文章编号: 1004-0609(2006)02-0219-09

Mg-Gd-Y-(Mn, Zr)合金的显微组织和力学性能

张新明, 陈健美, 邓运来, 肖 阳, 蒋 浩, 邓桢桢

(中南大学 材料科学与工程学院, 长沙 413083)

摘 要: 采用溶剂保护方法制备了合金Mg-9Gd-4Y-0.65Mn和Mg-9Gd-4Y-0.6Zr, 并挤压成棒材。 通过光学显微镜、 X射线衍射仪、 扫描电镜和透射电镜等分析研究了这两种合金铸态和变形态的显微组织和力学性能。 结果表明: 铸态含Mn合金的晶粒粗大, 而含Zr合金的晶粒细得多, Zr能有效地细化Mg-RE合金的晶粒; 热变形加工使两种合金的晶粒度大大减小, 拉伸强度大幅提高, 在同等加工条件下, 含Mn合金形变细化晶粒作用更显著; 两种变形合金都有非常高的室温和300℃高温强度, 但含Mn合金的延伸率较高; 含Zr变形镁合金适宜通过T5处理, 而含Mn变形镁合金适宜通过T6处理提高其综合拉伸力学性能。

关键词: 稀土镁合金; 显微组织; 晶粒细化; 力学性能

中图分类号: TG111.7; TG146.2 文献标识码: A

Microstructures and mechanical properties of

Mg-Gd-Y-(Mn, Zr) magnesium alloys

ZHANG Xin-ming, CHEN Jian-mei, DENG Yun-lai,

XIAO Yang, JIANG Hao, DENG Zhen-zhen

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Mg-9Gd-4Y-0.65Mn and Mg-9Gd-4Y-0.6Zr alloys were prepared by the fluxing procedures method and then extruded into rods. The microstructures and tensile properties of the alloys both at as-cast state and at deformation state were investigated by using optical microscopy, X-ray diffractometry, scanning electron microscopy, and transmitting electron microscopy. The results show that the grains of the alloy containing Mn at as-cast state are coarser and those of the alloy containing Zr are much finer, which obviously demonstrates grain refining effect of additional element Zr on Mg-RE alloys. Hot extrusion of the two alloys can enormously decrease the grain size and increase their strength. The grain refining effect of the magnesium alloy containing Mn through extrusion will be more remarkable than that of alloy containing Zr. The two extruded magnesium alloys at room temperature and at 300℃ have rather high strength, furthermore, the elongation of the alloy containing Mn is higher. It is suggested that the extruded magnesium alloy containing Zr is introduced to precipitation heat treatment to T5 temper for high mechanical properties, while the extruded magnesium alloy containing Mn to T6 temper.

Key words: rare earth magnesium alloys; microstructure; grain refining; mechanical properties

添加重稀土元素可提高镁合金的抗蠕变性能和力学性能[1-3]。 复合添加稀土元素, 可获得高热稳定性的镁合金[4-6]。 至今应用比较成功的商用合金有HK(Mg-Th-Zn-Zr)、 HM(Mg-Th-Zn-Mn)、 WE54(Mg-Y-Nd-Zr)和QE22(Mg-Ag-Nd-Zr)等。 由于Th的放射性, HK、 HM合金被限制使用。 近年来, 人们对Mg-Gd-Y-Zr系合金进行了大量研究, 发现Mg-Gd-Y-Zr合金的高温强度和抗蠕变特性优于WE合金[4]。 早在20世纪70年代, Drits等[7]就研究了变形镁合金Mg-9Gd-5Y-Mn优良的耐热性能。 Drits等[8, 9]提出的Mg-Y-Gd三元合金的过饱和固溶体基本上是按两种不同的析出序列分解的, 即Mg-Y 型和Mg-Gd型。 这些二元合金的析出序列因复杂的稀土而变化[7], 文献[10]对Mg-Gd-Y-Zr合金峰值时效时的析出相作了高倍透射电镜分析, 发现峰值时效的析出亚稳相β″和β′是并存的。 HM合金比HK合金更多应用于较高的温度场合, 它们在合金成分上的差别在于前者加Mn后者加Zr。 对于以Mg-Gd-Y为基的合金Mg-Gd-Y-Mn和Mg-Gd-Y-Zr, 它们的热加工样品都具有很好的室温和高温性能[1, 11]。 本文作者在Mg-9Gd-4Y合金的基础上, 分别加入0.65%Mn和0.60%Zr, 比较二种合金的晶粒组织和析出第二相的大小与形态, 及其对与力学性能的影响, 为合金材料的加工与应用提供依据。

