DOI: 10.11817/j.issn.1672-7207.2016.12.039

氧化铝蒸发工序用能分析及系统优化节能研究

张建智1,彭小奇1, 2,陶焰明1,宋彦坡1,伍雁鹏1

(1. 中南大学 能源科学与工程学院,湖南 长沙,410083;

2. 湖南第一师范学院 信息科学与工程系,湖南 长沙,410205)

摘要:利用 分析方法建立氧化铝蒸发工序的能耗模型,运用

分析方法建立氧化铝蒸发工序的能耗模型,运用 效率等评价准则对工序的用能状况进行分析。基于“三环节”能量系统优化理论提出利用余热回收工序预热原液的能量系统优化方法,建立蒸发工序当前运行状态下能量回收用于预热原液后的系统能耗模型,并进行优化计算。研究结果表明:适当提高蒸发工序入口料液温度可有效降低新蒸汽消耗,从而提高氧化铝生产蒸发工序的用能水平。

效率等评价准则对工序的用能状况进行分析。基于“三环节”能量系统优化理论提出利用余热回收工序预热原液的能量系统优化方法,建立蒸发工序当前运行状态下能量回收用于预热原液后的系统能耗模型,并进行优化计算。研究结果表明:适当提高蒸发工序入口料液温度可有效降低新蒸汽消耗,从而提高氧化铝生产蒸发工序的用能水平。

关键词:氧化铝;蒸发工序; 分析;系统优化;节能

分析;系统优化;节能

中图分类号:TF802.62 文献标志码:A 文章编号:1672-7207(2016)12-4263-07

Research of energy saving optimization system for alumina production evaporation process based on thermal analysis

ZHANG Jianzhi1, PENG Xiaoqi1, 2, TAO Yanming1, SONG Yanpo1, WU Yanpeng1

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Department of Information Science and Engineering, Hunan First Normal University, Changsha 410205, China)

Abstract: A energy analyzing model was developed by using exergy method, and the energy consumption level was evaluated according to exergy efficiency and other indexes. Based on “Three part” energy system optimization theory,an optimization scheme of preheating ore pulp with recycled waste heat was proposed. Energy consumption models for the evaporation systems before and after optimization were developed, and optimization computations were made. The results show that increasing ore pulp temperature at inlet of evaporator process can effectively reduce the amount of consumed new vapour and therefore improve the energy utilization level of the evaporation process.

Key words: alumina; evaporation process; exergy analysis; system optimization; energy saving

铝是民用、军事和高技术发展必不可少的基础材料。尽管我国原铝产量占全球1/4左右,氧化铝产量居世界第一,但以一水硬铝石型铝土矿为主要原料的氧化铝平均综合能耗约为国外先进水平的2~3倍,严重影响了铝工业的可持续发展和世界竞争力[1],因此,有必要对氧化铝生产过程的用能状况进行分析、诊断和评价,提出切实有效的用能方案,促进氧化铝生产过程节能降耗[2-3]。能量分析主要有热分析和 分析2种[4]。由于

分析2种[4]。由于 分析方法综合考虑了能量的“数量”和“质量”属性,通过建立

分析方法综合考虑了能量的“数量”和“质量”属性,通过建立 平衡方程,利用

平衡方程,利用 效率、热力学完善度等用能评价指标,可以更科学地评价系统、单元或设备的用能水平,因而在用能分析中被广泛使用。吴复忠等[5]通过建立烧结、球团和炼铁等工序的

