DOI: 10.11817/j.ysxb.1004.0609.2021-36595

超声和压力耦合场对Al-Cu合金的作用机理及显微组织影响

林 波1,林驰皓1, 3,范 滔1,张 杨2,张卫文2

(1. 贵州大学 机械工程学院,贵阳 550025;

2. 华南理工大学 机械与汽车工程学院,广州 510640

3. 广东省科学院 材料与加工研究所,广州 510640)

摘 要:采用数值模拟和实验验证相结合的方法,研究了超声压力耦合场对Al-Cu合金协同作用机理及对显微组织的影响。结果表明:相比单一超声场,超声压力耦合场会使得空化效应的强度和区域增大,还可以改变熔体内部压力分布从而导致熔体内部形成更强烈的对流。通过熔体内部温度测试和宏观、微观组织定量分析的方法,对数值模拟结果进行实验验证。超声-压力耦合作用更容易促使熔体内部出现均匀的温度场,同时消除单一超声作用导致的铸锭内部晶粒细化的差异性,使微观组织分布得更均匀。

关键词:超声振动;压力场;耦合场;数值模拟;铝铜合金

文章编号:1004-0609(2021)-07-1818-09 中图分类号:TG249 文献标志码:A

引文格式:林 波, 林驰皓, 范 滔, 等. 超声和压力耦合场对Al-Cu合金的作用机理及显微组织影响[J]. 中国有色金属学报, 2021, 31(7): 1818-1826. DOI: 10.11817/j.ysxb.1004.0609.2021-36595

LIN Bo, LIN Chi-hao, FAN Tao, et al. Effect of ultrasound vibration and pressure coupling field on function mechanism and microstructure of Al-Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(7): 1818-1826. DOI: 10.11817/j.ysxb.1004.0609.2021-36595

铝合金由于具有密度低、比强度高、耐腐蚀强、塑形和加工性能良好等一系列优点,广泛应用于航空航天、轨道交通、机械制造、石油化工等领域[1-2]。目前,我国高性能铝合金产品较短缺,对外进口依赖程度比较大[3-4],因此,获得高性能、高品质的铝合金铸锭尤其重要[5-6]。传统铸造工艺不可避免会出现偏析、夹渣、裂纹、缩松等缺陷,采用先进的成形工艺是制备高性能铝合金的关键。近来,在铝熔体凝固过程中通过施加外场作用,可以大幅改善铸件微观组织,提升铝合金的力学性能,如功率超声铸造[7]、脉冲电流铸造[8]、挤压铸造[9]等铸造工艺。严青松等[7]研究ZL205A合金在脉冲超声场下微观组织性能。结果表明:未施加超声场,合金组织呈现等轴晶状,尺寸253.56 μm,施加脉冲超声场之后,晶粒形核率提升,当超声功率为1200 W时,组织最细小圆整,晶粒尺寸为182.43 μm。何树先等[8]研究了高密度电脉冲对A356铝合金凝固组织的影响。在定量分析脉冲电流产生的电磁力对凝固组织的作用后发现:A356铝合金凝固组织施加电脉冲可干扰金属原子正常迁移,破坏固相树枝晶使其进一步成长为非枝晶或等轴晶组织。同时,脉冲电流施加越早,组织细化越明显。本课题组[9]研究了Al-5.0Cu合金在挤压压力为0到75 MPa下力学性能和显微组织的影响,发现随着挤压压力的增大,α(Al)二次枝晶间距尺寸减小,孔洞和缩松减少,抗拉强度和伸长率显著升高。当前,众多学者已针对单一外场在金属熔体凝固过程中的作用机制做了大量的数值模拟和实验验证研究工作。外场在熔体中形成的特殊效应(空化效应、机械冲击、辐射压力)是影响组织形貌的主要原因,上述效应会导致熔体凝固过程中枝晶熔断,晶粒细化[10-17]。然而,单一外场的工艺效率有限且工艺上存在缺陷,如功率超声传递过程中存在衰减现象[18],挤压铸造过程会加剧合金偏析[19]。因此,本文作者提出一种挤压铸造过程中耦合高能超声的技术,旨在开发一种力学性能较高的铝合金。通过流体力学分析软件Fluent[20],对超声-压力耦合作用Al-Cu熔体内部的空化效应和声流速度进行数值模拟,分析超声-压力耦合作用对熔体内部的空化气泡体积分数、压力以及声流速度等参数的影响,并进行试验实验验证,为多场耦合技术制备高性能铝合金提供理论指导和技术支撑。

