文章编号:1004-0609(2013)12-3367-07

电沉积弥散锡晶核对高压阳极铝箔电解腐蚀特性的影响

彭 宁1,何业东1,宋洪洲2,杨小飞2,蔡小宇2

(1. 北京科技大学 北京市腐蚀、磨蚀与表面技术重点实验室,北京 100083;

2. 广西贺州市桂东电子科技有限责任公司,贺州 542800)

摘 要:采用碱洗除去铝箔表面的富铅层,在其表面沉积出高度弥散的锡晶核,通过扫描电镜观察铝箔表面沉积锡晶核的分布,并对铝箔腐蚀后的表面形貌以及对腐蚀孔孔径大小进行统计。结合极化曲线测量铝箔的腐蚀电位,研究电沉积弥散锡晶核对高压阳极铝箔电解腐蚀特性的影响。结果表明:沉积锡晶核的电流密度越大,铝箔表面得到的锡晶核面密度越高,晶核越细小;弥散的锡晶核能够和铝基体组成腐蚀微电池,有效地引导铝箔腐蚀发孔,提高铝箔发孔的均匀性,从而提高铝箔的比电容;相对于表面富铅的铝箔,电沉积弥散锡晶核的铝箔表面微电池数量显著下降,使得腐蚀电位提高,铝箔表面未沉积锡晶核处表面活性低,从而导致铝箔的腐蚀减薄减少。

关键词:电解电容器;高压铝箔;锡晶核;比电容

中图分类号:TM535 文献标志码:A

Influence of electrodepositing tin nuclei on electrochemical corrosion of high voltage anode aluminum foil

PENG Ning1, HE Ye-dong1, SONG Hong-zhou2, YANG Xiao-fei2, CAI Xiao-yu2

(1. Beijing Key Laboratory for Corrosion, Erosion and Surface Technology,

University of Science and Technology Beijing, Beijing 100083, China;

2. Guangxi Hezhou Guidong Electronics Technology Company Limited, Hezhou 542800, China)

Abstract: The trace amount of lead at the surface of Al foils was removed by alkaline washing, and then, the tin nuclei were electrodeposited on the surface. The surface morphologies of the Al foils electrodeposited tin nuclei were observed by scanning electron microscopy. The size distribution of pits was calculated and the corrosion potential was analyzed by polarization curve. The influence of electrodepositing tin nuclei on the etching ability was studied. The results show that the surface density of the tin nuclei increases with the current density increase, and accompany with the volume of nuclei decreasing. The tin nuclei can form a lot of micro-batteries with Al foils so as to effectively initiate pitting, which promote the uniform distribution of pits and increase the specific capacitance of etched Al foils. Compared with lead-riched Al foils at the surface, the numbers of micro-batteries of the Al foils electrodeposited tin nuclei are far less than that of the lead-riched Al foils at the surface, which can decrease the corrosion thickness of the Al foils.

Key words: electrolytic capacitor; high voltage aluminum foil; tin nuclei; specific capacitance

铝电解电容器用高压阳极铝箔通常是采用电化学腐蚀的方法在其(100)面腐蚀出大量的垂直于表面的隧道孔,以提高其比表面积,进而获得高比电容。大量的研究表明,为了进一步提高腐蚀铝箔的比表面积和比电容,需要从提高发孔的均匀性、降低隧道孔的并孔和铝箔的腐蚀减薄等方面考虑,发展新的高压铝光箔和相应的腐蚀技术[1]。

