退火工艺对高压阳极铝箔发孔均匀性的影响

陈明安1,肖源泓1,张新明1,林林2,卢敬华2,周仁良2

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 西南铝业(集团)有限责任公司,重庆,401326)

摘 要:采用金相显微镜、扫描电镜研究不同退火工艺处理铝箔在盐酸硫酸腐蚀体系中表面腐蚀发孔的均匀性和表面形貌特征,用二次离子质谱仪分析铝箔表面Fe,Si,Cu和Mg等微量元素沿深度方向的分布。研究结果表明:退火工艺可以改变铝箔微量元素的表面聚集形式,从而改变腐蚀发孔率和发孔均匀性;在500 ℃退火时,Cu元素在表面富集太少,表面腐蚀发孔不均匀;在575 ℃退火时,铝箔表面富集了足够的微量元素,发孔面积明显增加。在二级退火方式下,各种微量元素表面聚集都很少,发孔率低。升温速度和冷却速度对铝箔内微量元素的聚集也有一定程度的影响。

关键词:铝箔;发孔;退火;微量元素

中图分类号:TG146.2 文献标志码:A 文章编号:1672-7207(2010)04-1315-06

Influence of annealing on pitting uniformity of aluminum foil for

high voltage electrolytic capacitor

CHEN Ming-an1, XIAO Yuan-hong1, ZHANG Xin-ming1, LIN Lin2, LU Jing-hua2, ZHOU Ren-liang2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Southwest Aluminum (Group) Limited Company, Chongqing 401326, China)

Abstract: The influence of the annealing of the high voltage aluminum foil on the pitting uniformity and the morphological features after etching in mixed solution of HCl and H2SO4 was studied by the optical micrograph and the scanning electron microscope (SEM). The distribution of trace elements such as Fe, Si, Cu and Mg in the surface layer was measured by secondary ion mass spectrometer. The results show that the annealing has obvious effects on the pitting uniformity and the morphology of aluminum foil, due to the influence of the annealing on the distribution of trace elements in the surface layer of aluminum foil. Due to the lack of Cu in the surface layer, the sample annealed at 500 ℃ is pitted unevenly. A quantity of trace elements are accumulated in the surface layer of the sample annealed at 575 ℃. After two-step annealing, only few trace elements are diffused to the surface layer. The heating rate and cooling rate also influences the distribution of trace elements in the surface layer of aluminum foil.

Key words: aluminum foil; pitting; annealing; trace element

高压阳极铝箔是生产高压铝电解电容器的重要材料。通过适当的腐蚀加工可使铝箔表面积大幅度增加,进而使比电容值增大,因此,铝箔的电化学腐蚀特性是提高该性能的关键。高压铝箔的电化学腐蚀工艺主要分为发孔和扩孔2个阶段。发孔阶段,在很大程度上决定了铝箔腐蚀的最终形貌,是整个腐蚀工艺的关键步骤。在这方面,国产高压铝箔与国外高压铝箔相比存在很大的差距[1]。为了提高发孔率和发孔均匀性,国内通常采用的方法是用重铬酸盐腐蚀,或在高压铝箔中加入微量铅[2-4]。在国外,基于环保原因,重铬酸盐腐蚀方法已经禁止使用,因此,采用环保型的硫酸腐蚀体系。但硫酸体系对高压铝箔表面质量以及组织结构的均匀性要求很高,国内生产的铝箔很难满足硫酸体系的要求。Arai等[5-7]研究表明:除Mg以外,铝箔中常规微量元素的标准电位要高于铝的标准电位,如果这些元素富集在铝箔表面会促进附近的铝原子被腐蚀,并萌生腐蚀小孔。若富集的微量原子在表面均匀分布,则可使腐蚀小孔也均匀分布,从而促进比电容的明显增加。毛卫民等[8]通过研究发现,适当的退火可以使铝箔内层的微量元素不同程度地向表面富集,借助热处理工艺可以对微量元素的表面富集进行一定程度的控制和调整,进而提高电解电容器铝箔的电化学和电学性能。本文作者对铝箔成品退火工艺对微量元素的表面富集程度和腐蚀发孔均匀性的影响规律进行研究。