1 数值模拟建立与求解

液态金属中的超声振动与空化效应和气泡动力学密切相关。本节利用Navier-Stokes[21]数值求解方法研究了超声压力耦合场下气泡空化从开始至溃灭的过程,同时对反应场内速度和压力进行求解。

根据合金铸造凝固过程的实际情况,为了便于建立数学模型,基本假设如下:

1) 将Al-Cu合金熔体视为绝热、均匀、不可压缩的非牛顿流体,忽略温度变化和流量波动的影响;

2) 浇注稳定后,视熔体流动为稳态的湍流运动;

3) 空化泡的形成在模型中对应为蒸发过程,溃灭对应凝结过程;

4) 流体中只存在液相和蒸汽相,允许少量不可凝结气体存在。

1.1 计算模型与边界条件

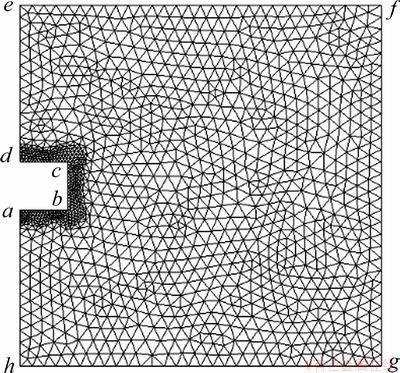

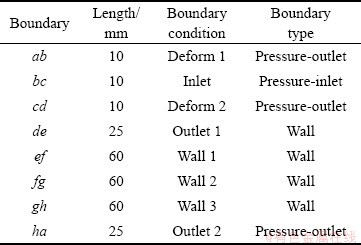

利用Gambit预处理软件生成二维计算网格并施加边界条件[22]。由于模型的尺寸较大,为了提高计算效率、节省计算时间,采用疏密结合方法划分网格。整个耦合计算区域内的网格划分采用三角形网格,变幅杆附近网格尺寸为0.05 mm,其余部分尺寸为1.0 mm,超声和压力耦合作用的有限元模型如图1所示。超声辐射杆直径为6 mm,插入深度为10 mm。表1显示了每条边的长度、名称和类型。

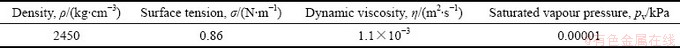

由于数值计算的对象为特定温度下铝合金熔体内部的空化效应,所需要的建模参数应为所需材料在700 ℃左右的热物性参数,如表2所示。

1.2 初始条件与模拟控制方程

1.2.1 初始条件

依据实验条件,铸锭的浇注温度设定为711 ℃。变幅杆的施振功率为1 kW,变幅杆振幅A=10 μm,此时,压力加载界面的上方施加75 MPa静压,在压力入口处施加超声压力,此时表达式为p= pA·sin(2πft) (其中p为超声发射器装载压力;声压幅值pA=2~10 MPa;超声频率f=20 kHz),用于模拟的超声波速度为3660 m/s,超声波波长为183 mm,超声波呈辐射状传播出去,最大声压在辐射杆端面处。数值求解采用时域计算方法,步长为1×10-4 s,总求解时间为120 s。

图1 超声-压力耦合计算的网格划分及边界定义

Fig. 1 Finite element mesh generation and boundaries definition under combined power ultrasonic and applied pressure

表1 计算模型与边界定义

Table 1 Calculation model and boundary setting

表2 Al-5.0Cu合金700 ℃下热物性参数

Table 2 Thermal properties parameters of Al-5.0Cu alloy at 700 ℃

1.2.2 模拟控制方程

由声压波动方程得出声压满足Helmholtz方程:

(1)

(1)

式中:p为声压(Pa);ω为角频率(rad/s);v为声速(m/s);ρ为液体及不可压缩气体混合物密度(kg/m3)。

采用有限体积法求解基于压力的两相Navier-Stokes控制方程:

(2)

(2)

(3)

(3)

(4)

(4)

传热方程:

(5)

(5)

由Rayleigh-Plesset[23]方程计算最终得到空化模型:

(6)

(6)

当pv>pm时,气泡瞬时半径R:

(7)

(7)

式中:w为空化气泡质量分数(%);ui为i方向上的速度;t为时间(s);g为重力加速度:Re为空化气泡的生成率;Rc为压缩比;μ为流体黏度(1.12×10-3 Pa·s); 为湍动黏度;b取3/4;n取1013;R、R0为气泡瞬时半径及初始半径(μm);p0为气泡的初始压力(1.013×105 Pa);pv为空化气泡内压;T为温度;K为导热系数;pm为声压振幅;ρv、ρg为可压与不可压气体密度;其中DELGOSHA等[24]修正了湍流黏度公式,关系式如下:

为湍动黏度;b取3/4;n取1013;R、R0为气泡瞬时半径及初始半径(μm);p0为气泡的初始压力(1.013×105 Pa);pv为空化气泡内压;T为温度;K为导热系数;pm为声压振幅;ρv、ρg为可压与不可压气体密度;其中DELGOSHA等[24]修正了湍流黏度公式,关系式如下:

(8)

(8)

式中: 为气体体积分数,空化气泡的初始体积分数为0.1;

为气体体积分数,空化气泡的初始体积分数为0.1; 可由单相流求出,令x=10。利用

可由单相流求出,令x=10。利用 模型求解方程(8)就可以模拟模具内湍流强度,同时可得到气体体积分数的运动方程:

模型求解方程(8)就可以模拟模具内湍流强度,同时可得到气体体积分数的运动方程:

(9)

(9)

超声振动对熔体的影响可以用Navier-Stokes动量方程的源项来描述。利用体积力Fu 来计算超声压力pu:

(10)

(10)

平面i方向上的超声压力由下式得到:

(11)

(11)

式中:A表示超声振动振幅;L为多变系数。

2 实验

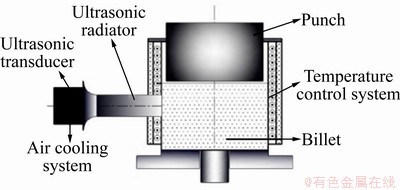

超声-压力耦合实验装置由熔炼系统、超声振动系统、立式四柱液压机以及温度和压力采集系统组成。铝合金熔炼在SG-7.5-12型井式电阻炉中进行。液压机最大挤压力为100 T,液压机冲头接触熔体后保压30 s。模具所用材料为H13钢,在模具型腔凹模以及凸模刷一层石墨机油,以方便脱模;同时在超声工具杆表面刷一层氧化锌涂料,保护工具杆表面不被高温熔液腐蚀。图2为实验装置图:首先在预热坩埚中熔化Al-Cu合金,并将预热的变幅杆水平插入模具。最终得到铸锭的尺寸为d 60 mm×70 mm。为了验证耦合场对合金熔体不同位置温度的影响,采用keller测温系统以及K型热电偶对铸锭不同位置A、B、C进行实时温度测量。

图2 超声和压力场耦合装置

Fig. 2 Combined ultrasonic vibration and applied pressure apparatus

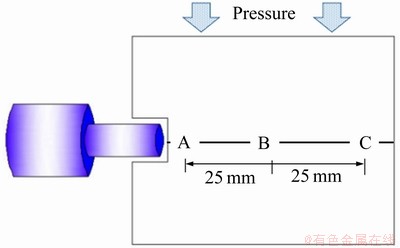

试样在线切机切割成d 12 mm×10 mm的样品,在如图3所示的铸锭不同位置A、B、C,取金相试样,经抛光后用0.5%HF(体积分数)水溶液腐蚀30 s。使用LEICA/DMI 5000M金相显微镜进行微观组织观察和定量分析。

图3 铸锭金相取样示意图

Fig. 3 Positions of samples taken from cross section of ingots

3 结果与讨论

3.1 数值模拟

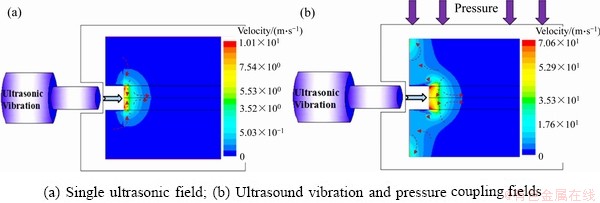

图4(a)所示为单一功率超声下熔体流速分布。

图4(b)所示为复合场的流速分布。结果表明,在复合场和超声场作用下,变幅杆附近声速最大,分别为7.06 m/s和1.01 m/s。根据蒋日鹏等[25-26]研究结果,发现在超声功率1 kW、超声振动频率20 kHz、不同振幅条件下数值模拟结果表明超声场下的流速为0.7914~1.328 m/s,与本文研究结果一致。