效率、热力学完善度等用能评价指标,可以更科学地评价系统、单元或设备的用能水平,因而在用能分析中被广泛使用。吴复忠等[5]通过建立烧结、球团和炼铁等工序的 效率、

效率、 损失的

损失的 分析模型,指出了炼铁系统的节能方向和途径;蒋爱华等[6]建立了SKS氧气底吹炉的

分析模型,指出了炼铁系统的节能方向和途径;蒋爱华等[6]建立了SKS氧气底吹炉的 分析模型,计算了系统热量损失、

分析模型,计算了系统热量损失、 损失及

损失及 效率,并将热分析和

效率,并将热分析和 分析2种方法进行比较,发现

分析2种方法进行比较,发现 分析比热分析更能反映系统物质流和能量流的本质;ARAUJO等[7]对生产氯乙烯的精馏系统进行了

分析比热分析更能反映系统物质流和能量流的本质;ARAUJO等[7]对生产氯乙烯的精馏系统进行了 分析,计算出各生产环节的

分析,计算出各生产环节的 效率,以此指导并借助Aspen流程仿真软件研究设备的节能优化。尽管

效率,以此指导并借助Aspen流程仿真软件研究设备的节能优化。尽管 分析法在化工、电力、钢铁等领域已得到广泛应用,但在有色冶金行业应用较少。为此,本文作者应用

分析法在化工、电力、钢铁等领域已得到广泛应用,但在有色冶金行业应用较少。为此,本文作者应用 分析法建立氧化铝蒸发工序的能耗模型,并据此对氧化铝蒸发过程开展用能优化研究。

分析法建立氧化铝蒸发工序的能耗模型,并据此对氧化铝蒸发过程开展用能优化研究。

1 氧化铝蒸发工序

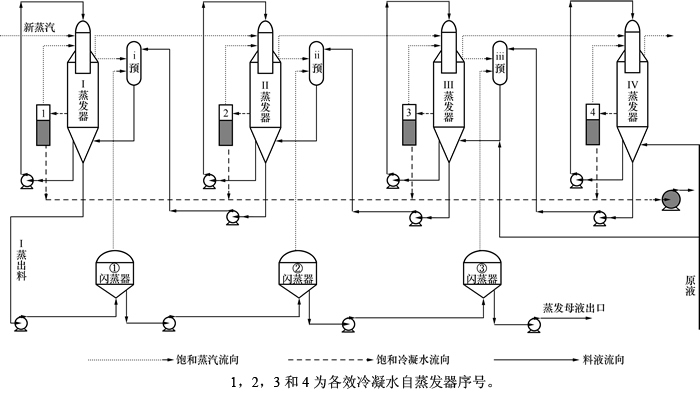

氧化铝生产是一个典型的长流程、高能耗的有色冶金过程。以拜耳法生产氧化铝为例,其流程主要工序为“原矿浆制备—高压溶出—溶出矿浆稀释—赤泥的分离和洗涤—晶种分解—氧化铝分级与洗涤—氧化铝焙烧—种分母液蒸发”等。种分母液蒸发过程在整个氧化铝生产过程中耗能最高,其能耗占生产总能耗的20%~25%,汽耗占总汽耗的48%~52%[8]。图1所示为某氧化铝厂蒸发工序采用的四效逆流三级闪蒸的管式降膜蒸发系统。蒸发原液泵送至Ⅳ效蒸发器,经Ⅳ—Ⅲ—Ⅱ—Ⅰ效蒸发器逆流逐级加热,再经三级闪蒸器闪蒸浓缩,由过料泵送出;新蒸汽进入Ⅰ效蒸发器对料液加热,Ⅰ效至Ⅲ效蒸发器的二次蒸汽分别作为下一效蒸发器的热源,Ⅳ效(末效)蒸发器的二次蒸汽经冷凝器降温后排出;①,②和③级闪蒸器的二次蒸汽以及Ⅰ,Ⅱ和Ⅲ效蒸发器的小部分二次蒸汽分别通入i,ii和iii效预热器,与预热器内的溶液混合,对溶液进行加热;Ⅰ,Ⅱ,Ⅲ和Ⅳ效蒸发器的冷凝水分别通入1,2,3和4效冷凝水自蒸发器,自蒸发产生的部分乏汽分别作为各效蒸发器的热源,其冷凝水汇入一次水泵并排出。

2 蒸发工序用能分析

2.1 蒸发工序 分析模型

分析模型

热力学系统的 是指系统经可逆过程达到与环境处于完全热力学平衡状态时所能获得的理论最大有用功[9-11]。氧化铝蒸发工序一般存在5类

是指系统经可逆过程达到与环境处于完全热力学平衡状态时所能获得的理论最大有用功[9-11]。氧化铝蒸发工序一般存在5类 流(如图2所示):

流(如图2所示):

