氧化铝生产蒸发工序的 分析

分析

彭小奇1, 2, 3,宋国辉1,宋彦坡1, 2,张建智1,刘振国1

(1. 中南大学 能源科学与工程学院,湖南 长沙,410083;

2. 中南大学 信息科学与工程学院,湖南 长沙,410083;

3. 湖南第一师范学院 信息科学与工程系,湖南 长沙,410205)

摘要:为降低氧化铝生产蒸发工序的能耗,根据工业铝酸钠溶液的密度、比热容、各组分的活度因子和标准化学 等性质,推导出工业铝酸钠溶液的

等性质,推导出工业铝酸钠溶液的 计算式;对四效蒸发器-三级闪蒸器系统

计算式;对四效蒸发器-三级闪蒸器系统 进行分析,计算蒸发系统及其各单元的

进行分析,计算蒸发系统及其各单元的 效率和

效率和 损系数。研究结果表明:蒸发系统的

损系数。研究结果表明:蒸发系统的 效率为13%~19%;三级闪蒸器的

效率为13%~19%;三级闪蒸器的 效率较高,均超过了90%;四效蒸发器的

效率较高,均超过了90%;四效蒸发器的 效率较低,几乎都低于80%,其中第4效蒸发器的

效率较低,几乎都低于80%,其中第4效蒸发器的 效率最低,为9%~12%;冷凝水和乏汽形式的外部

效率最低,为9%~12%;冷凝水和乏汽形式的外部 损失和蒸发器内传热过程引起的内部

损失和蒸发器内传热过程引起的内部 损失是蒸发系统的2类主要

损失是蒸发系统的2类主要 损失,其

损失,其 损系数分别为0.273~0.301和0.291~0.329;虽然预热器的混合

损系数分别为0.273~0.301和0.291~0.329;虽然预热器的混合 损系数仅为0.016~0.030,但其用能过程不合理,因此,建议加强冷凝水和乏汽的余热回收利用,优化蒸发系统的传热温差分布和操作参数,改进预热器的使用方式。

损系数仅为0.016~0.030,但其用能过程不合理,因此,建议加强冷凝水和乏汽的余热回收利用,优化蒸发系统的传热温差分布和操作参数,改进预热器的使用方式。

关键词:铝酸钠溶液;多效蒸发; 分析;

分析; 效率;

效率; 损系数

损系数

中图分类号:TF802.62 文献标志码:A 文章编号:1672-7207(2011)03-0829-06

Exergy analysis of evaporation process in an alumina refinery

PENG Xiao-qi1, 2, 3, SONG Guo-hui1, SONG Yan-po1, 2, ZHANG Jian-zhi1, LIU Zhen-guo1

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. School of Information Science and Engineering, Central South University, Changsha 410083, China;

3. Department of Information Science and Engineering, Hunan First Normal University, Changsha 410205, China)

Abstract: To reduce the energy consumption of evaporation process in the alumina refinery, the formulas for calculating the exergy of industrial sodium aluminate solution were derived in terms of the density, specific heat capacity, activity coefficients and standard chemical exergies of its species. Then exergy analysis was applied to the four-effect evaporators and three-stage flashes evaporation system to calculate and analyze the exergy efficiencies and exergy loss coefficients in the evaporation system and its individual units. The results show that the exergy efficiency of the evaporation system is 13%-19%; the three-stage flashes have higher exergy efficiencies in excess of 90% while the four-effect evaporators have poor efficiencies, which are almost lower than 80%, especially the exergy efficiency of the 4th effect evaporator is only 9%-12%, approximately. The external exergy losses in the form of condensed water and exhausted vapor and the internal exergy losses due to heat transfer in evaporations are the two main types of exergy losses in the evaporation system, whose exergy coefficients are 0.273-0.301 and 0.291-0.329, respectively; though the coefficient due to combined process in preheaters is only 0.016-0.030, which is unreasonable in view of energy conversion. Thus it’s proposed that waste heat recovery and utilization of condensed water and exhausted vapor should be enhanced; the distribution of temperature differences in the evaporation system and the operating parameters should be optimized and the method for using preheaters should be improved.

