文章编号:1004-0609(2010)01-0001-09

GWN751K镁合金均匀化热处理

马鸣龙,张 奎,李兴刚,李永军,张 康

(北京有色金属研究总院 有色金属材料制备加工国家重点实验室,北京 100088)

摘 要:通过OM、SEM及布氏硬度分析,研究GWN751K镁合金在不同状态下的显微组织与性能,确定该合金的双级均匀化工艺参数。结果表明:合金经过440 ℃、6 h初级均匀化后,共晶组织开始发生分解,晶粒开始长大;经过535 ℃、16 h热处理后,合金晶粒明显长大,但元素分布较为均匀,晶界处仅明显残留含Y化合物;均匀化处理使合金的力学性能得到改善,合金断裂强度为245 MPa,屈服强度为192 MPa,伸长率为12%,较铸态合金的力学性能均有所提高;合金变形抗力较铸态合金的有所增加,这种特性在450 ℃仍保留下来,但差别减小。

关键词:稀土镁合金;均匀化;显微组织

中图分类号:TG 162.83 文献标识码:A

Homogenization heat treatment of GWN751K magnesium alloy

MA Ming-long, ZHANG Kui, LI Xing-gang, LI Yong-jun, ZHANG Kang

(State Key Laboratory for Fabrication and Processing of Non-ferrous Metals,

Beijing General Research Institute for Non-ferrous Metals, Beijing 100088, China)

Abstract: The microstructures and properties of the as-cast and homogenized GWN751K magnesium alloy were investigated by optical microscopy, scanning electron microscopy and hardness measurement. The two-step homogenization parameters were determined. The results indicate that the eutectic structures in the as-cast alloy begin to decompose, and the grains begin to grow up after the alloy is homogenized at 440 ℃ for 6 h. After heat treatment at 535 ℃ for 16 h, the elements distribute uniformly and the grains grow up obviously, only yttrium element of intermetallic compounds leaves around boundary. The mechanical properties are improved after homogenization, with σb=245 MPa, σ0.2=192 MPa and δ=12%, which are better than those of the as-cast alloy. The flow stress of the homogenized alloy is higher than that of the as-cast alloy and this character is still retained until 450 ℃, but the difference decreases.

Key words: rare earth magnesium alloy; homogenization; microstructure

添加稀土元素可以提高镁合金室温和高温力学性能,改善合金的成形能力,因此稀土镁合金的研究与应用一直是国内外研究的热点[1?3]。熔炼过程中普遍存在由于非平衡凝固造成元素偏析[4?5],对合金的变形能力造成很大影响。均匀化热处理是合金进行变形前的重要过程,它可以明显改善铸态合金中的元素偏析现象,消除共晶组织,减少合金在变形过程中的应力集中点,提高合金的塑性变形能力[6?9],为强化相在随后的时效过程中沉淀析出做准备。马志新等[10]通过对Mg-10Gd-3Y-0.4Zr合金均匀化制度研究得出,温度在热处理过程中起主要作用,最佳的均匀化制度为 510 ℃、12 h。GAO等[11]通过对Mg-15Gd-5Y-0.5Zr合金经500~540 ℃热处理后的性能进行研究得出,经525 ℃、12 h热处理后,合金的综合性能较好。目前关于稀土镁合金均匀化制度的报道还很少,特别是双级均匀化的研究还处在起始阶段,而对于大型高强耐热变形镁合金的需求,使得对原始坯料在变形前的均匀化过程的研究显得十分重要,因此,本实验以 GWN751K合金为研究对象,分析其在均匀化过程中的组织变化规律,建立一种较为合理的双级均匀化制度,为该合金进行热加工提供相对良好的组织,并为在大尺寸条件下对该合金进行均匀化热处理提供一定的实验基础。

1 实验

本实验合金采用中频电磁感应熔炼炉进行熔炼,2#溶剂覆盖保护,纯镁在铁坩埚中熔化,750 ℃加入Y、Gd和Nd纯金属块,升温至820 ℃加入Mg-30Zr中间合金,静置20 min,同时加大电磁搅拌功率,随后降温至720 ℃浇铸,铸锭尺寸为d100 mm×400 mm,车去外表皮和冒口,截取铸锭R/2部位为原始合金,成分如表1所列。

表1 合金化学成分

Table 1 Chemical compositions of GWN751K magnesium alloy (mass fraction, %)

