文章编号:1004-0609(2013)05-1195-07

挤压铸造Al-5.0Cu-0.6Mn-0.5Fe合金的显微组织和力学性能

林 波,张卫文,程 佩,汪先送,李元元

(华南理工大学 机械与汽车工程学院,广州 510640)

摘 要:采用拉伸性能测试、定量金相分析、扫描电镜等手段研究挤压铸造Al-5.0Cu-0.6Mn-0.5Fe合金的显微组织和力学性能,分析挤压压力对合金的力学性能和显微组织的影响。结果表明:当挤压压力从0增大到75 MPa时,合金的抗拉强度(σb)和伸长率(δ)都显著增加。当挤压压力为75 MPa时,铸态合金的抗拉强度为298 MPa,伸长率达17.6%;经T5热处理后,合金的抗拉强度为395 MPa,伸长率为14.2%。当挤压压力从0增大到75 MPa时,α(Al)二次枝晶间距减小了69%,θ相(Al2Cu)和富Fe相的体积分数略有降低,针状β-Fe相消失,同时晶界处汉字状α-Fe相由连续的汉字状变成分散、细小的骨骼状。

关键词:铝合金;挤压铸造;显微组织; 力学性能

中图分类号:TG214 文献标志码:A

Microstructure and mechanical properties of Al-5.0Cu-0.6Mn-0.5Fe alloy prepared by squeeze casting

LIN Bo, ZHANG Wei-wen, CHENG Pei, WANG Xian-song, LI Yuan-yuan

(School of Mechanical and Automotive Engineering, South China University of Technology, Guangzhou 510640, China)

Abstract: The microstructure and mechanical properties of Al-5.0Cu-0.6Mn-0.5Fe alloy prepared by squeeze casting were studied by tensile test, image analysis and scanning electron microscope. The effects of applied pressure on the microstructure and mechanical properties of the alloy were investigated. The results show that the ultimate tensile strength (σb) and elongation (δ) of the alloy increase significantly with increasing the applied pressure from 0 to 75 MPa. When the applied pressure is 75 MPa, the σb and δ of the alloy are 298 MPa and 17.6% in as-cast condition and 395 MPa and 14.2% after T5 heat treatment, respectively. When the applied pressure increases from 0 to 75 MPa, the second dendritic arm spacing of α(Al) decreases by 69%, the volume fractions of θ(Al2Cu) phase and the iron-rich intermetallic phases decrease slightly, the platelet β-Fe phases disappear, and the continuous Chinese script α-Fe phases at the grain boundary become more dispersive and smaller.

Key words: aluminum alloy; squeeze casting; microstructure; mechanical property

铝合金的强韧化一直是铝合金研究中的一个重要课题,严格控制杂质元素含量是实现铝合金强韧化的一个重要途径。在高强韧铸造铝铜合金中,Fe是重要的杂质元素。Fe在铝合金中的固溶度很低,在655 ℃液态纯铝中的固溶度大约为1.8%(质量分数,下同),在450 ℃固态纯铝中的固溶度仅为0.005 2%,而当加入5%的Cu时,其固溶度将降低约80%[1-2]。因此,Fe在Al-Cu合金中常以富Fe的金属间化合物形式存在,特别是针片状的β-Al7Cu2Fe相,既硬又脆,严重恶化Al-Cu合金的力学性能。因此,在开发高强韧Al-Cu合金的过程中,往往需要严格控制杂质元素Fe的含量。如在206铝合金系列中,为了确保合金的性能,合金中的最高Fe含量一般控制在0.15%(206.0合金),或者低于0.10%(206.2合金),如果该材料用于航空工业中的重要铸件,其Fe含量更是要低于0.07%(A206.2合金)[3]。我国研发的高强韧铸造铝合金ZL205A,其Fe含量也要求不高于0.15%(GB/T1173—1995)。

