氧化铝生产蒸发工序能耗分析

彭小奇1, 2,伍雁鹏1, 3,李时民1,张建智1,宋彦坡1

(1. 中南大学 能源科学与工程学院,湖南 长沙,410083;

2. 湖南第一师范学院 信息科学与工程系,湖南 长沙,410205;

3. 邵阳学院 信息工程系,湖南 邵阳,422000)

摘要:为降低氧化铝生产蒸发工序的能耗,对测试结果误差进行修正;应用热分析和 分析方法研究四效蒸发器-三级闪蒸器系统的用能状况。研究结果表明:蒸发系统的热效率仅为15.39%,其中Ⅳ效蒸发器的热效率仅为7.23%,其他单元热效率较高;Ⅳ效蒸发器的热损失主要是外排的冷凝水和乏汽带走大量的热所致;蒸发系统的

分析方法研究四效蒸发器-三级闪蒸器系统的用能状况。研究结果表明:蒸发系统的热效率仅为15.39%,其中Ⅳ效蒸发器的热效率仅为7.23%,其他单元热效率较高;Ⅳ效蒸发器的热损失主要是外排的冷凝水和乏汽带走大量的热所致;蒸发系统的 效率仅为19.51%,其中各效蒸发器的

效率仅为19.51%,其中各效蒸发器的 效率均较低而

效率均较低而 损失率均较高,是提高系统

损失率均较高,是提高系统 效率的关键因素,因此,应加强乏汽和冷凝水的余热回收利用,并优化或改进蒸发器的操作参数和预热器使用方式。

效率的关键因素,因此,应加强乏汽和冷凝水的余热回收利用,并优化或改进蒸发器的操作参数和预热器使用方式。

关键词:蒸发工序;热; ;节能

;节能

中图分类号:TF802.62 文献标志码:A 文章编号:1672-7207(2013)01-0362-05

Energy consumption analysis for evaporation process in alumina refinery

PENG Xiaoqi1, 2, WU Yanpeng1, 3, LI Shimin1, ZHANG Jianzhi1, SONG Yanpo1

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Department of Information Science and Engineering, Hunan First Normal University, Changsha 410205, China;

3. Department of Information Engineering, Shaoyang University, Shaoyang 422000, China)

Abstract: In order to reduce energy consumption of evaporation process in alumina refinery, the errors of tested results were corrected, and thermal and exergy analysis were applied to study the four-effect evaporators and three-stage flashes evaporation system. The results show that the thermal efficiency of the evaporation system is only 15.39%, and the thermal efficiencies of other units are high in thermal efficiencies except for effect Ⅳ, which is only 7.23%. The heat losses in the evaporators of effect Ⅳ are large, which are mainly in the form of condensed water and exhausted vapor output. The exergy efficiency of the evaporation system is only 19.51%. The exergy utilizing ratios of the evaporators are low and losing ratios are high, respectively, which are the key factors for the improvement of the exergy efficiency of the evaporation system, thus waste heat recovery and utilization of condensed water and exhausted vapor should be enhanced, and the operating parameters in evaporators and usage ways about preheaters should be optimized.

Key words: evaporation process; thermal; exergy; energy saving

由于生产设备和操作水平不高,我国氧化铝生产蒸发工序存在汽耗高、循环效率低、换热管结垢严重、蒸发能力低等诸多弊端,其能耗、汽耗和成本分别占全厂总指标的20%~25%,30%~40%和10%~12%[1-2];因此,实现蒸发工序的节能降耗对降低氧化铝生产成本具有重要意义。郭晋梅等[3-4]介绍了近年来氧化铝生产蒸发技术、装置的主要进展及其能效状况。姜立宝[5]通过研究五效板式降膜蒸发器系统的热工测定报告,指出了工艺流程中存在的问题、影响蒸发产能的因素以及首效结垢的成因,并提出了提高产能和预防结垢的措施。李续平等[6]分析了超声波防垢、变频等新技术的应用及其节能效果。杨新民等[7]结合实际蒸汽消耗状况,分析了影响汽耗的因素。但总的来看,改进或更新蒸发技术或设备,或者根据运行经验调整工艺流程和操作参数是目前蒸发工序的主要节能措施,而关于蒸发工序的热力学分析及节能研究报道较少或不够深入。热力学分析可为工艺和设备的节能提供科学指导,对探讨节能途径具有非常重要的作用。基本的热力学分析方法主要有热分析和 分析。热分析能够揭示用能过程中能的数量关系,易于理解和应用,结果直观、易懂,因而被长期、广泛使用;

