含Bi易切削变形Zn-Al合金显微组织与性能

林高用1, 2,孙利平1,曾菊花1,王莉1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,湖南 长沙,410083)

摘要:采用力学性能测试、光学显微镜、扫描电镜和能谱分析技术、切削性能测试、电镀试验对自行配制的含Bi易切削变形Zn-Al合金铸态、挤压态的组织与性能进行研究。研究结果表明:低熔点的Bi相在Zn-Al合金中以针状弥散分布,改善Zn-Al合金的切削性能;Bi含量超过0.5%(质量分数)时,Bi对Zn-Al易切削变形合金电镀性能产生不良影响;自行配制的Zn-10%Al-0.3%Bi-X合金,切削性能良好,抗拉强度达到351 MPa,伸长率为18%,电镀不易起泡,表现出较好的综合性能,可作为部分铜合金替代材料,用于轴承、连接件、五金、家电等结构件。

关键词:变形锌合金;Bi;显微组织;切削性能

中图分类号:TG146.1+3 文献标志码:A 文章编号:1672-7207(2011)11-3296-07

Microstructure and properties of

free-cutting deformation Zn-Al alloy containing Bi

LIN Gao-yong1, 2, SUN Li-ping1, ZENG Ju-hua1, WANG Li1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. The Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: The microstructure and properties of self-developed free-cutting deformation Zn-Al alloys containing Bi in the cast and extruded conditions were investigated by mechanical tests, optical microscopy, scanning electron microscopy, energy spectrum analysis, machinability tests and plating performance tests. The results show that the machinability of the Zn-Al alloy can be improved by needle dispersion distributed low-melting Bi phase. The plating performance of free-cutting deformation Zn-Al alloys gets worse when the content of Bi is more than 0.5% (mass fraction). This self-developed Zn-10%Al-0.3%Bi-X alloy has excellent comprehensive properties, such as free-cutting without blistering when electroplated, tensile strength and elongation reaches 351 MPa and 18% respectively. So it can be used to replace some copper alloys as bearing, handware, household appliance and other structural parts.

Key words: deformation zinc alloy; Bi; microstructure; machinability

在有色金属中锌的矿物储量、产量和用量仅次于铝和铜,居第3位[1-2]。随着我国有色金属工业的快速发展,我国铜资源短缺与铜消费量增长的矛盾日益加剧,加速开发铜及铜合金替代材料,以满足现代工业的需求,成为材料工作者的共识[2-5]。我国锌资源不但储量多,居世界前列,品位也高[6]。锌合金具有熔点低、铸造性能好、力学性能优异、生产工艺流程短、能耗小等优点,是部分铜合金的理想替代材料,成为目前国内外研究的热点[7-12]。经过几十年的发展,锌合金已形成铸造锌合金和变形锌合金两大系列。变形锌合金的典型代表为Zn-Al和Zn-Cu-Ti合金。Zn-Cu-Ti合金是目前使用较多的变形锌合金,可用来制作拉链、千层锁和日用五金等,但由于其综合性能较低,应用范围有很大局限;而Zn-Al合金具有许多优异的性能,如熔点低、熔炼耗能少,生产效率高,力学性能良好等,目前已相继发展了几个成分的Zn-Al合金(ZnAl15,ZnAl10-1,ZnAl10-5,ZnAl0.2-4和ZnAl14-1)作为黄铜的代用品[2]。但变形Zn-Al合金,尤其是接近共晶成分的Zn-Al合金,在切削加工时通常会遇到较大困难,在自动车床和仪表车床上切削加工效率低,排屑不畅,易黏刀,易断刀,加工件表面不光洁等,限制了变形Zn-Al合金的应用[13]。因此,研究开发出一种既具有优良切削性能,又具有良好力学性能的变形Zn-Al合金,实现对已有易切削铅黄铜的替代具有重要意义。一般可通过添加Pb,Sn和Bi等低熔点元素来提高合金的切削性能[14],并通过添加适量的Al,Cu,Mg和Ti等合金元素提高Zn合金的力学性能与成形性能[2, 15-16]。目前,还没有关于易切削变形Zn-Al-Bi合金组织与性能的研究报道。本文作者通过较系统的试验,对自行配制的无铅含Bi易切削变形Zn-Al合金铸态、挤压态的组织与性能进行了研究。

