文章编号:1004-0609(2011)07-1734-07

氧化铝生产过程能耗的 分析

分析

陈乔平1, 2, 闫红杰1, 葛世恒1, 周孑民1

(1. 中南大学 能源科学与工程学院,长沙 410083;2. 中国铝业公司 河南分公司,郑州 450041)

摘 要:以 传递理论与

传递理论与 分析方法为基础,建立混联法氧化铝生产过程

分析方法为基础,建立混联法氧化铝生产过程 耗复杂灰箱模型;选取某氧化铝企业2008年两个月生产数据进行计算,得到氧化铝生产过程中各子工序的供给

耗复杂灰箱模型;选取某氧化铝企业2008年两个月生产数据进行计算,得到氧化铝生产过程中各子工序的供给 、

、 损及

损及 效率。计算结果表明:供给

效率。计算结果表明:供给 主要消耗在熟料烧成、焙烧、管道化溶出和蒸发工序,占总供给

主要消耗在熟料烧成、焙烧、管道化溶出和蒸发工序,占总供给 的85%左右;熟料烧成工序

的85%左右;熟料烧成工序 效率最低,仅为7%左右;针对

效率最低,仅为7%左右;针对 损较大的工序展开节能改造可有效降低生产能耗。采用

损较大的工序展开节能改造可有效降低生产能耗。采用 分析方法对流程工业能耗状况进行分析,可以有效评价企业能源利用状况及能量损失,有利于有针对性地挖掘企业节能潜力,降低企业能耗。

分析方法对流程工业能耗状况进行分析,可以有效评价企业能源利用状况及能量损失,有利于有针对性地挖掘企业节能潜力,降低企业能耗。

关键词:系统节能; 分析;氧化铝生产;流程工业

分析;氧化铝生产;流程工业

中图分类号:TK 01 文献标志码:A

Exergy analysis on energy consumption in alumina production

CHEN Qiao-ping1, 2, YAN Hong-jie1, GE Shi-heng1, ZHOU Jie-min1

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Henan Branch, Aluminum Corporation of China, Zhengzhou 450041, China)

Abstraction: A complex grey-box model of alumina production in mixed-combined process was built on the basis of exergy transfer theory and analysis means. According to the two months production data obtained from a certain aluminun corporation, the loss and efficiency of the exergy were calculated. The calculation results show that the supplied exergy is mainly consumed in such unit processes as slurry sintering, aluminium trihydrate calcining, tube digestion and evaporation, which consumes about 85% of the exergy in the alumina production. The slurry sintering process has the lowest exergy efficiency of about 7%. The innovation for energy saving can be proceeded on the unit process with low exergy efficiency. It is not only effective for evaluation of enterprise utilization of energy and quality of energy loss, but also advantageous for making the best of the potential energy saving capacity of enterprise by using exergy analysis method.

Key words:system energy saving; exergy analysis; alumina production; process industry

以系统的观点对流程工业进行能耗分析对于提高企业能源利用效率、降低能耗具有重要意义。以热力学第一定律为基础进行系统能耗分析可以从“量”的角度分析企业能源利用状况,挖掘企业节能潜力;而利用 理论从“品质”角度对系统能耗进行分析,则可以帮助企业更有针对性地进行节能改造,达到节能降耗目的[1-2]。由于

理论从“品质”角度对系统能耗进行分析,则可以帮助企业更有针对性地进行节能改造,达到节能降耗目的[1-2]。由于 分析兼顾能的“动态”与“静态”特性,又可将能的“质”与“量”有机地结合,能够反映能的真正价值,对于优化传递过程,提高用能水平具有很高的学术价值和实际意义[3]。

分析兼顾能的“动态”与“静态”特性,又可将能的“质”与“量”有机地结合,能够反映能的真正价值,对于优化传递过程,提高用能水平具有很高的学术价值和实际意义[3]。

20世纪70年代以后,随着基本概念、基准态模型的建立、 值计算、能级分析以及能理论研究的不断深入,

值计算、能级分析以及能理论研究的不断深入, 理论得到迅速发展,工程应用逐渐展开。通过对生产工艺系统的

理论得到迅速发展,工程应用逐渐展开。通过对生产工艺系统的 分析,可以展示系统

分析,可以展示系统 分布状况,揭示

分布状况,揭示 损分布规律,由此得到对系统能量和能质利用的科学评价。目前,国内外在石化、动力、冶金、制冷等技术领域及能源管理部门中,

损分布规律,由此得到对系统能量和能质利用的科学评价。目前,国内外在石化、动力、冶金、制冷等技术领域及能源管理部门中, 分析理论得到日益广泛的应用[4-10]。然而,由于在