Key words: sodium aluminate; multi-effect evaporation; exergy analysis; exergy efficiency; exergy loss coefficient

我国氧化铝生产与工业发达国家相比,在能耗方面存在较大差距[1]。其中,蒸发工序担负着平衡全厂水和碱的作用,能耗尤为显著:其汽耗占总汽耗的30%~40%,成本占总成本的10%~12%[2]。因此,降低蒸发工序的能耗对降低氧化铝生产成本具有重要意义。为提高蒸发工序的运行性能和用能效率,氧化铝生产科研工作者进行了长期探索和研究,其主要成果可概括为2类:通过更新升级设备提高蒸发系统或单元的性能[3-4];根据长期运行经验或工业试验优化操作参数或方式[5]。然而,关于蒸发工序能耗的热力学分析研究报道较少或不够深入。为降低蒸发工序的能耗,使用热力学分析方法研究其能耗状况非常必要。作为一种更科学的热力学分析方法, 分析已用于指导众多部门的节能工作,如电力、化工和钢铁等[6-8]。但

分析已用于指导众多部门的节能工作,如电力、化工和钢铁等[6-8]。但 分析在有色冶金工业尤其是氧化铝生产上的应用很少。郭沈[9]曾将

分析在有色冶金工业尤其是氧化铝生产上的应用很少。郭沈[9]曾将 分析应用于间接加热的预脱硅过程,但未将物料的化学

分析应用于间接加热的预脱硅过程,但未将物料的化学 考虑在内。目前,尚无氧化铝生产的主要中间物流,即工业铝酸钠溶液

考虑在内。目前,尚无氧化铝生产的主要中间物流,即工业铝酸钠溶液 值计算式的报道。而溶液的

值计算式的报道。而溶液的 值,尤其是化学

值,尤其是化学 的计算,需要使用溶液的密度、比热容,各组分的活度因子和标准化学

的计算,需要使用溶液的密度、比热容,各组分的活度因子和标准化学 等性质,常常成为应用

等性质,常常成为应用 分析的一大障碍。目前,已有成熟的工业铝酸钠溶液密度和比热容的计算方 法[10-12];Zhou等[13]和Li等[14]分别用实验和理论方法研究了NaOH-NaAl(OH)4-H2O体系的活度因子,彭小奇等[15]发展了一种基于Bromley模型的NaOH- NaAl(OH)4-Na2CO3-H2O体系活度因子的计算模型;郑丹星等[16]修正了龟山-吉田环境模型并更新了元素的标准化学

分析的一大障碍。目前,已有成熟的工业铝酸钠溶液密度和比热容的计算方 法[10-12];Zhou等[13]和Li等[14]分别用实验和理论方法研究了NaOH-NaAl(OH)4-H2O体系的活度因子,彭小奇等[15]发展了一种基于Bromley模型的NaOH- NaAl(OH)4-Na2CO3-H2O体系活度因子的计算模型;郑丹星等[16]修正了龟山-吉田环境模型并更新了元素的标准化学 。本文作者将在此基础上,推导并讨论工

。本文作者将在此基础上,推导并讨论工

业铝酸钠溶液 的计算式;对中国铝业中州分公司四效蒸发器-三级闪蒸器系统的

的计算式;对中国铝业中州分公司四效蒸发器-三级闪蒸器系统的 进行全面深入分析,以便寻找系统的用能薄弱环节,确定能耗损失的部位、大小及原因,为进一步的节能改造、优化指明方向。