1) 输入 流Exi,包括第一类载体(新蒸汽)和第二类载体(原液)所含的

流Exi,包括第一类载体(新蒸汽)和第二类载体(原液)所含的 。

。

2) 回收自用 流Exr。本工序回收自用的

流Exr。本工序回收自用的 ,主要包括:Ⅰ,Ⅱ和Ⅲ效蒸发器产生的二次蒸汽所含的

,主要包括:Ⅰ,Ⅱ和Ⅲ效蒸发器产生的二次蒸汽所含的 ;①,②和③级闪蒸器闪蒸二次蒸汽所含的

;①,②和③级闪蒸器闪蒸二次蒸汽所含的 ;1,2,3和4效冷凝水自蒸发器闪蒸二次蒸汽所含的

;1,2,3和4效冷凝水自蒸发器闪蒸二次蒸汽所含的 。

。

3) 内部损失 流Exil,包括传热过程

流Exil,包括传热过程 损失、混合过程

损失、混合过程 损失和流动过程

损失和流动过程 损失。

损失。

4) 外部损失 流Exol,包括散热

流Exol,包括散热 损失、Ⅳ效蒸发器产生二次蒸汽所含的

损失、Ⅳ效蒸发器产生二次蒸汽所含的 、各效冷凝水自蒸发器外排冷凝水所含的

、各效冷凝水自蒸发器外排冷凝水所含的 。

。

图1 蒸发工序工艺流程图

Fig. 1 Flow chart of evaporation process

图2 蒸发工序 流图

流图

Fig. 2 Exergy flow chart of evaporation process

5) 输出 流Exo,即本工序母液所含的

流Exo,即本工序母液所含的 。

。

通过 流分析,可建立如下蒸发工序的

流分析,可建立如下蒸发工序的 平衡方程:

平衡方程:

(1)

(1)

2.2 蒸发工序 计算

计算

2.2.1 环境基准模型

选用修正的龟山-吉田环境模型,死态条件为T0=298.15 K,p0=0.1 MPa;空气中含有的各种元素以空气相应的组成气体为基准物,以饱和湿空气的摩尔成分为基准物成分;其他元素以含有该元素的最稳定纯物质(液态或固态)为其基准物[12]。

2.2.2 料液 计算

计算

物料的 主要包含物理

主要包含物理 和化学

和化学 。物理

。物理 是系统相对于环境因温度和压力不同而具有的

是系统相对于环境因温度和压力不同而具有的 。化学

。化学 是混合物系统相对于环境因化学成分和浓度的不同而具有的

是混合物系统相对于环境因化学成分和浓度的不同而具有的 ,包括由该物质与环境反应物反应产生环境生成物所获得的反应

,包括由该物质与环境反应物反应产生环境生成物所获得的反应 及由环境生成物浓度扩散到非约束死态时的扩散

及由环境生成物浓度扩散到非约束死态时的扩散 [13]。

[13]。

1) 物理 。料液在状态(T,p)下的比物理

。料液在状态(T,p)下的比物理 为

为

(2)

(2)

式中:v为物料的比体积,m3/kg;T和T0分别为工况和环境基准热力学温度,K;p和p0分别为工况压力和环境基准压力,MPa。

2) 化学 。由于蒸发工序中无化学反应,故实际

。由于蒸发工序中无化学反应,故实际 分析中不计入反应

分析中不计入反应 [13, 7]。料液的比化学

[13, 7]。料液的比化学 为

为

(3)

(3)

式中:mi为料液中第i种组分的质量摩尔分数,mol/kg;ri为料液中第i种组分的活度因子,可由NaOH-NaAl(OH)4-Na2CO3-H2O体系的活度系数计算模型获得[14]。

2.2.3 饱和蒸汽 值计算

值计算

(4)

(4)

(5)

(5)

式中: 为饱和蒸汽比

为饱和蒸汽比 ,J/g;

,J/g; 和

和 分别为饱和蒸汽的比焓和比熵,J/g;h0和s0分别为基准温度下饱和蒸汽的比焓和比熵,h0=2 546.54 J/g,s0=8.556 8 J/g。

分别为饱和蒸汽的比焓和比熵,J/g;h0和s0分别为基准温度下饱和蒸汽的比焓和比熵,h0=2 546.54 J/g,s0=8.556 8 J/g。

2.2.4 饱和冷凝水 计算

计算

(6)

