文章编号:1004-0609(2008)12-2190-06

高压电子铝箔阳极电解扩孔行为

班朝磊,何业东

(北京科技大学 北京市腐蚀、磨蚀与表面技术重点实验室,北京100083)

摘 要:研究发孔铝箔在盐酸和硝酸溶液中的阳极极化行为与扩孔特性的关系。阳极扩孔的基本条件是将发孔箔的内、外表面都控制在钝化状态下。在盐酸溶液中,阳极极化时存在点蚀电位和一个较小的钝化电位区,当扩孔施加的电流密度大于临界点蚀电流密度时,铝箔表面发生二次发孔,导致形成孔蚀族与并孔,腐蚀箔厚度减薄,比电容显著降低。在硝酸溶液中,阳极极化时存在一个宽阔的钝化电位区,因此硝酸扩孔比盐酸扩孔容易控制,不会发生二次发孔。提高盐酸或硝酸浓度与温度均可以增大最大维钝电流密度,即增大扩孔的最大电流密度,提高扩孔的生产效率。

关键词:铝箔;电解电容器;电蚀;极化曲线;孔蚀

中图分类号:TG 172.8 文献标识码: A

Behavior of increasing diameter of tunnels on high voltage Al foil by anodic electrolysis

BAN Chao-lei, HE Ye-dong

(Beijing Key Laboratory for Corrosion, Erosion and Surface Technology, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: The relationship between anodic polarization of etched Al foils and performance in increasing tunnel diameter in both HCl and HNO3 etchants was studied. The essential condition to increase tunnel diameter by anodic electrolysis is to control both interior and exterior surfaces of tunnels under passivation. The anodic polarization curves in HCl solution are characteristic of a pitting potential and a narrow passivation range. When the etching current in HCl solution is above the critical pitting current density, pitting corrosion will occur again, leading to tunnel-clusters and tunnel-mergers and decrease in thickness and special capacitance of Al foil. The anodic polarization curves in HNO3 solution are characteristic of a wide passivation range. It is more convenient to control tunnel widening in HNO3 solution than in HCl solution, without pitting again. Increasing the temperature and concentration of both solutions can enhance the maximum passivation current density for tunnel widening and production efficiency.

Key words: aluminum foil; electrolytic capacitor; electro-etching; polarization curves; pitting

电解扩面技术可以大幅度增加铝箔的表面积,是制造高比容铝电解电容器的关键技术。高压铝电解电容器用腐蚀铝箔是在含有Cl?的酸性电解液中,采用直流阳极电解腐蚀,在高立方织构的高纯铝箔中形成隧道孔,其基本流程为:前处理→电化学发孔→电化学扩孔[1]。前处理是指发孔前对铝所箔所作的各种预处理,以提高发孔时隧道孔的密度与均匀性,松木等研究了8种预处理条件对铝箔表面形态和电蚀后铝箔比电容的影响[2];电化学发孔是指将前处理后的铝箔进行直流电解,在其表面发生点蚀萌生、隧道孔生长等一系列电化学步骤的过程。发孔将决定隧道孔的极限长度与密度。AWITT、HEBERT、ATSUSHI等[3?5]研究了腐蚀液温度、浓度、组成对隧道孔生长动力学规律及其极限长度的影响,阎康平、涂铭旌、王玫 等[6?8]曾研究了发孔电流密度对蚀孔密度与比电容的影响。电化学发孔后隧道孔直径细小,需进行电化学扩孔处理以满足高压化成的需要。

当前对高压铝箔电解扩面的研究主要集中在前处理与发孔2个阶段以及铝箔自身品质[9?18]的改进上,对于扩孔阶段的研究比较少见。为此,本文作者针对国内、外普遍采用的硝酸与盐酸2种阳极电解扩孔技术,利用阳极极化曲线分析阳极极化行为与扩孔特性的关系,结合扫描电镜观察腐蚀铝箔的形貌,分析扩孔条件对铝箔性能的影响。

1 实验

采用具有高立方织构占有率(>95%)的日本昭和高压电子铝箔(光箔)及其发孔箔(扩面倍率为70),其纯度为99.99%,厚度为112 μm。

采用CHI电化学分析仪测试光箔与发孔箔的阳极极化曲线,以Pt电极作为辅助电极,以铝箔为工作电极,其表观面积为1 cm×1 cm,以饱和甘汞电极(SCE)为参比电极;采样周期为500 ms,扫描速率为10 mV/s研究溶液为不同浓度与温度的HNO3溶液与HCl溶液。