目前,国内外提高高压铝箔发孔均匀性主要是通过以下2种途径:一是在高纯铝箔的制备过程中,加入10-6级的Pb、Sn、In等微量元素[2-6],然后通过退火热处理使这些元素富集在铝箔表面,在电解质中这些微量元素将与铝基体构成大量的腐蚀微电池。在阳极电解腐蚀过程中,铝箔表面存在的这些微电池可以诱导铝箔的腐蚀,从而提高铝箔发孔的均匀性。但是这样得到的铝箔表面微电池的面密度会很高,使得腐蚀隧道孔的并孔和坍塌严重,高密度的微电池还导致铝箔的腐蚀减薄,这不仅限制腐蚀铝箔比电容的提高,还将使腐蚀铝箔的机械性能下降。二是在高纯铝箔表面沉积铅、铟、锌等金属元素[7-8],与铝基体组成大量的微电池,提高铝箔表面上的活性点,从而提高铝箔腐蚀时的发孔均匀性。高纯铝箔表面沉积铅、铟、锌等金属元素,一般是采用化学置换的方法,在高纯铝箔表面形成一个疏松的沉积层。然而,在电化学腐蚀过程中,这些沉积层与铝箔之间组成的腐蚀微电池,其面密度远高于第一种情况的,虽然可以有效引导铝箔的发孔,但铝箔的腐蚀减薄将更加严重,因而这种技术没有在工业上获得应用。

针对上述高压铝箔腐蚀时发生并孔和腐蚀减薄的问题[9-10],本文作者采用碱洗除去铝箔表面的富铅层,然后通过电化学方法在铝箔表面沉积出弥散的锡晶核,研究弥散锡晶核对提高高压铝箔腐蚀发孔均匀性和抑制铝箔腐蚀减薄的影响。

1 实验

实验采用具有高立方织构占有率(>95%)的新疆众和公司生产的高压电子铝箔,其纯度为99.99%,厚度为120 μm,其表面具有富铅层,以下简称为众和铝箔。

将众和铝箔在40 ℃浓、2.5 mol/L NaOH溶液中处理90 s,去除表面氧化膜和富铅层;之后在40 ℃浓度为3.7 mol/L HNO3溶液中处理60 s,除去表面吸附的杂质。清洗、干燥后,采用精度为0.1 μm的数显测厚仪测量铝箔厚度。以上述处理后的铝箔为阴极,石墨为阳极,采用的镀液成分为:Na2SnO3·3H2O 10 g/L,CH3COOH 1 g/L的水溶液,温度控制在(60±2) ℃,铝箔带电入槽,改变镀锡电流密度和时间在铝箔表面电沉积弥散锡晶核。

将上述电沉积弥散锡晶核的铝箔和作为对比的众和铝箔进行以下发孔、扩孔处理:以铝箔为阳极,石墨板为阴极,铝箔处理面积为5 cm×9 cm;铝箔在72 ℃的1 mol/L HCl和3.5 mol/L H2SO4水溶液中发孔,发孔电流密度为260 mA/cm2,发孔时间为95 s;之后在70 ℃质量分数为3%的HNO3溶液中进行扩孔处理,电流密度为50 mA/cm2,扩孔时间为760 s。采用精度为0.1 μm的数显测厚仪测量扩孔后铝箔的厚度。按照中华人民共和国电子行业标准SJ/11140—1997对扩孔后的铝箔进行520 V电压化成并测试比电容。

采用METEK PRINCETON电化学工作站,通过三电极体系测试电沉积弥散锡晶核的铝箔和作为对比样的众和铝箔在70 ℃的1 mol/L HCl和3.5 mol/L H2SO4水溶液中的极化曲线。以Pt电极作为辅助电极,铝箔为工作电极,饱和甘汞电极(SCE)为参比电极;采样周期为500 ms,扫描速率为10 mV/s。采用JSM-6510A扫描电镜(SEM)观察电化学沉积弥散锡晶核的形貌和铝箔腐蚀后的表面形貌,并对腐蚀后的铝箔表面形貌采用Image-Pro软件进行腐蚀孔孔径大小的统计。