(6)

(7)

(7)

式中: 为饱和冷凝水比

为饱和冷凝水比 ,J/g;

,J/g; 和

和 分别为饱和冷凝水的比焓、比熵,J/g。

分别为饱和冷凝水的比焓、比熵,J/g。

2.2.5 外部 损失

损失

1) 散热 损失。经系统或装置表面散失到环境中的能量虽有

损失。经系统或装置表面散失到环境中的能量虽有 ,但一般难以利用。若系统或装置表面温度为Tsurroud,散失的热量为QL,则相应的

,但一般难以利用。若系统或装置表面温度为Tsurroud,散失的热量为QL,则相应的 损失EL,out-losses为

损失EL,out-losses为

(8)

(8)

2) 外排 损失。流经系统或装置的排出物所携带的能量若直接排到环境中,则构成“外排

损失。流经系统或装置的排出物所携带的能量若直接排到环境中,则构成“外排 损失”[15],如外排冷凝水、外排二次蒸汽。

损失”[15],如外排冷凝水、外排二次蒸汽。

2.2.6 内部 损失

损失

在不可逆过程中,能量的一部分将不能被利用,并因此造成可用能损失[16]。蒸发工序中的内部 损失主要有下面3种。

损失主要有下面3种。

1) 传热过程 损失。蒸发工序中传递的热量为Qchange,则传热过程产生的不可逆

损失。蒸发工序中传递的热量为Qchange,则传热过程产生的不可逆 损失为

损失为

(9)

(9)

式中:TH和TL分别为冷、热流体的平均温度,K。冷、热流体换热后的平均温度Tm为

(10)

(10)

其中:Tb和Te分别为某种流体的初态温度和末态温度,K。

2) 混合过程 损失。2种或多种物质的绝热混合过程虽无能量损失,但因其高度不可逆,故仍有

损失。2种或多种物质的绝热混合过程虽无能量损失,但因其高度不可逆,故仍有 损失。混合过程

损失。混合过程 损失为

损失为

(11)

(11)

式中: ,

, 和

和 分别为混合前流体1、流体2和混合后流体3的物理

分别为混合前流体1、流体2和混合后流体3的物理 ;

; ,

, 和

和 分别为混合前流体1、流体2和混合后流体3的化学

分别为混合前流体1、流体2和混合后流体3的化学 。

。

3) 流动过程 损失。蒸发工序中的流动过程

损失。蒸发工序中的流动过程 损失主要包括料液及饱和蒸汽在流动过程中的

损失主要包括料液及饱和蒸汽在流动过程中的 损失。

损失。

料液的流动过程 损失为

损失为

(12)

(12)

式中:Vm为料液体积,m3;Tm为料液温度,K;△p为料液前、后压差,Pa。

饱和蒸汽的流动过程 损失为

损失为

(13)

(13)