电化学扩孔时,发孔箔试样在扩孔液中暴露面积为5 cm×9 cm,扩孔液分别为70 ℃的3%HNO3、85 ℃的5%HCl,电解电量为33 C/cm2,电流密度为25~100 mA/cm2。扩孔后测量厚度并计算质量损失率,同时按照中华人民共和国电子行业标准SJ/11140?1997 进行520 V电压化成并测试比电容。采用JSM6480LV型扫描电镜观察扩孔后腐蚀箔的表面形貌。

2 结果与讨论

2.1 阳极极化行为与扩发孔特性的关系

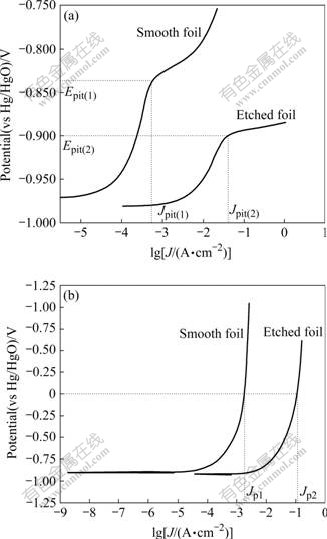

图1(a)、(b)所示分别为光箔和发孔箔在85 ℃的5%HCl溶液和70 ℃的3%HNO3溶液中的阳极极化曲线。由图1(a)可以看到,在盐酸溶液中光箔与发孔箔的阳极极化曲线都呈现出典型的阳极钝化和发生点蚀特征,但发孔箔的点蚀电位Epit(2)比光箔的点蚀电位Epit(1)低63 mV,发孔箔的临界点蚀电流密度Jpit(2)高达47 mA/cm2,是光箔的临界点蚀电流密度Jpit(1)的70倍。这是因为在发孔箔的隧道孔内发生了闭塞电池效应[11],隧道孔内溶液的Cl–离子富集,pH 值下降,使隧道孔表面的点蚀电位变负;发孔箔的临界点蚀电流密度提高70倍则对应于发孔使铝箔的真实表面积提高了70倍。由图1(b)可以看到,在硝酸溶液中光箔与发孔箔的阳极极化曲线均呈现出完全阳极钝化的特征,不发生点蚀,存在一个最大的钝化电流密度(为了便于比较,本文取极化电位等于0 V时的钝化电流密度)。发孔箔的最大钝化电流密度Jp2度高达100 mA/cm2,相对光箔Jp1提高了70倍,对应于发孔使铝箔的真实表面积提高了70倍。阳极电解扩孔的实质就是将铝箔控制在钝化状态,通过铝箔表面不断形成钝化膜和钝化膜不断地溶解,达到扩大隧道孔直径的目的。因此,在盐酸溶液中发孔箔的临界点蚀电流密度就是最大的扩孔电流密度,大于此电流密度将发生二次发孔。在硝酸溶液中的最大钝化电流密度代表最大的扩孔电流密度,但在最大钝化电流密度下电解过电位很大,电解耗能高。

图1 铝箔在85 ℃、5%HCl溶液与70 ℃、3%HNO3溶液中的极化曲线

Fig.1 Polarization curves of Al foil in different solutions: (a) 5%HCl at 85 ℃; (b) 3%HNO3 at 70 ℃

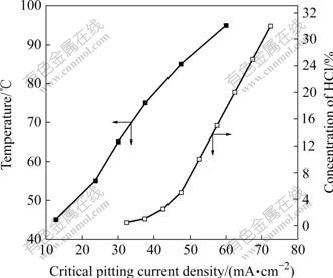

图2所示为根据发孔箔在不同浓度、温度盐酸溶液中所测极化曲线得出的相应临界点蚀电流密度图,可见,固定温度(85 ℃) 提高盐酸浓度时,临界点蚀电流密度增大;固定盐酸液浓度(5%HCl)提高温度时,临界点蚀电流密度急剧增大。这是由于随着盐酸浓度与温度的提高,强化了Cl–对钝化膜的吸附、渗透、扩散与电迁移,导致临界点蚀电流密度增大。由于临界点蚀电流密度对应于扩孔的最大电流密度,因此提高盐酸液温度或浓度可以提高扩孔的电流密度,从而提高生产的扩孔效率。

图2 盐酸浓度、温度对发孔箔临界点蚀电流密度的影响

Fig.2 Effects of HCl concentrations and temperatures on critical pitting current density