2 结果与分析

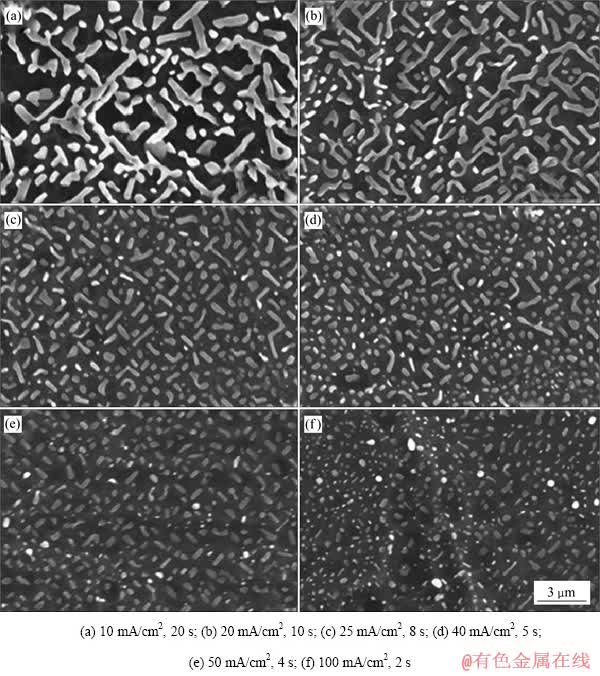

图1所示为众和铝箔经过碱洗、酸洗除去富铅层后,在恒定电量为0.2 C/cm2不同电流密度和沉积时间时表面沉积弥散锡晶核后的表面形貌。由图1可知,当电流密度为10 mA/cm2,沉积时间为20 s时,铝箔表面沉积的锡晶核呈长条状或棒状,锡晶核的面密度低,未沉积晶核区域大,如图1(a)所示;提高电流密度、缩短沉积时间时,铝箔表面沉积的锡晶核逐渐变小,相应的锡晶核面密度增加,如图1(b)~(f)所示。

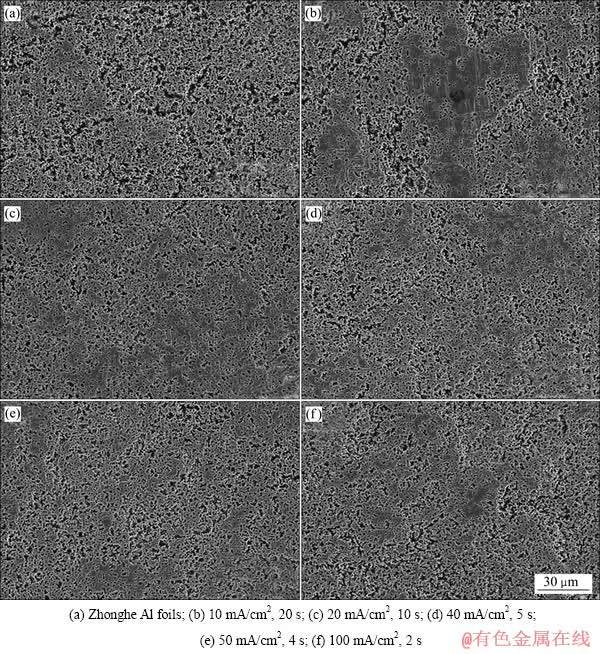

图2所示为众和铝箔对比样和不同电沉积条件下得到的铝箔在72 ℃的1 mol/L HCl和3.5 mol/L H2SO4水溶液中,电解腐蚀的电流密度为260 mA/cm2,发孔95 s,获得的发孔箔的表面形貌。图2(a)所示为众和铝箔腐蚀后的表面形貌,此时的铝箔表面腐蚀孔分布较均匀,但同时并孔也较为严重;图2(b)所示为沉积电流密度为10 mA/cm2、沉积时间为20 s时铝箔腐蚀后的表面形貌,此时铝箔表面腐蚀孔分布极不均匀,未腐蚀区大,而腐蚀区并孔严重,这对应着铝箔比电容的严重降低,因此也可以证明,铝箔经过长时间碱洗、酸洗后会严重降低比电容。随着沉积锡晶核的电流密度逐渐增大,铝箔腐蚀后表面腐蚀孔分布均匀,并孔程度逐渐降低,如图2(c)~(e)所示;然而当沉积锡晶核的电流密度高达100 mA/cm2、沉积时间为2 s时,腐蚀后铝箔表面并孔又有所增加,如图2(f)所示。上述结果表明,在适当的电沉积条件下,沉积一定面密度的弥散锡晶核能够有效地引导铝箔发孔,提高发孔均匀性和降低并孔。