1 实验方法

采用厚度为110 μm的高纯铝箔,其主要化学成分如表1所示。铝箔基本处理工序为:表面清洗→退火→预处理→发孔。

退火前表面清洗:在60 ℃、浓度为0.125 mol/L 的NaOH溶液中处理30 s,用蒸馏水冲洗后吹干。

退火:采用不同升温速度、退火温度、冷却方式对铝箔进行退火处理。

表1 高纯铝箔主要化学成分(质量分数)

Table 1 Chemical composition of high pure aluminum foil 10-6

发孔前预处理:先在40 ℃、浓度为0.5 mol/L的NaOH溶液中处理60 s,用蒸馏水冲洗后吹干;再在70 ℃、浓度为1 mol/L的HCl溶液中处理180 s,蒸馏水冲洗、吹干。

发孔:将试样装在试样夹中,使试样表面面积为2 cm2的区域暴露出来。发孔电流密度为0.2 A/cm2,发孔溶液浓度为1 mol/L的HCl和3.5 mol/L的H2SO4混合溶液,温度为70 ℃,发孔时间为120 s。

利用二次离子质谱仪检测铝箔表面Fe,Si,Cu和Mg等元素由表及里的分布,用金相显微镜以及扫描电镜观察腐蚀发孔后样品的表面形貌。

2 实验结果

2.1 铝箔表层元素富集

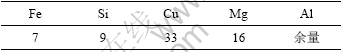

图1所示为不同退火条件下铝箔表面微量元素的分布。由图1可见:曲线1的二级退火工艺是先将试样升温到180 ℃保温0.5 h,再升温到500 ℃保温1 h后空冷,升温速度为10~14 ℃/min。曲线2和曲线3的退火工艺是将试样以10~14 ℃/min的升温速度分别升温到600 ℃和500 ℃,保温1 h后空冷。由图1可见:在500 ℃退火条件下,试样中Mg和Si的富集程度非常明显,最大离子数超过二级退火和600 ℃退火后试样中的Mg和Si的最大离子数30多倍。在二级退火下,微量元素聚集程度都比较低。Cu元素在600 ℃退火条件下富集程度最高。

(a) Cu; (b) Mg; (c) Fe; (d) Si

1—二级退火;2—600 ℃退火;3—500 ℃退火

图1 不同退火条件下铝箔表面微量元素的分布

Fig.1 Distributions of trace elements in surface layer of aluminum foil annealed at different temperatures

2.2 退火温度对发孔的影响

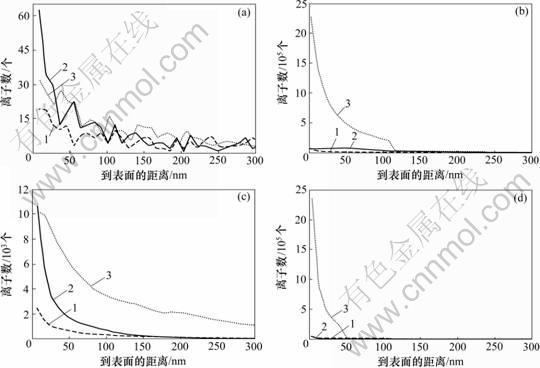

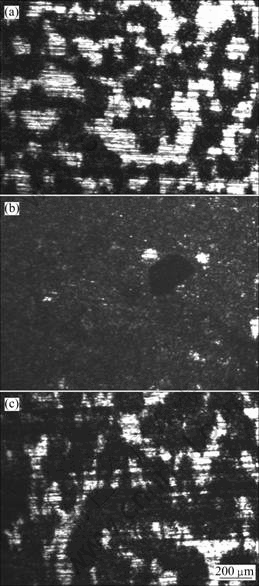

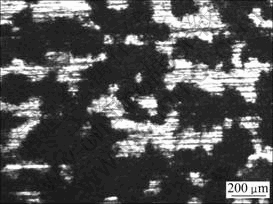

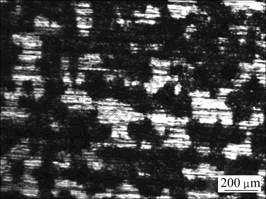

图2所示为以10~14 ℃/min的升温速度分别升温到500,575和600 ℃、保温1 h,随后空冷的退火铝箔发孔后的表面形貌。图中深色部分为已腐蚀区,浅色部分为未腐蚀区。可见:在500 ℃退火的试样表面有大部分区域未发孔,发孔率为50%左右。在575 ℃左右退火的试样表面发孔面积明显增大,发孔率达到94%。在600 ℃退火的试样表面发孔程度有所下降,发孔率仅为67%。图3所示为各试样腐蚀发孔区域的SEM像。在500 ℃退火后,样品表面起伏比较明显,可以看到一些凹陷的腐蚀坑。在600 ℃退火后,样品一些区域腐蚀发孔不够。这2种退火方式处理的样品表面都有比较明显的局部蚀孔合并现象。在575 ℃退火条件下,表面更平整,腐蚀孔排列更均匀。