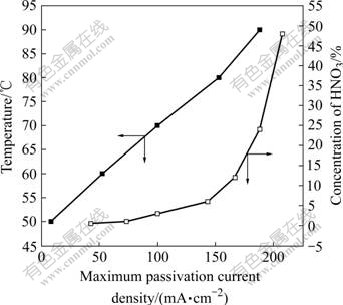

图3所示为根据发孔箔在不同浓度、温度的硝酸溶液中所测的阳极极化曲线获得的硝酸浓度、温度与最大钝化电流密度的关系。可以看到,当硝酸浓度固定为3%,提高温度时,最大钝化电流密度急剧增大;当温度固定为70 ℃,提高浓度时,最大钝化电流密度先迅速上升,在硝酸浓度为10%处出现拐点,硝酸 浓度大于10%时最大钝化电流密度的升幅变小。因此,提高硝酸液温度或浓度都可以提高扩孔的电流密 度,从而提高生产的扩孔效率,但温度的影响更为显著。

图3 硝酸浓度、温度对发孔箔最大钝化电流密度的影响

Fig.3 Effects of HNO3 concentrations and temperatures on maximum passivation current density

2.2 扩孔条件对铝箔性能的影响

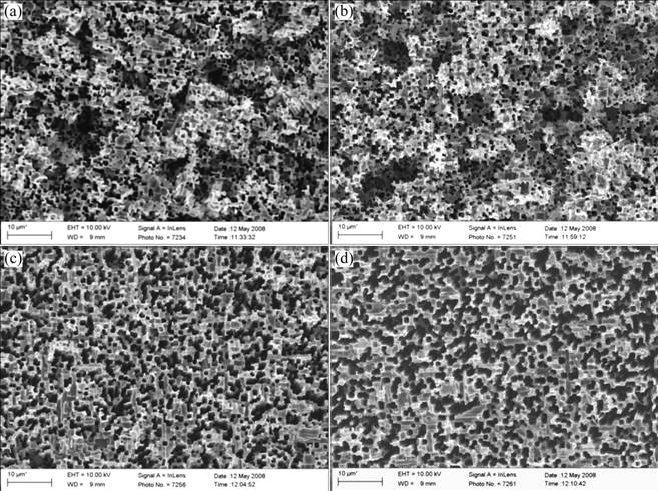

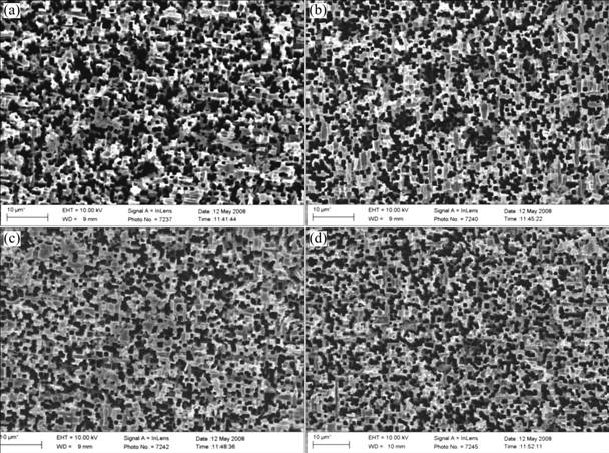

图4所示为发孔箔在85 ℃的5%HCl溶液中扩孔电流密度对腐蚀箔表面形貌的影响。可以看到,在盐酸中扩孔,当扩孔电流密度大于50 mA/cm2时(图4(a),(b)),铝箔表面出现粗大的孔蚀族与并孔特征,腐蚀箔表面出现局部凹陷;在≤50 mA/cm2的电流密度下扩孔(图4(c), (d)),铝箔表面蚀孔分布均匀,并孔较少。电流密度对扩孔效果的影响可由图1(a)发孔箔的阳极极化曲线得到解释。图1(a)中测得的的临界点蚀电流密度为 47 mA/cm2,扩孔的电流密度应当≤47 mA/cm2,大于此值时将会出现二次发孔行为,与图4的规律是一致的。

图4 在85 ℃的5%HCl中不同电流密度扩孔时腐蚀箔表面形貌

Fig.4 SEM images of Al foil surfaces etched in 5%HCl at 85 ℃ with different current densities: (a) 100 mA/cm2; (b) 75 mA/cm2; (c) 50 mA/cm2; (d) 25 mA/cm2

图5所示为发孔箔在70 ℃的3%HNO3溶液中扩孔,电流密度对腐蚀箔表面形貌的影响。可以看到,在硝酸溶液中,在不同的电流密度下都可以获得较好的扩孔效果,虽然电流密度增大时,铝箔表面也发生并孔现象,但比盐酸溶液中要轻微得多。根据图1(b)可知,在硝酸中发孔箔的阳极极化过程不发生点蚀,而且发生钝化的电流密度范围比盐酸溶液大得多。因此,在硝酸溶液中可以比在盐酸溶液中获得更好的扩孔效果,而且生产效率也高。