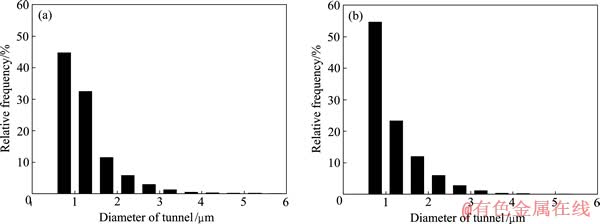

铝箔腐蚀后分为明显的两部分:明亮区为未发孔的区域,暗色区则为发孔处。利用这一差异,采用Image-Pro软件对图2铝箔腐蚀形貌图片中腐蚀孔的孔径分布进行统计。以每一个发孔处,如方孔、并孔形成的多边形孔,换算成为一个面积相等的圆孔的孔径,称为等效孔径,用其来表征这一发孔处的孔径,以等效孔径分布的均匀情况来表征发孔腐蚀的均匀性。图3所示为众和铝箔和在电流密度为50 mA/cm2、沉积4 s获得的弥散锡晶核的铝箔腐蚀发孔后等效孔径分布的情况。由图3可知,众和铝箔在腐蚀后,等效孔径小于1 μm的腐蚀孔数量占45%,等效孔径大于1 μm的腐蚀孔数量占55%;电沉积弥散锡晶核的铝箔腐蚀发孔后,等效孔径小于1 μm的腐蚀孔数量占55%,而等效孔径大于1 μm的腐蚀孔数量只占45%。由此可以进一步证明,在适当的电沉积条件下,沉积一定面密度的弥散锡晶核能够提高发孔的均匀性,同时降低并孔的发生。

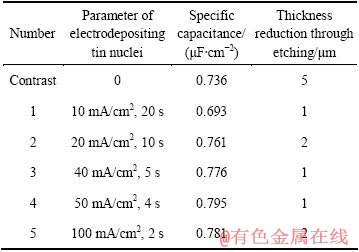

表1所列为众和铝箔和电沉积弥散锡晶核的铝箔经过腐蚀后的减薄量以及520 V化成后的比电容。由表1可知,在合适的电沉积条件下得到的锡晶核可以引导铝箔均匀发孔,比电容相对于众和铝箔提高了7%左右;而当电沉积锡晶核的条件不适宜时,比电容反而有所降低。此外,众和铝箔腐蚀后的减薄量为5 μm,而电沉积弥散锡晶核的铝箔经过腐蚀后的减薄量仅为1~2 μm。因此,通过电沉积锡晶核引导铝箔腐蚀发孔,可以显著降低铝箔的腐蚀减薄量。

图1 在不同电流密度和沉积时间下铝箔表面沉积弥散锡晶核的表面形貌

Fig. 1 Surface morphologies of aluminum foils electrodeposited tin nuclei at different current densities and times

图2 众和铝箔和不同电沉积条件下的铝箔腐蚀后的表面形貌

Fig. 2 Corrosion surface morphologies of Zhonghe Al foils and Al foils electrodeposited tin nuclei at different current densities and times

图3 众和铝箔和电沉积弥散锡晶核的铝箔经过腐蚀后腐蚀孔孔径分布的统计

Fig. 3 Pits diameter distribution statistics of Zhonghe etched Al foils (a) and etched Al foils with electrodeposited tin nuclei (b)

表1 众和铝箔和电沉积弥散锡晶核的铝箔腐蚀减薄及520 V化成后的比电容

Table 1 Specific capacitance at 520 V and thickness reduction of Zhonghe Al foils and electrodeposited tin nuclei Al foils