式中:m为饱和蒸汽流量,m3;R为摩尔气体常数;p1和p2为饱和蒸汽前、后压力,Pa。

2.3 蒸发工序 分析

分析

根据 分析模型和

分析模型和 计算方法,对某厂氧化铝蒸发工序进行

计算方法,对某厂氧化铝蒸发工序进行 平衡计算,发现该蒸发工序的

平衡计算,发现该蒸发工序的 损失Elosses=36 140.634 MJ/h,且外部

损失Elosses=36 140.634 MJ/h,且外部 损系数达到0.309 7,说明该系统除有较严重的内部

损系数达到0.309 7,说明该系统除有较严重的内部 损失外,还有较大的外部

损失外,还有较大的外部 损失;外部

损失;外部 损失主要表现为4个冷凝水自蒸发器外排冷凝水和Ⅳ效蒸发器外排二次蒸汽引起的外部

损失主要表现为4个冷凝水自蒸发器外排冷凝水和Ⅳ效蒸发器外排二次蒸汽引起的外部 损失,占总

损失,占总 损失30.90%,若能将这部分

损失30.90%,若能将这部分 回收利用,则能有效地提高系统的

回收利用,则能有效地提高系统的 效率。

效率。

3 蒸发工序能量系统优化

3.1 余热状况分析

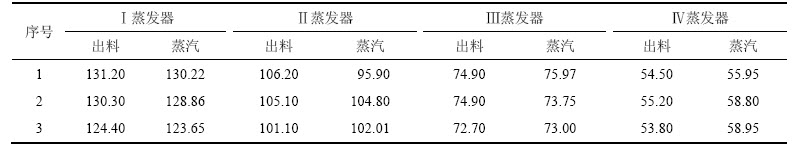

冷凝水自蒸发器外排冷凝水和Ⅳ效蒸发器外排二次蒸汽的余热资源状况如表1所示。从表1可见:蒸发工序的余热资源形态都是饱和蒸汽或饱和冷凝水,对其进行回收利用较方便。外排冷凝水温度高(最高达134.6 ℃),外排饱和蒸汽温度为58.8 ℃。余热资源丰富(达158 159.496 kJ/h),而且品质较好。

3.2 能量再利用方案

系统能量再利用先考虑降低单元设备或装置本身的能量损失,其次考虑工序内部的能量回收利用。因蒸发器的功能是蒸水提浓,且降低冷凝水自蒸发器外排能量损失不仅会降低系统压力能量,而且涉及设备结构强度。因此,蒸发工序的能量再利用应主要考虑如何在工序内部进行。

3.2.1 蒸发器能量再利用可行性分析

蒸发器热源是新蒸汽或前一效产生的二次蒸汽及冷凝水自蒸发器闪蒸出的部分二次蒸汽,热源在完成加热任务后完全冷凝成饱和冷凝水通入冷凝水自蒸发器,其余热无法直接回收利用。料液经预热器预热后进入蒸发器,为实现能量再利用,有必要分析蒸发器内的传热过程是否合理。

1) 蒸发器内料液沸点的确定。关于蒸发器内铝酸钠溶液的沸点未见报道,故本文参考其他对溶液沸点测量的研究结果,通过热平衡测试及现场经验来确定。表2和表3所示为蒸发器的出料温度与其二次蒸汽温度的关系,根据沸点升高原理可确定蒸发器内料液的沸点等于其二次蒸汽温度。

2) 蒸发器内传热过程合理性分析。传热过程是否合理主要体现在热源能否充分利用其本身热量对料液进行加热实现蒸发浓缩。表4和表5所示为蒸发器的料液沸点与进料温度的关系。从表4和表5可见:各效蒸发器进料温度比相应效料液的沸点低3~10 ℃,

即加热蒸汽必须把各效料液升温3~10 ℃达到沸点后才能使之蒸发,传热温差的增大势必造成不必要的能量损失,降低蒸发效率。以第2次测试结果为基础计算可得:加热蒸汽将蒸发器中的料液升温至沸点共需热量21 580 MJ/h,相当于7.79 t新蒸汽的热量。可见:增大进入预热器的加热蒸汽量,使预热器出料温度接近或达到料液的沸点,可以减少不必要的能量损失,提高蒸发器的能量利用效率。

表1 蒸发工序余热状况

Table 1 Waste heat condition of evaporation process

表2 3次测试工况下各效蒸发器出料温度与二次蒸汽温度的关系

Table 2 Relationship between temperature of each evaporator and secondary steams in three test conditions ℃

表3 3次测试工况各效出料与二次蒸汽的温度差

Table 3 Temperature difference of each evaporator and secondary steams in three test conditions ℃

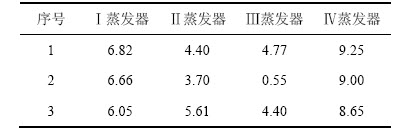

表4 3次测试工况下各效蒸发器料液沸点与进料温度

Table 4 Temperature of each evaporator liquid boiling point and feed in three test conditions ℃

表5 3次测试工况下料液沸点与进料温度之差

Table 5 Temperature difference of each evaporator liquid boiling point and feed in three test conditions ℃

3.2.2 预热器能量再利用可行性分析

余热资源主要是大量饱和冷凝水和小量饱和蒸汽,若将其直接与料液混合,则会降低蒸发器的蒸水提浓功能;若代之以换热器,将导致余热利用不经济,故余热不宜通过预热器回收利用。

