时效对无铅易切削Al-Cu合金的微观组织结构与性能的影响

黄志其,尹志民,马海龙

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘 要:采用力学性能测试、X射线物相分析、扫描电镜背散射和能谱分析、透射电子显微分析和金相实验方法,研究时效工艺对固溶-冷拉处理的Sn和Bi微合金化的无铅易切削Al-Cu合金棒材显微组织结构特征和力学性能的影响,并采用晶间腐蚀法研究合金的腐蚀性能。研究结果表明:合金最适宜的时效热处理工艺为160 ℃/6 h,在此工艺条件下,合金的抗拉强度、屈服强度和伸长率分别为473 MPa,391 MPa和11.2%。合金的物相组成为Al基固溶体,Al7Cu2Fe,CuAl2以及低熔点物质Bi,SnBi和Sn;合金的晶间腐蚀深度为0.4 mm,其综合性能与含铅2011合金的相当。

关键词:无铅;切削;Al-Cu合金;显微组织;性能;晶间腐蚀

中图分类号:TG174.3 文献标识码:A 文章编号:1672-7207(2007)04-0629-05

Effect of aging treatment on microstructure and properties of lead-free free-cutting Al-Cu alloy

HUANG Zhi-qi, YIN Zhi-min, MA Hai-long

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effect of aging treatment on the microstructure and mechanical properties of solution treated and cold drawn Sn, Bi alloying lead-free free-cutting Al-Cu alloy rod was investigated using mechanical properties test, XRD analysis, SEM back scattered and energy spectrum, TEM observation and OM, and the corrosive property was also studied by Huey test. The results show that the optimal aging technology of alloy is 160 ℃/6 h, and under this condition, the tensile strength, yield strength and elongation of alloy bar can reach 473 MPa, 391 MPa and 11.2%, respectively. The phase compositions of alloy include Al-based solid solution, Al7Cu2Fe, CuAl2 and low melting point phase (Bi, Sn and SnBi). The depth of intercrystalline corrosion is about 0.4 mm, and the overall property is equivalent to lead-containing 2011 alloy.

Key words: lead-free; cutting; Al-Cu alloy; microstructure; properties; intercrystalline corrosion

易切削铝合金有60多年的历史,主要是通过向 2×××和6×××合金中添加低熔点元素Pb和Bi来提高合金的切削性能,Pb和Bi不溶于铝基体,能在合金中形成低熔点组织组成物,在高速切削过程中通过这种低熔点组织组成物的熔化或者软化形成细小切屑,能显著改善合金的切削加工性和提高加工效率,其产品表面光洁度好,精度高,被广泛地应用于各种精密部件[1-3]。传统含Pb的2011是2×××易切削铝合金的基础,它们具有优良的力学性能和切削加工性能。然而,随着人们对环境问题的关注,含Pb易切削铝合金已被禁止使用,研究无铅易切削铝合金势在必行。从20世纪90年代开始,国外著名的铝业公司开展相关研究来寻找可取代传统2011铝合金的无铅Al-Cu合金[4-7],主要是通过向Al-Cu合金中添加Sn和Bi或者单独添加Sn来取代传统合金中的Pb和Bi,其研究结果表明,含Sn和Bi的无铅易切削铝合金完全可以取代传统的2011合金[8-9]。

目前,国内还没有2×××系无铅易切削铝合金的研究报道。为此,本文作者对Sn和Bi微合金化的无铅易切削2×××铝合金不同处理态棒材的显微组织结构与力学性能进行研究,探索时效工艺对固溶-冷拉处理的无铅易切削Al-Cu合金棒材力学性能和显微组织结构特征的影响,以及微量元素在合金中的存在形式和分布特征。

1 实 验

1.1 材料

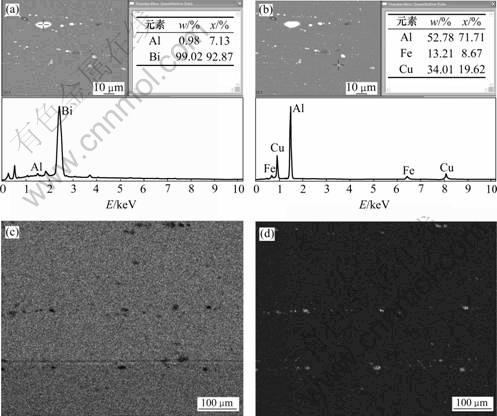

研究合金在线分析成分见表1。

表1 研究合金的成分

Table 1 Chemical composition of alloy

1.2 实验方法

研究用合金熔炼后采用半连续铸造成锭,铸锭在440 ℃锭温条件下热挤压成直径为11.5 mm的棒材,于480℃保温2 h后水冷淬火,用直径为10.5 mm的YG8硬质合金拉模预冷拉伸。为了比较时效工艺对合金组织性能的影响,淬火-冷拉处理的棒材在160,170和180 ℃进行时效,时效时间为0~30 h。