退火温度/℃:(a) 500; (b) 575; (c) 600

图2 不同退火温度铝箔表面的发孔形貌

Fig.2 Micrographs of pitting for aluminum foils annealed at different temperatures

退火温度/℃:(a) 500; (b) 575; (c) 600

图3 不同温度退火铝箔发孔后表面形貌SEM像

Fig.3 SEM images of pitting for aluminum foils annealed at different temperatures

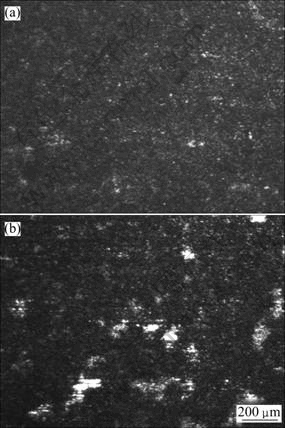

2.3 冷却方式对发孔的影响

在升温速度为10~14 ℃/min,于575 ℃保温1 h后炉冷的条件下,所得试样腐蚀发孔后的表面形貌如图4所示。由图4可见:试样有较多的未腐蚀区域,腐蚀区占67%。而退火温度相同、冷却方式不同的试样(图2(b)所示)的腐蚀面积达94%。说明冷却方式对发孔率也有影响,较快的冷却速度有利于铝箔腐蚀发孔。

图4 在575 ℃退火后随炉冷却方式下铝箔发孔的表面形貌

Fig.4 Micrographs of pitting for aluminum foils annealed at 575 ℃ and furnace cooled

2.4 退火升温速度对发孔的影响

图5所示为以不同的升温速度下升至575 ℃保温1 h、然后空冷的铝箔表面发孔形貌。由图5可见:当升温速度为5~8 ℃/min时,试样发孔率在93%以上;当升温速度为19~22 ℃/min时,试样的发孔率为87%。过快的升温速度使发孔率有所减少。

升温速度/(℃?min-1):(a) 5~8; (b) 19~22

图5 不同升温速度下铝箔发孔照片

Fig.5 Micrographs of pitting for aluminum foils annealed at different heating rates

2.5 分级退火对发孔的影响

图6所示为二级退火铝箔的发孔形貌。二级退火是铝箔先以10~14 ℃/min的速度升温到180 ℃保温0.5 h,然后以10~14 ℃/min的速度升温到500 ℃保温1 h后空冷。对比图6与图2(a)可知:分级退火并不能提高发孔率,腐蚀面积为50%左右。

图6 二级退火方式下铝箔发孔的表面形貌

Fig.6 Micrograph of pitting for aluminum foils after

two-step annealing

3 讨论

一般地,高纯铝中的微量元素含量极低,基本都呈固溶状态。据文献[8]报道:纯铝有很高的表面能,在适当的热激活条件下,铝箔内的微量元素在表面能的驱动下会向铝箔表层富集,而且会首先聚集于表面的缺陷、位错、轧痕等区域。根据热力学原理,微量元素在铝箔表面的偏聚浓度cb可以简单表示为:

(1)

(1)

其中:?G<0,为微量元素处在铝箔表面与其内层的吉布斯自由能之差;cc为溶质原子在铝箔内层的浓度;T为热力学温度;R为摩尔气体常数。根据式(1)可知:随着温度升高,微量元素在表面的平衡偏聚浓度降低。同样,在较高的温度下,微量元素在位错、晶界等晶体学缺陷附近的平衡浓度也会降低。因此,给予适当的热激活可以使铝箔内层的微量元素向表面聚集。但是,若加热温度过高,将使已经偏聚的微量元素在浓度梯度的影响下,重新向铝箔内层扩散。