分析。热分析能够揭示用能过程中能的数量关系,易于理解和应用,结果直观、易懂,因而被长期、广泛使用; 分析充分考虑了不可逆因素引起的能贬值,可以综合反映能的数量和品质的变化[1-8],深刻揭示能的传递、转化和消耗的本质,深入评价用能状况和科学指导节能方向。为此,本文作者在某氧化铝厂四效蒸发器-三级闪蒸器系统的热工测试基础上,运用热分析和

分析充分考虑了不可逆因素引起的能贬值,可以综合反映能的数量和品质的变化[1-8],深刻揭示能的传递、转化和消耗的本质,深入评价用能状况和科学指导节能方向。为此,本文作者在某氧化铝厂四效蒸发器-三级闪蒸器系统的热工测试基础上,运用热分析和 分析方法,研究蒸发系统的用能效率、用能损失和节能关键,提出进一步实现氧化铝生产蒸发工序节能降耗的措施。

分析方法,研究蒸发系统的用能效率、用能损失和节能关键,提出进一步实现氧化铝生产蒸发工序节能降耗的措施。

1 工艺流程

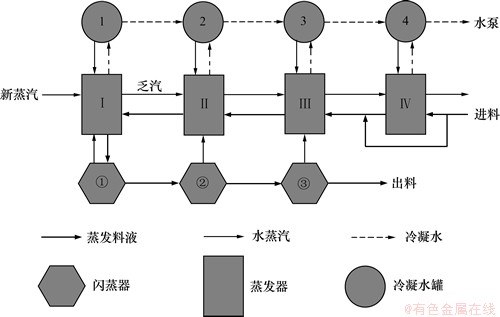

某氧化铝厂采用四效管式降膜蒸发器-三级闪蒸器的逆流作业方式实现铝酸钠溶液的蒸发浓缩,如图1所示。新蒸汽供入Ⅰ效蒸发器,其冷凝水依次经过冷凝水罐1~3后被排出,所产生的二次蒸汽分别用于加热Ⅰ,Ⅱ和Ⅲ效蒸发器。蒸发原液(工业铝酸钠溶液)首先分别进入Ⅳ和Ⅲ效蒸发器,然后,依次经过Ⅱ效和Ⅰ效蒸发器蒸发浓缩,再由①,②和③级闪蒸器闪蒸浓缩。Ⅳ效蒸发器的乏汽排出蒸发体系,其余各效产生的二次蒸汽依次分别用于加热前一效蒸发器和本效预热器。

2 热分析和 分析

分析

2.1 工业铝酸钠溶液焓和 的计算

的计算

工业铝酸钠溶液的比焓为:

(1)

(1)

式中:cp为溶液的比热容,kJ/(kg·K);T为溶液的热力学温度,K。物料的 由物理

由物理 和化学

和化学 组成。工况状态(T,p)下稳流物料的比物理

组成。工况状态(T,p)下稳流物料的比物理 为:

为:

(2)

(2)

图1 氧化铝生产蒸发工序的流程图

Fig.1 Flow sheet of evaporation process in alumina refinery

式中:V为物料的比体积,m3/kg;T和T0分别为工况温度和环境热力学温度,K;p和p0分别为工况压力和环境压力,MPa。压力对工业铝酸钠溶液物理 的影响较小[9-10],代入工业铝酸钠溶液比热容和密度的拟合式[11-12],即可计算其比物理

的影响较小[9-10],代入工业铝酸钠溶液比热容和密度的拟合式[11-12],即可计算其比物理 。

。

化学 包括反应

包括反应 和扩散

和扩散 [8],这里只计入扩散

[8],这里只计入扩散 。工业铝酸钠溶液比扩散

。工业铝酸钠溶液比扩散 eD为:

eD为:

(3)

(3)

式中:xi为溶液中第i种组分的摩尔分数;R为适用气体常数;T0为环境基准温度;ai为溶液中第i种组分的活度。借助工业铝酸钠溶液活度因子的计算模型[13-14],即可计算其比扩散 。

。

2.2 热平衡方程和 平衡方程

平衡方程

将此四效蒸发器-三级闪蒸器蒸发系统分解为7个操作单元,如图1所示。由于管式降膜蒸发器和闪蒸器均属于稳定流动的开口系统且无动力输出,因此,可忽略势能和动能改变,则单位时间内任意单元的质量、热和 平衡方程的一般形式分别为:

平衡方程的一般形式分别为:

(4)

(4)

(5)

(5)

(6)

(6)