3.2.3 工序内部能量再利用方案

对工艺过程进行分析发现,原液在进入蒸发工序前没有被预热,且Ⅳ效蒸发器内料液沸点与原液温差最大(达9 ℃),根据能级匹配、按质用能要求,可考虑利用余热对原液进行预热。

经计算可得原液的能级Ωraw=0.042 9,按表2计算余热的能级可得Ω4=0.028 4,低于Ωraw=0.042 9,其他能级均大于Ωraw。故除4号冷凝水自蒸发器的余热不能用于预热原液外,其他均可利用。

3.3 蒸发工序能量系统优化

3.3.1 系统模型及其验证

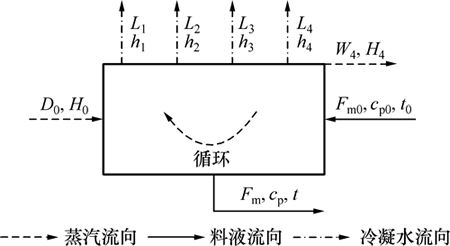

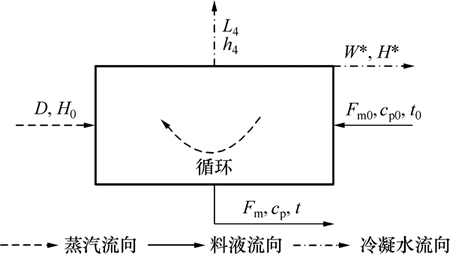

氧化铝生产蒸发工序当前运行状态下的系统模型如图3所示。

图3 氧化铝生产蒸发工序的系统模型

Fig. 3 System model of evaporation process in alumina refinery

蒸发工序的热平衡方程为

(14)

(14)

式中:D0 和W4分别为新蒸汽和Ⅳ效蒸发器二次蒸汽的质量流量,kg/h;H0 和h4分别为新蒸汽和Ⅳ效蒸发器二次蒸汽的比焓,J/g;Fmo和Fm 分别为原液和母液的质量流量,kg/h;cp0和cp 分别为原液和母液的比热容,J/(g·K);t0和t 分别为原液和母液的温度,℃;Li 为第i效冷凝水自蒸发器外排冷凝水的质量流量,kg/h;hi 为第i效冷凝水自蒸发器外排冷凝水的比焓,J/g。

新蒸汽的质量守恒方程为

(15)

(15)

(16)

(16)

表6 计算结果

Table 6 Compution results

式中:c* 为水的比热容,c*=4.18 J/(g·K);βi为第i效冷凝水自蒸发器的自蒸发系数。

对上述系统模型进行求解验证,计算结果如表6所示。从表6可见:根据本文所建系统模型求解的结果与实际运行结果相对误差低于1%,符合工程计算要求,表明模型正确且精度较高。

3.3.2 能量系统优化模型

能量系统优化模型如图4所示。能量系统优化后的热平衡方程为

(17)

(17)

式中:D,W*和L4分别为待求新蒸汽、Ⅳ效蒸发器二次蒸汽及第4效冷凝水自蒸发器外排冷凝水的质量流量,kg/h;h*和h4分别为Ⅳ效蒸发器二次蒸汽和第4效冷凝水自蒸发器外排冷凝水的比焓,J/g。

图4 能量系统优化模型

Fig. 4 Optimization model of energy system

前置预热器的热平衡方程为

(18)

(18)

式中:Fm1为前置预热器出口料液的质量流量,kg/h;cp1 为前置预热器出口料液的比热容,J/(g·K);t1c 为前置预热器出口料液的温度,℃。

前置预热器的质量平衡方程为

(19)

(19)

式中:W* 为前置预热器冷凝水的质量流量,kg/h。

求解能量系统优化模型的步骤如下。

1) 设定t1c,t1c应大于原液温度。

2) 根据下列公式计算各蒸发器的出料温度(t2,t3和t4)以及二次蒸汽温度(T2,T3和T4):

(20)

(20)

(21)

(21)

(22)

(22)