从空化效应的角度来讲—气泡在空化效应作用下的闭合时间为[27]:

(12)

(12)

式中:r0为气泡初始半径;ρ0为熔体密度;p0为熔体所受静压力;pm为熔体内部压力。在挤压力作用下,p0的数值增大,时间t数值减小,说明超声-挤压耦合作用可大大增加一个超声振动周期内完成气泡闭合的次数,从而更容易进入稳态空化阶段。从声流效应角度来讲,在金属熔体中施加超声振动,只在变幅杆端面附近区域能引起强烈搅动,其余范围的熔体由于超声传递的衰减受到的影响较小。在耦合场作用下,熔体内部发生流动的区域会增大。同时,由于挤压力的施加方向和功率超声的振动方向呈90°,因此,熔体内部的流动情况会更为复杂,使得耦合作用下熔体内部形成熔体流动的区域面积更大[28]。超声和超声-压力耦合作用均可在熔体内部形成稳定的空化区域以及熔体对流,但耦合作用下形成的区域更广,所对应的空化效应和声流效应强度也更高,因此更有利于改善合金的凝固组织。

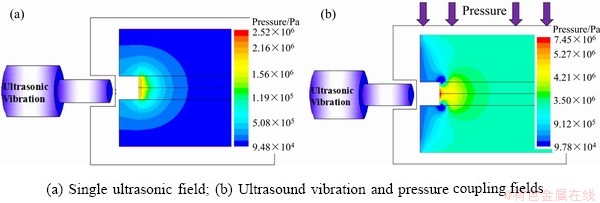

图5所示为单一超声场和超声压力耦合场下铝熔体内部压力分布图。在两种情况下,最高压力场均发生在杆尖附近,但单一超声场的值小于超声压力耦合场。根据图5,熔体在功率超声场和耦合场产生的最大应力分别约为2.52 MPa和7.45 MPa。这表明耦合场存在更大的波动压力场,导致模具内的空化活动更加激烈。

图4 熔体内部流速分布图

Fig. 4 Distribution of inner velocity in aluminum melts

图5 熔体内部压力分布图

Fig. 5 Distribution of inner pressure in aluminum melts

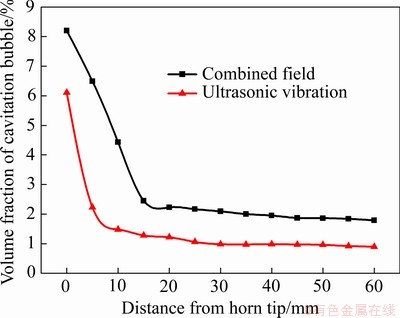

图6所示为不同条件下铝铜合金熔体中不同位置空化气泡的体积分数。从图6可以看出,在超声场和耦合场作用下,空化气泡随着距变幅杆距离的增加而减少。在同一位置,耦合场中空化气泡体积分数高于单一场。这表明耦合组合会导致更多空化气泡的存在,从而产生更大的声能。从图6中可以看出,在复合场中,变幅杆端面周围和距变幅杆60 mm处的空化气泡的体积分数分别为8.355%和2.012%。而对于单一超声场,体积分数分别为6.125%和0.95%。结果表明,在耦合场中,空化气泡更容易形成并转移到模具壁面,从而扩大耦合场在铸锭中的作用区域。

图6 熔体内部距变幅杆端面不同长度时的空化气泡体积分数

Fig. 6 Volume fraction of cavitation bubbles under different distance away from transducer in aluminum melts