3 讨论

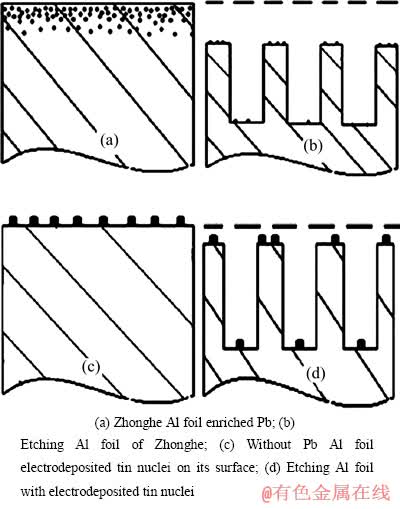

为了获得高立方织构占有率(>95%),以利于腐蚀时形成隧道孔,高压铝箔需要在500~600 ℃下进行长时间的退火处理[11-13],这样导致的结果是微量元素在表面能的驱动下向表面富集,以及在铝箔表面生成致密的氧化膜。图4所示为众和铝箔和电沉积弥散锡晶核铝箔的腐蚀示意图,图4(a)中众和铝箔近表面附近富集了大量的微量元素,这些微量元素的电极电位均高于铝的电极电位,当它们大量富集于铝箔表面时,会作为腐蚀微电池的正极促进铝箔的腐蚀发孔,但是这样得到的铝箔表面微电池的面密度很高,其面密度超过发孔需要的密度,导致铝箔腐蚀发孔时表面产生严重的并孔,不仅如此,表面高密度的微电池还使得铝箔的自腐蚀严重,导致铝箔的减薄量增加,如图4(b)所示。研究表明,不含铅的高纯铝箔在腐蚀中只出现了少量腐蚀大孔,大部分地区没有出现腐蚀的隧道孔[2]。因此,将表面富铅的众和铝箔进行碱洗和酸洗处理,以去除表面致密的氧化膜和富铅层[14-16],得到的高纯高压铝箔是难以发孔的。但是,在铝箔表面电沉积弥散的锡晶核可以有效引导铝箔的腐蚀发孔和减少铝箔的腐蚀减薄,如图4(c)和(d)所示。这是因为表面电沉积弥散的锡晶核与铝基体之间构成了面密度适宜的微电池,铝箔在腐蚀时,这些微电池将成为优先生成隧道孔的活性位置,从而使得铝箔腐蚀发孔均匀;而弥散锡晶核与铝箔之间构成微电池的数量比表面富铅的众和铝箔中微电池的数量大幅度下降,除发孔位置外,铝箔其他位置的微电池很少,使得铝箔表面其他部位自腐蚀降低,从而导致铝箔腐蚀减薄降低。