分析理论得到日益广泛的应用[4-10]。然而,由于在 传递现象的描述、传递机理及

传递现象的描述、传递机理及 分析的计算系统模型等方面研究不足,工程应用领域的

分析的计算系统模型等方面研究不足,工程应用领域的 评价与分析方法尚需进行深一步的研究[11]。本文作者选定混联法氧化铝生产工艺系统为研究对象,通过建立其

评价与分析方法尚需进行深一步的研究[11]。本文作者选定混联法氧化铝生产工艺系统为研究对象,通过建立其 分析模型,对氧化铝生产过程能耗现状进行分析与评价。

分析模型,对氧化铝生产过程能耗现状进行分析与评价。

1  分析模型

分析模型

在流程工业能源和资源的合理配置过程中,工程决策不仅要考虑能量的“数量”,更要考虑其“品质”。通过建立合理的系统 分析模型,求解

分析模型,求解 在系统中的时空分布,可以全面正确地反映用能系统中不同各子系统用能的“量”与“质”,进而确定降低不可逆

在系统中的时空分布,可以全面正确地反映用能系统中不同各子系统用能的“量”与“质”,进而确定降低不可逆 损的方向。目前,常用的

损的方向。目前,常用的 分析模型主要有黑箱模型、白箱模型与灰箱模型[12-15]。

分析模型主要有黑箱模型、白箱模型与灰箱模型[12-15]。

1) 黑箱模型

黑箱模型是借助于输入、输出子系统的能流信息来研究子系统内部用能过程宏观特性的一种方法只能对子系统的用能状况做出粗略分析。

其控制方程如下:

(1)

(1)

式中: 为供给

为供给 ,由

,由 源或具有

源或具有 源作用的物质供给体系的

源作用的物质供给体系的 ,通常有燃料

,通常有燃料 、蒸汽

、蒸汽 和电

和电 等。燃料

等。燃料 包括物理

包括物理 和化学

和化学 ;Ex, br带入

;Ex, br带入 ,

, 是除

是除 源以外的物质带入到体系的

源以外的物质带入到体系的 ,如送入炉内助燃的空气

,如送入炉内助燃的空气 ,生产子系统的原料

,生产子系统的原料 等;

等; 为有效

为有效 ,是被子系统有效利用或由子系统输出可有效利用的

,是被子系统有效利用或由子系统输出可有效利用的 。对于动力装置即为输出的机械能,对于工艺子系统即为达到工艺要求的产品离开系统所具有的

。对于动力装置即为输出的机械能,对于工艺子系统即为达到工艺要求的产品离开系统所具有的 ,如锅炉生产的蒸汽

,如锅炉生产的蒸汽 ,水泵出口的压力

,水泵出口的压力 、动能

、动能 等;

等; 为无效

为无效 ,体系输出的总

,体系输出的总 中除有效

中除有效 以外的部分。通常无效

以外的部分。通常无效 即是体系的外部

即是体系的外部 损;

损; 为耗散

为耗散 ,是体系内的不可逆性所引起的能量耗散,即内部

,是体系内的不可逆性所引起的能量耗散,即内部 损。

损。

2) 白箱模型

采用黑箱模型不能分析体系内部的各用能过程的状况,对于一些重要的耗能设备来说,单有黑箱分析显然是不够的。白箱模型为了克服黑箱模型的缺陷,将分析对象看作是由“透明”的边界所包围的系统,从而可以对系统内的各个用能过程逐个进行解剖,计算出各过程的耗散 。因此,白箱模型不仅可以计算子系统的

。因此,白箱模型不仅可以计算子系统的 效率和热力学完善度,而且还能计算出体系内各过程的

效率和热力学完善度,而且还能计算出体系内各过程的 损系数,揭示系统中用能不合理的“薄弱环节”,模型是一种精细的

损系数,揭示系统中用能不合理的“薄弱环节”,模型是一种精细的 分析。

分析。

定义子系统供给 为

为 ,带入

,带入 为

为 ,外部

,外部 损

损 ,内部

,内部 耗为

耗为 ,则有

,则有

(2)