1 实验

实验合金采用纯度(质量分数)为99.96%的Mg, 99.95%的Y, 市购化学纯MnCl2。 将Gd和Y分别配制成Mg-24.5%Gd和Mg-12.5%Y(质量分数)的中间合金, 将MnCl2在干燥箱中烘干, 自配保护溶剂和精炼剂。 采用电阻炉熔炼铁坩埚中的添加料。 熔炼的次序是, 先熔化纯镁和保护剂, 再添加过量的MnCl2, 搅拌后加适量的CaF2, 控制溶剂的稠度, 扒去“结壳”的溶剂, 撒上无MgCl2精炼溶剂, 加热至850℃, 再添加Mg-Y和Mg-Gd中间合金, 搅拌后又撒精炼剂静置10min。 Mg-Gd-Y-Zr合金熔体的制备只是在上述工序中最后加Mg-30%Zr的中间合金。 熔体浇注到预热的不锈钢薄壁管中, 立即水淬, 获得直径为d62mm的Mg-Gd-Y-Mn和Mg-Gd-Y-Zr合金圆锭。 圆锭经车皮后, 分别挤压成直径为d15mm和d18mm的圆棒, 相应的挤压比为16和11, 挤压模温控制在450℃。 热加工前, 样品都经过520℃、 12h均匀化处理, 挤压时, 圆锭选定保温温度为400℃。 在500t油压机上挤压, 挤压速度为1m/min。 对截取的圆棒试样进行了热处理、 常温和高温拉伸实验以及相应的维氏硬度检测。 两种合金是在Mg-9Gd-4Y合金的基础上分别添加质量分数为0.65%Mn和0.6%Zr熔炼而成。

采用NEOPHOT-21金相显微镜和JSM-5600LY扫描电镜观察合金显微组织, 采用XRD和TEM分析合金的相组成及其结构。 拉伸实验在CSS-44100型万能电子拉伸机上进行, 高温拉伸实验在Instron拉伸机上进行, 拉伸速率为1.0mm/min, 并采用KYKY-2800B扫描电镜作断口分析。