进行全面深入分析,以便寻找系统的用能薄弱环节,确定能耗损失的部位、大小及原因,为进一步的节能改造、优化指明方向。

1 流程简介

中国铝业中州分公司蒸发V组所采用的四效管式降膜蒸发器-三级闪蒸器蒸发系统如图1所示,其中除E4(末)效蒸发器无预热器外,其他各效均有预热器。新蒸汽进入E1效,经换热后变为冷凝水,再依次经过1-1号、1-2号和1-3号等冷水罐回收部分余热,其余冷凝水被排出体系,而相应3个冷凝水罐中产生的二次蒸汽分别用于加热E1,E2和E3效蒸发器。蒸发原液首先分别进入E4和E3效蒸发器,然后依次经过E2和E1效蒸发器以及S1,S2和S3级闪蒸器蒸发浓缩。E4效蒸发器产生的乏汽被水冷却后排出体系,其余各效产生的二次蒸汽依次分别用于加热前一效蒸发器和本效预热器。三级闪蒸器产生的二次蒸汽分别供入E1,E2和E3效预热器,与上一效蒸发器的出料进行混合预热。

2 工业铝酸钠溶液的 值计算

值计算

热力学系统的 是指系统经可逆过程达到与环境处于完全热力学平衡状态时所能获得的理论最大有用功[17]。一般对工业过程进行

是指系统经可逆过程达到与环境处于完全热力学平衡状态时所能获得的理论最大有用功[17]。一般对工业过程进行 分析时,物料的

分析时,物料的 包含物理

包含物理 、化学

、化学 。

。

图1 中国铝业中州分公司蒸发工序流程图

Fig.1 Flow sheet of the evaporation process in Zhongzhou Branch of Chalco

2.1 物理

物理 是指系统相对于环境因温度和压力的不同而具有的

是指系统相对于环境因温度和压力的不同而具有的 ,某物流在状态(T,p)下的比物理

,某物流在状态(T,p)下的比物理 ePH的计算式如下:

ePH的计算式如下:

(1)

(1)

式中:cp为物料的比定压热容,kJ/(kg·K);v为物料的比体积,m3/kg;T和T0分别为工况温度和环境基准温度,K;p和p0分别为工况压力和环境基准压力,MPa。

根据相关的计算方法[18-19],考虑到偏摩尔性质和易用性,将工业铝酸钠溶液密度[10]和比热容[11]的拟合式代入式(1),得其比物理 的计算式为:

的计算式为:

(2)

(2)

式中:

(3)

(3)

式中:ρNK,ρA和ρNC分别为工业铝酸钠溶液中苛性碱、氧化铝和碳酸碱的质量浓度,g/L;ρs为工业铝酸钠溶液的密度,kg/m3。

在蒸发工序运行条件下,工业铝酸钠溶液的密度为1 200~1 400 kg/m3且|p-p0|<0.5,故式(2)末项(即(p-p0)×103/ρs)的值相对较小。实测数据计算显示,式(2)末项的值占式(2)值的-3%~2%,因此,可忽略式(2)末项,即忽略压力对工业铝酸钠溶液物理 的影响,且在热工测试中可以省去对某些测试难度较大位置的压力测试。这既可减少测试工作量,也有利于设备安全运行和寿命维护。

的影响,且在热工测试中可以省去对某些测试难度较大位置的压力测试。这既可减少测试工作量,也有利于设备安全运行和寿命维护。

2.2 化学

化学 可分解为反应

可分解为反应 和扩散

和扩散 。本文选用修正的龟山-吉田环境模型[16],选取NaOH,NaAl(OH)4,Na2CO3和H2O作为工业铝酸钠溶液的成分基准物,并忽略NaAlO2和NaAl(OH)4之间的标准化学

。本文选用修正的龟山-吉田环境模型[16],选取NaOH,NaAl(OH)4,Na2CO3和H2O作为工业铝酸钠溶液的成分基准物,并忽略NaAlO2和NaAl(OH)4之间的标准化学 的差别。环境模型规定,水的标准化学

的差别。环境模型规定,水的标准化学 为0 kJ/mol。由元素的标准化学

为0 kJ/mol。由元素的标准化学 [16]和纯物质的热化学性质数据[20]可计算出NaOH,NaAlO2和Na2CO3的标准化学

[16]和纯物质的热化学性质数据[20]可计算出NaOH,NaAlO2和Na2CO3的标准化学 分别为100.708,83.762和90.127 kJ/mol。则工业铝酸钠溶液比反应