1 试验材料及方法

本文所用试验材料是自行配制的含Bi易切削变形Zn-Al合金。按照表1所示的合金成分进行配料,在工频感应炉内熔炼;熔炼过程中,Bi以纯金属加入,Ti以Cu-Ti中间合金加入,Mn以Al-Mn中间合金加入。将铸锭锯尾、车皮后在3 150 kN立式挤压机上进行挤压,挤压工艺参数为:模具、挤压筒预热温度200 ℃,铸锭加热温度250~260 ℃;挤压比λ=18.8。

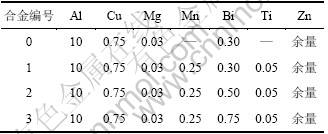

表1 试验合金化学成分(质量分数)

Table 1 Chemical compositions of experimental alloys %

采用POLYVAR-MET型金相显微镜观察铸锭金相组织;将合金挤压态按GB/T 228—2002制成拉伸试样,在CSS-44100型电子万能试验机上进行室温拉伸试验,拉伸速度为2 mm/min;利用Sirion200场发射扫描电子显微镜观察合金微观组织;在DJ-CL-1三向线性放大器/CD6140A机床上对合金挤压态进行切削力测试,并对合金铸态、挤压态车屑形貌进行对比 观察。

2 结果与讨论

2.1 力学性能

合金挤压态力学性能测试结果如表2所示。从表2可以看出:未加Mn和Ti的0号合金抗拉强度为351 MPa,伸长率为18%,虽比1号合金抗拉强度低12 MPa,但伸长率高5%,表现出较好的综合性能。2号合金抗拉强度最高,为368 MPa,但伸长率仅为7%,其塑性较差。3号合金强度最低,为345 MPa,伸长率和1号合金的相同,为13%。通过比较可以发现,0号合金和1号合金表现出了较好的综合力学性能,不但有较好的塑性,抗拉强度也达到350 MPa以上,能满足替代部分铜合金的要求[6]。

表2 挤压态Zn-Al-Bi合金力学性能

Table 2 Mechanical properties of extruded Zn-Al-Bi alloys

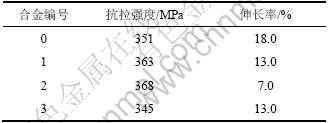

2.2 合金铸态金相组织

对合金铸态进行金相组织观察,结果如图1所示。从图1可以看出:未添加Ti合金元素的0号合金铸态金相组织呈树枝状,而添加了Ti的1号、2号和3号合金铸态组织枝晶被打破,晶粒明显细化,表明Ti能对Zn-Al合金晶粒产生明显细化作用,这与文献 [2, 7]的结果是一致的。从图1还可以看出:2号合金金相组织中存在大而不规则的相,结合室温拉伸试验结果可知,该相对Zn-Al合金的塑性可能产生明显恶化作用。

