只经历固溶处理和时效,位错密度低(见图4(b)),因此,AA-(100 ℃, 72 h)状态试样中位错强化贡献(

)大于后者;尽管时效发生位错回复,但AA-(100 ℃, 72 h)状态试样仍含有高位错密度(见表2),而PA试样只经历固溶处理和时效,位错密度低(见图4(b)),因此,AA-(100 ℃, 72 h)状态试样中位错强化贡献( )高于PA试样;由于AA-(100 ℃, 72 h)状态试样(见图4(j))和PA试样(见图4(b))均含有高密度析出相,可以认为二者析出强化贡献(

)高于PA试样;由于AA-(100 ℃, 72 h)状态试样(见图4(j))和PA试样(见图4(b))均含有高密度析出相,可以认为二者析出强化贡献( )相近;最后,因为120 ℃、24 h时效不足以改变晶粒形态和尺寸,因而PA试样应与ST试样具有相同的织构特征,二者MA值也应相同,但都低于轧制织构显著增加的AA-(100 ℃, 72 h)状态试样的MA值(3.17)。上述不同强化机制定性分析表明,PA试样强度主要取决于析出强化、较弱的晶界强化和较低的MA值,相比之下,AA-(100 ℃, 72 h)状态试样中除了析出强化外,还引入了较强的位错强化和晶界强化以及较高的MA值(即较强的冷轧加工硬化效果),因而,AA-(100 ℃, 72 h)状态试样能比PA试样获得更高的强度。

)相近;最后,因为120 ℃、24 h时效不足以改变晶粒形态和尺寸,因而PA试样应与ST试样具有相同的织构特征,二者MA值也应相同,但都低于轧制织构显著增加的AA-(100 ℃, 72 h)状态试样的MA值(3.17)。上述不同强化机制定性分析表明,PA试样强度主要取决于析出强化、较弱的晶界强化和较低的MA值,相比之下,AA-(100 ℃, 72 h)状态试样中除了析出强化外,还引入了较强的位错强化和晶界强化以及较高的MA值(即较强的冷轧加工硬化效果),因而,AA-(100 ℃, 72 h)状态试样能比PA试样获得更高的强度。

从图1(a)和(b)可以看出,80、100、120 ℃时效过程中AA试样均出现两个强度峰。以100 ℃时效为例,时效过程中,冷轧残余压应力发生松弛,使得早期AA-100 ℃状态试样强度略低于CR试样,例如AA-(100 ℃, 4 h)状态试样。鉴于AA-(100 ℃, 4 h)状态试样基体析出相为GP区(见图4(e)),而AA-(100 ℃, 12 h)状态试样中除了GP区,同时析出少量的n'相(见图4(f)),表明在此时效过程中GP区逐渐增加,因而试样强度也相应增加,并于时效12 h达到强度峰Ⅰ(见图1)。然而,继续时效,AA-100 ℃状态试样强度开始下降,这一现象可以如下解释:Al-Zn-Mg-Cu合金中GP区包括GPⅠ区和GPⅡ区[25],后续时效过程中,GPⅡ区可以直接转变为强化效果更佳的n'相,有利于与提高强度,而GPⅠ区发生溶解,使得其析出强化贡献降低;与此同时,过饱和空位的减少使得n'相析出速率降低,造成AA-(100 ℃, 12 h)状态试样在随后一段时效时间内,n'相增加造成的强化增量不足以弥补GP区减少产生的强化损失,导致AA-100 ℃状态试样强度逐渐减小,并在时效48 h时达到最低值。此后,继续时效,AA-100 ℃状态试样基体中大量析出n'相,其强化增量超过GP区强化损失,试样强度再次上升,并在时效72 h时达到强度峰Ⅱ;同时,由于n'相的强化效果高于GP区的,使得强度峰Ⅱ要高于强度峰Ⅰ。当AA-(100 ℃, 72 h)状态试样继续时效时,基体n'相不断转变为强化效果更弱的n相,并且,随时效时间延长,n相不断粗化、数密度减小,因此,AA-100 ℃状态试样强度再次降低,例如析出相以n相为主的AA-(100 ℃, 120 h)状态试样(见图4(l))。需要说明的是,时效过程中,AA-100 ℃状态试样的织构特征和晶粒尺寸基本不变,只有析出相特征和位错密度发生改变。然而,不断降低的位错密度只会使合金强度单调下降,因而,AA-100 ℃状态试样强度的双峰变化规律只能取决于析出相特征的不断改变。此外,AA-80 ℃状态和AA-120 ℃状态试样的强度变化规律与100 ℃时效态试样的基本相同(见图1),主要差异在于80 ℃时效出现强度峰的时间延长,而120 ℃时效出现强度峰的时间缩短,这是因为时效温度的高低影响了强化相的析出速率,而未改变析出序列。