实际上,Fe在铝合金中很难避免,铝合金中的Fe主要来自于以下几个方面:1) 原材料和中间合金;2) 熔炼和铸造过程中使用的铁坩埚、铁制熔炼工具和金属铸型将Fe带入Al液中;3) 回收的铝合金。因此,为了防止制备的铝合金中Fe含量增加,必须严格控制原材料来源和熔炼铸造工艺,这些都导致材料成本大幅度升高和工艺控制难度增大,限制了低铁含量高强韧铝合金的应用,特别是随着世界范围内对节能环保要求的不断提高,需要大量使用回收铝合金。因此,通过优化工艺、降低原材料中Fe含量,从而降低材料的成本和扩大选材范围,实现材料的高效利用,具有重要意义。

国内外在如何控制和去除铝合金熔体中Fe的有害影响方面开展了较多研究。目前,一般存在两种方法:一种是通过改变铝合金中富Fe相的形貌,使针片状的Fe相转变为危害较小的块状、汉字状Fe相,或是使针片状的Fe相细化,主要方法有中和变质[4-5]、熔体过热[6-8]和改变冷却速度[2, 9-10]等;另一种是直接去除铝合金中的Fe元素。主要方法有重力沉降、离心分离、过滤、电磁分离、硼化物除铁等。CAO等[11-13]采用自由对流重力沉降工艺和熔体过热研究了Al-11.5Si-0.4Mg和Al-4.5Cu-0.3Fe合金中Fe相的形核及其凝固过程。人们采用电磁分离技术[14]、加入硼化物除铁[15]等工艺研究了Al-Si合金中Fe杂质的分离与净化。DONG等[16]和MAENG等[17]分别研究了挤压铸造过程Al-7Si-0.3Mg和B390合金中Fe相对其组织和力学性能的影响,结果表明,挤压铸造可以细化合金中的Fe相,提高合金的力学性能。可见,目前针对铸造铝合金中富Fe相的凝固行为研究主要集中在Al-Si系列合金,针对高强韧Al-Cu合金中富Fe相的研究较少。

挤压铸造是一种较为先进的高效近净成形技术,它将铸造和锻造工艺的特点融为一体,使液态金属在高压作用下凝固成形,可获得晶粒细小、组织致密度高、材料性能好的毛坯或零件[18-19]。将挤压铸造成形工艺与高性能材料研究有机结合,是开发高效回收铝合金材料的有效途径之一。本文作者以一种成分简单、具有较高Fe含量的Al-5.0Cu-0.6Mn合金为研究对象,研究挤压压力对该合金的显微组织和力学性能的影响,为获得高性能、易再生的高强韧铸造铝合金奠定基础。

1 实验

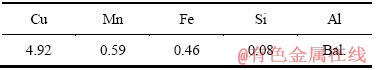

实验所用原材料为A00铝锭、Al-50Cu、Al-10Mn和Al-5Fe中间合金。在井式电阻炉中进行合金熔炼,熔体经过精炼、除气和除渣后,于710 ℃左右进行浇注。合金的化学成分如表1所列。

表1 合金的化学成分

Table 1 Chemical composition of alloy (mass fraction, %)

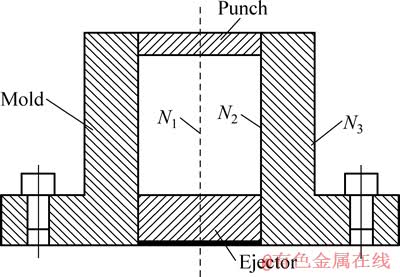

在1 MN四柱液压力机上进行挤压铸造实验,模具预热温度为250 ℃,挤压压力分别为0、25、50和75 MPa,挤压速度为0.01~0.018 m/s,保压时间为30 s。获得的铸锭尺寸为d 68 mm×65 mm。采用瑞士Kistler公司生产的温度测量系统测量不同压力下模具、模壁和熔体内部金属熔体在凝固过程中的冷却曲线,测温点示意图如图1所示。T5热处理工艺在(538±5) ℃固溶处理12 h,室温水淬,然后在(155±5) ℃时效8 h,空冷。