3.2 实验验证

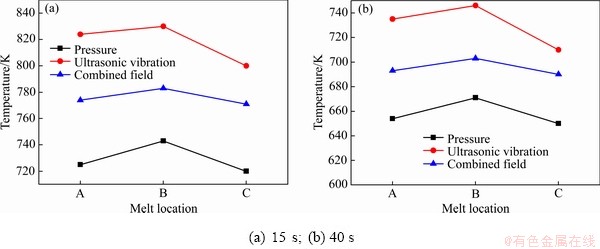

图7所示为不同作用时间后熔体内部不同位置的温度。由图7可以看出,经过不同时间超声振动,熔体内部温度场分布不均匀(TB>TA>TC),即靠近超声杆处(A)、熔体中心处(B)和远离超声杆处(C)均存在温度差。这是因为超声的空化效应引起靠近A处出现“过热现象”,这也会导致凝固时间的延 后[29]。在不同时间的挤压力和耦合场作用下,熔体温度分布相对均匀(TB>TA≈TC),其中耦合场下熔体内部不同位置温度的变化梯度更小。这是因为挤压力均匀作用于熔体上,但靠近模具内壁的熔体由于和模具的热交换,导致熔体中心和边缘的温度差较大。在耦合功率超声的情况下,由于耦合作用引起更加强烈的熔体流动,导致铸锭内部各位置之间的热交换增强,最终体现为更均匀的温度分布。因此,超声-压力耦合作用更容易促进熔体内部出现均匀的温度场分布,从而可以提高合金过冷度,增加相变驱动力。同时,耦合作用下形成的大量晶核趋于同时凝固,导致凝固加快并且合金结晶间距变小,抑制柱状晶的生成。

图7 不同作用时间后合金熔体内部不同位置的温度

Fig. 7 Temperature of different locations in Al-5.0Cu melt with different treating time and different conditions

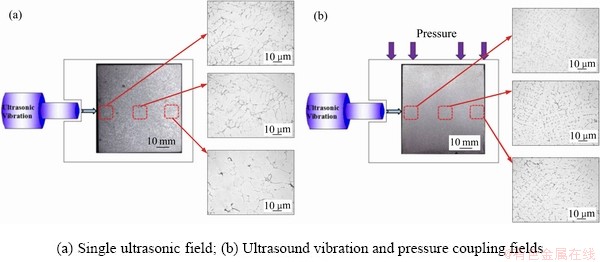

图8 铸锭不同部位的宏观组织和显微组织

Fig. 8 Macrostructures and microstructures of Al-5.0Cu under different positions and conditions

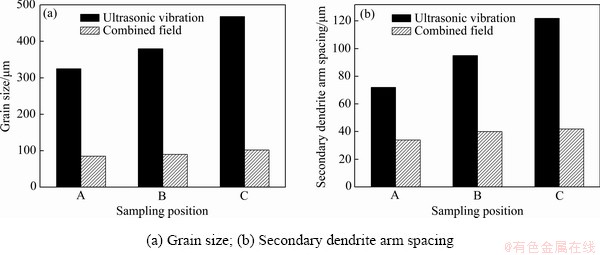

图9 组织定量分析

Fig. 9 Quantitative analysis of microstructure

图8所示为超声和超声-压力耦合作用下铸锭不同位置的微观组织,对图中各工艺条件下的合金的晶粒尺寸和二次枝晶间距(SDAS)尺寸进行了定量计算,得到结果如图9所示。从图8和9可以看出,超声-压力耦合作用导致整个铸锭范围内晶粒尺寸进一步减小;在单一超声作用下,靠近变幅杆(A)、熔体中心(B)以及远离变幅杆(C)处,平均晶粒尺寸存在一定的差异。在距变幅杆端面较远的宏观组织区域,其平均晶粒尺寸在400~450 μm之间,SDAS约为100~120 μm之间。而在靠近变幅杆端面附近区域,平均晶粒尺寸约为300 μm,SDAS约为70 μm。这也反映了超声在熔体内部传播的衰减。而超声-压力耦合作用导致整个铸锭范围内晶粒和SDAS尺寸进一步减小。铸锭不同部位(A、B和C)的平均晶粒尺寸相差不大,约为80 μm,SDAS约为40 μm。这是由于耦合作用增强了熔体内部对流,从而使得树枝晶的枝晶臂根部发生断裂,最终细化了整个铸锭组织。