分别为100.708,83.762和90.127 kJ/mol。则工业铝酸钠溶液比反应 和比扩散

和比扩散 如下。

如下。

(1) 比反应 为:

为:

(4)

(4)

(2) 比扩散 为:

为:

(5)

(5)

式中:xi为溶液中第i种组分的摩尔分数;ei为溶液中第i种组分的标准化学 ,kJ/mol;fi为使用摩尔分数时溶液中第i种组分的活度因子;R为摩尔气体常数,8.314 J/(mol·K)。

,kJ/mol;fi为使用摩尔分数时溶液中第i种组分的活度因子;R为摩尔气体常数,8.314 J/(mol·K)。

根据热力学基本原理,将式(4)和(5)改写为:

(6)

(6)

(7)

(7)

式中:mi为溶液中第i种组分的质量摩尔浓度,mol/kg;γi为使用质量摩尔浓度时溶液中第i种组分的活度因子,可由NaOH-NaAl(OH)4-Na2CO3-H2O体系的活度系数计算模型[15]获得。

将RT0/1 000=2.479代入式(7),并经单位换算和简化后,可得工业铝酸钠溶液比化学 的计算式为:

的计算式为:

(8)

(8)

式中 :ρw为单位体积工业铝酸钠溶液所含水的质量,kg/m3。

式(2)和(8)即为工业铝酸钠溶液比 的计算式,适用于氧化铝生产的各工序。

的计算式,适用于氧化铝生产的各工序。

以某次稳定运行状态下热工测试所得数据为例,根据式(2)和(8)计算蒸发原液和各效(级)出料的比物理 、比反应

、比反应 和比扩散

和比扩散 ,结果如表1所示。由表1可见:比反应

,结果如表1所示。由表1可见:比反应 远大于其他两者之和,因此,总

远大于其他两者之和,因此,总 对其变化非常敏感,在具有化学反应的其他氧化铝生产工序的

对其变化非常敏感,在具有化学反应的其他氧化铝生产工序的 分析中,需注意成分分析的精度。而蒸发工序无化学反应,理论上溶质各组分的总质量不变,实测数据也近似守恒,故可认为蒸发料液的反应

分析中,需注意成分分析的精度。而蒸发工序无化学反应,理论上溶质各组分的总质量不变,实测数据也近似守恒,故可认为蒸发料液的反应 总量不变,可不计入反应

总量不变,可不计入反应 项。在表1中,比扩散

项。在表1中,比扩散 出现了正、负两类值,这与环境模型的规定和活度因子有关,不影响

出现了正、负两类值,这与环境模型的规定和活度因子有关,不影响 分析结果的正确性。

分析结果的正确性。

为简化起见,以下计算只涉及物理 和扩散

和扩散 。

。

表1 蒸发料液的工艺参数及其 值

值

Table 1 Process parameters and exergy values of materials in evaporation process

3 蒸发工序的 效率分析

效率分析

该蒸发工序被分解为如图1中虚线框所示的7个单元。定义 效率ηe如下:

效率ηe如下:

(9)

(9)