拉伸力学性能实验在CSS-44100型万能电子拉伸机上进行,拉伸速度为2 mm/min;X射线衍射物相分析在日本理学D/Max-2550/PC型X射线衍射仪上进行;晶间腐蚀实验按照文献[10]中的铝合金晶间腐蚀测定方法进行,并在POLYVAR-MET金相显微镜上进行金相组织观察;扫描电镜观察在带能谱的Sirion200场发射扫描电镜和带能谱的KYKY-2800扫描电镜上进行;薄膜样品双喷电解液为30%HNO3+ 70%CH3OH,电解抛光电压为15 V,电流为80~100 mA,温度为-25 ℃,薄膜样品在Tecnai G2 20分析型电子显微镜上进行观察。

2 结果与讨论

2.1 时效工艺对合金拉伸力学性能的影响

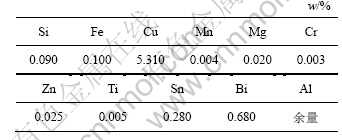

时效工艺对淬火-冷拉处理的合金棒材力学性能的影响如图1所示。

(a) 抗拉强度σb; (b) 屈服强度σ0.2; (c) 伸长率δ5

图1 研究合金的时效特性

Fig.1 Aging characteristics of studied alloy

从图1可知,淬火后冷拉处理的合金在160~ 180 ℃时效,合金的强度先升而后降,而延伸率则开始下降,峰值时效后才稍有回升;时效温度越高,达到强度峰值的时间缩短,强度峰值也随之下降。在160 ℃时效6 h,合金综合拉伸性能较好。在此条件下,合金强度σb和σ0.2分别为473 MPa和391 MPa,伸长率δ5为11.2%。与具有相同Cu含量的传统2011合金相比,性能相当(见表2),而且相同温度下达到峰值的时间缩短。研究结果表明,含Sn和Bi的无铅易切削Al-Cu合金完全可以取代传统的2011合金。

表2 2011和无铅Al-Cu合金的力学性能比较

Table 2 Mechanical properties of Al-Cu alloy with and without Pb

与2011合金[11]相比,本研究合金在170 ℃时效时达到峰值的时间减少约2/3。根据L. Bourgeois 等[12-13]的研究结果,这是因为Al-Cu合金中加入Sn可影响合金的时效过程,影响机制有2种:一种认为人工时效时,淬火后在含Sn的Al-Cu合金中会预先形成Sn沉淀,其粒径很小,约为5 nm,这些粒子会作为θ′相的非均匀形核质点,从而促进θ′相的形核;另一种机制认为Sn原子有很高的空位粘接能,与空位一起形成Sn-空位团,这种Sn-空位团会进行相对移动,当它们与Cu原子相遇时,就会促进形成θ′相,且它们容易在条状θ′相和基体之间聚集,降低2种相之间的界面能量,因而能够促进θ′相的析出,使得合金在相同温度下达到峰值强度的时间缩短。

2.2 X射线衍射物相分析

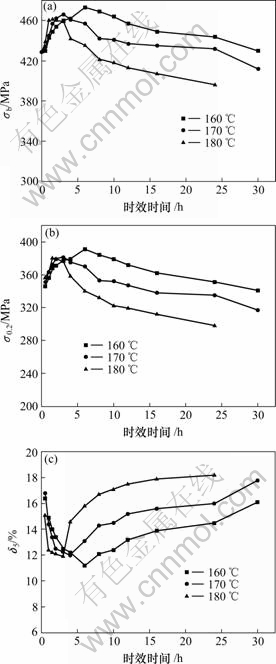

合金T3态和T8态(160 ℃/6 h)的X射线衍射谱如图2所示。

图2 合金不同处理态的X射线衍射谱

Fig.2 XRD patterns of alloy with different treatments

从图2可知,T8态合金的物相组成除铝基体外,还有CuAl2,Al7Cu2Fe, SnBi化合物以及Bi和Sn的单质。其中,CuAl2是合金的主要强化相,而SnBi,Bi和Sn是合金元素Sn和Bi所形成的低熔点组织组成物。与T3态相比,合金T8态中的CuAl2量明显增多。