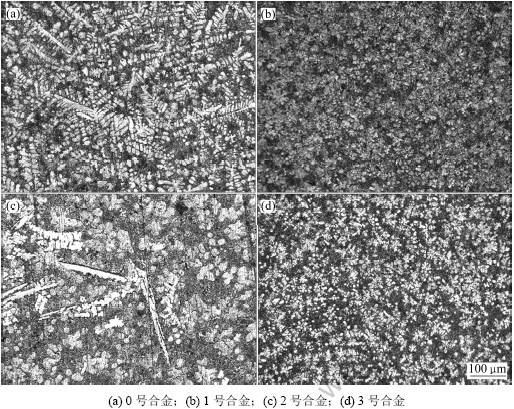

2.3 扫描电镜观察

0号、1号和2号合金铸态及挤压态的SEM微观组织如图2所示,其中图2(a)~(c) 所示为合金铸态微观组织,图2(d)~(f)所示为合金挤压态微观组织。从图2(a)~(c)可以看出:未添加Ti的0号合金铸态组织呈枝状(见图2(a));而添加了Ti的1号合金铸态组织枝晶被打破,晶粒明显细化(见图2(b));2号合金铸态组织中存在大而不规则的相(见图2(c)),这与合金铸态金相组织结果是一致的。此外,通过背散射电子扫描电镜还可以观察到,合金中Bi的分布为均匀细小的粒子(如图2中高亮的白色相),正是由于低熔点Bi相的弥散分布,改善了试制Zn-Al合金的切削性能。从图2(d)~(f)可以看出:挤压后合金组织均匀细小。未添加Ti的0号合金铸态组织枝晶被打破,组织细小均匀,Bi相弥散分布(图2(d)),因此,其挤压态力学性能及切削性能都较好。添加了Mn,Ti和Bi的1号试样挤压态组织均匀细小,富Mn相和Bi相弥散分布(图2(e))。2号合金挤压铸态组织中存在大而不规则的块状相(图2(f)中的黑色相),根据表1合金力学性能测试结果,2号合金塑性明显低于0号和1号合金的塑性,这可能是由于2号合金中大而不规则的块状相为脆性相。因此,本文作者认为:加Ti虽然能明显细化Zn-Al合金铸态组织,但由于变形Zn-Al合金经过挤压成形,组织已经非常细小,因此,不添加Ti的0号合金其组织与性能已经能够满足要求。此外,Mn的加入对于提高变形Zn-Al的力学性能作用不明显。

图1 Zn-Al-Bi合金铸态显微组织(OM)

Fig.1 Optical micrographs of as-cast Zn-Al-Bi alloys

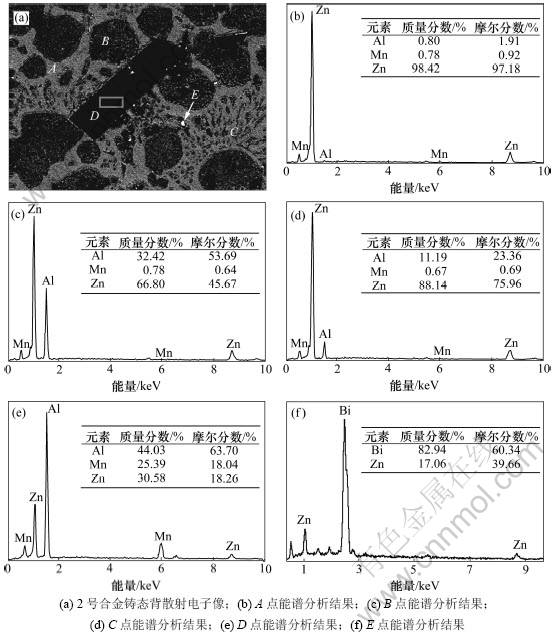

2号合金铸态组织微区成分分析结果如图3所示。由图3可知:2号合金的铸态组织包含了5种不同的相:η-Zn基体相(A点)、初生α相(B点)、共晶α+η相(C点)、Mn富集的化合物(D点)和微量的Bi相(E点)。η-Zn基体相是以Zn为基,固溶有微量Al和Mn的固溶体(如图3(b)所示),为密排六方晶体结构;初生α相是以Al为基,固溶有大量Zn、微量Mn的固溶体(见图3(c)),为面心立方晶体结构;共晶α+η相由η固溶体和α固溶体共同组成(见图3(d));Mn富集的化合物呈块状或其他不规则形状分布(见图3(e));微量的Bi相以点状弥散分布在η-Zn基体相、初生α相、共晶α+η相和Mn富集的化合物上(见图3(f)),正是由于低熔点的Bi相在合金中弥散分布,在合金切削时起到断屑作用,从而提高了变形Zn-Al合金的切削性能。

2.4 切削性能

试制易切削变形锌合金挤压态切削力测试是在DJ-CL-1三向线性放大器/CD6140A机床上进行的,测试结果如表3所示。三向切削力是在固定切削速 度、进给量和背吃刀量的情况下获得的,进行比较时主要针对切向力。从表3可知:0号合金切向力平均值最低,为42.30 N;1号合金切向力平均值最高,为48.03 N;2号和3号合金切向力平均值比1号合金的稍低,分别为47.28 N和46.51 N。以上结果表明:未添加Mn和Ti,添加0.3% Bi的0号合金切削性能最好,其切削力最低;添加了Mn和Ti的1号、2号和3号合金随着Bi含量的增加,切削力下降,切削性能有所提高。