与CR试样相比,AA试样伸长率也能够得到一定程度改善(见图1(c))。通常,金属材料的伸长率大小与其在拉伸变形过程中累积位错能力密切相关。由于80%压下量冷轧变形,CR试样已经引入高密度位错(见图4(c)),在随后拉伸变形过程中难以进一步累积位错,因而伸长率较低(2.5%)。在80、100、120 ℃时效过程中,一方面,回复过程造成位错密度随着时效时间延长而逐渐下降(见表2),为拉伸变形时存储位错重新提供了晶格空间,从而改善了试样累积位错能力;另一方面,基体时效析出特征也会影响试样累积位错能力。当基体析出相为共格GP区,其在拉伸变形过程中可以被滑移位错切割,因而不影响位错的累积效果;相比之下,当基体析出相为半共格n'相和非共格n相时,由于不能被滑移位错切割,二者占据的晶格空间不再为拉伸变形时累积位错提供位置。然而,当时效至析出相粗化阶段,析出相间距增加、数密度减少,基体中容纳位错的晶格空间再次增大,试样在拉伸变形时累积位错能力再次增强。综合来看,时效过程中,AA试样中位错密度不断下降,始终有利于提高伸长率,而析出相的影响则是不断变化的。以100 ℃时效为例,时效早期,AA-100 ℃状态试样基体析出相为GP区,例如AA-(100 ℃, 4 h)状态试样(见图4(e)),其对位错累积效果基本无不利影响,伸长率主要取决于位错密度的下降,因此,时效早期AA试样的伸长率逐渐增加,并于时效4 h达到最大值(5.1%)。继续时效,基体中析出n'相并逐渐增多,当其对位错累积效果的不利影响超过位错密度下降的有利影响时,AA-100 ℃状态试样伸长率逐渐下降,并在时效72 h达到最低值(3.8%)。进一步时效,当AA-100 ℃状态试样时效至基体析出相以n相为主并开始粗化时,试样伸长率将再次增加,例如AA-(100 ℃, 120 h)状态试样伸长率增加至5%。此外,80 ℃和120 ℃时效对AA试样伸长率的影响规律与100 ℃时效基本相同,只是达到峰值伸长率的时间有所增加或缩短。

4 结论

1) 采用固溶+冷轧+时效这种形变热处理工艺,能够显著提高时效硬化铝合金强度并保持一定塑性。例如,经(475 ℃, 1 h)固溶处理+80%压下量冷轧+(80 ℃, 48 h)时效,7075铝合金抗拉强度和屈服强度分别为773 MPa和720 MPa,伸长率为5%。

2) 合金强度的提高源于析出强化和冷轧加工硬化(高的位错密度、高的平均Taylor因子值和细化的晶粒尺寸)的共同作用,但强度变化规律主要取决于时效析出特征的改变。时效过程中,第一强度峰的出现主要归功于基体GP区,第二强度峰的出现主要源于基体n'相。

3) 合金伸长率与位错密度和析出相同时相关。时效过程中,位错密度不断下降,始终有利于提高伸长率,而析出相特征的改变对伸长率产生不同影响。

REFERENCES

[1] WILLIAMS J C, STARKE E A. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51: 5775–5799.

[2] 张纪帅, 陈志国, 任杰克, 陈继强, 魏 祥, 方 亮. 新型热机械处理对Al-Zn-Mg-Cu合金显微组织与性能的影响[J]. 中国有色金属学报, 2015, 25(4): 910–917.

ZHANG Ji-shuai, CHEN Zhi-guo, REN Jie-ke, CHEN Ji-qiang, WEI Xiang, FANG Liang. Effect of new thermomechanical treatment on microstructure and properties of Al-Zn-Mg-Cu aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(4): 910–917.

[3] BERGSMA S C, KASSNER M E, LI X, WALL M A. Strengthening in the aluminum alloy AA6069[J]. Materials Science and Engineering A, 1998, 254: 112–118.