2 结果与分析

2.1 铸态显微组织

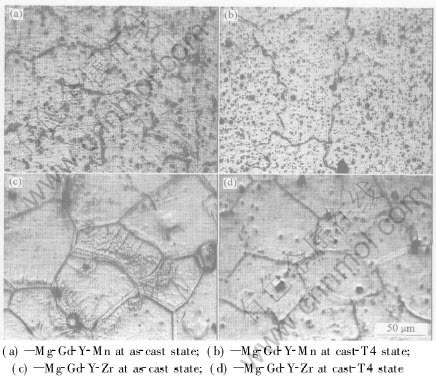

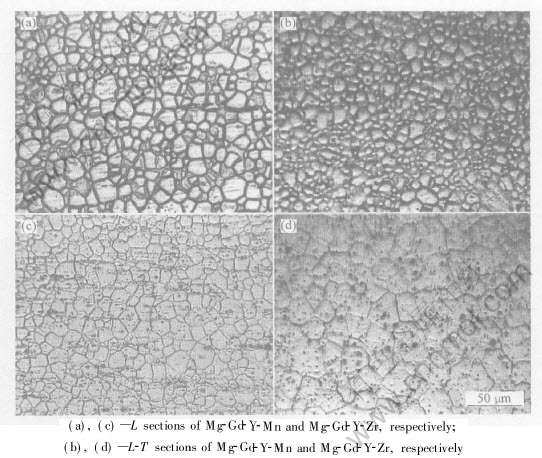

图1所示为浇铸水淬圆锭样品的显微组织。 由图可见, 铸态Mg-Gd-Y-Mn合金的显微组织是由α-Mg基体与一些不连续的伪共晶、 枝晶和颗粒相构成的。 铸态Mg-Gd-Y-Zr合金的显微组织很少观察到Mg-Gd-Y合金常有的伪共晶和枝晶组织, 晶界清晰可辨, 但比较粗, 有许多“蛛网”状组织分布在晶界附近或遍布晶内(见图1(c)), 晶内有形核痕迹的富Zr粒子。 两种合金都经520℃、 6h固溶处理后, Mg-Gd-Y-Mn合金的伪共晶和枝晶消失, 显露出晶界和不溶解的第二相粒子, 它们弥散分布在晶内和晶界; Mg-Gd-Y-Zr合金的枝晶组织也消失, 晶界细化, 残留有偏聚的颗粒相, 但晶粒并没有粗化。 含Zr合金的晶粒细得多, 并且是类等轴的。

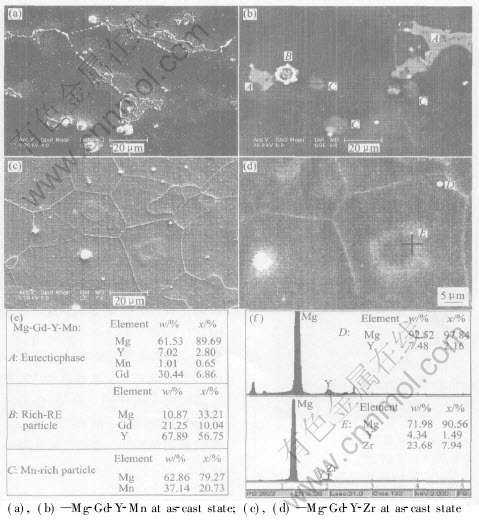

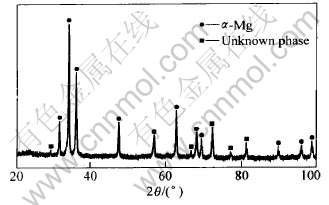

图2所示为两种合金铸态组织的扫描电镜照片及能谱分析结果。 由图可见, Mg-Gd-Y-Mn合金中除α-Mg基体和共晶组织外, 还存在富稀土粒子和富Mn粒子, 从其X射线衍射谱分析可知相结构比较复杂(见图3), 而含Zr合金的X射线衍射谱简单得多(见图4)。

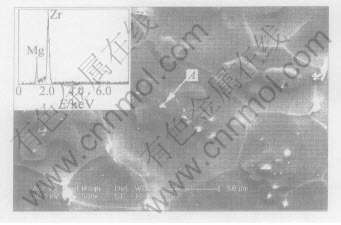

Mg-Gd-Y-Zr合金中的环状物是合金凝固时Zr的包晶反应产物, 环的中心是富Zr粒子(见图5)。

Zr是许多镁合金十分有效的晶粒细化剂[12]。 Zr的细化作用需考虑其与合金化元素的相溶性。 研究表明, 下列元素与Zr在镁合金熔炼过程中是相溶的: Zn、 Cd、 Ag、 Cu、 Ca、 Pb、 Bi、 Ti和稀土金属元素; 而Al、 Si、 Sn、 Ni、 Fe、 Co、 Mn和Sb等与锆元素易形成高熔点中间化合物, 因此只有在它们不存在的情况下, 锆元素才能溶入镁熔液中并得到晶粒细化结果[13]。

Mn元素能提高镁合金的耐热性、 耐腐蚀性, 在一些合金中还能起到晶粒细化的作用。 Mn和稀土元素在镁合金中可能形成金属间相, 这些中间相在镁合金热加工的组织结构演变中发挥作用[1]。 Mn细化晶粒的作用并不局限于凝固过程, 很大的可能性在于热加工中协助破碎变形组织和热处理过程中阻止

图1 浇注水淬的两种合金的铸态显微组织

Fig.1 Micostructures of two cast alloys quenched in water

图2 两种合金铸态组织的SEM照片及能谱分析

Fig.2 SEM images and EDAX of microstructures of two cast alloys

图3 Mg-Gd-Y-Mn合金铸态的X射线衍射谱

Fig.3 XRD pattern of as-cast Mg alloy

图4 Mg-Gd-Y-Zr合金铸态的X射线衍射谱

Fig.4 XRD pattern of as-cast Mg-Gd-Y-Zr alloy

图5 Mg-Gd-Y-Zr铸态合金的SEM像及A粒子能谱

Fig.5 SEM image and EDAX pattern of particle A in as-cast Mg-Gd-Y-Zr alloy showing exitting of Zr element in center of particle A