图1 测温点示意图

Fig. 1 Schematic diagram of temperature measurement locations

在挤压铸件同半径的周边截取d 5的标准拉伸试样,在SANS CMT5105微机控制万能材料试验机上进行拉伸力学性能测试,每个测量点为3个试验样的平均值。在每个挤压铸造铸件上表面的相同位置截取金相试样,抛光后采用的腐蚀剂为0.5%HF(质量分数)水溶液,在LEICA/DMI 5000M金相显微镜上进行微观组织观察,并利用Leica Materials Workstation V3.6.1图像分析软件进行定量金相分析,每个试样放大500倍下选取至少30个视场。拉伸断口观察和能谱分析在Quanta2000扫描电子显微镜上进行。

2 结果与分析

2.1 合金的力学性能

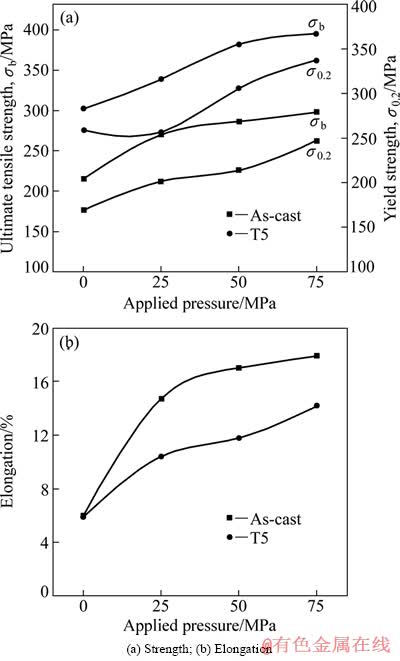

不同挤压压力下铸态和T5热处理态合金的拉伸力学性能如图2所示。从图2可以看出,合金的抗拉强度、屈服强度和伸长率均随着挤压压力的增大而增大。当挤压压力从0增大到50 MPa,抗拉强度和伸长率增幅很明显;挤压压力超过50 MPa后,抗拉强度和伸长率变化不是很明显。当挤压压力由0增大到75 MPa时,铸态合金的抗拉强度由215 MPa增大至298 MPa,增幅为38.6%,屈服强度由169 MPa增大至247 MPa,增幅为46.2%,伸长率由6.8%增加到17.6%,增幅为158.8%;经过T5处理后,拉强度由302 MPa增大至395 MPa,增幅为30.8%,屈服强度由259 MPa增大至337 MPa,增幅为30.1%,伸长率由5.9%增加到14.2%,增幅为140.7%;与铸态相比,T5热处理后的合金抗拉强度和屈服强度明显增加,而延伸率稍有下降。

