基于热分析和 分析的氧化铝生产蒸发工序节能研究

分析的氧化铝生产蒸发工序节能研究

张建智1,彭小奇1, 2,李时民1,宋彦坡1,伍雁鹏1, 3

(1. 中南大学 能源科学与工程学院,湖南 长沙,410083;

2. 湖南第一师范学院 信息科学与工程系,湖南 长沙,410205;

3. 邵阳学院 信息工程系,湖南 邵阳,422000)

摘要:阐述热分析和 分析在氧化铝蒸发工序节能降耗中的意义,建立工序的热分析和

分析在氧化铝蒸发工序节能降耗中的意义,建立工序的热分析和 分析模型,并以此对某厂蒸发工序进行热效率和

分析模型,并以此对某厂蒸发工序进行热效率和 效率的分析。研究结果表明:蒸发工序热效率仅为30.67%,

效率的分析。研究结果表明:蒸发工序热效率仅为30.67%, 效率仅为15.08%,热损失严重,用能水平低,节能潜力大;热分析确定的高耗能环节为冷凝水自蒸发器和末效蒸发器,

效率仅为15.08%,热损失严重,用能水平低,节能潜力大;热分析确定的高耗能环节为冷凝水自蒸发器和末效蒸发器, 分析确定的高耗能环节不仅为冷凝水自蒸发器和末效蒸发器,还有传热过程

分析确定的高耗能环节不仅为冷凝水自蒸发器和末效蒸发器,还有传热过程 损失和流动过程

损失和流动过程 损失。通过对蒸发工序进行热分析和

损失。通过对蒸发工序进行热分析和 分析,评价工序用能水平,确定耗能的主要环节、部位及节能潜力,指出蒸发工序的节能降耗途径。

分析,评价工序用能水平,确定耗能的主要环节、部位及节能潜力,指出蒸发工序的节能降耗途径。

关键词:氧化铝;蒸发工序;热分析; 分析;节能降耗

分析;节能降耗

中图分类号:TF802.62 文献标志码:A 文章编号:1672-7207(2011)11-3556-08

Research of energy saving for alumina production evaporation process based on thermal analysis and exergy analysis

ZHANG Jian-zhi1, PENG Xiao-qi1, 2, LI Shi-min1, SONG Yan-po1, WU Yan-peng1, 3

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Department of Information Science and Engineering, Hunan First Normal University, Changsha 410205, China;

3. Department of Information Engineering, Shaoyang University, Shaoyang 422000, China)

Abstract: The importance of thermal analysis and exergy analysis in alumina evaporation process was described; a thermal analysis model and an exergy analysis model were established. The models were applied in a factory to analyze the thermal efficiency and exergy efficiency of the alumina evaporation process, to evaluate the energy consumption level in the alumina evaporation process, and to identify key areas of energy consumption and energy saving potential. The methods of energy saving and consumption lowering of the alumina evaporation process are put forward.

Key words: alumina; evaporation process; thermal analysis; exergy analysis; energy saving and consumption lowering

蒸发作为一种重要的化工单元过程,在氧化铝生产中占有重要地位。其作用在于排除流程中多余的水分,保持生产中液量的平衡,使母液蒸发浓缩到符合溶出铝土矿配制原矿浆的要求[1]。据第十届氧化铝技术信息交流会数据统计,蒸发能耗约占生产能耗的20%~25%,汽耗占总汽耗的48%~52%,占生产成本的10%~12%,可见,蒸发工序能耗的高低直接制约了氧化铝工业的发展[2]。因此,实现氧化铝蒸发工序的节能降耗具有重要意义。科学分析和评价能耗状况是实现节能降耗的基础。为了确定能量系统中能量损失 的性质、大小与分布,提高能量的利用率,有必要对系统用能水平进行深入分析[3]。能量分析方法通常有热分析和 分析2种:热分析以热效率为基本准则来揭示能量在“数量”上转换、传递、利用和损失的情况;

分析2种:热分析以热效率为基本准则来揭示能量在“数量”上转换、传递、利用和损失的情况; 分析综合考虑了能的“数量”和“品质”2个属性,不仅可以反映能量的数量,更重要的是可以反映能量的品质,它以

分析综合考虑了能的“数量”和“品质”2个属性,不仅可以反映能量的数量,更重要的是可以反映能量的品质,它以 效率为基本准则来揭示

效率为基本准则来揭示 损失的环节和部位,可以对系统或装置的用能状况进行更科学深入的分析和评价[4-6]。吴复忠等[3]建立了炼铁系统铁前工序的

损失的环节和部位,可以对系统或装置的用能状况进行更科学深入的分析和评价[4-6]。吴复忠等[3]建立了炼铁系统铁前工序的 分析模型,分析了各个工序的

分析模型,分析了各个工序的 效率、

效率、 损失,指出各工序的节能方向和途径;杨洛鹏等[7]建立了喷射器低温多效蒸发海水淡化系统的数学模型,计算分析了各种温度损失随温度的变化,实现了系统的优化运行。能量分析方法已经成功应用于钢铁、化工行业,然而在氧化铝等有色冶金行业中还很少应用。对氧化铝蒸发工序进行能量分析,可以全面地评价工序的用能水平,科学地诊断用能薄弱环节,正确判断节能潜力的大小、部位和限度,从而为有针对性地采取的节能降耗措施提供科学指导。