图2 Zn-Al-Bi合金SEM背散射电子像

Fig.2 SEM back-scattered electron images of Zn-Al-Bi alloys

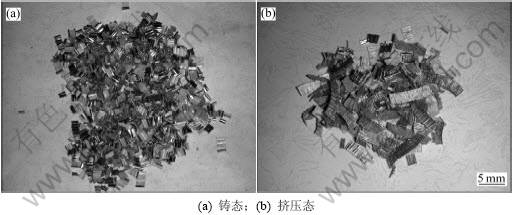

0号合金铸态及挤压态车屑形貌如图4所示。从图4可以看出:合金铸态、挤压态车加工时易断 屑,车屑均呈直条状,且车屑较细小,其切削性能好。

表3 挤压态Zn-Al-Bi合金切削力测量结果

Table 3 Cutting force measurements of extruded Zn-Al-Bi alloys

图3 2号合金铸态背散射电子像及能谱分析结果

Fig.3 Back-scattered electron image and EDS analyses results of as-cast alloy 2

图4 0号合金车屑形貌

Fig.4 Photos of cuttings of alloy 0

2.5 电镀预处理和电镀试验结果

Zn-Al合金存在一定的晶间腐蚀倾向,目前合金实际应用时采用电镀保护,以提高合金耐腐蚀性能,因此,试制的Zn-Al-Bi合金需能够实现电镀。Bi虽能明显提高Zn-Al合金的切削性能,但是实验中发现其对合金电镀性能产生了不良影响,Bi可能导致变形Zn-Al合金电镀起泡。通过对试制的含Bi易切削变形Zn-Al合金进行电镀预处理及电镀试验,得出以下主要试验结果:

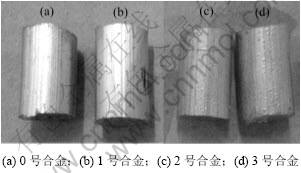

(1) 将0号、1号、2号、3号合金挤压态试样进行电镀预处理,Bi含量较少的0号、1号合金不起泡,而2号、3号试样起泡,表明Bi含量较高的Zn-Al合金,容易起泡,如图5所示。

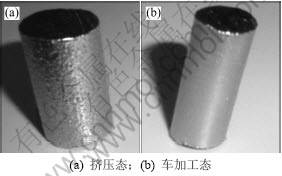

(2) 对2号合金挤压态和车加工态分别进行电镀,电镀结果见图6。由图6可以看出:经过车加工后的试样电镀起泡程度明显降低。

含Bi易切削变形Zn-Al合金电镀起泡主要与Bi含量、制品表面光洁度等因素有关,Bi含量超过0.5%时,合金易电镀起泡。综合比较发现:本文试制的含0.3%Bi的0号合金不但具有良好的切削性能和综合力学性能,电镀也不易发生起泡,能够满足使用要求,可作为部分铜合金替代材料,用于轴承、连接件、五金和家电等结构件。

图5 Zn-Al-Bi合金挤压态试样电镀预处理后照片

Fig.5 Photos of extrusion Zn-Al-Bi alloys after plating pretreatment

图6 2号合金电镀试验试样照片

Fig.6 Photos of alloy 2 after plating

3 结论

(1) 低熔点的Bi相在Zn-Al合金中以针状弥散分布,在机加工时起到断屑作用,改善了Zn-Al合金的切削性能。

(2) Bi含量超过0.5%时,Bi对Zn-Al合金电镀性能产生不良影响,因此,易切削Zn-Al合金中Bi含量不宜超过0.5%。

(3)自行配制的Zn-10%Al-0.3%Bi-0.75%Cu- 0.03%Mg合金,切削性能良好,抗拉强度达到351 MPa,伸长率为18%,电镀不易起泡,表现出较好的综合性能,可作为部分铜合金替代材料,用于轴承、连接件、五金、家电等结构件。

参考文献:

[1] 包小波, 黄其兴. 世界锌技术经济[M]. 北京: 冶金工业出版社, 1996: 143-248.

BAO Xiao-bo, HUANG Qi-xing. Zinc technical economics in the world[M]. Beijing: Metallurgical Industry Press, 1996: 143-248.

[2] 孙连超, 田荣璋. 锌及锌合金物理冶金学[M]. 长沙: 中南工业大学出版社, 1994: 11-20.

SUN Lian-chao, TIAN Rong-zhang. Physical metallurgy of zinc and Zn-alloy[M]. Changsha: Central South University of Technology Press, 1994: 11-20.

[3] Prasad B K. Influence of some material and experimental parameters on the sliding wear behaviour of a zinc-based alloy, its composite and a bronze[J]. Wear, 2003, 254(1/2): 35-46.