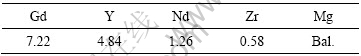

图1所示为GWN751K镁合金的DSC曲线。由图1可看出,低熔点相变区间为546.8~553.5 ℃,设定第一级均匀化温度在380~480 ℃,时间为6 h。根据固相开始熔化温度为605.4 ℃和均匀化退火经验公式Te=0.9?0.95Tm[12],合金的第二级热处理温度选定为505、520及535 ℃,均匀化过程在前期最为剧烈,过分的延长保温时间意义不大[13],所以本实验选择保温时间为2~24 h。将所有经过双级均匀化的试样在220 ℃时效,时间为6 h。对均匀化后的合金进行高温热压缩实验,研究均匀化热处理对合金高温变形能力的影响,变形温度为350~450 ℃,变形速率为0.01 s?1,变形程度为50%(真应变为0.7)。硬度测试在HBS?62.5型小负荷布氏硬度计上进行,加载时间为30 s,重复5次取平均值。材料的拉伸性能在MTS?810型万能试验机上测定,拉伸速度为1 mm/min。在CarlZeiss Axiovet 2000MAT金相显微镜下进行金相组织观察。用荷兰PANalytical公司制造的X' Pert PRO MPD多晶X射线衍射仪进行相分析。利用扫描电镜对合金微区成分及断口进行研究。

图1 铸态GWN751K合金的DSC曲线

Fig.1 DSC curves of as-cast GWN751K magnesium alloy

2 结果与分析

2.1 铸态组织分析

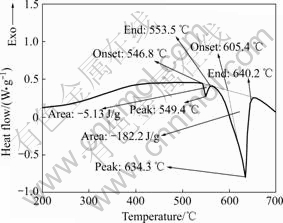

铸态合金的显微组织、XRD谱与EDS谱如图2所示。由图2可看出,合金由α-Mg基体和骨骼状的共晶组织构成,平均晶粒尺寸在35 μm左右(见图2(a))。通过XRD分析可知,除基体外,合金主要的相为Mg24Y5、Mg5Gd及Mg41Nd5(见图2(b))。对合金中骨骼状的共晶组织进行扫描电镜观察(见图2(c))和能谱分析(见图2(d)和(e)),可知共晶组织主要由Mg-Nd- Y-Gd四元素混合相构成,并没有Zr元素。Zr常作为合金形核的核心,起到细化组织的作用[14]。合金在凝固过程中,首先形成树枝状的先共晶α-Mg基体,树枝主干及二次枝晶长大时,溶质原子被排到界面附近的液相中,当富集达到共晶成分时便凝固形成共晶。

图2 铸态合金的显微组织、XRD谱和EDS谱

Fig.2 Microstructures, XRD pattern and EDS spectra of as-cast alloy: (a) OM image; (b) XRD pattern; (c) SEM image; (d) EDS spectrum of area 1; (e) EDS spectrum of area 2

2.2 第一级均匀化处理

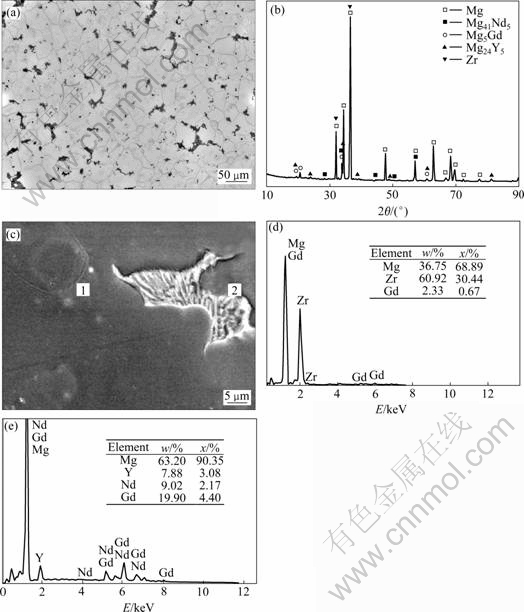

不同温度下合金经过6 h热处理后的显微组织如图3所示。由图3可看出,在380及400 ℃时,合金的共晶组织周围析出了很多棒状相,能谱分析(未给出)其主要为Mg-(GdY)相化合物;当温度超过400 ℃后,先前析出的棒状相回溶,并随着温度的提高,共晶组织分解程度加大,在晶界周围残留一些点状相;当温度超过440 ℃后,晶粒尺寸有所长大。镁合金中第一级均匀化处理的目的是使共晶组织少量回溶至基体