损失,指出各工序的节能方向和途径;杨洛鹏等[7]建立了喷射器低温多效蒸发海水淡化系统的数学模型,计算分析了各种温度损失随温度的变化,实现了系统的优化运行。能量分析方法已经成功应用于钢铁、化工行业,然而在氧化铝等有色冶金行业中还很少应用。对氧化铝蒸发工序进行能量分析,可以全面地评价工序的用能水平,科学地诊断用能薄弱环节,正确判断节能潜力的大小、部位和限度,从而为有针对性地采取的节能降耗措施提供科学指导。

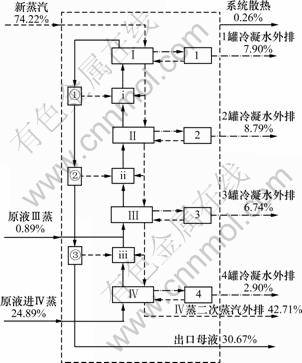

1 工艺流程简介

某厂氧化铝蒸发工序采用的是四效逆流三级闪蒸的管式降膜蒸发系统。其工艺流程如图1所示:蒸发原液大部分由泵送至Ⅳ效蒸发器,小部分送至Ⅲ效蒸发器,经Ⅳ-Ⅲ-Ⅱ-Ⅰ效蒸发器逆流逐级加热,再经三级闪蒸器闪蒸浓缩后,由过料泵送出;新蒸汽进入Ⅰ效蒸发器对料液进行加热,Ⅰ效至Ⅲ效蒸发器的二次蒸汽分别作下一效蒸发器的热源,Ⅳ效(末效)蒸发器的二次蒸汽降温后排出;①,②和③级闪蒸器的二次蒸汽和Ⅰ,Ⅱ和Ⅲ效蒸发器的小部分二次蒸汽分别通入ⅰ,ⅱ和ⅲ效预热器,与预热器内的溶液混合,对溶液进行加热;Ⅰ,Ⅱ,Ⅲ和Ⅳ效蒸发器的冷凝水分别通入1,2,3和4效冷凝水自蒸发器,自蒸发产生的部分乏汽分别作为各效蒸发器的热源,其冷凝水汇入一次水泵后排出。

2 蒸发工序热分析

热分析的科学基础是热力学第一定律[8]。第一定律指出:一个体系的能量总量不变,但在体系内可以进行转换和传递。

2.1 蒸发工序热分析模型

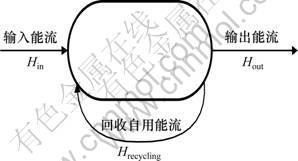

图2所示为某厂蒸发工序流程图。蒸发工序中存在3种能流(见图2):

(1) 输入能流Hin:包括第1类载体(新蒸汽)和第2类载体(原液)所含的热量;

(2) 回收自用能流Hrecycling:本工序回收自用的热量,主要包括Ⅰ,Ⅱ和Ⅲ效蒸发器所产生的二次蒸汽和①,②和③级闪蒸器闪蒸的二次蒸汽所含的热量,以及1,2,3和4效冷凝水自蒸发器闪蒸的二次蒸汽所含的热量。

(3) 输出能流Hout:包括本工序产生母液所含的热量Hproducts,Ⅳ效蒸发器产生二次蒸汽所含的热量,各效冷凝水自蒸发器外排冷凝水所含的热量,以及系统散热量。

图1 某厂蒸发工序工艺流程图

Fig.1 Evaporation process flow chart of a factory

图 2 蒸发工序能流图

Fig.2 Energy flow chart of evaporation process

蒸发工序的热平衡关系式如下:

(1)

(1)

简化得:

(2)

(2)

2.2 焓的计算

2.2.1 料液焓

(3)

(3)

(4)

(4)

式中:m表示料液;i-j表示4效蒸发器、3效预热器、3级闪蒸器、4级冷凝水罐; 为料液的质量流量,kg/h;

为料液的质量流量,kg/h; 为料液的体积流量,m3/h;

为料液的体积流量,m3/h; 为料液的密度,kg/m3;cp为料液的比热容,kJ/(kg·K);