图5 在70 ℃的3%HNO3中不同电流密度扩孔时腐蚀箔表面形貌

Fig.5 SEM images of Al foil surfaces etched in 3%HNO3 at 70 ℃ with different current densities: (a) 100 mA/cm2; (b) 75 mA/cm2; (c) 50 mA/cm2; (d) 25 mA/cm2

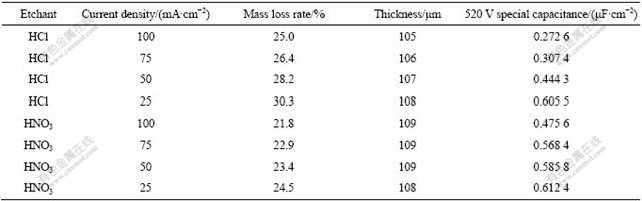

表1所列为发孔箔经在70 ℃的3%硝酸液和85 ℃的5%盐酸液中,采用不同电流密度扩孔后腐蚀箔的厚度、质量损失率及其520 V化成电压比电容。可以看到,在2种扩孔液中,随着扩孔电流密度的降低,质量损失率呈上升趋势。这是因为电流密度的降低延长了扩孔时间导致铝箔自腐蚀增加的结果;与盐酸相比,硝酸钝化能力强,自腐蚀较弱,相同扩孔电流密度下质量损失率也较小;盐酸扩孔时,随着电流密度的增加,二次发孔导致的并孔与孔蚀族造成铝箔表面剥落严重、厚度急剧减薄;硝酸扩孔时,铝箔厚度随电流密度变化基本不变。由表1还可以看到,在盐酸和硝酸溶液中,电流密度下降,扩孔铝箔化成的比电容上升。这与电流密度上升加剧隧道孔的电流密度分布不均程度有关,导致距离隧道孔口越远腐蚀速率越小,隧道孔的锥度增大,结果造成比电容的下降。因此,采用小电流密度扩孔有利于获得高的比电容。

表1 扩孔液与电流密度对腐蚀箔质量损失、厚度及比电容的影响

Table1 Effects of etchants and current densities on mass loss, thickness and special capacitance

3 结论

1) 在盐酸溶液中,阳极极化时存在点蚀电位和一个较小的钝化电位区,当扩孔施加的电流密度大于临界点蚀电流密度时,铝箔表面发生二次发孔,导致形成孔蚀族与并孔行为,腐蚀箔厚度减薄,比电容显著降低。

2) 在硝酸溶液中,阳极极化时存在一个宽阔的钝化电位区,因此硝酸扩孔比盐酸扩孔容易控制,不会发生二次发孔。提高盐酸或硝酸浓度与温度均可以增大最大维钝电流密度,即增大扩孔的最大电流密度,提高扩孔的生产效率。

3) 采用小电流密度扩孔可以提高在隧道孔中电流分布的均匀性,有利于获得高的比电容。

REFERENCES

[1] THIERRY M, KURT R H. Atomic force microscopy study of anodic etching of aluminum[J]. Journal of the Electrochemical Society, 2001, 148(2): B101?B109.

[2] 杨邦朝, 肖占文. 预处理对铝箔电蚀特性的影响[J]. 电子元件与材料, 1997, 16(3): 1?9.

YANG Bang-chao, XIAO Zhan-wen. Effect of pretreatment for aluminum foil on its electrochemical properties[J]. Electronic Components & Materials, 1997, 16(3): 1?9.

[3] ALWITT R S, UCHI H, BECK T R, ALKIRE R C. Electrochemical tunnel etching of aluminum[J]. Journal of the Electrochemical Society, 1984(131): 13?18.

[4] HEBERT K, ALKIRE R C. Growth and passivation of aluminum etch tunnels[J]. Journal of the Electrochemical Society, 1988(135): 2146?2157.

[5] ATSUSHI H. The effect of sulfuric acid on tunnel etching of aluminum in hydrochloric acid[J]. Light Metals, 1992, 42(8): 440?445.

[6] 阎康平, 罗春晖, 涂铭旌. 电流对高纯铝箔交流电侵蚀的影响[J]. 中国有色金属学报, 1999, 9(3): 582?585.

YAN Kang-ping, LUO Chun-hui, TU Ming-jing. Effect of AC current density on etching of aluminum foil[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(3): 582?585.

[7] 阎康平, 罗泸蓉. 中高压阳极箔直流电扩面侵蚀研究[J]. 四川大学学报(工程科学版), 2000, 32(2): 33?35.

YAN Kang-ping, LUO Lu-rong. On Etching aluminum foil for capacitors using DC[J]. Journal of Sichuan University (Engineering Science Edition), 2000, 32(2): 33?35.