防止在高温状态下发生过烧现象。另外,更重要的目的在于,在大型工业化试验中,由于铸锭尺寸较大,若直接升温至高温状态,铸锭外部晶粒尺寸长大明显,而内部从升高至加热温度,再到元素扩散均匀需要较长时间,在此过程中造成铸锭内外组织差别较大,不利于合金的后续变形。因此,采用双级均匀化的方式,通过观察可知,当温度为440 ℃时,晶粒开始长大,共晶组织已经开始分解,因此选定440℃作为第一级均匀化的温度。

图3 不同温度条件下合金经过6 h热处理后的显微组织

Fig.3 Microstructures of GWN751K magnesium alloy after heat treatment at different temperatures for 6 h: (a) 380 ℃; (b) 400 ℃; (c) 420 ℃; (d) 440 ℃; (e) 460 ℃; (f) 480 ℃

2.3 双级均匀化处理

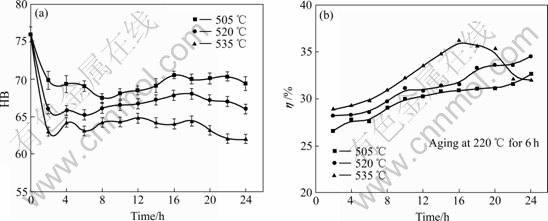

根据菲克第一定律[15],温度是影响原子扩散速度的主要因素,温度越高,原子越容易迁移,扩散系数和扩散速度也就越大,达到均匀化所需的时间也就越短,因此为了缩短均匀化所需的时间,必须提高均匀化温度。合金在不同温度下热处理后,硬度随时间变化曲线如图4(a)所示。3种状态下的合金的硬度曲线变化趋势相近。合金的硬度先下降,然后稍微提高,3条曲线都有各自的峰值。如果合金均匀化充分,在时效过程中就会表现出良好的时效硬化特征,所以本研究提出时效硬化率概念。将全部合金在相同条件下进行时效,时效后的硬度值减去均匀化后的硬度值,再除以均匀化后的硬度值,得出硬化率η。采用硬化率的好处在于硬度值取自同一试样的不同状态,将由合金原始组织差异引起的干扰尽量降低到最小。图4(b)所示为不同状态下合金在相同条件下进行时效后的硬化率曲线。由图4(b)可看出,在505 ℃和520 ℃条件下,合金的硬化率曲线均有上升趋势,而535 ℃条件下的合金硬化率曲线在16 h存在峰值,间接说明在此条件下合金的均匀化效果较好,延长时间,晶粒长大导致均匀化效果降低。

图4 不同均匀化状态时合金硬度和时效硬化率随时间的变化曲线

Fig.4 Change curves of hardness(a) and aging hardening efficiency(b) of GWN751K alloy with time at different homogenization situations