为料液的密度,kg/m3;cp为料液的比热容,kJ/(kg·K); 为料液的温度,℃。

为料液的温度,℃。

2.2.2 饱和蒸汽焓

(5)

(5)

式中:v表示饱和蒸汽; 为饱和蒸汽的质量流量,kg/h;

为饱和蒸汽的质量流量,kg/h; 为饱和蒸汽的比焓,kJ/kg。

为饱和蒸汽的比焓,kJ/kg。

2.2.3 饱和冷凝水焓

(6)

(6)

式中: 为饱和冷凝水的质量流量,kg/h;

为饱和冷凝水的质量流量,kg/h; 为饱和冷凝水的比焓,kJ/kg。

为饱和冷凝水的比焓,kJ/kg。

3 蒸发工序 分析

分析

是在给定的环境条件下系统能量理论上能转换为有用功的那部分能量,也称为有效能[8-9]。热力学第二定律指出:能量的转化和传递具有方向性,有的能量可以全部转化为有效能量,而有的能量只能部分转化为有效能量,也即能量在“品质”上是有差异的,不同形式的能量间的转换存在“不等价”现象。

是在给定的环境条件下系统能量理论上能转换为有用功的那部分能量,也称为有效能[8-9]。热力学第二定律指出:能量的转化和传递具有方向性,有的能量可以全部转化为有效能量,而有的能量只能部分转化为有效能量,也即能量在“品质”上是有差异的,不同形式的能量间的转换存在“不等价”现象。

3.1 蒸发工序 分析模型

分析模型

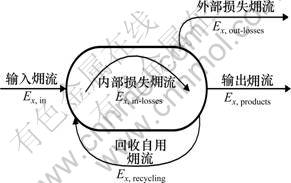

图3所示为蒸发工序 流图。蒸发工序中存在5种

流图。蒸发工序中存在5种 流[3](见图3):

流[3](见图3):

图3 蒸发工序 流图

流图

Fig.3 Exergy flow chart of evaporation process

(1) 输入 流Ex,in:包括第1类载体(新蒸汽)和第2类载体(原液)所含的

流Ex,in:包括第1类载体(新蒸汽)和第2类载体(原液)所含的 。

。

(2) 回收自用 流Ex,recycling:本工序回收自用的

流Ex,recycling:本工序回收自用的 ,主要包括Ⅰ,Ⅱ和Ⅲ效蒸发器所产生二次蒸汽所含的

,主要包括Ⅰ,Ⅱ和Ⅲ效蒸发器所产生二次蒸汽所含的 ,①,②和③级闪蒸器闪蒸二次蒸汽所含的

,①,②和③级闪蒸器闪蒸二次蒸汽所含的 ,1,2,3和4效冷凝水自蒸发器闪蒸二次蒸汽所含的

,1,2,3和4效冷凝水自蒸发器闪蒸二次蒸汽所含的 。

。

(3) 内部损失 流Ex,in-losses:包括传热

流Ex,in-losses:包括传热 损失、混合

损失、混合 损失和流动过程

损失和流动过程 损失。

损失。

(4) 外部损失 流Ex,out-losses:包括散热

流Ex,out-losses:包括散热 损失,Ⅳ效蒸发器产生二次蒸汽所含的

损失,Ⅳ效蒸发器产生二次蒸汽所含的 ,各效冷凝水自蒸发器外排冷凝水所含的

,各效冷凝水自蒸发器外排冷凝水所含的 。

。

(5) 输出 流Ex,products:本工序母液所含的

流Ex,products:本工序母液所含的 。

。

蒸发工序的 平衡关系式如下:

平衡关系式如下:

(7)

(7)

简化得:

(8)

(8)

3.2  的计算

的计算

3.2.1 环境基准模型

选用修正的龟山-吉田环境模型[10],死态条件为:T0=298.15 K,p0=0.1 MPa;空气中含有的各种元素以空气相应的组成气体为基准物,以饱和湿空气的摩尔成分为基准物成分;其他元素以含有该元素的、最稳定的纯物质(液态或固态)为其基准物。

3.2.2 料液 的计算

的计算

热力学系统的 是指系统经可逆过程达到与环境处于完全热力学平衡状态时所能获得的理论最大有用功[11-13]。一般对工业过程进行

是指系统经可逆过程达到与环境处于完全热力学平衡状态时所能获得的理论最大有用功[11-13]。一般对工业过程进行 分析时,物料的

分析时,物料的 主要是物理

主要是物理 和化学

和化学 。

。

(1) 物理

物理 是指系统相对于环境因温度和压力的不同而具有的

是指系统相对于环境因温度和压力的不同而具有的 [14-16]。料液在状态(T,p)下的比物理

[14-16]。料液在状态(T,p)下的比物理 为:

为:

(9)

(9)