[4] ZHANG H, LI L X, YUAN D, PENG D S. Hot deformation behavior of the new Al-Mg-Si-Cu aluminum alloy during compression at elevated temperature[J]. Materials Characterization, 2007, 58(2): 168–173.

[5] ZHAO Y L, YANG Z Q, ZHANG Z, SU G Y, MA X L. Double-peak age strengthening of cold-worked 2024 aluminum alloy[J]. Acta Materialia, 2013, 61: 1624–1638.

[6] SABIROV I, MURASHKIN M Y, VALIEV R Z. Nanostructured aluminum alloys produced by severe plastic deformation: New horizons in development[J]. Materials Science and Engineering A, 2013, 560: 1–24.

[7] CEPEDA C M, GARCIA J M, RUANO O A, CARRENO F. Mechanical properties at room temperature of an Al-Zn-Mg-Cu alloy processed by equal channel angular pressing[J]. Journal of Alloy and Compounds, 2011, 590: 8649–8656.

[8] SHA G, TUGCU K, LIAO X Z, TRIMBY P W, MURASHKIN M Y, VALIEV R Z, RINGER S P. Strength, grain refinement and solute nanostructures of an Al-Mg-Si alloy (AA6060) processed by high-pressure torsion[J]. Acta Materialia, 2014, 63: 169–179.

[9] JAYAGANTHAN R, BROKMEIER H G, SCHWEBKE B, PANIGRAHI S K. Microstructure and texture evolution in cryorolled Al 7075 alloy[J]. Journal of Alloy and Compounds, 2010, 496: 183–188.

[10] 张 兵, 袁守谦, 张西锋, 吕 爽, 王 超. 累积复合轧制对镁合金组织和力学性能的影响[J]. 中国有色金属学报, 2008, 18(8): 1607–1612.

ZHANG Bing, YUAN Shou-qian, ZHANG Xi-feng, Lü Shuang, WANG Chao. Effect of accumulative roll bonding on microstructures and mechanical properties of MB2 magnesium[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(8): 1607–1612.

[11] PESIN A, PUSTOVOYTOV D, LOKOTUNINA N. Modeling of the roll wear and material damage during high-ratio differential speed rolling of aluminum alloy 7075[J]. MATEC Web of Conferences, 2016, 80: 1–6.

[12] 李 海, 毛庆忠, 王芝秀, 苗芬芬, 方必军, 宋仁国, 郑子樵. 预时效+冷轧变形+再时效对6061铝合金微观组织和力学性能的影响[J]. 金属学报, 2014, 50(10): 1244–1252.

LI Hai, MAO Qing-zhong, WANG Zhi-xiu, MIAO Fen-fen, FANG Bi-jun, SONG Ren-guo, ZHEN Zi-qiao. Effect of the thermo-mechanical treatment of pre-ageing, cold-rolling and re–ageing on microstructures and mechanical properties on 6061 Al alloy[J]. Acta Metallurgica Sinica, 2014, 50(10): 1244–1252.

[13] 顾 媛, 陈江华, 刘春辉, 朱东晖, 刘力梅, 陶冠辉. 预变形对Al-Mg-Si-Cu合金时效硬化和显微结构的影响[J]. 金属学报, 2015, 51(11): 1400–1406.

GU Yuan, CHEN Jiang-hua, LIU Chun-hui, ZHU Dong-hui, LIU Li-mei, TAO Guan-hui. Effect of pre-deformation on age-hardening and microstructure in Al-Mg-Si-Cu alloy[J]. Acta Metallurgica Sinica, 2015, 51(11): 1400–1406.

[14] HUANG Y J, CHEN Z G, ZHENG Z Q. A conventional thermo-mechanical process of Al-Cu-Mg alloy for increasing ductility while maintaining high strength[J], Scripta Materials, 2010, 64(5): 382–385.

[15] PANIGRAHI S K, JAYAGANTHAN R. Effect of ageing on microstructure and mechanical properties of bulk, cryorolled, and room temperature rolled Al 7075 alloy[J]. Journal of Alloy and Compounds, 2011, 509: 9609–9616.

[16] TANG J G, ZHANG X M, DENG Y L, DU Y X, CHEN Z Y. Texture decomposition with particle swarm optimization method[J]. Computational Materials Science, 2006, 38: 395–399.