3) 根据步骤2)所得结果求h2,h3,h4及H4等。

4) 根据式(18)和(19)求W*和h*。

5) 根据式(17)求D。

3.3.3 余热回收利用效果评价

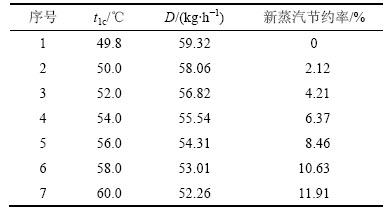

以蒸发工序能量分析采用过的数据为基础,对氧化铝蒸发工序能量系统优化后的效果进行分析和评价,设定t1c>49.8 ℃,所得结果如表7所示。从表7可见:适当提高Ⅳ效蒸发器入口料液的温度,可有效降低新蒸汽的消耗。例如,当入口料液温度t1c提高至60 ℃时,汽耗可降低11.91%,吨水汽耗比为0.375,此时可以节省7.06 t新蒸汽,相当于节省19 559 .17 MJ/h的热量。

表7 能量系统优化后模型求解结果

Table 7 Results by the optimization model of energy

4 结论

1) 根据 分析模型和

分析模型和 计算方法对某厂氧化铝蒸发工序进行能量平衡计算,发现该系统的

计算方法对某厂氧化铝蒸发工序进行能量平衡计算,发现该系统的 损失为36 140.634MJ/h,外部

损失为36 140.634MJ/h,外部 损系数为0.309 7,能量损失严重,用能水平较低,具备节能潜力。

损系数为0.309 7,能量损失严重,用能水平较低,具备节能潜力。

2) 对蒸发工序进行 计算和耗能分析,发现外部

计算和耗能分析,发现外部 损失主要表现为4个冷凝水自蒸发器外排冷凝水和Ⅳ效蒸发器外排二次蒸汽引起的外部

损失主要表现为4个冷凝水自蒸发器外排冷凝水和Ⅳ效蒸发器外排二次蒸汽引起的外部 损失,占总

损失,占总 损失的30.90%,建议对此部分能量进行回收再利用。

损失的30.90%,建议对此部分能量进行回收再利用。

3) 对蒸发系统余热资源进行分析,对蒸发器和预热器能量再利用的各种方案进行可行性验证,提出利用系统余热来提高Ⅳ效蒸发器入口料液的温度,降低氧化铝蒸发过程新蒸汽消耗和吨水汽耗,使系统能量获得充分利用。经计算,当入口料液温度提高至60 ℃时,汽耗可降低11.91%,可节省7.06 t的新蒸汽。

参考文献:

[1] 毕诗文, 于海燕. 氧化铝生产工艺[M]. 北京: 化学工业出版社, 2006: 34-37.

BI Shiwen, YU Haiyan. The technology of alumina production[M]. Beijing: Chemical Industry Press, 2006: 34-37.

[2] LIU L, AYE L, LU Z, et al. Analysis of the overall energy intensity of alumina refine-ry process using unit process energy intensity and product ratio method[J]. Energy, 2006, 31(8/9): 116-1176.

[3] 郭晋梅, 冯文洁, 焦淑红, 等. 浅析氧化铝生产工艺节能途径[J]. 有色冶金节能, 2004, 21(4): 27-28.

GUO Jinmei, FENG Wenjie, JIAO Shuhong, et al. Humble opinion of the energy saving way of alumina production technology[J]. Energy Saving of Non-Ferrous Metallurgy, 2004, 21(4): 27-28.

[4] 彭小奇, 伍雁鹏, 李时民, 等. 氧化铝生产蒸发工序能耗分析[J]. 中南大学学报(自然科学版), 2013, 44(1): 362-366.

PENG Xiaoqi, WU Yanpeng, LI Shimin, et al. Energy consumption analysis for evaporation process in alumina refinery[J]. Journal of Central South University (Science and Technology), 2013, 44(1): 362-366.

[5] 吴复忠, 蔡九菊, 张琦, 等. 炼铁系统的物质流和能量流的 分析[J]. 工业加热, 2007, 36(1): 15-19.

分析[J]. 工业加热, 2007, 36(1): 15-19.

WU Fuzhong, CAI Jiuju, ZHANG Qi, et al. Exergy analysis of energy and materials flows in the system of ironmaking plants[J]. Industrial Heating, 2007, 36(1): 15-19.

[6] 蒋爱华, 梅炽, 时章明, 等. SKS炼铅鼓风炉的能量分析和 分析[J]. 湖南大学学报(自然科学版), 2011, 38(6): 38-42.