式中:V0为物料的比体积,m3/kg;T和T0分别为工况温度和环境基准温度,K;p和p0分别为工况压力和环境基准压力,MPa。

(2) 化学

化学 是指混合物系统相对于环境因化学成分和浓度的不同而具有的

是指混合物系统相对于环境因化学成分和浓度的不同而具有的 [14-15, 17]。包括由该物质与环境反应物反应产生环境生成物所获得的反应

[14-15, 17]。包括由该物质与环境反应物反应产生环境生成物所获得的反应 ,还包括由反应产生的环境生成物浓度扩散到非约束死态时的扩散

,还包括由反应产生的环境生成物浓度扩散到非约束死态时的扩散 。

。

由于蒸发工序中无化学反应,理论和实际中各组分都近似质量守恒,因此,实际 分析中可以不计入反应

分析中可以不计入反应 项。料液的比化学

项。料液的比化学 为:

为:

(10)

(10)

式中: 为料液中第n种组分的质量摩尔分数,mol/kg;rn为料液中第n种组分的活度因子,可由NaOH-NaAl(OH)4-Na2CO3-H2O体系的活度系数计算模型[18]获得。

为料液中第n种组分的质量摩尔分数,mol/kg;rn为料液中第n种组分的活度因子,可由NaOH-NaAl(OH)4-Na2CO3-H2O体系的活度系数计算模型[18]获得。

3.2.3 饱和蒸汽 的计算

的计算

(11)

(11)

(12)

(12)

式中: 为饱和蒸汽比

为饱和蒸汽比 ,kJ/kg;

,kJ/kg; 和

和 分别为饱和蒸汽的比焓和比熵,kJ/kg;h0和s0分别为基准温度下饱和蒸汽的比焓和比熵,h0=2 546.54 kJ/kg,s0=8.556 8 kJ/kg。

分别为饱和蒸汽的比焓和比熵,kJ/kg;h0和s0分别为基准温度下饱和蒸汽的比焓和比熵,h0=2 546.54 kJ/kg,s0=8.556 8 kJ/kg。

3.2.4 饱和冷凝水 的计算

的计算

(13)

(13)

(14)

(14)

式中: 为饱和冷凝水比

为饱和冷凝水比 ,kJ/kg;

,kJ/kg; 和

和 分别为饱和冷凝水的比焓和比熵,kJ/kg。

分别为饱和冷凝水的比焓和比熵,kJ/kg。

3.2.5 外部 损失

损失

(1) 散热 损失

损失

经系统或装置表面散失到环境中的能量。这类能量虽然具有 ,但一般难以利用或不利用[8, 19]。

,但一般难以利用或不利用[8, 19]。

若系统或装置表面温度为Tsurroud,散失的热量为QL,则相应的 损失EL,out-losses为:

损失EL,out-losses为:

(15)

(15)

(2) 外排 损失

损失

流经系统或装置的排出物所携带的能量如果直接排到环境中,则构成“外部 损失”[8, 19],如外排冷凝水、外排二次蒸汽;但是其中的部分能量一般是可以回收利用的,这时就不能将其当成“损失”,如冷凝水罐的闪蒸二次蒸汽等。

损失”[8, 19],如外排冷凝水、外排二次蒸汽;但是其中的部分能量一般是可以回收利用的,这时就不能将其当成“损失”,如冷凝水罐的闪蒸二次蒸汽等。

3.2.6 内部 损失

损失

在不可逆过程中,能量的一部分将不能被利用,并因此造成可用能的损失[14, 20]。蒸发工序中,比较典型的有下面3种 损失。

损失。

(1) 传热过程 损失

损失

冷、热2种流体之间的传热通常总是在有温差的条件下进行的,而且冷、热流体本身又有摩阻耗散,因而就伴有不可逆 损失。

损失。

传热过程 损失是由于传热温差的存在而引起的,蒸发工序中,这种

损失是由于传热温差的存在而引起的,蒸发工序中,这种 损失主要发生在蒸发器内。传热过程

损失主要发生在蒸发器内。传热过程 损失为:

损失为:

(16)

(16)

式中:TH和TL分别为冷和热流体的平均温度,K。冷、热流体的平均温度Tm为:

(17)

(17)

式中:Tb和Te分别为流体的初态温度和末态温度,K。

(2) 混合过程 损失

损失

2种或多种物质的混合过程是高度不可逆的。在绝热条件下,混合过程必导致熵的增加,引起 的损失。绝热混合过程可以是参数不同的同种物质之间的混合,也可以是不同物质之间的混合;而不同物质混合时,参数可以相同,也可以不同;相互混合的几种物质既可以是流动的,也可以是静止的。混合过程中,两股流体不发生化学反应,虽然混合过程没有能量损失,但仍有