晶粒长大, 原子能用镁合金往往是高Mn含量镁合金, 利用了加Mn镁合金的耐热性能[13]。

本实验研究的两种镁合金在铸态使用条件下, Mg-Gd-Y-Zr合金因晶粒细化而占有优势, 这是由于镁合金的室温强度强烈地依赖于镁合金的晶粒度[14], 作为铸造镁合金, 含Mn镁合金的晶粒粗大。 Mn和Zr与Mg的二元相图都是包晶的, 但Zr的晶格最适合异质形核条件, 是目前稀土镁合金最有效的变质剂。

2.2 挤压变形后合金的显微组织

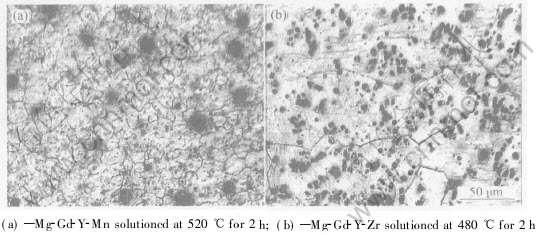

图6所示为在同样条件下两种合金挤压变形后棒材的显微组织。 由图可知, 两种合金在450℃下挤压, 都发生了完全再结晶, 晶粒细小, 但含Mn合金的晶粒更细小, 虽然加工前它的晶粒较粗大, 这说明Mn对合金形变细化晶粒的作用比Zr大。 根据文献[7]的相图, Mg-9Gd-4Y 合金熔点温度为547℃, 添加Mn和Zr使熔点有所降低。 为了考察两种变形合金的耐热性能, 对其进行480、 500和520℃的固溶处理, 观察晶粒长大情况。 图7所示为两变形合金经固溶处理后的显微组织。 由图可见, 含Zr合金经480℃、 2h固溶处理, 晶粒发生了明显长大, 而含Mn合金即使经520℃、 2h固溶处理, 晶粒未长大, 因此, 含Mn合金的耐热性能较好。 文献[15]对Mg-Gd-Y合金在热处理过程中的相演变行为作了研究, 在此基础上, 添加Mn或Zr所成的新合金, 它们的组织结构演变行为出现了新的特点, 通过挤压变形, 提高了两种实验合金的强度, Zr或Mn都发挥了形变强化的有效作用。 但对于沉淀析出强化, 由于两者的相结构与相演变规律的有所差别, 实验表明, Mg-Gd-Y-Zr合金适宜进行T5处理, 不宜进行T6处理; 而Mg-Gd-Y-Mn合金既可进行T5处理, 又可进行T6处理。 实验发现含Zr合金经T5处理的时效强化效果比含Mn合金显著, 这可能是由于在热加工过程中, Zr有助于稀土的固溶。 但是, 实验发现含Mn合金经T6处理既能够大大提高峰值强度, 又能增加相应状态的延伸率, 这得益于Mn的高温耐热性及其阻止晶粒长大的作用。 含Zr合金的峰值强度高, 但室温延伸率较低, 一般在5%左右, 而含Mn合金在不失强度的情况下, 通过T6处理可提高延伸率至10%以上。

2.3 合金的力学性能及其其显微组织

图6 两种合金挤压态(F态)的显微组织

Fig.6 Deformation micostructures of two alloys at F state

图7 两种变形合金T4处理后的显微组织

Fig.7 Microstructures of two alloys after extruded and solutioned

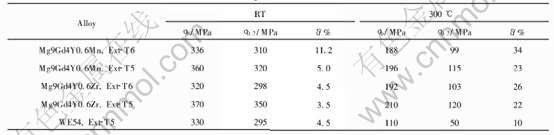

实验研究中对两种合金进行了室温(RT)和高温拉伸实验(300℃)。 表1所列为两种挤压合金在不同温度下的力学性能, 表中也列出WE54合金的相应性能。 由表可见, 两种合金的力学性能都较WE54的高, 特别是高温拉伸力学性能, 表明两种合金具有高温应用开发前景。