[17] ZHAO Y H, LIAO X Z, JIN Z, VALIEV R Z, ZHU Y T. Microstructures and mechanical properties of ultra fine grained 7075 Al alloy processed by ECAP and their evolutions during annealing[J]. Acta Materialia, 2004, 52: 4589–4599.

[18] LI H, XU W, WANG Z X, FANG B J, SONG R G, ZHENG Z Q. Effects of re-ageing treatment on microstructure and tensile properties of solution treated and cold-rolled Al-Cu-Mg alloys[J]. Materials Science and Engineering A, 2016, 650: 254–263.

[19] STILLERA K, WARREN P J, HANSEN V, ANGENETE J , GJOMMES J. Investigation of precipitation in an Al-Zn-Mg alloy after two-step ageing treatment at 100 and 150 ℃[J]. Materials Science and Engineering A, 1999, 270: 55–63.

[20] SHA G, CEREZO A. Early-stage precipitation in Al-Zn-Mg-Cu alloy (7050)[J]. Acta Materialia, 2004, 52: 4503–4516.

[21] NIE X W, ZHANG L J, DU Y. Experiments and modeling of double-peak precipitation hardening and strengthening mechanisms in Al-Zn-Mg alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2138–2144.

[22] STARINK M J, WANG S C. A model for the yield strength of overaged Al-Zn-Mg-Cu alloys[J]. Acta Materialia, 2003, 51: 5131–5150.

[23] NES E, MARTHINSEN K. Modeling the evolution in microstructure and properties during plastic deformation of f.c.c.-metals and alloys–an approach towards a unified model[J]. Materials Science and Engineering A, 2002, 322: 176–193.

[24] ESMAEILI S, LLOYD D J, POOLE W J. Modeling of precipitation hardening for the naturally aged Al-Mg-Si-Cu alloy AA6111[J]. Acta Materialia, 2003, 51: 3467–3481.

[25] BERG L K, GJONNES J, HANSEN V, LI X Z, KNUTSON-WEDEL M, WATERLOO G, SCHRYVERS D, WALLENBERG. GP-zone in Al-Zn-Mg alloys and their role in artificial aging[J]. Acta Materialia, 2001, 49: 3443–3451.

Effect of ageing on mechanical properties and microstructures of solution treated and cold-rolled 7075 Al alloy

LI Hai1, 2, CHEN Peng1, WANG Zhi-xiu1, 2, ZHENG Zi-qiao3

(1. School of Materials Science and Engineering, Changzhou University, Changzhou 213164, China;

2. Jiangsu Key Laboratory of Materials Surface Science and Technology, Changzhou University, Changzhou 213164, China;

3. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effects of ageing at 80, 100 and 120 ℃ on the mechanical properties and microstructures of 7075 Al alloy solution treated at 475 ℃ for 1 h and cold-rolled at room temperature by thickness reduction of 80% were studied by tensile test, optical microscopy, X-ray diffractometry (XRD) and transmission electron microscopy (TEM). Tensile test results show that the strength of the alloy is significantly improved by the thermomechanical treatment with acceptable ductility. Especially, after being aged at 80 ℃ for 48 h, the ultimate tensile strength, yield strength and elongation to failure of the alloy are 773 MPa, 720 MPa and 5%, respectively. Microstructural observations show that the strength of the alloy is attributed to the combination of cold-rolling work hardening (high dislocation density, increased rolling textures and refined grains) and precipitation strengthening. Meanwhile, the improved elongation of the alloy is mainly due to dislocation recovery and ageing precipitation. Furthermore, the change in strength and ductility of the alloy during ageing was analyzed further based on the dislocation density and precipitation characterization.

Key words: 7075 aluminum alloy; thermomechanical treatment; microstructure; mechanical property

Foundation item: Projects(51571038, 51671038) supported by the National Natural Science Foundation of China; Projects(BK20151188, BK20171195) supported by the Natural Science Foundation of Jiangsu Province, China

Received date: 2018-02-08; Accepted date: 2018-06-26

Corresponding author: LI Hai; Tel: +86-519-86330069; E-mail: lehigh_73@163.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51571038,51671038);江苏省自然科学基金资助项目(BK20151188,BK20171195)

收稿日期:2018-02-08;修订日期:2018-06-26

通信作者:李 海,教授,博士;电话:0519-86330069;E-mail: lehigh_73@163.com