的损失。绝热混合过程可以是参数不同的同种物质之间的混合,也可以是不同物质之间的混合;而不同物质混合时,参数可以相同,也可以不同;相互混合的几种物质既可以是流动的,也可以是静止的。混合过程中,两股流体不发生化学反应,虽然混合过程没有能量损失,但仍有 损失,这种

损失,这种 损失主要发生在预热器内。混合过程

损失主要发生在预热器内。混合过程 损失为:

损失为:

(18)

(18)

式中: ,

, 和

和 分别为混合前流体1、流体2和混合后流体3的物理

分别为混合前流体1、流体2和混合后流体3的物理 ;

; ,

, 和

和 分别为混合前流体1、流体2和混合后流体3的化学

分别为混合前流体1、流体2和混合后流体3的化学 。

。

(3) 流动过程 损失

损失

由于机械的不可逆因素,比如流体的黏性流动等所引起的 损失,称为流动过程

损失,称为流动过程 损失。蒸发工序中,这种

损失。蒸发工序中,这种 损失主要包括料液及饱和蒸汽在系统或装置的流动过程中的

损失主要包括料液及饱和蒸汽在系统或装置的流动过程中的 损失。

损失。

料液的流动过程 损失为:

损失为:

(19)

(19)

饱和蒸汽的流动过程 损失为:

损失为:

(20)

(20)

式中:Rg为摩尔气体常数。

3.3 拟合公式

(1) 料液的密度

(21)

(21)

式中: ,

, 和

和 分别为料液中苛性碱、氧化铝、碳酸碱的质量浓度,g/L。

分别为料液中苛性碱、氧化铝、碳酸碱的质量浓度,g/L。

(2) 料液的比热容

(22)

(22)

(3) 饱和蒸汽的比焓和比熵

(23)

(23)

(24)

(24)

式中: 为饱和蒸汽的温度,℃。

为饱和蒸汽的温度,℃。

(4) 饱和冷凝水的比焓和比熵

(25)

(25)

(26)

(26)

式中: 为饱和冷凝水的温度,℃。

为饱和冷凝水的温度,℃。

3.4 热平衡测试和物料衡算

热平衡测试是衡量热工设备技术水平和经济性、了解其能量利用率的重要步骤[8]。 ,

, ,

, ,

, ,

, ,

, 和

和 等物性参数必须通过热平衡测试才能获得。

等物性参数必须通过热平衡测试才能获得。

物料衡算可以确定蒸发工序过程或设备输入及输出的物料的流量,它是能量分析的前提[21]。 ,

, 和

和 等参数必须通过物料衡算才能获得。

等参数必须通过物料衡算才能获得。

4 效率

效率就是收益量与支出量之比,主要有热效率和 效率2种。

效率2种。

4.1 热效率

在氧化铝蒸发工序中,热效率 是指实际收益热量与所提供热量之比,即:

是指实际收益热量与所提供热量之比,即:

(27)

(27)

4.2  效率

效率

效率是衡量系统或装置热力学完善度的重要指标,它表明了系统中可用能的利用程度[7, 19]。

效率是衡量系统或装置热力学完善度的重要指标,它表明了系统中可用能的利用程度[7, 19]。 效率越高,表示系统中不可逆因素所引起的

效率越高,表示系统中不可逆因素所引起的 损失越小。

损失越小。

在氧化铝蒸发工序中, 效率ηex是指整个工序在进行转换过程中,收益

效率ηex是指整个工序在进行转换过程中,收益 与支付

与支付 之比,即:

之比,即:

(28)

(28)

效率与热效率有着本质的不同。热效率计算的能量是等价的,不考虑其品位的高低,而

效率与热效率有着本质的不同。热效率计算的能量是等价的,不考虑其品位的高低,而 效率计算的能量是不等价的,考虑了其品位的高低。热效率从数量上说明了有多少能量转变成有用功,

效率计算的能量是不等价的,考虑了其品位的高低。热效率从数量上说明了有多少能量转变成有用功, 效率从质量上说明了有多少可用能被实际利用。所以,

效率从质量上说明了有多少可用能被实际利用。所以, 效率和热效率相结合,可以完整反映出系统或装置的热力学完善度。

效率和热效率相结合,可以完整反映出系统或装置的热力学完善度。

对氧化铝蒸发工序进行能量分析,从平衡表中可以获得系统或装置的热效率和 效率,评价工序的用能水平;从能流图和

效率,评价工序的用能水平;从能流图和 流图中可以看出系统或装置的能量流向,准确把握工序的用能情况;针对热效率小、

流图中可以看出系统或装置的能量流向,准确把握工序的用能情况;针对热效率小、 效率小的高能耗单元环节,能够正确地判断工序节能潜力的大小、部位和限度,确定出用能薄弱环节、节能的主攻方向,增强节能降耗措施的针对性。