图2 不同挤压压力下合金的力学性能

Fig. 2 Mechanical properties of alloys at different applied pressures

2.2 合金的显微组织

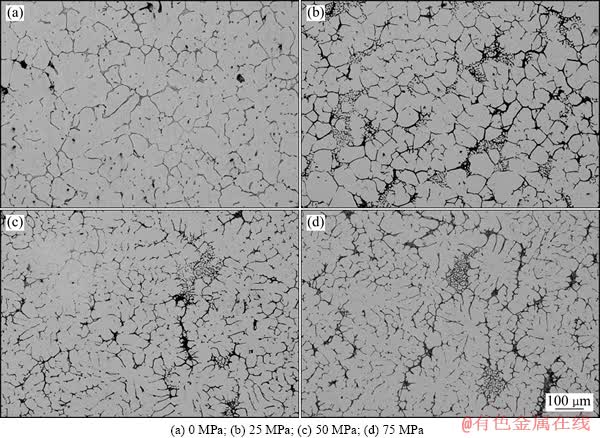

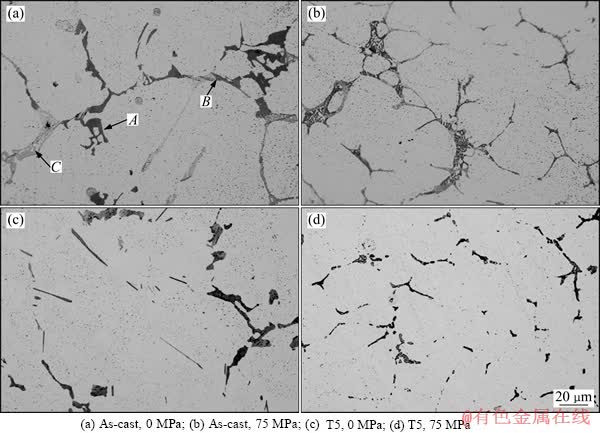

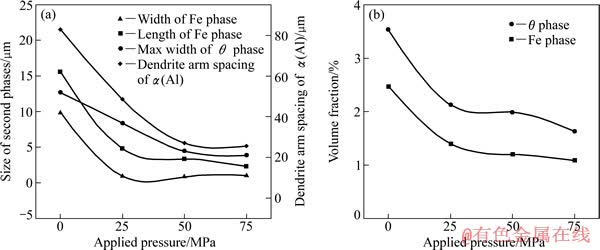

不同挤压压力下铸态合金的显微组织如图3所示。从图3可见,铸态合金的显微组织主要由α(Al)基体以及分布在基体之间的各种第二相组成。随挤压压力的增加,合金中α(Al)二次枝晶间距明显减小。此外,在有挤压压力存在的条件下凝固时,合金中的α枝晶间出现一些网状析出物,这是在挤压铸造合金中易出现的双峰组织,其形成机理已有比较深入的分析[20]。

不同挤压压力下铸态和T5热处理态合金的显微组织如图4所示。在高倍下可以比较清楚地看出第二相的形貌,这些第二相包括网状共晶相、针状富Fe相和汉字状的富Fe相等。图4(a)中所示为未施加挤压压力时合金中的3种第二相形貌(如箭头所指点A,B,C)。这3种第二相的能谱分析结果如表2所列。其所对应的相分别是汉字状富Fe铁相(A)为Al15(FeMn)3(CuSi)2(α-Fe)、针状富铁相(B)为Al7Cu2Fe (β-Fe)和白色花纹状相(C)为θ(Al2Cu),与文献[1-3]中结果一致。

从图4(a)和(b)可见,随着挤压压力的增大,铸态合金晶界处的α-Fe相逐渐由连续的汉字状变为分散的细小骨骼状,θ(Al2Cu)相也逐渐变得细小和分散,而黑色针状β-Fe相已经消失。从图4(c)和(d)可见,经T5热处理后,合金的显微组织相对铸态时出现了明显的变化,晶界还残留着部分黑色物质。而当挤压压力为0时,针状相并没有消失,经能谱分析结果表明,残留物为少量β-Fe和α-Fe相;当挤压压力为75 MPa时,残留的汉字状α-Fe相随着挤压压力的增大逐渐变得分散、细小,可见,挤压压力增大加速β-Fe相消失。与铸态相比,合金经T5热处理后,θ(Al2Cu)相固溶时效后弥散析出,但α-Fe相的形貌变化很小(图4(d))。

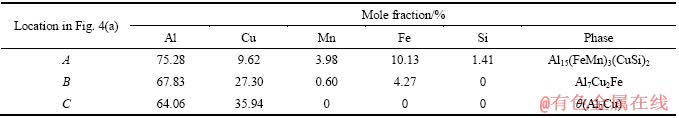

铸态合金各相的尺寸和体积分数随挤压压力变化如图5所示。从图5(a)可见,当挤压压力由0增大到75 MPa时,α(Al)二次枝晶间距从82.8 μm 减小到25.5 μm,减小了69%。汉字状α-Fe相的平均长度由15.56 μm减小到2.29 μm,平均宽度由9.88 μm 减小到1.05 μm,θ相的最大宽度也由12.7 μm减小到3.87 μm。从图5(b)可见,随着挤压压力的增大,富Fe相和θ相的体积分数逐渐降低,当挤压压力由0增大到75 MPa时,富Fe相体积分数由2.47%减小到1.09%,θ相的体积分数由3.53%减小到1.63%。可见,随着挤压压力的增大,合金中各相尺寸变小,相同面积下合金中的第二相体积分数减小。

图3 不同挤压压力下铸态合金的显微组织

Fig. 3 Microstructures of as-cast alloys at different applied pressures

图4 不同挤压压力下铸态和T5热处理态合金的显微组织

Fig. 4 Microstructures of as-cast and T5-treated alloys at different applied pressures