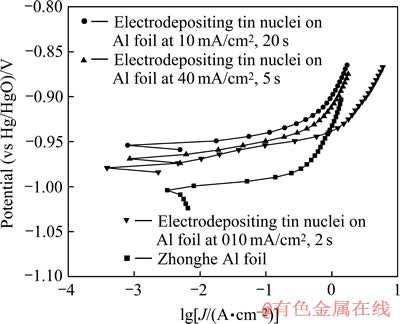

为了证明上述模型的合理性,测试表面富铅的众和铝箔和沉积锡晶核铝箔在腐蚀液中的极化曲线。图5所示为表面富铅的众和铝箔和不同电沉积条件下得到的铝箔在温度为70 ℃ 1mol/L HCl和3.5 mol/L H2SO4混合溶液中的极化曲线。由图5可以看到,所有弥散锡晶核的铝箔的腐蚀电位都高于表面富铅的众和铝箔,腐蚀电流都小于表面富铅的众合铝箔。这种规律可由图4的模型加以解释,即由于沉积锡晶核的铝箔表面微电池的面密度远小于众和铝箔表面微电池的面密度,使得沉积锡晶核的铝箔表面活性远低于表面富铅的众和铝箔,从而导致沉积锡晶核的铝箔表面自腐蚀小于表面富铅的众和铝箔的自腐蚀。换句话 说,由于表面沉积锡晶核的铝箔在腐蚀时隧道孔外表面的钝化能力大于表面富铅的众和铝箔,导致铝箔表面腐蚀速率减少。此外,由图5还可以看到,低电流密度下沉积弥散锡晶核的铝箔比高电流密度下沉积弥散锡晶核的铝箔腐蚀电位稍高,但腐蚀电流却稍大。这是由于在相同的沉积电量下,一方面,低电流密度下沉积弥散锡晶核的铝箔,其表面微电池的面密度要小于高电流密度下沉积得到的面密度,导致低电流密度下沉积弥散锡晶核的铝箔表面活性低;另一方面,较低的沉积电流密度下铝箔表面会得到粗大的锡晶核,如图1(a)所示,这会导致铝箔在此粗大锡晶核区发生严重的自腐蚀减薄,从而产生大的腐蚀电流。由此可以解释低电流密度沉积弥散锡晶核的铝箔腐蚀发孔时,会形成发孔密度很小的区域和腐蚀严重的区域,如图2(b)所示。因此,只有在合适的电沉积条件下铝箔表面沉积得到的锡晶核才可以有效引导铝箔均匀地腐蚀发孔,同时降低并孔和腐蚀减薄。

图4 众和铝箔和电沉积锡晶核铝箔的腐蚀过程

Fig. 4 Etching process of Zhonghe Al foil and Al foil with electrodeposited tin nuclei

图5 电沉积锡晶核对铝箔阳极极化曲线的影响

Fig. 5 Influence of electrodepositing tin nuclei on anodic polarized of Al foils

4 结论

1) 富铅铝箔在高浓度的碱液、酸液中清洗,能够去除表面致密的氧化膜和富铅层,采用电沉积方法可以在铝箔表面沉积出高度弥散的锡晶核。

2) 电沉积弥散的锡晶核不仅能够有效引导铝箔进行腐蚀发孔,提高发孔的均匀性和降低并孔,从而提高铝箔的比电容, 还可以减少铝箔的腐蚀减薄。

3) 表面沉积弥散锡晶核与铝箔构成腐蚀微电池的数量远低于富铅和表面沉积金属层的铝箔,既满足引导发孔的需要,又使得腐蚀隧道孔外的表面活性低于表面富铅和表面沉积金属层的铝箔,从而导致铝箔腐蚀减薄减少。

REFERENCES

[1] 冯哲圣. 高比容铝电极箔制造技术及其机理研究[D]. 成都: 电子科技大学, 2003.

FENG Zhe-sheng. Study on the technology and mechanism of manufacturing aluminum electrolytic capacitor foils with high capacitance[D]. Chengdu: University of Electronic Science and Technology of China, 2003.

[2] 左 宏, 刘春明. 微量Zn对高压电解电容器阳极铝箔比电容的影响[J]. 中国有色金属学报, 2012, 22(11): 3129-3134.

ZUO Hong, LIU Chun-ming. Influence of trace Zn on specific capacitance of high voltage aluminum anode foil used in high voltage electrolytic capacitors[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 3129-3134.

[3] 左 宏, 毛卫民. 微量铅和铬酸盐对高压铝箔腐蚀行为的影响[J]. 材料科学与工程学报, 2005, 23(4): 604-606.

ZUO Hong, MAO Wei-ming. Influence of micro-alloyed Pb and chromate on the corrosion behavior of high voltage anode aluminum foil[J]. J Mater Sci Technol, 2005, 23(4): 604-606.

[4] LIN W, TU G C, LIN C F, PENG Y M. The effects of indium impurity on the DC-etching behavior of aluminum for electrolytic capacitor usage[J]. Corros Sci, 1997, 39(9): 1531-1543.

[5] 张新明, 孟 亚, 周卓平, 周鸿章. Fe杂质对高纯铝箔再结晶织构及比电容的影响[J]. 中国有色金属学报, 1999, 9(1): 19-24.