式中:Eg为系统或单元的收益 (系统或E4效蒸发器的收益

(系统或E4效蒸发器的收益 是进出蒸发系统或E4效蒸发器的物料的

是进出蒸发系统或E4效蒸发器的物料的 增;其他单元的收益

增;其他单元的收益 是相应单元的出料(包括增浓后的料液和二次蒸汽)与进料相比的

是相应单元的出料(包括增浓后的料液和二次蒸汽)与进料相比的 増);Ep为系统或单元的支付

増);Ep为系统或单元的支付 (系统或E1效蒸发器的支付

(系统或E1效蒸发器的支付 是新蒸气供入的

是新蒸气供入的 ;其他单元的支付

;其他单元的支付 是相应蒸发器或闪蒸器所供入的二次蒸汽的

是相应蒸发器或闪蒸器所供入的二次蒸汽的 )。

)。

根据蒸发系统(SYS)和各单元的 平衡方程,应用稳定运行状态下1号、2号和3号热工测试数据,经计算,可得蒸发系统及各单元的

平衡方程,应用稳定运行状态下1号、2号和3号热工测试数据,经计算,可得蒸发系统及各单元的 效率如图2所示。

效率如图2所示。

图2 蒸发系统及各单元的 效率

效率

Fig.2 Exergy efficiencies of evaporation system and its units

在3次测试工况下,蒸发系统的 效率为13%~ 19%,表明其用能状况不理想,用能效率有待提高。三级闪蒸器的

效率为13%~ 19%,表明其用能状况不理想,用能效率有待提高。三级闪蒸器的 效率均超过90%,表明其节能潜力较小。四效蒸发器的

效率均超过90%,表明其节能潜力较小。四效蒸发器的 效率较低,几乎都在80%以下,其中E4效蒸发单元的

效率较低,几乎都在80%以下,其中E4效蒸发单元的 效率最低,仅为9%~12%;其次为E3效蒸发器,其

效率最低,仅为9%~12%;其次为E3效蒸发器,其 效率为54%~67%。结合各单元支付

效率为54%~67%。结合各单元支付 的值,可知四效蒸发单元为蒸发系统的用能薄弱环节,节能潜力较大,应重点分析四效蒸发器的

的值,可知四效蒸发单元为蒸发系统的用能薄弱环节,节能潜力较大,应重点分析四效蒸发器的 损失。

损失。

4 四效蒸发器的 损失分析

损失分析

损失可分为2类:外部

损失可分为2类:外部 损失和内部

损失和内部 损失。前者是由生产过程向环境散热、排放废物或不为人们期望的副产品所携带走的

损失。前者是由生产过程向环境散热、排放废物或不为人们期望的副产品所携带走的 ;后者由生产过程内各种不可逆因素引起。定义分析对象中某种

;后者由生产过程内各种不可逆因素引起。定义分析对象中某种 损失I的

损失I的 损系数r为:

损系数r为:

(10)

(10)

式中:I为系统或单元的某种 损失。

损失。

4.1 外部 损失

损失

四效蒸发器的外部 损失形式主要有:设备及管道表面散热;1-3号、3号和4号等3个冷凝水罐外排的冷凝水;E4效蒸发器外排的乏汽。在测试工况下,蒸发系统的散热

损失形式主要有:设备及管道表面散热;1-3号、3号和4号等3个冷凝水罐外排的冷凝水;E4效蒸发器外排的乏汽。在测试工况下,蒸发系统的散热 损系数约为0.000 55,表明设备及管道的保温效果良好。