[8] 王 玫, 何业东, 洪 涛. 影响高压阳极铝箔隧道孔极限长度的因素[J]. 电子元件与材料, 2007, 26(7): 17?20.

WANG Mei, HE Ye-dong, HONG Tao. Effects of etching conditions on the limiting tunnel length of anodic Al foil for high voltage[J]. Electronic Components & Materials, 2007, 26(7): 17–20.

[9] 毛卫民, 杨 宏, 余永宁, 冯惠平, 许 进. 微量Mg对高压电子铝箔腐蚀结构的影响[J]. 中国有色金属学报, 2003, 13(5): 1057?1059.

MAO Wei-min, YANG Hong, YU Yong-ning, FENG Hui-ping, XU Jin. Influence of trace Mg on corrosion structure of high voltage aluminum foil[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(5): 1057?1059.

[10] 张新明, 孟 亚, 周卓平, 周鸿章. Fe杂质对高纯铝箔再结晶织及比电容的影响[J]. 中国有色金属学报, 1999, 9(1): 19?24.

ZHANG Xin-ming, MENG Ya, ZHOU Zhuo-ping, ZHOU Hong-zhang. Effects of Fe impurity on recrystallization textures and specific capacitances of high pure aluminium foils[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(1): 19–24.

[11] 毛卫民, 陈 垒, 萨丽曼, 余永宁, 李云峰. 晶界对低压电解电容器铝箔腐蚀结构的影响[J]. 中国有色金属学报, 2004, 14(1): 1?5.

MAO Wei-min, CHEN Lei, SA Li-man, YU Yong-ning, LI Yun-feng. Influence of grain boundaries on corrosion structure of low voltage aluminum foil[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 1?5.

[12] 蔡双雨, 何业东. 高压阳极箔隧道枝孔的形成机理[J]. 电子元件与材料, 2007, 26(12): 39?42.

CAI Shuang-yu, HE Ye-dong. Mechanism of sub pits growth in main pits of aluminium foil for high voltage anode[J]. Electronic Components & Materials, 2007, 26(12): 39?42.

[13] 靳 丽, 张新明, 唐建国, 游江海, 周卓平. 高温退火对阴极铝箔腐蚀性能的影响[J]. 中国有色金属学报, 2003, 13(2): 423?427.

JIN Li, ZHANG Xin-ming, TANG Jian-guo, YOU Jiang-hai, ZHOU Zhuo-ping. Effect of high temperature annealing on corrosion property of cathode aluminium foil[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 423?427.

[14] 毛卫民, 蒋 恒, 杨 平, 冯惠平, 余永宁. 微观结构和微量元素对铝箔腐蚀结构的影响[J]. 中国有色金属学报, 2004, 14(10): 1627?1631.

MAO Wei-min, JIANG Heng, YANG Ping, FENG Hui-ping, YU Yong-ning. Influence of microstructure and microelements on corrosion structure of aluminum foil[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(10): 1627?1631.

[15] 徐 进, 毛卫民, 冯惠平, 舒龙卫. 退火加热过程对高压电解电容器阳极铝箔立方织构的影响[J]. 中国有色金属学报, 2001, 11(s2): 42?46.

XU Jin, MAO Wei-min, FENG Hui-ping, SHU Long-wei. Influence of annealing process on cube texture formation in aluminum foil of high voltage anode electrolytic capacitor[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(S2): 42?46.

[16] SERNA L M, JOHNSON C M, WALL F D, BARBORU J C. Effect of implanted Cl and deposited oxides on the pitting behaviour of aluminum[J]. Journal of The Electrochemical Society, 2005, 152(7): B244?B249.

[17] 黄 涛, 曲家辉, 高 明, 王 福, 左 良. 异步轧制速比对高纯铝箔织构转变的影响[J]. 中国有色金属学报, 2006, 16(1): 110?115.

HUANG Tao, QU Jia-hui, GAO Ming, WANG Fu, ZUO Liang. Effect of speed ratio on textures transformation in cross shear rolled high purity aluminum foils[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(1): 110?115.

[18] SERNA L M, ZAVADIL K R, JOHNSON C M, WALL F D. A critical implanted Cl concentration for pit initiation on aluminum thin films[J]. Journal of The Electrochemical Society, 2006, 153(8): B289?B295.

基金项目:北京地区高等学校新材料学科群建设资助项目

收稿日期:2008-06-17;修订日期:2008-09-16

通讯作者:何业东,教授;电话:010-62332715;E-mail: htgroup@mater.ustb.edu.cn

(编辑 陈爱华)