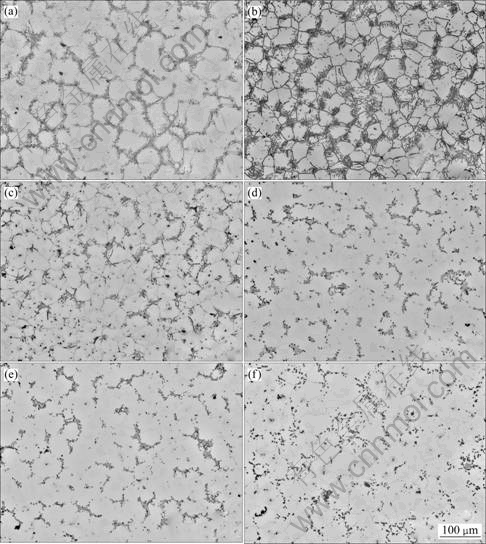

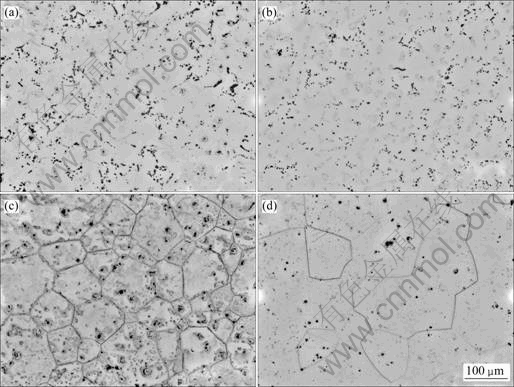

图5所示为不同均匀化温度和时间时GWN751K镁合金的显微组织。由图5可看出,均匀化过程改变合金的晶粒尺寸,与铸态合金相比,共晶组织由原始的骨骼状形态分布于晶粒间,逐渐转变成为小的颗粒状相,有报道称,这种颗粒相是由Mg5(GdY)相转变而来[16]。在505和520 ℃条件下,经24 h处理后,晶界处残留相仍很多,说明以上两种温度过低,共晶组织分解不够充分;在535 ℃条件下,当时间为16 h时(图5(c)),原始的共晶组织几乎完全分解,仅在局部留下少量的未溶相;当时间为24 h时(图5(d)),未溶颗粒相较少且分布较均匀,但晶粒长大较为明显。

图5 不同均匀化温度和时间时GWN751K镁合金的显微组织

Fig.5 Microstructures of GWN751K alloys at different homogenizating temperatures and times: (a) 440 ℃, 6 h+505 ℃, 24 h; (b) 440 ℃, 6 h+520 ℃, 24 h; (c) 440 ℃, 6 h+535 ℃, 16 h; (d) 440 ℃, 6 h+535 ℃, 24 h

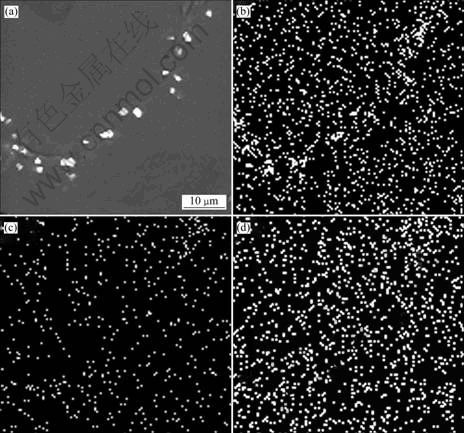

图6所示为合金经过440 ℃、6 h+535 ℃、16 h条件下均匀化热处理后合金的面扫描分析。由图6可看出,经过热处理后,在晶界存在的主要是含Y的化合物,而Gd元素及Nd元素的偏聚现象不明显。由于Mg-Y共晶温度在均匀化温度以上,Mg24Y5具有高温稳定性,易在晶界处残留;Gd元素在镁中的固溶度较大,且共晶温度相对较低,因此扩散相对容易,在晶界没有出现明显的偏聚。另外,由于Nd元素含量较少,且共晶温度同样较低,在晶界处鲜见偏析,说明在此条件下,已经达到了均匀化的目的。综上所述,第二级均匀化制度为535 ℃、16 h。

图6 经过双级均匀化后合金的微观组织相应的晶界元素面扫描分析

Fig.6 Microstructure(a) of GWN751K alloy after two step homogenization and corresponding element scanning analysis of Y(b), Nd(c) and Gd(d)

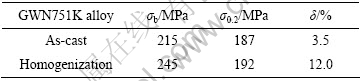

2.4 均匀化前后合金性能比较

表2所列为合金均匀化前后的力学性能。由表2可看出,铸态合金的力学性能较低,经过均匀化处理后,合金的力学性能有所提高,3项指标(σb、σ0.2和δ)分别为245 MPa、192 MPa和12%。

表2 均匀化前后合金的力学性能

Table 2 Mechanical properties of GWN751K magnesium alloy before and after homogenization

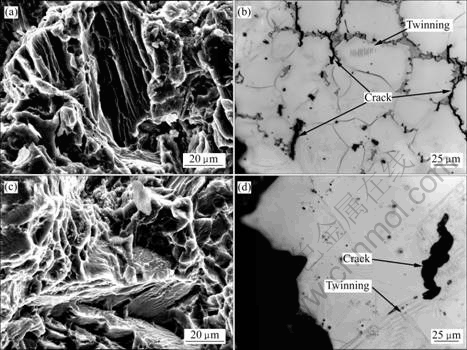

合金的断口形貌及附近显微组织如图7所示。由图7可看出:铸态合金的断裂主要以脆性断裂为主,存在少量的韧窝和撕裂棱(见图7(a));合金的二次裂纹主要存在于晶界处,特别是在共晶组织中(见图7(b)),同时还发现了孪晶。室温条件下合金塑性变形需要5个独立的滑移系,而镁是密排六方结构,室温下仅有3个滑移系,因此孪晶成为其重要的变形机制;经过均匀化后,共晶组织消失,沿晶的二次裂纹也明显减少,合金的韧窝的数量有所增加,塑性提高(见图7(c));二次裂纹主要萌生于晶粒内部(见图7(d))。