(2)

3) 灰箱模型

从节能的实际效益考虑,单元子系统的 分析只能解决个别的、局部的问题,总能系统的

分析只能解决个别的、局部的问题,总能系统的 分析才能解决整体的、全局的问题。灰箱模型主要用于对系统整体用能状况的评价及对系统中薄弱环节的判别。

分析才能解决整体的、全局的问题。灰箱模型主要用于对系统整体用能状况的评价及对系统中薄弱环节的判别。

灰箱模型是将系统中所有设备均视为黑箱,黑箱与黑箱之间以主 流线连接起来形成网络。因此,灰箱模型实际上是一种黑箱网络模型。

流线连接起来形成网络。因此,灰箱模型实际上是一种黑箱网络模型。

无论何种设备,按黑箱模型分析都是5个量,即供给 、带入

、带入 、有效

、有效 、内部

、内部 损和外部

损和外部 损。为使网络单元能以简化形式表示,将上述5个量组合为4个量,即:供给

损。为使网络单元能以简化形式表示,将上述5个量组合为4个量,即:供给 ,以

,以 表示;带入

表示;带入 ,有效

,有效 (输出净收益

(输出净收益 )。总

)。总 损为内、外

损为内、外 损之和,以

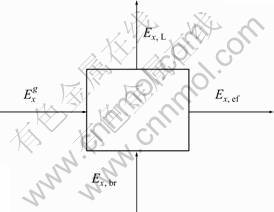

损之和,以 表示。因此,系统中的任何子系统或设备均可以表示为4个量组成的网络单元,如图1所示。

表示。因此,系统中的任何子系统或设备均可以表示为4个量组成的网络单元,如图1所示。

以黑箱网络表示的灰箱模型有下面两种基本形式:

1) 黑箱串联网络模型(串联模型)。若系统中的所有设备都是由主 流线或主物流线串联起来的,该系统就可以表示为串联网络模型。

流线或主物流线串联起来的,该系统就可以表示为串联网络模型。

图1 黑箱网络单元

Fig.1 Black box network unit

2) 黑箱并联网络模型(并联模型)。一个由多台设备组成的系统,各台设备的主要物流或主 流线都互相平行而不相交,且各台设备的输出有效

流线都互相平行而不相交,且各台设备的输出有效 最终汇集在一起后再向外输出,这样的系统叫做并联网络系统。当将系统内所有设备视为黑箱组成灰箱模型时,就构成黑箱并联网络模型。

最终汇集在一起后再向外输出,这样的系统叫做并联网络系统。当将系统内所有设备视为黑箱组成灰箱模型时,就构成黑箱并联网络模型。

2 氧化铝生产工艺过程 分析模型的建立

分析模型的建立

本实验所研究氧化铝企业的生产工艺为混联法,各子工序之间的关系既有串联、又有并联,个别还有混联关系,因此,根据氧化铝生产过程的特点,采用复杂灰箱模型对其进行 分析比较合理。

分析比较合理。

在建立混联法氧化铝生产工艺 分析模型的过程中,作了如下考虑:

分析模型的过程中,作了如下考虑:

1) 以工序为控制单元,将氧化铝生产工艺过程中每个工序看作单独的黑箱模型进行分析,其中由于氢氧化铝是不定晶型,相关热力学参数不全,因此,把晶种分解和焙烧看作是一个黑箱模型。

2) 每个工序的的 分析模型都包括原料(上游工序来料)的带入

分析模型都包括原料(上游工序来料)的带入 、中间设备或能源的供给

、中间设备或能源的供给 、有效

、有效 和

和 损4个部分。

损4个部分。

3) 由于2008年企业能耗波动较大,故采用2008年上半年工艺能耗最高的2月份和工艺能耗最低的6月份的生产数据进行计算分析。通过纵向和横向的比较,分析各个环节的用能状况,以及各环节用能随生产状况改变时的变化情况。