效率小的高能耗单元环节,能够正确地判断工序节能潜力的大小、部位和限度,确定出用能薄弱环节、节能的主攻方向,增强节能降耗措施的针对性。

5 实例分析

以国内某铝厂某年的测试数据为基础,运用本文方法,具体分析氧化铝蒸发工序的用能状况。

5.1 蒸发工序热分析

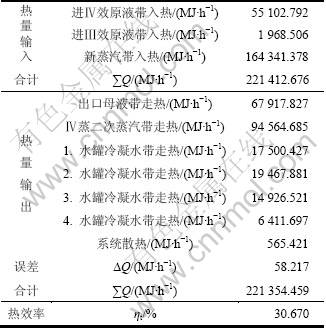

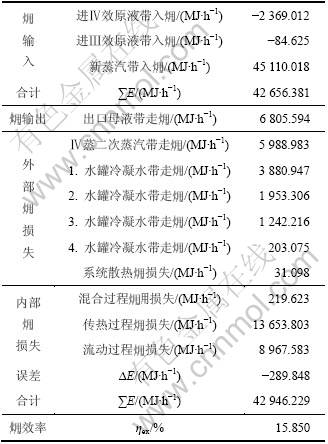

表1所示为某厂蒸发工序热分析结果。图4所示为某厂蒸发工序能流图。

表1 某厂蒸发工序热分析结果

Table 1 Thermal analysis results of evaporation process

系统热量损失Qlosses=152 871.211 MJ/h,折算成标准煤(?Hul=29 260 kJ/kg)为:

kg/h

kg/h

图4 某厂蒸发工序能流图

Fig.4 Energy flow chart of evaporation process

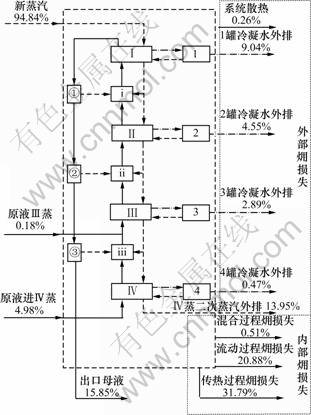

5.2 蒸发工序 分析

分析

表2所示为某厂蒸发工序 分析表。图5所示为某厂蒸发工序

分析表。图5所示为某厂蒸发工序 流图。

流图。

表2 某厂蒸发工序 分析表

分析表

Table 2 Exergy analysis of evaporation process

系统热量损失Elosses=36 140.634 MJ/h,折算成标准煤(?Hul=29 260 kJ/kg)为:

kg/h

kg/h

5.3 结果分析

(1) 整个蒸发工序的热效率(仅为30.67%)和 效率(仅为15.85%)都很低,热损失严重,用能水平低,节能潜力巨大。

效率(仅为15.85%)都很低,热损失严重,用能水平低,节能潜力巨大。

(2) 热损失为Qlosses=15 2871.211 MJ/h,相当于 5 224.58 kg/h的标准煤。热损失表现为:4个冷凝水自蒸发器热损失占26.33%;Ⅳ效蒸发器二次蒸汽热损失占42.71%。

(3)  损失为Elosses=36 140.634 MJ/h,相当于 1 235.15 kg/h的标准煤。

损失为Elosses=36 140.634 MJ/h,相当于 1 235.15 kg/h的标准煤。 损失表现为:① 外部

损失表现为:① 外部 损失:4个冷凝水自蒸发器

损失:4个冷凝水自蒸发器 损失占16.95%;Ⅳ效蒸发器二次蒸汽

损失占16.95%;Ⅳ效蒸发器二次蒸汽 损失占13.95%;② 内部

损失占13.95%;② 内部 损失:混合过程

损失:混合过程 损失占0.51%;传热过程

损失占0.51%;传热过程 损失占31.79%;流动过程

损失占31.79%;流动过程 损失占20.88%。

损失占20.88%。

图5 某厂蒸发工序 流图

流图

Fig.5 Exergy flow chart of evaporation process

(4) 从热分析的角度看:热损失严重的高能耗装置主要是冷凝水自蒸发器和Ⅳ效蒸发器,应重点对其进行分析改进。提高热效率的途径主要是设法利用冷凝水和二次蒸汽的热量。如果将冷凝水用于直接采暖或继续闪蒸利用,则热效率可大幅度提高;如果将Ⅳ效二次蒸汽用于预热原液,热效率也可以大幅度提高。

(5) 从 分析的角度看:

分析的角度看: 损失严重的装置也是冷凝水自蒸发器和Ⅳ效蒸发器,提高

损失严重的装置也是冷凝水自蒸发器和Ⅳ效蒸发器,提高 效率的途径与提高热效率的途径相同,虽然热损失在“数量”上很大,占69.04%,但从“质量”上来说,仅仅占30.90%,所以,节能潜力相对不足;