无铅Al-Cu合金的易切削性是通过向合金中加入Sn和Bi来实现的,Sn和Bi在合金中会形成Sn,Bi

和SnBi组织组成物。合金在高速切削过程中机械能转变成热能,使得工件的温度升高,当工件温度接近或者超过低熔点组织组成物的熔点时,低熔点粒子发生软化和融化,切削产物会变得不连续,切屑容易断裂,这是合金具有良好的切削加工性能的主要原因。

2.3 扫描电子显微分析

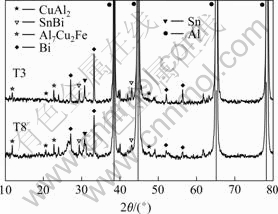

合金峰时效态(160 ℃/6 h)背散射电子图像及元素点分析、面分布如图3所示。图中,w为质量分数,x为原子数分数。

(a) 含Bi的点(带“+”的点)的合金的背散射电子象和能谱分析; (b) 含Al,Fe和Cu的点(带“+”的点)的合金的

背散射电子象和能谱分析;(c) Al元素的面分布;(d) Bi元素的面分布

图3 合金的扫描电子显微分析

Fig.3 SEM analyses of alloy

如图3(a)和(b)所示,合金基体中存在2种微米级的第二相粒子,较大的第二相粒子粒径约为10 μm,能谱分析表明为Bi单质相,较小粒子粒径约为1 μm,其主要成分为Al,Cu和Fe,按其原子个数比来看应该为X射线衍射物相分析中所对应的Al7Cu2Fe;图3(d)所示的元素面分布表明,Bi元素所形成的物质主要沿着合金的轧制方向排列(白色质点部分),与图3(c)形成对应关系。

2.4 合金TEM显微组织

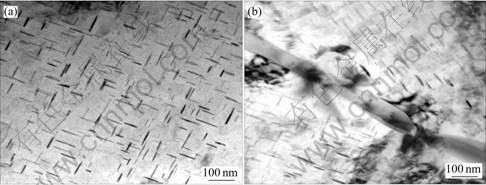

合金T8态的TEM观察结果如图4所示。

(a) T8态(晶内);(b) T8态(晶界附近)

图4 合金时效态的TEM显微组织

Fig.4 TEM images of alloy with aging treatment

从图4(a)可知,合金时效后大量弥散细小的片状粒子沿合金基体的不同位向析出,如图4(c)和(d)所示。弥散析出相应为图2中峰值时效态合金X射线物相分析中确定的CuAl2相,与相同条件下的2011合金[11]相比,其粒径更加细小,分布也更加弥散。这是因为合金中Sn的加入能够阻碍CuAl2相的长大[12-13],从而使得析出相更加细小和弥散。

2.5 合金的晶间腐蚀结果

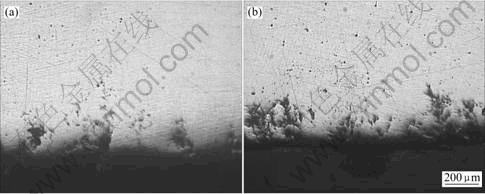

含铅易切削2011合金和含Sn和Bi的无铅易切削Al-Cu合金的晶间腐蚀结果如图5所示。

(a) 2011合金; (b) 无铅Al-Cu合金

图5 2011合金与无铅Al-Cu合金的晶间腐蚀结果

Fig.5 Intercrystalline corrosion results of alloys

由图5可见,在相同腐蚀条件下,2种合金都存在轻微的晶间腐蚀,2011合金的晶间腐蚀最深处深度约为0.59 mm,无铅Al-Cu合金的晶间腐蚀深度最深处为0.40 mm,与2011合金的相当。Al-Cu系合金在时效硬化处理时,在晶间会沉淀出平衡的CuAl2,在晶粒边界形成贫铜区,而贫铜区的电位最负,于是,腐蚀沿着晶界贫铜区进行,产生晶间腐蚀[14]。在本研究中,无铅易切削Al-Cu合金是通过向合金中加入Sn来代替2011合金中的Pb,Sn与Pb的标准电极电位(标准甘汞电极)分别为-0.49和-0.55 V,两者相当,因此,从微观上讲,以Sn来取代Pb并不会降低合金的耐蚀性能。图5所示结果也可证明这一点。