4) 所有计算的 流均是计算周期内每产1 t氧化铝该工序的

流均是计算周期内每产1 t氧化铝该工序的 流量,单位为GJ/t。

流量,单位为GJ/t。

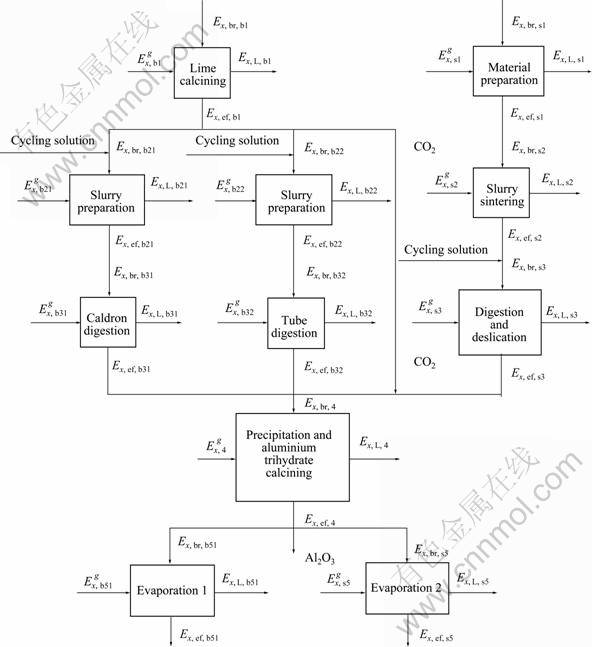

氧化铝生产工艺过程的 流程图如图2所示。在对各子工序进行

流程图如图2所示。在对各子工序进行 分析计算时,遵循热力学第一定律,

分析计算时,遵循热力学第一定律, 平衡方程如下:

平衡方程如下:

(3)

(3)

式中: 为原料(或上级工序来料)的带入

为原料(或上级工序来料)的带入 ,GJ/t;

,GJ/t; 为能源或设备的供给

为能源或设备的供给 ,GJ/t;Ex, ef为工序有效

,GJ/t;Ex, ef为工序有效 ,GJ/t;

,GJ/t; 为工序

为工序 损,GJ/t。

损,GJ/t。

则 效率可以定义为

效率可以定义为

(4)

(4)

3 氧化铝生产工艺过程 耗计算与 分析

耗计算与 分析

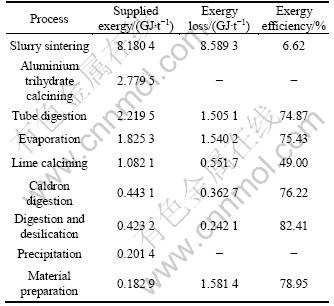

通过对氧化铝生产工艺 分析灰箱模型的合理分解,对各子工序采用黑箱模型进行求解,其吨氧化铝各生产工序的

分析灰箱模型的合理分解,对各子工序采用黑箱模型进行求解,其吨氧化铝各生产工序的 耗、

耗、 损和

损和 效率如表1和2所列,计算结果分析如下:

效率如表1和2所列,计算结果分析如下:

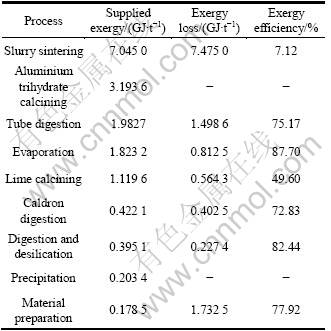

1) 从表1和2可以看出,氧化铝生产过程供给 主要集中在熟料烧成、焙烧、管道化溶出和蒸发工序。2008年2月份,上述4个工序供给

主要集中在熟料烧成、焙烧、管道化溶出和蒸发工序。2008年2月份,上述4个工序供给 占整个生产过程供给

占整个生产过程供给 的86.55%;6月份,上述4个工序供给

的86.55%;6月份,上述4个工序供给 占整个生产过程供给

占整个生产过程供给 的85.83%。提高单个工序或单体设备能源利用率的研究应主要针对这4个工序展开。

的85.83%。提高单个工序或单体设备能源利用率的研究应主要针对这4个工序展开。

2) 2008年6月份,该企业氧化铝生产过程吨氧化铝供给 为16.363 2 GJ/t,比2月份的17.337 4 GJ/t降低5.62%。在整体能耗下降的情况下,2008年6月份,焙烧工序和石灰煅烧工序的能耗反而有所上升,说明上述两个工序主要设备运行状况与操作存在一定问题。

为16.363 2 GJ/t,比2月份的17.337 4 GJ/t降低5.62%。在整体能耗下降的情况下,2008年6月份,焙烧工序和石灰煅烧工序的能耗反而有所上升,说明上述两个工序主要设备运行状况与操作存在一定问题。