效率的途径与提高热效率的途径相同,虽然热损失在“数量”上很大,占69.04%,但从“质量”上来说,仅仅占30.90%,所以,节能潜力相对不足; 损失更严重的是蒸发器内传热过程的不可逆损失和料液及蒸汽在工序中由于内部摩擦、涡流、黏性流动等造成的不可逆损失。提高

损失更严重的是蒸发器内传热过程的不可逆损失和料液及蒸汽在工序中由于内部摩擦、涡流、黏性流动等造成的不可逆损失。提高 效率的途径主要有:对蒸发器建立优化模型,获得最优传热温差,以减小传热过程

效率的途径主要有:对蒸发器建立优化模型,获得最优传热温差,以减小传热过程 损失;使用摩擦因数小的管道并尽量减少弯道,可以有效减小流动过程

损失;使用摩擦因数小的管道并尽量减少弯道,可以有效减小流动过程 损失。

损失。

6 结论

(1) 建立了氧化铝蒸发工序的热分析和 分析模型,并应用于蒸发工序节能研究中。计算出蒸发工序的热效率、

分析模型,并应用于蒸发工序节能研究中。计算出蒸发工序的热效率、 效率及

效率及 损失,评价了工序用能水平,确定了耗能的主要环节、部位及节能潜力,指出了蒸发工序的节能降耗途径。

损失,评价了工序用能水平,确定了耗能的主要环节、部位及节能潜力,指出了蒸发工序的节能降耗途径。

(2)  分析是热分析的继续和发展。

分析是热分析的继续和发展。 分析比热分析能更好地确定蒸发工序中的主要耗能环节、部位和节能潜力。

分析比热分析能更好地确定蒸发工序中的主要耗能环节、部位和节能潜力。

参考文献:

[1] 毕诗文, 于海燕. 氧化铝生产工艺[M]. 北京: 化学工业出版社, 2006: 34-37.

BI Shi-wen, YU Hai-yan. The technology of alumina production[M]. Beijing: Chemical Industry Press, 2006: 34-37.

[2] 毕诗文. 拜耳法生产氧化铝[M]. 北京: 冶金工业出版社, 2007: 261-271.

BI Shi-wen. Alumina manufacture with Bayer method[M]. Beijing: Metallurgical Industry Press, 2007: 261-271.

[3] 吴复忠, 蔡九菊, 张琦, 等. 炼铁系统的物质流和能量流的 分析[J]. 工业加热, 2007, 36(1): 15-19.

分析[J]. 工业加热, 2007, 36(1): 15-19.

WU Fu-zhong, CAI Jiu-ju, ZHANG Qi, et al. Exergy analysis of energy and materials flows in the system of ironmaking plants[J]. Industrial Heating, 2007, 36(1): 15-19.

[4] 傅秦生. 能量系统的热力学分析方法[M]. 西安: 西安交通大学出版社, 2005: 87-197.

FU Qin-sheng. Methods of energy analysis of energy system[M]. Xi’an: Xi’an Jiaotong University Press, 2005: 87-197.

[5] 仵浩, 华贲.  的计算及应用[J]. 化工学报, 2007, 58(11): 2697-2704.

的计算及应用[J]. 化工学报, 2007, 58(11): 2697-2704.

WU Hao, HUA Ben. Calculation and application of exergy[J]. Journal of Chemical Industry, 2007, 58(11): 2697-2704.

[6] Noam L, ZHANG Na. Energy, exergy, and second law performance criteria[J]. Energy, 2007, 32(4): 281-296.

[7] 杨洛鹏, 沈胜强, Genthner K, 等. 低温多效蒸发海水淡化系统热力分析[J]. 化学工程, 2006, 34(11): 20-24.

YANG Luo-peng, SHEN Sheng-qiang, Genthner K, et al. Thermal analysis of low temperature seawater multi-effect distillation system[J]. Chemical Engineering, 2006, 34(11): 20-24.

[8] 周乃君. 能源与环境[M]. 长沙: 中南大学出版社, 2008: 124-152.

ZHOU Nai-jun. Energy and environment[M]. Changsha: Central South University Press, 2008: 124-152.

[9] 郑艳梅, 韩郁林. 氯化铵回收的三效降膜蒸发系统的 分析[J]. 天津大学学报, 2007, 40(3): 377-380.

分析[J]. 天津大学学报, 2007, 40(3): 377-380.

ZHENG Yan-mei, HAN Yu-lin. Exergy analysis of three-effect falling-film evaporation system for ammonium chloride recycle[J]. Journal of Tianjin University, 2007, 40(3): 377-380.

[10] 郑丹星, 武向红, 郑大山.  函数的一致性基础[J]. 化工学报, 2002, 53(7): 673-679.

函数的一致性基础[J]. 化工学报, 2002, 53(7): 673-679.