3 结 论

a. Sn和Bi微合金化的无铅易切削Al-Cu合金固溶-冷拉后的最佳时效热处理工艺为160 ℃/6 h,在此工艺条件下,合金棒材的抗拉强度为473 MPa,屈服强度为391 MPa,伸长率为11.2%,力学性能与2011合金的相当。

b. Sn和Bi微合金化的无铅易切削Al-Cu合金固溶-冷拉-时效处理态的物相组成有铝基固溶体和铝基固溶体基体上弥散分布的析出相CuAl2,Al7Cu2Fe,Cu10Sn3和低熔点组织组成物Bi,Sn和SnBi。

c. Sn和Bi微合金化的无铅易切削Al-Cu合金固溶-冷拉-时效处理态合金的耐腐蚀性能与相同处理条件下的2011合金的耐腐蚀性能相当。

参考文献:

[1] Leskovar N, Polde P. Machinability of aluminum alloys for free cutting and importance of machinability research[J]. Strojniski Vestink, 1978, 24(1): 1-7.

[2] Louis A. Unleaded aluminum alloys gives A-Rated machinability[J]. Advanced Material and Process, 2004, 162(11): 11-12

[3] Charlie S. UltrAlloy? 6020: A lead free aluminum alloy featuring “A” rated machinability[J]. SAE Special Publication, 1998, 1350: 23-26.

[4] Leon C, Noah L, Jackson F. Aluminum-copper alloy: US 5916385[P]. 1999-06-29.

[5] Correggio B, Walter C, Julius T. 2××× series aluminum alloy: US 6113850[P]. 2000-09-05.

[6] Smolej L, Anton D, Dragojevic K. Process for the manufacture of a free-cutting aluminum alloy: US 6423163[P]. 2002-07-23.

[7] Smolej L, Anton D, Dragojevic K. Free-cutting aluminum alloy, process for the production thereof and use thereof: US 6248188[P]. 2001-06-19.

[8] Correggio B, Lin J S. Effect of Sn additions on GP zone formation in Al-Cu alloys[J]. Scripta Metallurgica et Materialia, 1993, 28(10): 1283-1286.

[9] James F, Stulikova I, Hajek M. Aluminum alloys on the basis of Al-Cu-Mg lead-free intended for cutting[J]. Material science Forum, 2002, 396-402(3): 1641-1646.

[10] GB7998—87, 铝合金晶间腐蚀测定方法[S].

GB7998—87, Testing method of the intercrystalline corrosion of aluminum alloy[S].

[11] 黄志其, 尹志民, 冯泽锡. 2011易切削铝合金的微观组织结构与性能[J]. 铝加工, 2006, 167(2): 15-18.

HUANG Zhi-qi, YIN Zhi-min, FENG Ze-xi. Microstructure and property of free cutting 2011 alloy[J]. Aluminum Fabrication, 2006, 167(2): 15-18.

[12] Bourgeois L, Nie J F, Muddle B C.  Assisted nucleation of θ prime phase in Al-Cu-Sn: The modified crystallography of tin precipitates[J]. Philosophical Magazine, 2005, 85(29): 3487-3509.

Assisted nucleation of θ prime phase in Al-Cu-Sn: The modified crystallography of tin precipitates[J]. Philosophical Magazine, 2005, 85(29): 3487-3509.

[13] Silcock J M, Flower H M. Comment on a comparison of early and recent work on the effect of trace additions of Cd, In, or Sn on nucleation and growth of θ′ in Al-Cu alloys[J]. Scripta Materialia, 2002, 46: 389-394.

[14] 李金桂, 赵闺彦. 腐蚀和腐蚀控制手册[M]. 北京: 国防工业出版社, 1988: 11.

LI Jin-gui, ZHAO Gui-yan. Corrosion and corrosion control volume[M]. Beijing: Defense Industrial Press, 1988: 11.

收稿日期:2006-10-17

基金项目:中国铝业新材料研制项目(20060098001); 教育部有色金属材料科学与工程重点实验室基金资助项目(2006年)

作者简介:黄志其(1983-),男,湖南湘乡人,硕士,从事易切削铝合金研究

通讯作者:尹志民,男,教授;电话:0731-8830262;E-mail: yin-grp@mail.csu.edu.cn