损系数约为0.000 55,表明设备及管道的保温效果良好。

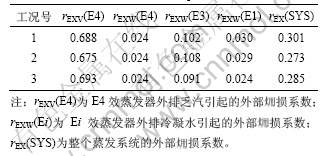

在3次测试工况下,蒸发系统及各效冷凝水和末效乏汽外排形式的外部 损系数rEX见表2。

损系数rEX见表2。

表2中末效乏汽的 损系数分别为0.688,0.675和0.693,表明其

损系数分别为0.688,0.675和0.693,表明其 损失是E4效蒸发器

损失是E4效蒸发器 效率低的主要原因。由于E2和E3效蒸发器产生的冷凝水都从

效率低的主要原因。由于E2和E3效蒸发器产生的冷凝水都从

表2 冷凝水和末效乏汽的 损系数

损系数

Table 2 Exergy loss coefficients of condensed waters and exhausted vapor

3号冷凝水罐排出,故E3效蒸发器中冷凝水形式的 损系数也较大。从蒸发系统来看,各效冷凝水和末效乏汽的总外部

损系数也较大。从蒸发系统来看,各效冷凝水和末效乏汽的总外部 损系数分别为0.301,0.273和0.285,这说明蒸发系统的冷凝水和末效乏汽形式的外部

损系数分别为0.301,0.273和0.285,这说明蒸发系统的冷凝水和末效乏汽形式的外部 损失是造成蒸发系统

损失是造成蒸发系统 效率低的一个重要原因,是总

效率低的一个重要原因,是总 损失的一个主要形式。因此,应加强冷凝水和乏汽的余热回收利用。

损失的一个主要形式。因此,应加强冷凝水和乏汽的余热回收利用。

测试数据表明:1-3号和4号冷凝水罐排水的平均温度约为95 ℃,末效冷凝水和乏汽的平均温度约为60 ℃,而蒸发原液的平均温度约为49 ℃。可见,1-3号和4号冷凝水罐的排水与蒸发原液间温差较大;另外,虽然末效乏汽温度较低,但其相变潜热较大。因此,用冷凝水和乏汽预热蒸发原液是一条值得探索的节能途径。

4.2 内部 损失

损失

引起四效蒸发器内部 损失的主要原因有蒸发器内的有限温差传热过程和预热器内的混合过程。

损失的主要原因有蒸发器内的有限温差传热过程和预热器内的混合过程。

4.2.1 传热 损失

损失

在3次测试工况下,四效蒸发器的传热 损系数rHT见表3。

损系数rHT见表3。

表3 四效蒸发器的传热 损系数

损系数

Table 3 Exergy loss coefficients due to heat transfer in four-effect evaporations

由表3可知:各效蒸发单元传热 损系数均较大,其中E4和E3效的传热

损系数均较大,其中E4和E3效的传热 损系数尤为显著,是造成E4和E3效蒸发单元

损系数尤为显著,是造成E4和E3效蒸发单元 效率较低的另一个重要原因。从蒸发系统来看,蒸发系统的传热

效率较低的另一个重要原因。从蒸发系统来看,蒸发系统的传热 损系数分别为0.291,0.313和0.329,与系统的冷凝水和乏汽形式的外部

损系数分别为0.291,0.313和0.329,与系统的冷凝水和乏汽形式的外部 损系数相近。因此,传热

损系数相近。因此,传热 损失是蒸发系统

损失是蒸发系统 效率低的另一个重要原因,也是总

效率低的另一个重要原因,也是总 损失的另一个主要形式。

损失的另一个主要形式。

由于传热 损失与传热量、冷热流体的绝度温度及其温差有关;同时,蒸发器两侧温度与蒸发浓度、压力等参数紧密耦合。因此,为减少蒸发系统的传热

损失与传热量、冷热流体的绝度温度及其温差有关;同时,蒸发器两侧温度与蒸发浓度、压力等参数紧密耦合。因此,为减少蒸发系统的传热 损失,需优化传热温差的分布及操作参数。建立以蒸发系统传热

损失,需优化传热温差的分布及操作参数。建立以蒸发系统传热 损失最小为目标的优化模型是关键步骤。

损失最小为目标的优化模型是关键步骤。

4.2.2 混合 损失

损失

E1,E2和E3等三效蒸发器中预热器内混合过程造成的混合 损失均较小,系统的总混合

损失均较小,系统的总混合 损失相应较小。在3次测试工况下,蒸发系统的混合

损失相应较小。在3次测试工况下,蒸发系统的混合 损系数rMT分别为0.023,0.016和0.030。

损系数rMT分别为0.023,0.016和0.030。

相对冷凝水和乏汽形式的外部 损系数或者传热

损系数或者传热 损系数,虽然蒸发系统的混合

损系数,虽然蒸发系统的混合 损系数较小,但是,从能量转换的角度考察,预热器内的混合过程并不合理:首先,混合与分离相反,它消耗了上一效蒸发浓缩所获得的扩散

损系数较小,但是,从能量转换的角度考察,预热器内的混合过程并不合理:首先,混合与分离相反,它消耗了上一效蒸发浓缩所获得的扩散 ;其次,混合又造成了高温流体的

;其次,混合又造成了高温流体的 下降。因此,应在不使蒸发器内壁结疤状况恶化的条件下,探索改进办法,例如,废除使用蒸发器,或者使用无混合的间接预热器代替目前的混合式预热器。