表2 图4(a)中各点的EDS能谱分析结果

Table 2 EDS analysis results of locations in Fig. 4(a)

2.3 合金的断口形貌

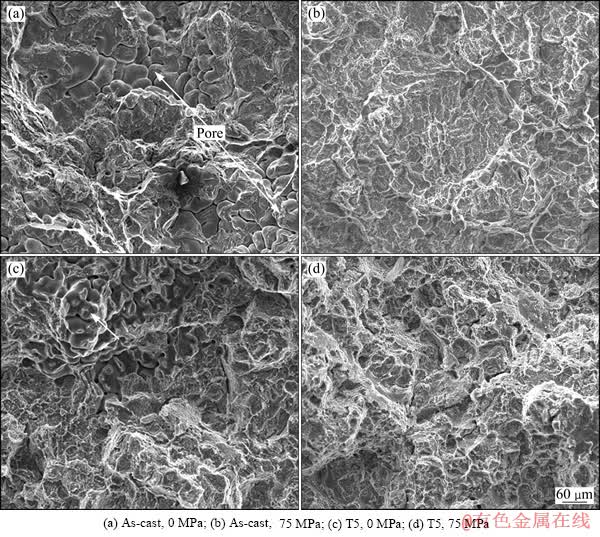

不同挤压压力下铸态和T5热处理态合金的断口形貌如图6所示。从图6可见,不同挤压压力下,合金显著差别如下:0 MPa压力下,合金断口上出现很多枝晶状缩松组织;而75 MPa压力下,显微缩松基本消失,合金发生了很大的塑性变形,出现大量的韧窝。此外,相对于铸态合金,T5热处理态合金的韧窝中存在许多细小的第二相质点。

图5 不同挤压压力下铸态合金各相的尺寸和体积分数

Fig. 5 Sizes (a) and volume fractions (b) of phases in as-cast alloys at different applied pressures

图6 不同挤压压力下铸态和T5热处理态合金的拉伸断口形貌

Fig. 6 Tensile fracture morphologies of as-cast and T5-treated alloys at different applied pressures

3 讨论

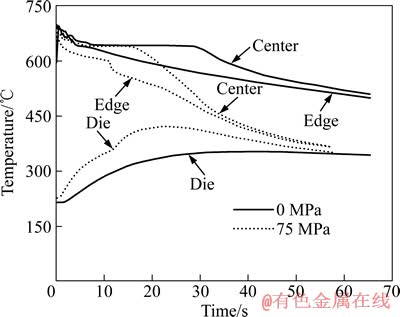

对于挤压铸造的Al-5.0Cu-0.6Mn-0.5Fe合金,合金铸态组织中分布于晶界处的α-Fe相随着挤压压力的增大逐渐由连续的汉字状变得分散和细小,针状β-Fe相完全消失,合金的力学性能得到很大的提高。这与挤压压力下引起的组织变化密切相关,主要表现是导致第二相细化,α(Al)二次枝晶间距尺寸减小,孔洞和缩松减少。上述组织变化主要受挤压铸造工艺影响。图7所示为挤压铸造过程中铸件和模具不同部位的冷却曲线。从图7可以看出,当挤压压力从0增大到75 MPa时,铸件中心点的凝固时间由42.5 s减少到23.9 s;模具内表面峰值温度由354.4 ℃升高到423.1 ℃,这是由于合金在压力下凝固,铸件与模具之间的气隙减小,导致界面传热系数增大,使得铸件冷却速度加大,凝固速度加快[21-22]。KAMGUO-KAMGA等[2]研究发现,大多数晶间第二相的形成与长大与其晶体结构有关,汉字状的富Mn铁相为立方晶格,与针状β-Fe相的四方晶格相比,汉字状的富Mn铁相形核和长大更容易,也更快。而当冷却速度很快时,Fe原子更容易被其他具有更大形核动力学的晶间相捕获,从而更容易形成汉字状的富Mn铁相。且冷却速度越快,合金越接近非平衡凝固,Fe原子越来不及扩散析出,而针片状β-Fe具有小平面择优生长趋势(在单一方向有特殊的生长优势),在较高的冷却速度下,Fe原子越不容易聚集,因此,增大冷却速度可以抑制针状β-Fe相的形成。在挤压铸造过程中,增大挤压压力,可使合金的冷却速度加快,从而抑制针状β-Fe相的形成,使Fe相全部变为汉字状,同时抑制汉字状Fe相的长大,减小Fe对合金的有害作用,提高合金的力学性能。此外,挤压压力能使合金的相变点提高,导致相析出时的过冷度增大[23],形核数目增多,从而使Fe相变得细小,分布越均匀。可见,挤压压力可以改善合金中金属间化合物的形态和分布,降低Fe相的有害影响,降低材料含Fe量的要求。