在铝箔所含的元素中,Cu的标准电极电位最正,与较负的Al基体组成原电池后,会促进铝箔的腐蚀。Mg能与Fe和Si形成金属间化合物,防止Fe-Al间形成局部电池,且该金属间化合物与Al有相近的电极电位,因此,Mg含量过高会降低发孔率[9]。

Cu元素在600 ℃退火时富集程度最大(图1),说明500 ℃退火并没有足够的热激活使Cu元素达到最大平衡偏聚浓度,这些富集到表面的Cu也大量聚集在表面缺陷和位错等区域。而Mg和Si在500 ℃退火时富集程度相当高,因此,500 ℃退火的铝箔表面腐蚀困难,发孔率低,并且发生局部连孔现象,如图2(a)和图3(a)所示。在更高的退火温度下,Cu元素富集增加,开始在表面均匀分布;Mg和Si受浓度梯度影响扩散到铝箔内层,富集程度下降。因此,当退火温度为575 ℃时,铝箔表面发孔率达到94%,并且由图3(b)可见,腐蚀孔均匀分布,表面平整。当退火温度达到600 ℃以后,过高的热激活使得Cu等微量元素开始向铝箔内层迁移。并且,由于是在空气中退火,较高的温度使得铝箔表面的氧化膜增厚,阻碍了腐蚀的进行[10-12],最终导致试样发孔率有所降低(图2(d)),出现局部未腐蚀区(图3(c))。

微量元素在铝箔中迁移是一个缓慢的扩散过程,可由下式表示[13]:

(2)

(2)

式中:D0为扩散频率因子;Q为热激活能;D为扩散系数。在一定温度下,同种元素在Al基体中的扩散系数一定。并根据扩散距离d与时间t的关系[13]:

(3)

(3)

可知:在一定温度下,扩散距离只与时间相关。

将试样从575 ℃炉冷到室温的过程中,已经在保温阶段大量富集的Cu等元素有足够的时间在浓度梯度的驱动下向铝箔内层扩散。并且,试验中得到炉冷试样晶粒粒径为141 μm,空冷试样晶粒粒径为112 μm,说明炉冷试样表面晶界要比空冷试样表面晶界少很多,而且在晶粒长大过程中,也减少了表面的位错等缺陷。长时间的高温使得氧化膜有机会进一步增加。据文献[14-15]报道:腐蚀开始的区域化学势能较高,可能是杂质元素富集区,也可能是晶界区,还可能是位错区或缺陷。炉冷使得这些区域的化学势能都有所下降,最终导致试样发孔率明显下降。

当升温速度较慢时,升温时间大约为100 min,而当升温速度较快时,升温时间为30 min。过快的升温速度使得微量元素没有足够的时间在表面富集并且均匀分布,从而使得试样腐蚀发孔率有所降低(如图5所示)。

在二级退火状态下,在低温退火阶段的保温过程中会发生回复、位错迁移等,从而能够减小铝箔的表面能,使得在高温阶段保温过程中驱动Si,Mg和Cu等元素向表面富集的能量减少,最终各种元素在表面聚集的程度都比较低,导致腐蚀发孔率只有51%(如图6所示)。

4 结论

(1) 退火温度是控制有利元素在铝箔表面大量富集的主要因素。于575 ℃退火使得Cu元素在铝箔表面均匀富集,降低了Mg元素的富集程度,提高了发 孔率。

(2) 快速的空冷方式是防止已经大量富集到铝箔表面的微量元素再扩散回铝箔内层的有效方法,有利于腐蚀发孔。

(3) 升温速度过快使得微量元素没有足够的时间在表面富集并且均匀分布,使得试样腐蚀发孔率有所降低。

(4) 在二级退火工艺中,低温阶段时大部分能量已经得到释放,使得在以后的退火过程中没有足够的能量驱动微量元素向表面扩散,不利于微量元素在表面富集,从而使铝箔发孔率降低。

参考文献:

[1] 杨宏, 毛卫民, 钮震霖. 国内外高压电解电容器用铝箔的性能比较[J]. 电子元件与材料, 2005, 24(11): 62-65.

YANG Hong, MAO Wei-min, NIU Zhen-lin. Comparison of properties with aluminum foil for high voltage electrolytic capacitor both domestic and abroad[J]. Electronic Components and Materials, 2005, 24(11): 62-65.