式中:mi和mo分别为进、出体系的物料质量;hi和ho分别为进、出体系的物料比焓;ei和eo分别为进、出体系的物料的比 ;IH为体系的热损失;IE为体系的

;IH为体系的热损失;IE为体系的 损失。

损失。

2.3 热损失和 损失

损失

热损失IH为各效冷凝水和末效乏汽等带走的热量,设备表面向环境散失的热量很小,可忽略不计。

损失IE可分为外部

损失IE可分为外部 损失和内部

损失和内部 损失。外部

损失。外部 损失主要为外排冷凝水和乏汽等带走的

损失主要为外排冷凝水和乏汽等带走的 ,而内部

,而内部 损失主要是蒸发器内的有限温差传热过程和预热器内的混合过程所致。

损失主要是蒸发器内的有限温差传热过程和预热器内的混合过程所致。

2.4 热效率和 效率

效率

热分析中衡量系统或设备用能效率的准则为热效率,定义为:

(7)

(7)

其中:ηh,Hg和Hp分别为分析对象的目的热效率、收益焓和支付焓。

根据该蒸发系统及其各单元的工艺目的,系统和Ⅳ效蒸发器的收益焓是蒸发系统进出物料的焓增;而对于Ⅰ,Ⅱ和Ⅲ效蒸发器以及①,②和③级闪蒸器,收益焓是物料的焓增与二次蒸汽的焓之和。进入系统的支付焓是新蒸汽的焓;而对于Ⅱ,Ⅲ和Ⅳ效蒸发,支付焓是前一效的二次蒸汽的焓;对于①,②和③级闪蒸器,支付焓则是前一效进入的物料的焓。

分析中衡量系统或设备用能效率的参数为

分析中衡量系统或设备用能效率的参数为 效率,其定义为:

效率,其定义为:

(8)

(8)

其中:ηe,Eg和Ep分别为分析对象的目的 效率、收益

效率、收益 和支付

和支付 。类似地,蒸发系统及其各单元的收益

。类似地,蒸发系统及其各单元的收益 和支付

和支付 分别与收益焓和支付焓类似。

分别与收益焓和支付焓类似。

3 数据测量及修正

3.1 数据测量

由于蒸发系统的设备大多属于压力容器,直接测定部分热工数据较困难,故使用在线监测与人工测量相结合的方法采集数据。与生产的有关的参数如压强、温度、流量等由蒸发系统的实时监控系统获得,溶液成分数据采用人工定时采集分析方式获得,环境温度为实时测试温度。根据蒸发系统的生产规律,连续进行30 d共120次重复数据采集。为尽量减少测量误差给热能分析带来的偏差,使用信任度分析算法对重复测量数据进行修正。

3.2 重复测量数据修正模型

对t个测量变量(a1, a2, …, at)进行n次重复测量,测量值为Ti=(a1i, a2i, …, ani), i=1, …, n。

假设根据机理模型,其中有j个变量(a1, a2, …, aj)间存在某种确定的函数关系。利用线性回归分析可计算出具体的函数关系表达式。不失一般性,设所得函数关系表达式为:

g(a1, a2, …, aj)=0 (9)

g(a1i, a2i, …, aji)=εi; i=1, …, n (10)

其中:εi为计算误差。令 ,表示平均误差,则Ti对于函数g(a1, a2, …, aj)的误差为:

,表示平均误差,则Ti对于函数g(a1, a2, …, aj)的误差为: ;信任度为

;信任度为 。

。

对于测量变量间存在的所有机理关系,均可使用上述方法计算对应Ti的信任度。设共有m个机理函数g1( ), g2( ), …, gm( ),则测量结果对于机理函数的信任度为σji (j=1, …, m; i=1, …, n)。

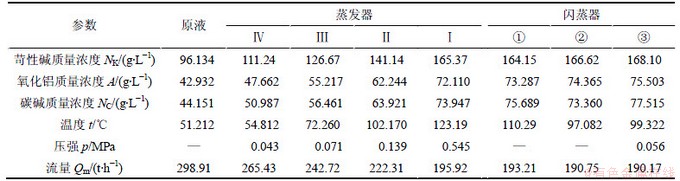

表1 蒸发工序物料的成分及热工参数

Table 1 Concentrations and thermodynamic properties of material in evaporation process

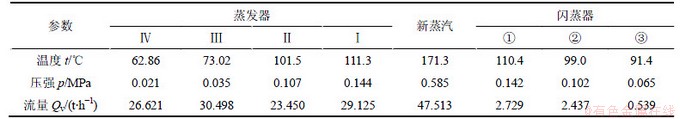

表2 新蒸汽和二次蒸汽的热工参数

Table 2 Thermodynamic properties of fresh and secondary steams

定义测量数据Ti的综合信任度为:

(11)

(11)

令 ,则重复测量结果Ti的可信任度为:

,则重复测量结果Ti的可信任度为:

(12)

(12)

3.3 数据获取

运用热平衡、 平衡等机理模型,对蒸发系统的重复测试结果进行修正计算,各效(或级)出料的成分和状态参数见表1,新蒸汽和各效(或级)二次蒸汽的状态参数见表2。

平衡等机理模型,对蒸发系统的重复测试结果进行修正计算,各效(或级)出料的成分和状态参数见表1,新蒸汽和各效(或级)二次蒸汽的状态参数见表2。

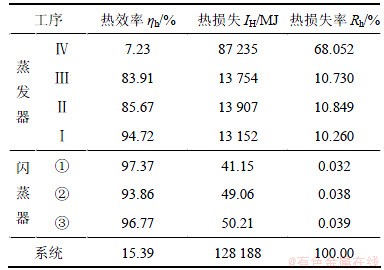

4 分析

蒸发的热分析基准温度取25 ℃。根据修正的龟 山-吉田环境模型, 分析中环境基准温度和压力分别取298.15 K和0.1 MPa,热分析结果如表3所示。其中:热损失率Rh为某单元的热损失占系统总热损失的百分比。

分析中环境基准温度和压力分别取298.15 K和0.1 MPa,热分析结果如表3所示。其中:热损失率Rh为某单元的热损失占系统总热损失的百分比。

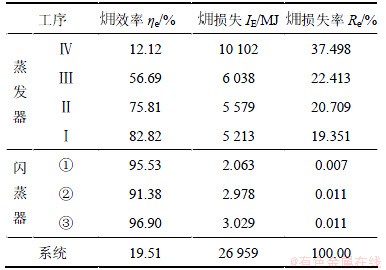

然而,由于热分析只反映能的数量守恒而未考虑能的品质区别,分析结果可能误导节能方向。 分析结果如表4所示,表中

分析结果如表4所示,表中 损失率Re指某单元的

损失率Re指某单元的 损失占系统总

损失占系统总 损失的百分比。

损失的百分比。

表3 蒸发工序的热分析结果

Table 3 Results of thermal analysis of evaporation process

表4 蒸发工序的 分析结果

分析结果

Table 4 Results of exergy analysis of evaporation process

(1) 蒸发系统的热效率仅为15.22%,系统用能较低;Ⅳ效蒸发器的热效率仅为7.23%,其他蒸发单元的热效率较小。Ⅰ至Ⅲ效蒸发器热损失主要是排放的冷凝水带走的热量,Ⅳ效蒸发器的热损失主要为Ⅳ效蒸发器乏汽和冷凝水带走的热量。

(2) 蒸发工序的系统 效率仅为19.51%,节能潜力较大。各效蒸发器的用能状况较差,其中Ⅳ效蒸发器

效率仅为19.51%,节能潜力较大。各效蒸发器的用能状况较差,其中Ⅳ效蒸发器 效率最低,仅为12.12%。三级闪蒸器的

效率最低,仅为12.12%。三级闪蒸器的 效率超过90%,节能潜力较小。

效率超过90%,节能潜力较小。

(3) 为提高蒸发系统的用能效率,应加强Ⅳ效蒸发器乏汽和冷凝水的余热回收利用,同时,应优化蒸发工序的操作参数或设备使用方式,如各效蒸发器内的传热温差分布和直接混合预热器的使用。

5 结论

(1) 热力学分析是一种有效的节能降耗分析方法,其中热分析能够揭示用能过程中能的数量关系, 分析能够综合反映能的数量和品质的变化。

分析能够综合反映能的数量和品质的变化。

(2)针对某氧化铝厂四效蒸发器-三级闪蒸器系统,采用在线监测与人工测量相结合的方法进行数据采集并进行数据修正。

(3) 热分析显示蒸发系统的热效率较低,Ⅳ效蒸发器热损失最大,主要为乏汽和冷凝水带走的热量; 分析显示蒸发工序的火用效率较低,Ⅳ效蒸发器系统节能潜力最大,三级闪蒸器节能潜力较小。提高蒸发系统用能效率的措施为加强Ⅳ效蒸发器乏汽和冷凝水的余热回收利用,以及优化蒸发工序的操作参数或设备使用方式。

分析显示蒸发工序的火用效率较低,Ⅳ效蒸发器系统节能潜力最大,三级闪蒸器节能潜力较小。提高蒸发系统用能效率的措施为加强Ⅳ效蒸发器乏汽和冷凝水的余热回收利用,以及优化蒸发工序的操作参数或设备使用方式。

参考文献:

[1] LIU Liru, LU Aye, LU Zhongwu, et al. Analysis of the overall energy intensity of alumina refinery process using unit process energy intensity and product ratio method[J]. Energy, 2006, 31(8/9): 1167-1176.