图7 不同挤压压力下铸件和模具不同部位的冷却曲线

Fig. 7 Cooling curves for different parts of castings and die at different applied pressures

合金经T5热处理后,抗拉强度和屈服强度明显增加,而伸长率稍有下降。这主要是因为合金中的θ(Al2Cu)相在固溶时效后弥散析出,而富Fe相形貌基本上不发生变化,从而导致强度增高,伸长率稍有下降。

4 结论

1) 挤压铸造Al-5.0Cu-0.6Mn-0.5Fe合金具有合金元素少、Fe含量较高的特点。铸态合金的抗拉强度为298 MPa,伸长率为17.6%;经T5热处理后,其抗拉强度为395 MPa,伸长率为14.2%。

2) 当挤压压力从0增大到75 MPa,合金的抗拉强度和伸长率显著升高,α(Al)二次枝晶间距尺寸减小了69%,针状的β-Fe相消失,同时晶界处汉字状α-Fe相由连续的汉字状变成分散、细小的骨骼状。

3) 当压力从0增大到75 MPa时,合金的冷却速度显著增加,铸件与模具壁的界面传热增强。合金的力学性能随着挤压压力的增大而提高,与第二相细化、α(Al)二次枝晶间距尺寸减小、孔洞和缩松减少有关。挤压铸造能够改善合金中金属间化合物的形态和分布,减小Fe相的有害影响,提高合金的力学性能,降低材料含Fe量的要求。

REFERENCES

[1] LIU K, CAO X, CHEN X G. Solidification of iron-rich intermetallic phases in Al-4.5Cu-0.3Fe cast alloy[J]. Metallurgical and Materials Transactions A, 2011, 42(7): 2004-2016.

[2] KAMGUO KAMGA H, LAROUCHE D, BOURNANE M, RAHEM A. Solidification of aluminum-copper B206 alloys with iron and silicon additions[J]. Metallurgical and Materials Transactions A, 2010, 41: 2844-2855.

[3] 刘伯操. 铸造手册: 铸造非铁合金[M]. 北京: 机械工业出版社, 2001.

LIU Bo-cao. Foundry manual: Non-ferrous cast alloys[M]. Beijing: Mechanical Industry Press, 2001.

[4] HWANG J Y, DOTYB H W, KAUFMAN M J. The effects of Mn additions on the microstructure and mechanical properties of Al-Si-Cu casting alloys[J]. Materials Science and Engineering A, 2008, 488: 496-504.

[5] TSENG C J, LEE S L,TSAI S C, CHENG C J. Effect of manganese on microstructure and mechanical properties of A206 alloys containing iron[J]. Journal of Materials Research, 2002, 17(9): 2243-2250.

[6] JIE W Q, CHEN Z W, REIF W, MULLER K. Superheat treatment of Al-7Si-0.55Mg melt and its influences on the solidification structures and the mechanical properties[J]. Metallurgical and Materials Transactions A, 2003, 34: 799-806.

[7] 王建华, 易丹青, 陈康华, 卢 斌, 刘 沙. 熔铸工艺对2618合金中Al9FeNi相形态的影响[J]. 中国有色金属学报, 2001, 11(2): 206-209.

WANG Jian-hua, YI Dan-qing, CHEN Kang-hua, LU Bin, LIU Sha. Effect of casting process on microstructure of Al9FeNi phase in 2618 alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(2): 206-209.

[8] ANANTHA L. Crystallization behavior of iron-containing intermetallic compounds in 319 aluminum alloy[J]. Metallurgical and Materials Transactions A, 1994, 25: 1761-1773.