ZHENG Dan-xing, WU Xiang-hong, ZHENG Da-shan. Fundamental of thermodynamic consistence of exergy functions[J]. Journal of Chemical Industry and Engineering, 2002, 53(7): 673-679.

[11] Tsatsaronis G. Definitions and nomenclature in exergy analysis and exergoeconomics[J]. Energy, 2007, 32(4): 249-253.

[12] 曹建华, 王捷, 杨小勇, 等. 高温气冷堆氦气透平直接循环的Exergy分析[J]. 原子能科学技术, 2007, 41(2): 211-214.

CAO Jian-hua, WANG Jie, YANG Xiao-yong, et al. Exergy analysis of gas turbine combined 100 MW high-temperature gas-cooled reactor[J]. Atomic Energy Science and Technology, 2007, 41(2): 211-214.

[13] 王志国, 宋永臣, 刘瑜, 等. NGL深冷分离装置的 分析方法及应用[J]. 哈尔滨工业大学学报, 2006, 38(6): 990-993.

分析方法及应用[J]. 哈尔滨工业大学学报, 2006, 38(6): 990-993.

WANG Zhi-guo, SONG Yong-chen, LIU Yu, et al. Exergy analsis and application for NGL cryogenic separation plant[J]. Journal of Harbin Institute of Technology University, 2006, 38(6): 990-993.

[14] 彭小奇, 宋国辉, 宋彦坡, 等. 氧化铝生产蒸发工序的 分析[J]. 中南大学学报: 自然科学版, 2011, 42(3): 829-834.

分析[J]. 中南大学学报: 自然科学版, 2011, 42(3): 829-834.

PENG Xiao-qi, SONG Guo-hui, SONG Yan-po, et al. Exergy analysis of the evaporation process in an alumina refinery[J]. Journal of Central South University: Science and Technology, 2011, 42(3): 829-834.

[15] 宋国辉, 彭小奇, 宋彦坡, 等. 含相变过程的机械 计算方法[J]. 热科学与技术, 2009, 8(1): 64-68.

计算方法[J]. 热科学与技术, 2009, 8(1): 64-68.

SONG Guo-hui, PENG Xiao-qi, SONG Yan-po, et al. Method for mechanical exergy calculation including phase change process[J]. Journal of Thermal Science and Technology, 2009, 8(1): 64-68.

[16] 朱明善. 能量系统的 分析[M]. 北京: 清华大学出版社, 1988: 101-123.

分析[M]. 北京: 清华大学出版社, 1988: 101-123.

ZHU Ming-shan. Exergy analysis of energy system[M]. Beijing: Tsinghua University Press, 1988: 101-123.

[17] Araujo A B, Brito R P, Vasconcelos L S. Exergetic analysis of distillation processes—A case study[J]. Energy, 2007, 32(7): 1185-1193.

[18] 彭小奇, 宋国辉, 宋彦坡, 等. NaOH-NaAl(OH)4-Na2CO3-H2O体系活度因子的计算模型[J]. 中国有色金属学报, 2009, 19(7): 1332-1337.

PENG Xiao-qi, SONG Guo-hui, SONG Yan-po, et al. Activity coefficient calculation model for NaOH-NaAl(OH)4-Na2CO3- H2O system[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(7): 1332-1337.

[19] El-Nashar A M, Al-Baghdadi A A. Exergy losses in a multiple-effect stack seawater desalination plant[J]. Desalination, 1998, 116(1): 11-24.

[20] 葛斌, 张俊礼, 殷戈. 火电机组热力系统与设备 损分布通用矩阵模型[J]. 东南大学学报: 自然科学版, 2009, 39(5): 1043-1048.

损分布通用矩阵模型[J]. 东南大学学报: 自然科学版, 2009, 39(5): 1043-1048.

GE Bin, ZHANG Jun-li. YIN Ge. General matrix model of exergy distribution of thermodynamic system and its components for coal-fired power unit[J]. Journal of Southeast University: Natural Science Edition, 2009, 39(5): 1043-1048.

[21] 郭怀胜. 宏观物料平衡式推导及其应用[J]. 山东冶金, 2009, 31(6): 50-53.

GUO Huai-sheng. Derivation of macro material balance formula and its application[J]. Shandong Metallurgy, 2009, 31(6): 50-53.

(编辑 陈爱华)

收稿日期:2011-01-15;修回日期:2011-03-28

基金项目:国家自然科学基金重点资助项目(61134006);湖南省高等学校科学研究项目(10W007);湖南省科技计划项目(2010FJ4132);湖南省科技计划项目(2010FJ3056)

通信作者:张建智(1977-),男,福建永安人,讲师,从事有色冶金节能及智能优化等研究;电话:0731-88836713;E-mail: zhangjz@csu.edu.cn