[2] 陈勤霞. 降低氧化铝生产汽耗的途径探讨[J]. 有色金属节能, 2006, 23(1): 27-29.

CHEN Qinxia. Discussion on the ways to reduce steam consumption in alumina production[J]. Energy Saving of Non-Ferrous Metallurgy, 2006, 23(1): 27-29.

[3] 郭晋梅, 冯文洁, 焦淑红, 等. 浅析氧化铝生产工艺节能途径[J]. 有色冶金节能, 2004, 21(4): 27-28.

GUO Jinmei, FENG Wenjie, JIAO Shuhong, et al. Humble opinion of the energy saving way of alumina production technology[J]. EnergySavingofNon-FerrousMetallurgy, 2004, 21(4): 27-28.

[4] 孙克萍, 先晋聪, 宋强, 等. 我国氧化铝业中蒸发装置技术进步及效能分析[J]. 有色冶金, 2004(3): 43-45.

SUN Keping, XIAN Jinchong, SONG Qiang, et al. Technical progress and analysis of efficiency and energy on the evaporation installations to China’s alumina industry[J]. Non-ferrous Metallurgy, 2004(3): 43-45.

[5] 姜立宝. 板式降膜蒸发器在氧化铝厂应用问题探讨[J]. 辽宁化工, 2004, 33(6): 345-348.

JIANG LIbao. Discussion of application of plate type evaporator in Shanxi alumina plant[J]. Liaoning Chemical Industry, 2004, 33(6): 345-348.

[6] 李续平, 周在毅. 氧化铝蒸发节能降耗途径的探讨[J]. 轻金属, 2006(8): 37-39.

LI Xuping, ZHOU Zaiyi. Discussion about energy saving for alumina evaporation process[J]. Light Metals, 2006(8): 37-39.

[7] 杨新民, 吴红应, 梅永峰. 氧化铝生产中降低蒸汽消耗的生产实践[J]. 轻金属, 2008(9): 28-30.

YANG Xinmin, WU Hongying, MEI Yongfeng. The practice of reducing steam consumption during producing alumina[J]. Light Metals, 2008(9): 28-30.

[8] Tsatsaronis G. Definitions and nomenclature in exergy analysis and exergoeconomics[J]. Energy, 2007, 32(4): 249-253.

[9] Szargut J, Morris D R, Steward F R. Exergy analysis of thermal, chemical and metallurgical process[M]. New York: Hemisphere Publishing, 1988: 152-158.

[10] 宋国辉, 彭小奇, 宋彦坡, 等. 含相变过程的机械 计算方法[J]. 热科学与技术, 2009, 8(1): 64-68.

计算方法[J]. 热科学与技术, 2009, 8(1): 64-68.

SONG Guohui, PENG Xiaoqi, SONG Yanpo, et al. Method for mechanical exergy calculation including a phase change process[J]. Journal of Thermal Science and Technology, 2009, 8(1): 64-68.

[11] Reynolds J G, Carter R. Density model for sodium hydroxide- sodium aluminate solutions[J]. Hydrometallurgy, 2007(89): 233-241.

[12] 刘建新. 适应我国铝土矿特点的氧化铝生产工艺技术探讨[J]. 轻金属, 2010(10): 13-16.

LIUJianxin. The technology of alumina production[J]. LightMetals, 2010(10): 13-16.

[13] LI Xiaobin, LU Weijun, LIU Guihua, et al. Activity coefficient calculation model for NaAl(OH)4-NaOH-H2O system[J]. Transactions of Nonferrous Metals Society of China, 2005, 15(4): 908-912.

[14] 彭小奇, 宋国辉, 宋彦坡, 等. NaOH-NaAl(OH)4-Na2CO3-H2O体系活度系数的计算模型[J]. 中国有色金属学报, 2009, 19(7): 1332-1337.

PENG Xiaoqi, SONG Guohui, SONG Yanpo, et al. Calculation model of activity coefficient for NaOH-NaAl(OH)4- Na2CO3-H2O system[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(7): 1332-1337.

(编辑 陈灿华)

收稿日期:2012-01-11;修回日期:2012-03-25

基金项目:国家自然科学基金重点资助项目(61134006);国家自然科学基金资助项目(61105080);湖南省自然科学基金资助项目(11JJ4057)

通信作者:彭小奇(1962-),男,四川武胜人,教授,博士生导师,从事有色冶金节能及智能优化等研究;电话:0731-88836713;E-mail: pengxq126@126.com