[9] SEIFEDDINE S, JOHANSSON S, SVENSSON I L. The influence of cooling rate and manganese content on the β-Al5FeSi phase formation and mechanical properties of Al-Si-based alloys[J]. Materials Science and Engineering A, 2008, 490: 385-390.

[10] SIGWORTH G K,SHIVKUMAN S,APELIAN D. The influence of molten metal processing on mechanical properties of cast Al-Si-Mg alloys[J]. AFS Transactions, 1989, 139: 811-824.

[11] CAO X, CAMPBELL J. The solidification characteristics of Fe-rich intermetallics in Al-11.5Si-0.4Mg cast alloys[J]. Metallurgical and Materials Transactions A, 2004, 35: 1425-1435.

[12] CAO X, CAMPBELL J. The nucleation of Fe-rich phases on oxide films in Al-11.5Si-0.4Mg cast alloys[J]. Metallurgical and Materials Transactions A, 2003, 34: 1409-1420.

[13] CAO X. Effect of iron and manganese contents on convection-free precipitation and sedimentation of primary α-Al(FeMn)Si phase in liquid Al-11.5Si-0.4Mg alloy[J]. Journal of Material Science, 2004, 39: 2303-2314.

[14] LI Tian-xiao, XU Zhen-ming, SUN Bao-de,SHU Da, ZHOU Yao-he. Electromagnetic separation of primary iron-rich phases from aluminum-silicon melt[J]. Transaction of Nonferrous Metals Society of China, 2003, 13(1): 121-125.

[15] 高建卫. 硼化物对铝熔体中杂质铁的净化作用及机理[D]. 上海: 上海交通大学, 2010.

GAO Jian-wei. Effect and mechanism of iron removal from aluminum melt by boron compounds[D]. Shanghai: Shanghai Jiao Tong University, 2010.

[16] DONG J X, KARNEZIS P A , DURRANT G, CANTOR B. The effect of Sr and Fe additions on the microstructure and mechanical properties of a direct squeeze cast Al-7Si-0.3Mg Alloy[J]. Metallurgical and Materials Transactions A, 1999, 30: 1341-1356.

[17] MAENG D Y, LEE J H, WON C W, CHO S S, CHUN B S. The effects of processing parameters on the microstructure and mechanical properties of modified B390 alloy in direct squeeze casting[J]. Journal of Materials Processing Technology, 2000, 105: 196-203.

[18] 罗守靖, 陈炳光, 齐丕骧. 液态模锻与挤压铸造技术[M]. 北京: 化学工业出版社, 2006.

LUO Shou-jing, CHEN Bing-guang, QI Pi-xiang. Liquid forging and squeeze casting technology[M]. Beijing: Chemical Industry Press, 2006.

[19] HAJJARI E, DIVANDARI M. An investigation on the microstructure and tensile properties of direct squeeze cast and gravity die cast 2024 wrought Al alloy[J]. Materials and Design, 2008, 29: 1685-1689.

[20] YUE T M. Squeeze casting of high-strength aluminum wrought alloy AA7010[J]. Journal of Materials Processing Technology, 1997, 66: 179-185.

[21] GALLERNEAULT M, DURRANT G, CANTOR B. The squeeze casting of hypoeutectic binary Al-Cu[J]. Metallurgical and Materials Transactions A, 1996, 27: 4121-4123.

[22] GHOMASHCHI M R, VIKHROV A. Squeeze casting: An overview[J]. Journal of Materials Processing Technology, 2000, 101: 1-9.

[23] FRANKLIN J R, DAS A A. Squeeze casting—A review of status[J]. Foundryman, 1984, 77(3): 150-158.

(编辑 陈卫萍)

基金项目:国家科技支撑计划项目(2011BAE21B00);GD-NSFC联合基金项目(U1034001);省部产学研重点专项(2009A090100026);广东省科技攻关项目(2008A010300003)

收稿日期:2011-11-22;修订日期:2013-03-25

通信作者:张卫文,教授,博士;电话:13642315239;E-mail:mewzhang@scut.edu.cn