[2] 左宏, 毛卫民. 微量铅和铬酸盐对高压铝箔腐蚀行为的影响[J]. 材料科学与工程学报, 2005, 23(4): 605-607.

ZUO Hong, MAO Wei-min. Influence of micro-alloyed Pb and chromate on the corrosion behavior of high voltage anode aluminum foil[J]. Journal of Materials Science and Engineering, 2005, 23(4): 605-607.

[3] Tsubakino H, Nogami A, Yamanoi T. Segregation of lead in oxide film of high-purity aluminum containing 100 ppm lead[J]. Appl Surf Sci, 2002, 185: 298-302.

[4] Ashitaka Z, Thompson G. E, Skelden P, et al. The behavior of copper and lead during heat treatment and surface treatment of aluminum capacitor foils[J]. J Electrochem Soc, 1999, 146(4): 1380-1385.

[5] Arai K, Suzuki T, Atsumi T. Effect of trace elements on etching of aluminum electrolytic capacitor foil[J]. J Electrochem Soc, 1985, 132(7): 1667-1671.

[6] 罗兵辉, 单毅敏, 柏振海. 退火温度对淬火后冷轧5083铝合金组织及腐蚀性能影响[J]. 中南大学学报: 自然科学版, 2007, 35(5): 802-808.

LUO Bing-hui, SHAN Yi-min, BO Zhen-hai. Effect of annealing temperature on microstructure and corrosive properties of cold-rolled 5083 aluminum alloy after quenching[J]. Journal of Central South University: Science and Technology, 2007, 35(5): 802-808.

[7] Wu X, Asoka-Kumar P, Lynn K G , et al. Detection of corrosion related defects in aluminum using positron annihilation spectroscopy[J]. J Electrochem Soc, 1994, 141(12): 3361-3368.

[8] 毛卫民, 杨宏, 杨平. 退火对高压电解电容器铝箔微量元素分布和腐蚀性能的影响[J]. 金属热处理, 2004, 29(9): 3-6.

MAO Wei-min, YANG Hong, YANG Ping. Influence of annealing on distribution of trace elements and corrosion properties of aluminum foil for high voltage electrolytic capacitor[J]. Heat Treatment of Metals, 2004, 29(9): 3-6.

[9] Nes E, Solberg J K. Growth of cube grains during recrystallization for aluminum[J]. Materials Science and Technology, 1986, 2(l): 19-21.

[10] Chi C S, Jeong Y, Ahn H J. Transition of hydrated oxide layer for aluminum electrolytic capacitors[J]. Mater Sci Eng A, 2006, 2007, 449/451: 314-317.

[11] 赵旭辉, 左禹, 赵景茂. 铝阳极氧化膜在NaCI溶液中的电化学性能[J]. 中国有色金属学报, 2004, 14(4): 563-567.

ZHAO Xu-hui, ZUO Yu, ZHAO Jing-mao. Electrochemical properties of anodized aluminum films in sodium chloride solution[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(4): 563-567.

[12] Wiersma B J, Hebert K R. Observations of the early stages of the pitting corrosion of aluminum[J]. J Electrochem Soc, 1991, 138(1): 48-54.

[13] 郑子樵. 材料科学基础[M]. 长沙: 中南大学出版社, 2005: 305-316.

ZHENG Zi-qiao. Materials science-based[M]. Changsha: Central South University Press, 2005: 305-316.

[14] Osawa N, Fukuoka K. Pit nucleation behavior of aluminum foil for electrolytic capacitors during early stage of DC etching[J]. Corrosion Science, 2000, 42(3): 585-597.

[15] 王辉. 高压电子铝箔的发孔与扩孔技术研究[D]. 北京: 北京科技大学材料科学与工程学院, 2005: 44-49.

WANG Hui. Electrochemical pitting and tunnel-widening of aluminum foil for high voltage electrolytic capacitor[D]. Beijing: University of Science and Technology Beijing. School of Materials Science and Engineering, 2005: 44-49.

收稿日期:2009-08-15;修回日期:2009-11-04

基金项目:湖南省自然科学基金重点资助项目(05JJ20015)

通信作者:陈明安(1964-),男,湖南安乡人,教授,博士,从事有色金属材料加工与表面技术等研究;电话:13873163116;E-mail: ma-chen@mail.csu.edu.cn

(编辑 陈爱华)