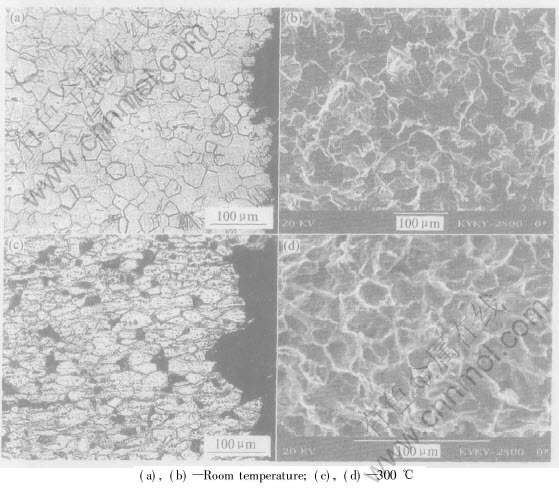

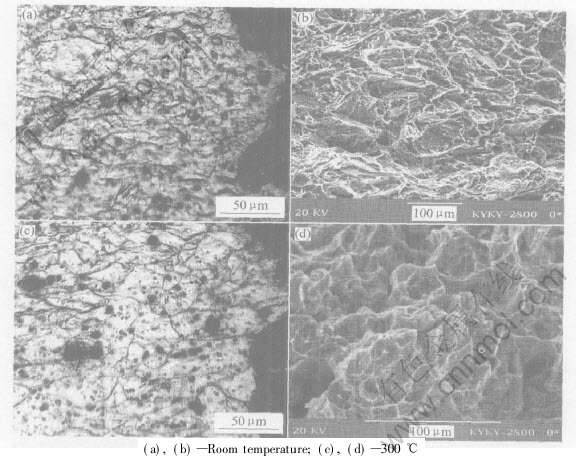

图8所示为Mg-Gd-Y-Zr合金拉伸断口与断口附近的组织形貌。 研究表明, 室温拉伸, 断口属于穿晶脆性断裂。 断口附近表面出现许多孪晶, 晶粒没有明显被变形拉长的迹象。 这是由于合金属于六方晶系, 滑移系少, 合金通过滑移、 孪生和扭折实现整体变形的协调, 但当应变达到比较小的程度时, 协调变形就难以继续进行, 因而导致裂纹萌生和扩展。 虽多个样品室温拉伸的极限强度都超过370MPa, 屈服强度超过350MPa, 但延伸率不超过5%。

含Zr合金300℃拉伸时的极限强度超过220MPa, 屈服强度超过200MPa, 延伸率超过20%,[CM(22]这是镁合金中非常高的拉伸力学性能, 远远超过合金WE54和WE43。 由图8(c)、 (d)可见, 在断口附近表面的金相照片中, 显示了晶粒明显被拉长, 界面上在萌生裂纹, 扩展成空洞, 导致高温下的沿晶韧性断裂。 合金在高温热激活和热扩散的作用下, 虽然位错会发生滑移、 交滑移和攀移, 位错机制的变化引起了塑性的增加, 但同时也弱化了晶界。

表1 合金在室温和300℃时的力学性能

Table 1 Mechanical properties of studied alloys at room temperature and 300℃

图8 Mg-Gd-Y-Zr挤压合金室温、 高温拉伸断口及断口附近表面的显微组织形貌

Fig.8 Morphologies of ruptured sections and near fracture of Mg-Gd-Y-Zr extruded alloys at T5 peak temper, stretched at room temperature and 300℃,respectively

对于Mg-Gd-Y-Mn合金, 两种温度下拉伸的断口和断口附近的组织形貌如图9所示。 含Mn合金T5态的拉伸强度比含Zr合金的都低, 但相应的延伸率都要高。 从断口表面的形貌可以看出, 在常

图9 Mg-Gd-Y-Mn挤压合金室温、 高温拉伸断口及断口附近表面的显微组织形貌

Fig.9 Morphologies of ruptured sections and near fracture of Mg-g-Gd-Y-Mn extruded alloys at T5 peak temper, stretched at room temperature and 300℃, respectively

温下拉伸, 晶粒就有可辨别的变形, 虽然断口也显示出一些平台, 但相比含Zr合金少得多, 且有很多韧性断裂的组织。 同时可观察到, 含Mn合金组织中, 有许多颗粒相, 并没有像含Zr合金那样清晰的组织形貌, 这与含Mn合金复杂的第二相成分有关。