[4] 耿浩然, 王守仁, 王艳. 铸造锌、铜合金[M]. 北京: 化学工业出版社, 2006: 9-20.

GENG Hao-ran, WANG Shou-ren, WANG Yan. Casting zinc and copper alloys[M]. Beijing: Metallurgical Industry Press, 2006: 9-20.

[5] 林高用, 郑小燕, 周佳, 等. 一种锌基合金热变形行为的试验模拟[J]. 机械工程材料, 2007, 31(7): 60-62.

LIN Gao-yong, ZHENG Xiao-yan, ZHOU Jia, et al. Thermo- compression behavior of a zinc based alloy[J]. Materials for Mechanical Engineering, 2007, 31(7): 60-62.

[6] 黄伯云, 李成功, 石力开, 等. 中国材料工程大典[M]. 北京: 化学工业出版社, 2006: 431-455.

HUANG Bo-yun, LI Cheng-gong, SHI Li-kai, et al. The material engineering tome of China[M]. Beijing: Chemistry Industry Press, 2006: 431-455.

[7] 蔡强. 锌合金[M]. 长沙: 中南工业大学出版社, 1987: 102-170.

CAI Qiang. Zinc alloy[M].Changsha: Central South University of Technology, 1987: 102-170.

[8] Savakan T, Hekimolu A P, Purcek G. Effect of copper content on the mechanical and sliding wear properties of monotectoid-based zinc-aluminium-copper alloys[J]. Tribology International, 2004, 37(1): 45-50.

[9] Zhang F, Vincent G, Sha Y H, et al. Experimental and simulation textures in an asymmetrically rolled zinc alloy sheet[J]. Scripta Materialia, 2004, 50(7): 1011-1015.

[10] 林高用, 郑小燕, 曾菊花, 等. 锌基合金挤压型材的组织与性能[J]. 中南大学学报: 自然科学版, 2008, 39(2): 246-250.

LIN Gao-yong, ZHENG Xiao-yan, ZENG Ju-hua, et al. Microstructure and properties of extruded profiles of zinc-based alloys[J]. Journal of Central South University: Science and Technology, 2008, 39(2): 246-250.

[11] 琚宏昌. 4×60 m回转窑托轮轴瓦应用锌合金替代铜合金的可行性研究[J]. 安阳大学学报, 2003(3): 10-14.

JU Hong-chang. The studies of Zn-alloy replacing Cu-alloy as supporting wheel axle bush material of 4×60 m rotating kiln[J]. Journal of Anyang University, 2003(3): 10-14.

[12] Nilsson A, Gabrielson P, Stahl J E. Zinc-alloys as tool materials in short-run sheet-metal forming processes: Experimental analysis of three different zinc-alloys[J]. Journal of Materials Processing Technology, 2002, 125/126(9): 806-813.

[13] 林高用, 肖弦, 郑小燕. 锌合金切削性能的研究[J]. 矿冶工程, 2006, 25(5): 68-70.

LIN Gao-yong, XIAO Xian, ZHENG Xiao-yan. Study on the cutting property of Zn-alloy[J]. Mining and Metallurgical Engineering, 2006, 25(5): 68-70.

[14] 陈日曜. 金属切削原理[M]. 北京: 机械工业出版社, 1992: 132-170.

CHEN Ri-yao. Principle of metal cutting[M]. Beijing: China Machine Press, 1992: 132-170.

[15] 张忠明, 王锦程, 徐东辉, 等. 铝、铜、镁对铸态锌基合金组织和阻尼性能的影响[J]. 中国有色金属学报, 1999, 9(1): 1-6.

ZHANG Zhong-ming, WANG Jing-cheng, XU Dong-hui, et al. Effects of Al, Cu, Mg on the microstructure and damping properties of cast zinc-based alloys[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(1): 1-6.

[16] LI Yuan-yuan, Ngai T L, XIA Wei, et al. Effects of Mn content on the tribological behaviors of Zn-27%A1-2%Cu alloy[J]. Wear, 1996, 198(1/2): 129-135.

(编辑 陈爱华)

收稿日期:2011-01-11;修回日期:2011-04-06

基金项目:国家“十一五”科技支撑计划项目(2009BAE71B01)

通信作者:林高用(1966-),男,湖南洞口人,博士,教授,从事有色金属材料加工、模具设计和数值模拟方面的研究;电话:13507422779;E-mail: gylin6609@yahoo.com.cn