对超声压力耦合场和功率超声作用下空化气泡的速度场、压力场和体积分数进行了数值模拟,并与实验结果进行比较。结果表明,在复合场中,熔体中的空化气泡较多,流速较高,压力场波动较大。对液态金属中超声处理的应用进行了大量的研究,结果表明,熔体中的空化、声流、压力波动有助于细化组织。在复合场作用下,模具内形成的固态晶粒通过声流被分离并带到模具内任意位置,提供了大量的成核点。超声空化效应会对异质颗粒表面进行清洗和浸润,从而增强异质成核。实验结果表明,超声和压力耦合场处理可以细化整个结晶组织。相反,超声功率只在变幅杆端面附近发生微结构演化。

4 结论

1) 通过二次开发子程序以及添加源项的方式分别在空化模型中导入挤压力和超声声流,模拟耦合作用下Al-5.0Cu合金熔体内部的空化气泡体积分数、空化区域大小和强度以及熔体内部压力、流体速度等。研究发现,耦合场会使得空化效应的强度和区域增大,还可以改变熔体内部压力分布从而导致熔体内部形成更强烈的对流,即超声-压力耦合作用可以增强熔体内部的空化效应和声流效应,这会导致熔体内部出现更大过冷度,降低形核功,增加相变驱动力,促进更多的晶核产生和晶核游离,最终形成细小均匀的凝固组织。

2) 通过对熔体内部温度分布以及宏、微观组织进行定量分析,验证了数值模拟的预测。实验发现:超声-压力耦合作用更容易促进熔体内部出现均匀的温度场分布,从而提高合金过冷度,增加相变驱动力;同时,耦合作用下形成的大量晶核趋于同时凝固,导致凝固加快并且合金结晶间距变小;超声-压力耦合作用可以基本消除单一超声作用导致的铸锭内部晶粒细化的差异性,提高微观组织被改善的均匀程度。

REFERENCES

[1] 刘 兵, 彭超群, 王日初, 等. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(9): 1705-1715.

LIU Bing, PENG Chao-qun, WANG Ri-chu, et al. Recent development and prospects for giant plane aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1705-1715.

[2] WIILLIAMS J C, EDGAR A, SRAKE J R. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51(19): 5775-5799.

[3] 马世光. 中国铝加工产业现状及发展[J]. 轻合金加工技术, 2013, 41(7): 1-4.

MA Shi-guang. Current situation and development of China aluminium fabrication industry[J]. Light Alloy Fabrication Technology, 2013, 41(7): 1-4.

[4] NAKAI M. New aspects of development of high strength aluminum alloys for aerospace applications[J]. Materials Science and Engineering A, 2000, 285(1): 62-68.

[5] YANG Wei-wei, GUO Zhi-meng, CAO Hui-qin, et al. Fabrication and mechanical properties of high-performance aluminum alloy[J]. Rare Metals, 2014, 33(4): 400-403.

[6] HEINZ A, HASZLER A, KEIDEL C, et al. Recent development in aluminum alloys for aerospace applications[J]. Materials Science and Engineering A, 2000, 280(1): 1-10.

[7] 严青松, 芦 刚, 王 清, 等. 脉冲超声工艺对ZL205A合金微观组织及偏析的影响[J]. 中国有色金属学报, 2019, 29(2): 279-285.

YAN Qing-song, LU Gang, WANG Qing, et al. Effect of pulsed ultrasonic process on microstructure and microsegregation of ZL205A alloy[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(2): 279-285.

[8] 何树先, 王 俊, 孙宝德, 等. 高密度脉冲电流对A356铝合金凝固组织的影响[J]. 中国有色金属学报, 2002, 12(3): 426-429.

HE Shu-xian, WANG Jun, SUN Bao-de, et al. Effect of high density pulse current on solidification structure of A356 alloy[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 426-429.

[9] 林 波, 张卫文, 程 佩, 等. 挤压铸造Al-5.0Cu-0.6Mn- 0.5Fe合金的显微组织和力学性能[J]. 中国有色金属学报, 2013, 23(5): 1195-1201.

LIN Bo, ZHANG Wei-wen, CHENG Pei, et al. Microstructure and mechanical properties of Al-5.0Cu- 0.6Mn-0.5Fe alloy prepared by squeeze casting[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1195-1201.