3) 由于氧化铝生产过程基本封闭进行,外排物质较少,因此各工序 效率较高。但熟料烧成和石灰煅烧工序

效率较高。但熟料烧成和石灰煅烧工序 效率很低,分别在6%~8%和49%左右。这是由于熟料烧成和石灰煅烧生产工序中,都涉及燃料的燃烧过程,而燃料的燃烧过程的不可逆

效率很低,分别在6%~8%和49%左右。这是由于熟料烧成和石灰煅烧生产工序中,都涉及燃料的燃烧过程,而燃料的燃烧过程的不可逆 损(内部

损(内部 损)较大,一般占燃料

损)较大,一般占燃料 的20%~30%以上。这是造成工序

的20%~30%以上。这是造成工序 利用效率低的一个主要原因。

利用效率低的一个主要原因。

表1 2008年2月份各生产工序供给 、

、 损和

损和 效率

效率

Table 1 Supplied exergy, exergy loss and exergy efficiency of processes in February, 2008

图2 氧化铝生产工艺 分析模型示意图

分析模型示意图

Fig.2 Exergy analysis model of alumina production process (The third subscript is code of alumina production procoss)

4) 工序 利用效率低的另一个主要原因为外部

利用效率低的另一个主要原因为外部 损。外部

损。外部 损是系统向外界无意义的泄露和排放的能量。管道化溶出、高压溶出和熟料溶出工序向生产系统外界排出赤泥(部分赤泥送入烧结法工序继续利用),虽然热含量很大,但能量的能级低,且赤泥的形态特殊,难以利用。

损是系统向外界无意义的泄露和排放的能量。管道化溶出、高压溶出和熟料溶出工序向生产系统外界排出赤泥(部分赤泥送入烧结法工序继续利用),虽然热含量很大,但能量的能级低,且赤泥的形态特殊,难以利用。

5) 熟料烧成是用能最多、 效率最低的工序。

效率最低的工序。 损失甚至超过供给

损失甚至超过供给 ,其主要原因除了燃烧过程的不可逆热损失以外,该工序还向系统外排放了大量含水蒸汽的烟气,导致较高的外部

,其主要原因除了燃烧过程的不可逆热损失以外,该工序还向系统外排放了大量含水蒸汽的烟气,导致较高的外部 损,回收这部分烟气的

损,回收这部分烟气的 将有助于提高工序的能源利用效率,降低生产成本。该工序另一个主要的外部

将有助于提高工序的能源利用效率,降低生产成本。该工序另一个主要的外部 损为设备表面散热带来的

损为设备表面散热带来的 损。由于熟料烧成设备为回转窑,表面温度较高,散热损失较大,且余热回收困难。如果能够通过技术研发解决回收回转窑表面余热的难题,将使熟料烧成工序的

损。由于熟料烧成设备为回转窑,表面温度较高,散热损失较大,且余热回收困难。如果能够通过技术研发解决回收回转窑表面余热的难题,将使熟料烧成工序的 效率提高到一个新的水平。石灰煅烧工序产生的CO2用于二精液的碳酸化分解,烟气带走的热量得以充分利用,且石灰炉散热损失较少,减少外部

效率提高到一个新的水平。石灰煅烧工序产生的CO2用于二精液的碳酸化分解,烟气带走的热量得以充分利用,且石灰炉散热损失较少,减少外部 损,因此,尽管存在燃烧过程的不可逆

损,因此,尽管存在燃烧过程的不可逆 损,但该工序的

损,但该工序的 效率相对于熟料烧成工序较高。

效率相对于熟料烧成工序较高。

表2 2008年6月份各生产工序供给 、

、 损和

损和 效率

效率

Table 2 Supplied exergy, exergy loss and exergy efficiency of processes in June, 2008

6) 由于氢氧化铝是非定型晶体,无法计算出其化学 ,因此把分解工序和焙烧工序合并,看成一个黑箱模型。该模型的主要能源供应在焙烧工序, 2月份和6月份的

,因此把分解工序和焙烧工序合并,看成一个黑箱模型。该模型的主要能源供应在焙烧工序, 2月份和6月份的 效率分别是45.12%和46.78%。焙烧工序中不但存在燃烧过程的不可逆