图7 不同状态合金的断口形貌及表面微观组织

Fig.7 Morphologies of fractures and microstructures of surfaces of GWN751K magnesium alloys under different conditions: (a) SEM, as-cast; (b) OM, as-cast; (c) SEM, T4 condition; (d) OM, T4 condition

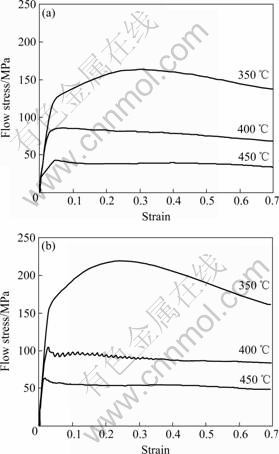

合金均匀化前后热变形曲线如图8所示。由图8可见,两种状态的合金应力均随着温度的升高而下降,均匀化后的合金变形抗力要高于铸态合金的,这种特性在450 ℃条件下仍可保留。

图8 均匀化前后合金的热变形曲线

Fig.8 Hot deformation curves of GWN751K magnesium alloy with strain rate of 0.01 s?1 before (a) and after (b) homogenization

3 讨论

3.1 双级均匀化的原因

对于铝合金而言,双级均匀化往往是低温长时加热配合高温短时加热,目的是使低熔点相发生转变,生成相变点更高的相,防止过烧,完成均匀化过程。通常第一级热处理温度仅比低熔点相的相变温度低一点,两级热处理温度相差很近。而对于镁合金而言,除了防止过烧外,更重要的是防止低熔点相在高温条件下燃烧。由于铝合金室温下可开动的滑移系较多,具有良好的塑性加工能力,而镁合金室温下可开动的滑移系较少,必须进行高温变形,而晶粒的相互协调对提高合金的变形能力有相当重要的意义。因此,对于较大尺寸的镁合金来说,如直接进行高温均匀化处理,很容易造成内外晶粒尺寸差别较大,外部大尺寸晶粒与内部小尺寸晶粒间很难相互协调,而双极均匀化是降低这种差别的办法。

3.2 双级均匀化的作用

第一级均匀化的温度选定为440 ℃、6 h,在此条件下,共晶组织开始回溶,而晶粒尺寸长大有限,该温度下的均匀化作用主要是使铸锭升温,同时让合金元素少量扩散,减少过烧的可能。然后随炉升温至 535 ℃后保温16 h,在此过程中,共晶组织大量回溶,元素扩散加速,均匀化效果明显。经过第一级升温过程,合金内外温差缩小,因此在第二级升温过程中,铸锭心部升至设定温度所需时间缩短,这将有利于元素均衡扩散,晶粒尺寸内外差别减小。由于在24 h内经505 ℃及520 ℃均匀化处理后,仍有大量的未溶相存在,因此必须提高均匀化温度。在535 ℃时,均匀化时间的影响显得尤为重要,保温时间过长导致晶粒尺寸过大,综合分析可知,16 h的效果最好。

3.3 均匀化对合金性能的影响

铸态合金在拉伸变形过程中,二次裂纹主要出现在晶界处的共晶组织中。原因主要是由于硬脆的共晶组织形貌为树枝状,造成应力集中,形成裂纹后便会沿着共晶组织扩展开来。同时,由于晶粒的强度很低,微小的裂纹便会发生穿晶断裂,因此在断口中存在解理台阶。合金经过均匀化处理后,共晶组织消失,存在一定的固溶强化,同时残留的点状相的尺寸说明其对阻碍位错运动有一定的作用,因此,合金的强度有所提高。另外,由于共晶组织的分解,由其造成的应力集中也就不存在,晶粒间整体的协调有益于提高合金的塑性。由此可以发现,合金均匀化后虽然晶粒尺寸明显长大,但力学性能却有所提高,说明合金在拉伸变形时,共晶组织是造成差异的主要原因。从均匀化前后合金的应力应变曲线可以发现,具有典型的动态再结晶特征。均匀化前后合金的应力不同,最主要的原因可能如下:1) 铸态合金变形过程中,共晶组织首先被压碎,并且存在于晶粒间,可有效地起到滑动作用,作为协调合金变形的有效机制[17];2) 被压碎的共晶组织,在晶界处起到诱导动态再结晶的作用[18],因此铸态合金的变形抗力较低;3) 合金的共晶组织分解,溶质原子固溶到基体中,形成固溶强化,对提高合金的变形抗力起到一定作用,这种作用随着温度的提高而下降,两种状态合金变形抗力随温度的升高差别减小。