下降。因此,应在不使蒸发器内壁结疤状况恶化的条件下,探索改进办法,例如,废除使用蒸发器,或者使用无混合的间接预热器代替目前的混合式预热器。

5 结论

(1) 提出了完整的工业铝酸钠溶液 的计算方法。该计算方法不仅适用于蒸发工序,也可用于其他含化学反应工序的

的计算方法。该计算方法不仅适用于蒸发工序,也可用于其他含化学反应工序的 分析。

分析。

(2) 计算并分析了蒸发工序的系统及各单元的 效率。此蒸发系统的

效率。此蒸发系统的 效率为13%~19%;三级闪蒸器的

效率为13%~19%;三级闪蒸器的 效率均超过90%,节能潜力较小;四效蒸发器的

效率均超过90%,节能潜力较小;四效蒸发器的 效率较低,几乎都在80%以下,其中E4效蒸发单元的

效率较低,几乎都在80%以下,其中E4效蒸发单元的 效率最低,仅为9%~12%。四效蒸发器的节能潜力较大。

效率最低,仅为9%~12%。四效蒸发器的节能潜力较大。

(3) 冷凝水和末效乏汽形式的外部 损系数分别为0.301,0.273和0.285,蒸发器内传热过程引起的内部

损系数分别为0.301,0.273和0.285,蒸发器内传热过程引起的内部 损系数约为0.291,0.313和0.329,两者是蒸发系统的主要

损系数约为0.291,0.313和0.329,两者是蒸发系统的主要 损失,也是造成相应蒸发单元

损失,也是造成相应蒸发单元 效率低的主要原因。预热器内混合过程引起的内部

效率低的主要原因。预热器内混合过程引起的内部 损系数为0.016~0.030,虽然较小,但也说明其用能过程不 合理。

损系数为0.016~0.030,虽然较小,但也说明其用能过程不 合理。

(4) 为了实现蒸发工序的节能,建议加强冷凝水和二次蒸汽的余热回收利用,优化蒸发系统操作参数及传热温差分布,并改进预热器的使用方式。

参考文献:

[1] LIU Li-ru, LU A-ye, Lu Zhong-wu, et al. Analysis of the overall energy intensity of alumina refinery process using unit process energy intensity and product ratio method[J]. Energy, 2006, 31(8/9): 1167-1176.

[2] 李续平, 周在毅. 氧化铝蒸发节能降耗途径的探讨[J]. 轻金属, 2006(8): 37-39.

LI Xu-ping, ZHOU Zai-yi. Discussion about energy saving for alumina evaporation process[J]. Light Metals, 2006(8): 37-39.

[3] Green J. Opportunities to reduce energy intensity in the aluminum industry[EB/OL]. [2002-03-26]. http://www.eere. energy.gov/evision/pdfs/presentation s/j_green.pdf.

[4] 孙克萍, 先晋聪, 宋强, 等. 我国氧化铝业中蒸发装置技术进步及效能分析[J]. 有色金属, 2004(3): 43-45.

SUN Ke-ping, XIAN Jin-chong, SONG Qiang, et al. Technical progress and analysis of efficiency and energy on the evaporation installations to Chinas alumina industry[J]. Non- ferrous Metallurgy, 2004(3): 43-45.

[5] 杨新民, 吴红应, 梅永峰. 氧化铝生产中降低蒸汽消耗的生产实践[J]. 轻金属, 2008(9): 28-30.

YANG Xin-min, WU Hong-ying, MEI Yong-feng. The practice of reducing steam consumption during producing alumina[J]. Light Metals, 2008(9): 28-30.

[6] Kamate S C, Gangavati P B. Exergy analysis of cogeneration power plants in sugar industries[J]. Applied Thermal Engineering, 2009, 29(5/6): 1187-1194.

[7] Antonio B A, Romildo P B, Luis S V, Exergetic analysis of distillation processes: A case study[J]. Energy, 2007, 32(7): 1185-1193.