效率分别是45.12%和46.78%。焙烧工序中不但存在燃烧过程的不可逆 损,且烟气、成品氧化铝带走一定量的能量,这必将导致该工序

损,且烟气、成品氧化铝带走一定量的能量,这必将导致该工序 损大,

损大, 效率低,可以考虑回收烟气余热以提高

效率低,可以考虑回收烟气余热以提高 效率。

效率。

7) 蒸发工序 效率为75%~88%。

效率为75%~88%。 损主要原因是由于该工序末效蒸发器从原液蒸发出的大量蒸汽采用水喷淋吸收、自然降温的方法处理,这部分余热未得到有效利用。

损主要原因是由于该工序末效蒸发器从原液蒸发出的大量蒸汽采用水喷淋吸收、自然降温的方法处理,这部分余热未得到有效利用。

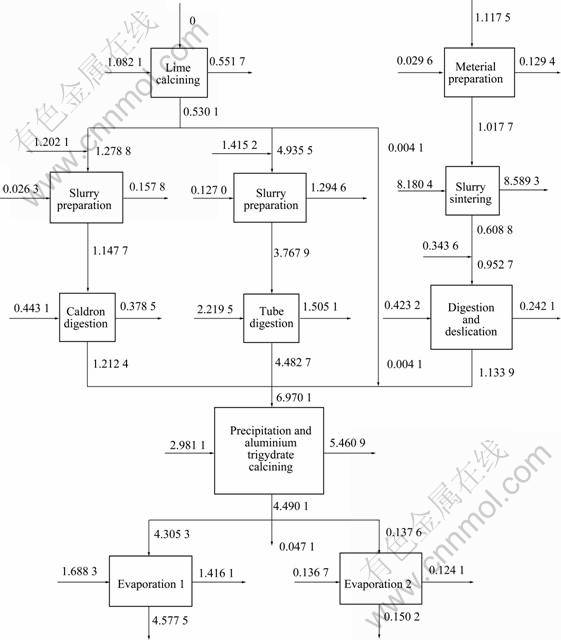

在利用 分析灰箱模型计算的基础上,绘制出混联法氧化铝生产工艺过程的

分析灰箱模型计算的基础上,绘制出混联法氧化铝生产工艺过程的 流图(2008年2月份数据)如图3所示。从图3可以清晰看出,氧化铝生产工艺过程中能量流动与分布状况。

流图(2008年2月份数据)如图3所示。从图3可以清晰看出,氧化铝生产工艺过程中能量流动与分布状况。

4 氧化铝生产过程单个工序 损分布计算

损分布计算

生产过程中的 损,一般是由机械、热与化学3种不可逆因素引起的。氧化铝生产是湿法冶金过程,生产流程比较封闭,除熟料烧成、石灰煅烧和分解与焙烧工序外,其他各工序

损,一般是由机械、热与化学3种不可逆因素引起的。氧化铝生产是湿法冶金过程,生产流程比较封闭,除熟料烧成、石灰煅烧和分解与焙烧工序外,其他各工序 效率均较高;这些工序主要的