ZHANG Xin-ming, MENG Ya, ZHOU Zhuo-ping, ZHOU Hong-zhang. Effects of Fe impurity on recrystallization textures and specific capacitances of high pure aluminum foils[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(1): 19-24.

[6] 王向阳, 李文学. Ce 含量对稀土铝箔直流电解腐蚀的影响[J]. 内蒙古科技大学学报, 2007, 26(4): 310-313.

WANG Xiang-yang, LI Wen-xue. Effect of Ce content on DC etching of the rare earth aluminum foil[J]. Journal of Inner Mongolia University of Science and Technology, 2007, 26(4): 310-313.

[7] 杨邦朝, 肖占文. 预处理对铝箔电蚀特性的影响[J]. 电子元件与材料, 1997, 16(3): 1-9.

YANG Bang-chao, XIAO Zhan-wen. Effect of pretreatment for aluminum foil on its electrochemical properties[J]. Electronic Components and Materials, 1997, 16(3): 1-9.

[8] LIN W, TU G C, LIN C F, PENG Y M. The effects of lead impurity on the DC-etching behavior of aluminum for electrolytic capacitor usage[J]. Corros Sci, 1996, 38(6): 889-907.

[9] 毛卫民, 杨 宏, 余永宁, 冯惠平, 许 进. 微量Mg对高压电子铝箔腐蚀结构的影响[J]. 中国有色金属学报, 2003, 13(5): 1057-1059.

MAO Wei-min, YANG Hong, YU Yong-ning, FENG Hui-ping, XU Jin. Influence of trace Mg on corrosion structure of high voltage aluminum foil[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(5): 1057-1059.

[10] ARAR K, SUZUKI T, ATSUMI T. Effect of trace elements on etching of aluminum electrolytic capacitor foil[J]. J Electrochem Soc, 1985, 132(7): 1667-1671.

[11] ASHITAKA Z, THOMPSON G E, SKELDON P, WOOD G C, HABAZAKI H, SHIMIZU K. Influence of thermal and surface treatment on distributions of lead in Al-Pb foils[J]. J Electrochem Soc, 2000, 147(1): 132-139.

[12] 毛卫民, 杨 宏, 杨 平, 冯惠平. 退火对高压电解电容器铝箔微量元素分布和腐蚀性能的影响[J]. 金属热处理, 2004, 29(9): 3-6.

MAO Wei-min, YANG Hong, YANG Ping, FENG Hui-ping. Influence of annealing on distribution of trace-elements and corrosion properties of aluminum foils for high voltage electrolytic capacitor[J]. Heat Treatment of Metals, 2004, 29(9): 3-6.

[13] ASHITAKA Z, THOMPSON G E, SKELDEN P, WOOD G C, SHIMIZU K. The behavior of copper and lead during heat-treatment and surface treatment of aluminum capacitor foils[J]. J Electrochem Soc, 1999, 146(4): 1380-1385.

[14] THIERRY M, KURT R H. Atomic force microscopy study of anodic etching of aluminum[J]. J Electrochem Soc, 2001, 148(2): B101-B109.

[15] LEE J, KIM J, CHUNG H, TAK Y. Effects of pretreatment on the aluminum etch pit formation[J]. Corros Sci, 2009, 51(7): 1501-1505.

[16] 刘建才, 张新明, 陈明安, 唐建国, 刘胜胆. 密度泛函理论预测微量元素在Al(100)表面的偏聚[J]. 物理化学学报, 2009, 25(12): 2519-2523.

LIU Jian-cai, ZHANG Xin-ming, CHEN Ming-an, TANG Jian-guo, LIU Sheng-dan. Prediction of the surface segregation of trace elements on the Al(100) surface by density functional theory[J]. Acta Physico-Chimica Sinica, 2009, 25(12): 2519-2523.

(编辑 李艳红)

基金项目:广西科学研究与技术开发计划项目(桂科合1346011-7)

收稿日期:2013-01-20;修订日期:2013-05-20

通信作者:何业东,教授,博士;电话:010-62332715;E-mail: htgroup@mater.ustb.edu.cn