3 讨论

实验研究的两种合金都是以Mg-9Gd-4Y为基本合金成分的, 热变形加工可细化晶粒, 热处理造成沉淀析出, 晶粒的细化和沉淀强化都提高了合金的力学性能。 实验的结果表明, 在挤压态下, 两种合金的显微组织有差别, 含Zr合金第二相多为块状的富稀土相和形状不规则的富Zr粒子; 含Mn合金的第二相多为弥散分布的富Mn粒子。 在铸造凝固过程中形成的粗大第二相对材料的力学性能不利, 特别是当粗大的第二相处于晶界上时, 会成为应力集中点和裂纹源。

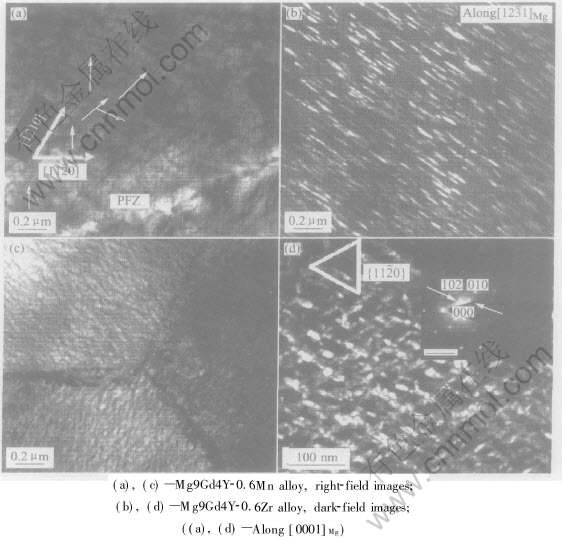

两种合金在300℃下都有超过200MPa的拉伸强度, 说明它们的耐热性能是优良的。 合金的耐热性来自于耐热相的热稳定性。 在225℃等温时效24h后, 形成了细小的β″和β′相, 像板状或棒状, 在两种合金中沿棱柱面{112[TX-]0}析出。 图10(d)所示为合金Mg9Gd4Y-0.6Zr析出物形貌的透射电镜照片及衍射图, 拍摄是沿晶带轴[0001]Mg方向。 由图可知, 正是这种析出相结构及相本身的热稳定性带来了合金的高温强度。 根据基体和析出相的衍射斑分析, 析出相和基体的取向关系为: 对于β″相, [0001]Mg∥[0001]β″, [101[TX-]0]Mg∥[101[TX-]0]β″, 其特征斑点是处于中心斑点与基体斑点[102]之间, 这和前述的D019六方超晶格结构是吻合的, 就像许多关于稀土镁合金所作的研究中提出的Mg-Gd型析出相结构; 对于β′相, [0001]Mg∥{001}β′, [101[TX-]0]Mg∥{010}β′和{112[TX-]0}∥{100}β′, 这是一种底心正交晶体结构(cbco), 其特征斑点是处于中心斑点与基体斑点[010]之间。

从图10的暗场像可见, 析出物从3个方向(黑 色条纹沿[112[TX-]0]Mg)一层层叠加形成一些椭圆形相, β″和β′相在当前的条件下难以区分, 因为它们彼此叠加在一起。 3个棱柱面上的析出相连锁形成“网络”。 Mg9Gd4Y-0.6Mn合金的析出相结构与Mg9Gd4Y-0.6Zr合金的相似, 只是析出的“网络”稀疏一些, 见图10(a)和(b)。 这种棱柱面上析出的交叉板状相能够有效地阻止位错的滑移和交滑移, 基面的滑移位错也受到交叉板的钉扎。 由于析出相的热稳定性好, 再加上相的网络配置, 导致了合金良好的高温强度及蠕变抗力。 类似于Mg-Th基合金[16]。 析出相被认为是抗粒子粗化的, 一种高温强化的保障[8]。

图10 Mg9Gd4Y-0.6Mn和Mg9Gd4Y-0.6Zr合金的TEM显微照片

Fig.10 TEM micrographs of Mg9Gd4Y-0.6Mn alloy aged at 225℃ for 24h and Mg9Gd4Y-0.6Zr alloy aged at 225℃ for 24h