效率均较高;这些工序主要的 损是内部的燃烧过程、传热过程以及化学反应过程的不可逆

损是内部的燃烧过程、传热过程以及化学反应过程的不可逆 损和外部的排放

损和外部的排放 损。

损。

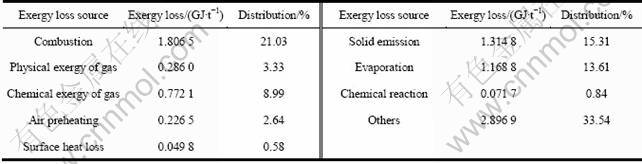

孰料烧成工序为 效率较低的工序,因此,对2008年2月份熟料烧成工序主要

效率较低的工序,因此,对2008年2月份熟料烧成工序主要 损分布进行了计算,结果列于表3。从表3可以看出:1) 生料浆水分蒸发、烟气化学

损分布进行了计算,结果列于表3。从表3可以看出:1) 生料浆水分蒸发、烟气化学 、主要化学反应、空气预热等过程的

、主要化学反应、空气预热等过程的 损占熟料烧成工序总

损占熟料烧成工序总 损的26.08%,这部分

损的26.08%,这部分 损主要为不可逆

损主要为不可逆 损,比较难以回收,但合理降低生料浆含水量可有效降低水分蒸发所造成的不可逆

损,比较难以回收,但合理降低生料浆含水量可有效降低水分蒸发所造成的不可逆 损。2) 绝热燃烧过程的

损。2) 绝热燃烧过程的 损占工序总

损占工序总 损的21.03%,提高助燃空气温度,减少空气过剩系数是降低绝热燃烧

损的21.03%,提高助燃空气温度,减少空气过剩系数是降低绝热燃烧 损主要方式。3) 烟气物理

损主要方式。3) 烟气物理 损、外排杂质及炉体散热造成的

损、外排杂质及炉体散热造成的 损占工序总

损占工序总 损的19.22%,针对这些过程强化余热回收利用,减少不必要的

损的19.22%,针对这些过程强化余热回收利用,减少不必要的 损,可有效提高能源利用效率。以烟气物理

损,可有效提高能源利用效率。以烟气物理 损和炉体散热

损和炉体散热 损计算,尽管两者仅占工序

损计算,尽管两者仅占工序 损的3.91%,但折合成标准煤为 1 193×103 kg/a(34 919.11 GJ/a),其经济效益与社会效益非常可观。4) 其他

损的3.91%,但折合成标准煤为 1 193×103 kg/a(34 919.11 GJ/a),其经济效益与社会效益非常可观。4) 其他 损主要包括流动、混合、副化学反应、传热(不含生料浆水分蒸发部分)等过程产生的

损主要包括流动、混合、副化学反应、传热(不含生料浆水分蒸发部分)等过程产生的 损,占工序

损,占工序 损的33.54%。这部分

损的33.54%。这部分 损就目前设备状况难以回收利用,但可采用优化操作结构与参数的方式,如提高生料预热温度和强化烧结过程等进行改善,以达到提高设备的能源利用率和降低能耗的目的。

损就目前设备状况难以回收利用,但可采用优化操作结构与参数的方式,如提高生料预热温度和强化烧结过程等进行改善,以达到提高设备的能源利用率和降低能耗的目的。

表3 熟料烧成工序 损分布

损分布

Table 3 Distribution of exergy loss in process of slurry sintering

图3 2008年2月份吨氧化铝的 流图

流图

Fig.3 Exergy flow diagram per ton alumina in February, 2008 (GJ/t)

5 结论

1) 对流程工业采用 分析的方法进行企业生产过程能耗水平分析,可以有效评价工艺过程中能源品质与使用效率,有利于企业合理调配资源,更有针对性地挖掘企业节能潜力。

分析的方法进行企业生产过程能耗水平分析,可以有效评价工艺过程中能源品质与使用效率,有利于企业合理调配资源,更有针对性地挖掘企业节能潜力。

2) 以中国铝业某分公司氧化铝厂生产工艺系统为研究对象,以 传递理论及

传递理论及 分析方法为基础,建立混联法氧化铝生产工艺系统

分析方法为基础,建立混联法氧化铝生产工艺系统 分析的灰箱模型,并对生产过程进行合理分解,形成独立的单元子系统,便于计算分析。

分析的灰箱模型,并对生产过程进行合理分解,形成独立的单元子系统,便于计算分析。

3) 对混联法氧化铝生产过程 耗进行了计算与分析,结果表明,熟料烧成、焙烧、管道化溶出和蒸发4个工序的供给

耗进行了计算与分析,结果表明,熟料烧成、焙烧、管道化溶出和蒸发4个工序的供给 较大,占整个生产工艺过程总供给

较大,占整个生产工艺过程总供给 的86%左右,应着重关注这4个工序的能源利用效率。

的86%左右,应着重关注这4个工序的能源利用效率。

4) 熟料烧成与石灰煅烧工序 效率较低,对熟料烧成工序的

效率较低,对熟料烧成工序的 损分布进行了计算与分析,提出了节能建议。

损分布进行了计算与分析,提出了节能建议。

REFERENCES

[1] 殷瑞钰. 冶金流程工程学[M]. 北京: 冶金工业出版社, 2004: 72-112

YIN Rui-yu. Metallurgical process engineering[M]. Beijing: Metallurgical Industry Press, 2004: 72-112.

[2] DAI Yi-ping, WANG Jian-feng, GAO Lin. Exergy analysis, parametric analysis and optimization for a novel combined power and ejector refrigeration cycle[J]. Applied Thermal Engineering, 2009, 29: 1983-1990.

[3] 成庆林, 周海莲, 项新耀.  传递系数的定义及其影响机制[J]. 华北电力大学学报, 2009, 36(3): 43-46.