分析[J]. 湖南大学学报(自然科学版), 2011, 38(6): 38-42.

JIANG Aihua, MEI Chi, SHI Zhangming, et al. Energy and exergy analysis of the blast furnace in SKS lead smelting system[J]. Journal of Hunan University (Natural Science), 2011, 38(6): 38-42.

[7] ARAUJO A B, BRITO R P, VASCONCELOS L S. Energetic analysis of distillation processes: a case study[J]. Energy, 2007, 32(7): 1185-1193.

[8] 毕诗文. 拜耳法生产氧化铝[M]. 北京: 冶金工业出版社, 2007: 261-271.

BI Shiwen. Alumina manufacture with Bayer method[M]. Beijing: Metallurgical Industry Press, 2007: 261-271.

[9] 傅秦生. 能量系统的热力学分析方法[M]. 西安: 西安交通大学出版社, 2005: 87-94.

FU Qinsheng. Methods of energy analysis of energy system[M]. Xi’an: Xi’an Jiaotong University Press, 2005: 87-94.

[10] 周乃君. 能源与环境[M]. 长沙: 中南大学出版社, 2008: 124-152.

ZHOU Naijun. Energy and environment[M]. Changsha: Central South University Press, 2008: 124-152.

[11] 郑艳梅, 韩郁林. 氯化铵回收的三效降膜蒸发系统的 分析[J]. 天津大学学报, 2007, 40(3): 377-380.

分析[J]. 天津大学学报, 2007, 40(3): 377-380.

ZHENG Yanmei, HAN Yulin. Exergy analysis of three-effect falling-film evaporation system for ammonium chloride recycle[J]. Journal of Tianjin University, 2007, 40(3): 377-380.

[12] 郑丹星, 武向红, 郑大山.  函数的一致性基础[J]. 化工学报, 2002, 53(7): 673-679.

函数的一致性基础[J]. 化工学报, 2002, 53(7): 673-679.

ZHENG Danxing, WU Xianghong, ZHENG Dashan. Fundamental of thermodynamic consistence of exergy functions[J]. Journal of Chemical Industry and Engineering, 2002, 53(7): 673-679.

[13] 宋国辉, 彭小奇, 宋彦坡, 等. 含相变过程的机械 计算方法[J]. 热科学与技术, 2009, 8(1): 64-68.

计算方法[J]. 热科学与技术, 2009, 8(1): 64-68.

SONG Guohui, PENG Xiaoqi, SONG Yanpo, et al. Method for mechanical exergy calculation including phase change process[J]. Journal of Thermal Science and Technology, 2009, 8(1): 64-68.

[14] 彭小奇, 宋国辉, 宋彦坡, 等. NaOH-NaAl(OH)4-Na2CO3-H2O体系活度因子的计算模型[J]. 中国有色金属学报, 2009, 19(7): 1332-1337.

PENG Xiaoqi, SONG Guohui, SONG Yanpo, et al. Activity coefficient calculation model for NaOH-NaAl(OH)4-Na2CO3- H2O system[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(7): 1332-1337.

[15] EL-NASHAR A M, AL-BAGHDADI A A. Exergy losses in a multiple-effect stack seawater desalination plant[J]. Desalination, 1998, 116(1): 11-24.

[16] 葛斌, 张俊礼, 殷戈. 火电机组热力系统与设备 损分布通用矩阵模型[J]. 东南大学学报(自然科学版), 2009, 39(5): 1043-1048.

损分布通用矩阵模型[J]. 东南大学学报(自然科学版), 2009, 39(5): 1043-1048.

GE Bin, ZHANG Junli, YIN Ge. General matrix model of exergy distribution of thermodynamic system and its components for coal-fired power unit[J]. Journal of Southeast University (Natural Science Edition), 2009, 39(5): 1043-1048.

(编辑 陈灿华)

收稿日期:2016-01-16;修回日期:2016-03-12

基金项目(Foundation item):国家自然科学基金重点资助项目(61134006)(Project(61134006) supported by the National Natural Science Foundation of China)

通信作者:张建智,博士研究生,从事有色冶金节能及智能优化等研究;E-mail:zhangjz@csu.edu.cn