[8] Costa M M, Schaeffer R, Worrell E. Exergy accounting of energy and materials flows in steel production systems[J]. Energy, 2001, 26(4): 363-384.

[9] 郭沈. 间接加热脱硅系统的有效能分析[J]. 轻金属, 2005(8): 11-14.

GUO Shen. Exergy analysis of indirect heating desilication process[J]. Light Metals, 2005(8): 11-14,

[10] 杨重愚. 氧化铝生产工艺学[M]. 北京: 冶金工业出版社, 1982: 37-41.

YANG Zhong-yu. The technology of alumina production[M]. Beijing: Metallurgical Industry Press, 1982: 37-41.

[11] 毕诗文, 于海燕. 氧化铝生产工艺[M]. 北京: 冶金工业出版社, 2006: 23-27.

BI Shi-wen, YU Hai-yan. The technology of alumina production[M]. Beijing: Chemical Industry Press, 2006: 23-27.

[12] Reynolds J G , Carter R. Density model for sodium hydroxide- sodium aluminate solutions[J]. Hydrometallurgy, 2007, 89(3/4): 233-241.

[13] ZHOU Jun, CHEN Qi-yuan, LI Jie, et al. Isopiestic measurement of the osmotic and activity coefficients for the NaOH- NaAl(OH)4-H2O system at 313.2 K[J]. Geochim Cosmochim Ac, 2003: 67(18): 3459-3472.

[14] LI Xiao-bin, LU Wei-jun, LIU Gui-hua, et al. Activity coefficient calculation model for NaAl(OH)4-NaOH-H2O system[J]. Transactions of Nonferrous Metal Society of China, 2005, 15(4): 908-912.

[15] 彭小奇, 宋国辉, 宋彦坡, 等. NaOH-NaAl(OH)4-Na2CO3-H2O体系活度系数的计算模型[J]. 中国有色金属学报, 2009, 19(7): 1332-1337.

PENG Xiao-qi, SONG Guo-hui, SONG Yan-po, et al. Activity coefficient calculation model for NaOH-NaAl(OH)4-Na2CO3- H2O system[J]. Chinese Journal of Nonferrous Metals, 2009, 19(7): 1332-1337.

[16] 郑丹星, 武向红, 郑大山.  函数的一致性基础[J]. 化工学报, 2002, 53(7): 673-679.

函数的一致性基础[J]. 化工学报, 2002, 53(7): 673-679.

ZHENG Dan-xing, WU Xiang-hong, ZHENG Da-shan. Fundamental of thermodynamic consistence of exergy functions[J]. Journal of Chemical Industry and Engineering, 2002, 53(7): 673-679.

[17] Tsatsaronis G. Definitions and nomenclature in exergy analysis and exergoeconomics[J]. Energy, 2007, 32(4): 249-253.

[18] Szargut J, Morris D R, Steward F R. Exergy analysis of thermal, chemical and metallurgical process[M]. New York: Hemisphere Publishing, 1988: 51-53.

[19] 宋国辉, 彭小奇, 宋彦坡, 等. 含相变过程的机械 计算方法[J]. 热科学与技术, 2009, 8(1): 64-68.

计算方法[J]. 热科学与技术, 2009, 8(1): 64-68.

SONG Guo-hui, PENG Xiao-qi, SONG Yan-po, et al. Method for mechanical exergy calculation including phase change process[J]. Journal of Thermal Science and Technology, 2009, 8(1): 64-68.

[20] Barin I, Gregor P G. Thermochemical data of pure substances[M]. New York: Wiley-VCH, 2004: 1117-1136.

(编辑 陈爱华)

收稿日期:2009-12-27;修回日期:2010-03-18

基金项目:国家自然科学基金重点资助项目(60634020);湖南教育厅科技资助项目(08W003)

通信作者:宋彦坡(1979-),男,河南西平人,博士,讲师,从事工业过程节能与优化等研究;电话:0731-88836713;E-mail: songyanpo@mail.csu.edu.cn