[10] LEE Y K, YOUNJ I, HWANG J H, et al. Modeling of the effect of ultrasonic amplitude and frequency on acoustic streaming[J]. Japanese Journal of Applied Physics, 2019, 58(SG): 1-7.

[11] 费卓铭, 林 冲, 李 浩, 等. 超声及电磁场对铝合金熔体影响的数值模拟及试验研究[J]. 特种铸造及有色合金, 2020, 40(4): 435-440.

FEI Zhuo-ming, LIN Chong, LI Hao, et al. Numerical simulation and experimental verification on effect of ultrasonic and electromagnetic field on aluminum alloy melt[J]. Special Casting and Nonferrous Alloys, 2020, 40(4): 435-440.

[12] 程建玲, 郭汉东. 电磁搅拌作用下铝合金凝固组织的数值模拟[J]. 特种铸造及有色合金, 2017, 37(7): 763-765.

CHENG Jian-lin, GUO Han-dong. Numerical simulation of solidification microstructure in aluminum alloy under electromagnetic stirring[J]. Special Casting and Nonferrous Alloys, 2017, 37(7): 763-765.

[13] 杨日福, 洪旭烨. 流体控制方程的超声空化泡动力学模 拟[J]. 应用声学, 2018, 37(4): 455-461.

YANG Ri-fu, HONG Xu-ye. Dynamic simulation of ultrasonic cavitation bubble based on governing equation of fluid[J]. Applied Acoustics, 2018, 37(4): 455-461.

[14] LOUISNARD O. A viable method to predict acoustic streaming in presence of cavitation[J]. Ultrasonics Sonochemistry, 2017, 35: 518-524.

[15] 王宝剑, 翟 薇, 魏炳波. 超声场中亚共晶Al-5%Si合金的动态凝固及其力学性能[J]. 中国有色金属学报, 2019, 29(1): 1-10.

WANG Bao-jianZHAI Wei,WEI Bing-bo. Dynamic solidification and mechanical properties of hypoeutectic Al-5%Si alloy within ultrasonic field[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(1): 1-10.

[16] 李 捷, 张忠涛, 石 婷, 等. 复合场对A356合金凝固行为的影响[J]. 铸造, 2009, 58(7): 681-683.

LI Jie, ZHANG Zhong-tao, SHI Ting,et al. Effect of compound field on solidification behavior of A356 alloy[J]. China Foundry, 2009, 58(7): 681-683.

[17] 张 鹏, 杜云慧, 曾大本. 电磁-机械复合场对合金凝固组织影响的研究[J]. 物理学报, 2002, 52(3): 696-699.

ZHANG Peng, DUN Yun-hui, ZENG Da-ben. Effect of electromagnetic-mechanical field on solidified structure of alloys[J]. Acta Physica Sinica, 2002, 52(3): 696-699.

[18] 刘 玮. 圆锥过渡形变幅杆设计及超声粉碎实验研究[D]. 太原: 太原理工大学, 2016.

LIU Wei. Design of tapered transition step and experimental study on ultrasonic grinding[D]. Taiyuan: Taiyuan University of Technology, 2016.

[19] WANG S Z, JI Z S, SUGIYAMA S, et al. Segregation behavior of ADC12 alloy differential support formed by near-liquidus squeeze casting[J]. Materials & Design, 2015, 65: 591-599.

[20] 李 林. 超声场下空化气泡运动的数值模拟和超声强化传质研究[D]. 成都: 四川大学, 2006.

LI Lin. Numercial simulation on the motion equation of cavitation bubble and the enhancement of mass transfer due to ultrasonic[D]. Chengdu: Sichuan University, 2006.

[21] HU An-jie, YANG Xiang-jie, GUO Hong-ming. Phase field lattice Boltzmann model for non-dendritic structure formation in aluminum alloy from LSPSF machine[J]. Transactions of Nonferrous Metals Society of China, 2020, 30(3): 559-570.

[22] SHAO Zhi-wen, LE Qi-chi, ZHANG Zhi-qiang, et al. Numerical simulation of acoustic field for ultrasonic grain refinement of AZ80 magnesium alloy[J]. Transaction of Nonferrous Metals Society of China, 2011, 21(11): 2476-2483.

[23] NASTAC L. Mathematical modeling of the solidification structure evolution in the presence of ultrasonic stirring[J]. Metallurgical &Materials Transactions B, 2011, 42(6): 1297-1305.