传递系数的定义及其影响机制[J]. 华北电力大学学报, 2009, 36(3): 43-46.

CHENG Qing-lin, ZHOU Hai-lian, XIANG Xin-yao. The definition of exergy transfer coefficient and its influence mechanism[J]. Journal of North China Electric Power University, 2009, 36(3): 43-46.

[4] 成庆林, 刘 扬, 项新耀.  传递—热力学理论研究的新领域[J]. 大庆石油学院学报, 2007, 31(4): 63-67.

传递—热力学理论研究的新领域[J]. 大庆石油学院学报, 2007, 31(4): 63-67.

CHENG Qing-lin, LIU Yang, XIANG Xin-yao. Exergy transfer—new field of thermodynamics theory study[J]. Journal of Daqing Petroleum Institute, 2007, 31(4): 63-67.

[5] 李亚奇, 何雅玲, 王巍巍. 碟式集热器驱动斯特林热机系统 效率分析[J]. 工程热物理学报, 2009, 30(6): 911-914.

效率分析[J]. 工程热物理学报, 2009, 30(6): 911-914.

LI Ya-qi, HE Ya-ling, WANG Wei-wei. Exergy efficiency analysis of Stirling heat engine driven by solar dish collector based on FTT[J]. Journal of Engineering Thermophysics, 2009, 30(6): 911-914.

[6] 冯俊小, 张 宇, 谢知音, 张 材, 果乃涛. 回转窑内铁矿氧化球团焙烧过程的能量和 分析[J]. 华北电力大学学报, 2009, 36(3): 33-37.

分析[J]. 华北电力大学学报, 2009, 36(3): 33-37.

FENG Jun-xiao, ZHANG Yu, XIE Zhi-yin, ZHANG Cai, GUO Nai-tao. Energy and exergy analysis of iron ore pellets induration in the kiln[J]. Journal of North China Electric Power University, 2009, 36(3): 33-37.

[7] ROSEN M A, DINCER I. Exergy-cost-energy-mass analysis of thermal systems and processes[J]. Energy Conversion and Management, 2003, 44: 1633-1651.

[8] CAMDALI U, TUNC M. Exergy analysis and efficiency in an industrial AC electric ARC furnace[J]. Applied Thermal Engineering, 2003, 23: 2255-2267.

[9] BECERRA-LOPEZ H R, GOLDING P. Dynamic exergy analysis for capacity expansion of regional power-generation systems: Case study of far west Texas[J]. Energy, 2007, 32: 2167-2186.

[10] OLADIRAN M T, MEYER J P. Energy and exergy analysis of energy consumptions in the industrial sector in South Africa[J]. Applied Energy, 2007, 84: 1056-1067.

[11] 谷雅秀, 吴裕远.  传递与

传递与 经济分析的研究进展与展望[J]. 西安交通大学学报: 社会科学版, 2005, 25(2): 21-25.

经济分析的研究进展与展望[J]. 西安交通大学学报: 社会科学版, 2005, 25(2): 21-25.

GU Ya-xiu, WU Yu-yuan. Research progress and prospect of exergy transfer and exergoeconmic analysis[J]. Journal of Xi’an Jiaotong University: Social Sciences Edition, 2005, 25(2): 21-25.

[12] 朱明善. 能量系统的 分析[M]. 北京: 清华大学出版社, 1988: 195-201.

分析[M]. 北京: 清华大学出版社, 1988: 195-201.

ZHU Ming-shan. Exergy analysis on energy systems[M]. Beijing: Tsinghua University Press, 1988: 195-201.

[13] GARDEL A. Energy-economy and prospective[M]. Pergamon Press, 1981: 30-92.

[14] 傅秦生. 能量系统的热力学分析方法[M]. 西安: 西安交通大学出版社, 2005: 78-134.

FU Qing-sheng. Thermodynamics analysis method of energy system[M]. Xian: Xian Jiaotong University Press, 2005: 78-134.

[15] REISTAD G M, FABRYCKY W J. Available-energy costing, thermodynamics: Second law analysis[J]. ACS Symposium Series, 1980, 122: 143-159.

(编辑 龙怀中)

基金项目:湖南省自然科学青年基金资助项目(07JJ4016)

收稿日期:2010-05-05;修订日期:2010-05-27

通信作者:闫红杰,副教授,博士;电话:0731-88836239;E-mail:s-rfy@mail.csu.edu.cn