4 结论

1) 含Mn合金铸态的晶粒粗大, 含Zr合金铸态的晶粒细小得多, Zr能有效细化Mg-RE合金的晶粒。

2) 热挤压加工使两种合金的晶粒度大大减小, 拉伸强度得到大幅提高, 在同等加工条件下, 含Mn合金形变细化晶粒作用更显著。

3) 两种变形合金都有非常高的室温和300℃高温强度, 但含Mn合金相应的延伸率较高。

4) 含Zr镁合金适宜进行T5处理, 而含Mn镁合金适宜进行T6处理, 可显著提高其综合拉伸力学性能。

REFERENCES

[1]Drits M E, Sviderskaya Z A, Rokhlin L L, et al. Effect of alloying on the properties of Mg-Gd alloys[J]. Metallovedenie I Termicheskaya Obrabotka Metallov, 1979, 21(11): 62-64.

[2]Rkhlin L L, NiKítina N I. Magnesium-gadolinium and magnesium-yttrium alloys[J]. Z Metallkd, 1994, 85(12): 819-823.

[3]Apps P J, Karimzadeh H, King J F, et al. Phase compositions in magnesium-rare earth alloys containing yttrium, gadolinium or dysprosium[J]. Scripta Material, 2003, 48: 475-481.

[4]Negishi Y, Nishimura T, Iwasawa S, et al. Aging characteristics and tensile properties of Mg-Gd-Nd-Zr alloys[J]. Light Metals, 1994, 44(10): 555-561.

[5]Rkhlin L L, NiKítina N I, Dobatkina T V. Solid-state phase equilibria in the Mg corner of the Mg-Gd-Sm phase diagram[J]. Journal of Alloys and Compounds, 1996, 239: 209-213.

[6]Smola B, StulíkováI. Equilibrium and transient phases in Mg-Y-Nd ternary alloys[J]. Journal of Alloys and Compounds, 2004, 381: L1-L2.

[7]Drits M E, Rokhlin L L, Nikitina N I. State diagram of the Mg-Y-Gd system in the range rich in magnesium[J]. Izvestiya Akademii Nauk SSSR, Metally, 1983, 5: 215-219.

[8]Lorimer G W. Proceedings Magnesium Technology[M]. England: London Press, 1986: 47.

[9]Vostry P, Smola B, StulíkováI, et al. Microstructure evolution in isochronally heat treated Mg-Gd alloys[J]. Physica Status Solidi A, 1999, A175: 491-500.

[10]Kawabata T, Matsuda K, Kamado S, et al. HRTEM[CM(23]observation of the precipitates in Mg-Gd-Y-Zr alloy[J].[CM)] Materials Science Forum, 2003, 419-422: 303-306.

[11]Anyanwu I A, Kamado S, Kojima Y. Aging characteristics and high temperature tensile properties of Mg-Gd-Y-Zr alloys[J]. Mater Trans, 2001, 42(7): 1206-1211.

[12]Qian M, StJohn D H, Frost M T. Effect of soluble and insoluble zirconium on the grain refinement of magnesium alloys[J]. Materials Science Forrum, 2003, 419-422: 593-598.

[13]Emley E F. Principles of Magnesium Technology[M]. England: Pergamon Press(Scotland) Ltd, 1966. 256-303.

[14]Ono N, Nowak R, Miura S. Effect of deformation temperature on Hall-petch relationship registered for polycrystalline magnesium[J]. Materials Letters, 2003, 58: 39-43.

[15]Kunyavskaya T M, Ehina E V. Phase transformation occurring during the heat-treatment of magnesium rare earth alloys[J]. Advanced Performance Materials, 1995, 2(1): 67-77.

[16]Mordike B L, Kainer K U. Mg Alloys and Their Applications[M]. Frankfurt: Werkstoff-Informationsgesell Schaft, 1998. 229.

(编辑陈爱华)

基金项目: 国家安全重大基础研究资助项目(5133001E); 国家高技术研究发展计划资助项目(2003AA741043)

收稿日期: 2005-07-07; 修订日期: 2005-11-07

作者简介: 张新明(1946-), 男, 教授, 博士

通讯作者: 张新明, 教授; 电话: 0731-8830265; E-mail: xmzhang@mail.csu.edu.cn