[24] DELGOSHA C, FORTES-PATELLA R, REBOUND J L. Simulation of unsteady cavitation with a two-equation turbulence model including compressibility effects[J]. Journal of Turbulence, 2002, 3(1): 58-65.

[25] 蒋日鹏, 李晓谦, 鞠增业, 等. 铝合金超声波半连铸多场耦合的模拟与实验[J]. 华南理工大学学报(自然科学版), 2014, 42(4): 85-90.

JIANG Ri-peng, LI Xiao-qian, JU Zeng-ye, et al. Simulation and experimental investigation of multi-field coupling for semi-continuous casting of aluminum alloy with ultrasonic treatment[J]. Journal of South China University of Technology (Natural Science Edition), 2014, 42(4): 85-90.

[26] 蒋日鹏. 超声场对高强铝合金凝固过程的影响规律与作用机理研究[D]. 长沙: 中南大学, 2014.

JIANG Ri-peng. Effect rules and function mechanism of ultrasonic field on the solidification of high strength aluminum alloy[D]. Changsha: Central South University, 2014.

[27] CURIEL L, HOBSON D, CHAPELON J Y, et al. High intensity focused ultrasound optimal device design for targeted prostate cancer treatment: a numerical study[J]. Journal of Modern Physics, 2013, 4(2): 240-245

[28] 李 成. 超声功率-凝固压力协同作用对真空差压铸造铝合金微观组织的影响[D]. 南昌: 南昌航空大学, 2015.

LI Cheng. Effect of synergy between ultrasound power and solidification pressure on the microstructure of Vacuum counter-pressure casting aluminum alloy[D]. Nanchang: Nanchang Hangkong University, 2015.

[29] ZHANG XL, LI T J, TE H T, et al. Semisolid processing AZ91 magnesium alloy by electromagnetic stirring after near-liquidus isothermal heat treatment[J]. Materials Science and Engineering A, 2008, 475(1/2): 194-201.

Effect of ultrasound vibration and pressure coupling field on function mechanism and microstructure of Al-Cu alloy

LIN Bo1, LIN Chi-hao1, 3, FAN Tao1, ZHANG Yang2, ZHANG Wei-wen2

(1. School of Mechanical Engineering, Guizhou University, Guiyang 550025, China;

2. School of Mechanical and Automotive Engineering, South China University of Technology, Guangzhou 510640, China;

3. Institute of Materials and Processing, Guangdong Academy of Sciences, Guangzhou 510640, China)

Abstract: The effect of ultrasound vibration and pressure coupling fields on the function mechanism and microstructure of Al-Cu alloy was studied by numerical simulation and experimental validation. The results show that, compared with the single ultrasonic field, the ultrasound vibration and pressure coupling field can increase the intensity and region of cavitation effect. The distribution of inner pressure in aluminum melt can also be raised under the coupling field, which leads to the enhanced convection in the aluminum melt. By measuring the temperature in melt and analyzing the macro/microstructure of the Al-Cu alloy quantitatively, the numerical simulation result was verified. The coupling field can promote the uniform temperature distribution of Al-Cu melt. The coupling field can also eliminate the difference of grain refinement in the ingot caused by single ultrasonic field, and improve the uniformity of the microstructure obviously.

Key words: ultrasonic vibration; applied pressure; coupling fields; numerical simulation; Al-Cu alloy

Foundation item: Projects(51704084, 52074131) supported by the National Natural Science Foundation of China; Project(2015A030312003) supported by the Natural Science Foundation of Guangdong for Team Research, China; Project(RC2017(5788)) supported by the Science and Technology Plan of Guizhou Province, China; Project(2019(23)) supported by the Cultivation Project of Guizhou University, China

Received date: 2020-06-30; Accepted date: 2021-06-10

Corresponding author: ZHANG Wei-wen; Tel: +86-13642315239; E-mail: mewzhang@scut.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51704084,52074131);广东省自然科学基金团队项目(2015A030312003);贵州省科技计划资助项目(黔科合平台人才[2017]5788);贵州大学培育项目(2019[23])

收稿日期:2020-06-30;修订日期:2021-06-10

通信作者:张卫文,教授,博士;电话:13642315239;E-mail:mewzhang@scut.edu.cn