4 结论

1) 在均匀化过程中,合理的均匀化工艺为440 ℃保温6 h,而后随炉升温至535 ℃保温16 h。经过双级均匀化热处理后,元素分布较为均匀,仅含Y元素的化合物明显残留在晶界,Gd及Nd元素鲜见偏析。

2) 均匀化处理提高合金的室温力学性能,断裂强度为245 MPa,屈服强度为192 MPa,伸长率为12%,均匀化处理后合金的高温变形抗力提高。

REFERENCES

[1] 刘 正, 张 奎, 曾小勤. 镁基轻质合金理论基础及应用[M]. 北京: 机械工业出版社, 2002: 9.

LIU Zheng, ZHANG Kui, ZENG Xiao-qin. Theory basis and application of magnesium matrix light alloy[M]. Beijing: China Machine Press, 2002: 9.

[2] MORDIKE B L. Magnesium properties applications potential[J]. Mater Sci Eng A, 2001, 302: 37?45.

[3] ZHANG Kui, LI Xing-gang, LI Yong-jun, MA Ming-long. Effect of Gd content on microstructure and mechanical properties of Mg-Y-RE-Zr alloys[J]. Trans Nonferrous Met Soc China, 2008, 18(s1): s12?s16.

[4] 杨君刚, 赵美娟, 蒋百灵. 均匀化退火对AZ91D镁合金组织与性能的影响[J]. 材料热处理报, 2008, 29(4): 69?73.

YANG Jun-gang, ZHAO Mei-juan, JIANG Bai-ling. Effect of homogenizing annealing on microstructure and mechanical properties of AZ91D magnesium alloy[J]. Transactions of Materials and Heat Treatment, 2008, 29(4): 69?73.

[5] 李国锋, 张新明, 朱航飞, 李鹏辉. 均匀化处理对7B50铝合金的组织与性能的影响[J]. 特种铸造及有色合金, 2008, 28(5): 344?347.

LI Guo-feng, ZHANG Xin-ming, ZHU Hang-fei, LI Peng-hui. Effects of homogenization treatment on microstructure and properties of 7B50 aluminum alloy[J]. Special Casting and Nonferrous Alloys, 2008, 28(5): 344?347.

[6] 邓子玉, 商琳琳, 张雪飞, 崔建忠. 铸态AZ80 镁合金均匀化处理及高温塑性研究[J]. 特种铸造及有色合金, 2008, 29(3): 258?261.

DENG Zi-yu, SHANG Lin-lin, ZHANG Xue-fei, CUI Jian-zhong. Effects of homogenization treatment on microstructure and high temperature deformation behavior of as-cast AZ80 magnesium alloy[J]. Special Casting and Nonferrous Alloys, 2008, 29(3): 258?261.

[7] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277?288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qi. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277?288.

[8] 李永军, 张 奎, 李兴刚, 赵 欣, 张 凯, 邹京滨, 宋 薇. Mg-Y-Nd-Zr合金均匀化处理工艺及微观组织的研究[J]. 稀有金属, 2008, 32(6): 679?683.

LI Yong-jun, ZHANG Kui, LI Xing-gang, ZHAO Xin, ZHANG Kai, ZOU Jing-bin, SONG Wei. Homogenizing and microstructure of Mg-Y-Nd-Zr alloy[J]. Chinese Journal of Rare Metals, 2008, 32(6): 679?683.

[9] 潘晓林, 孙文儒, 杨树林, 李 战, 郭宁仁, 杨洪才, 胡壮麒. 均匀化过程中铸态GH421合金的组织转变[J]. 材料研究学报, 2008, 22(6): 651?656.

PAN Xiao-lin, SUN Wen-ru, YANG Shu-lin, LI Zhan, GUO Ning-ren, YANG Hong-cai, HU Zhuang-qi. Microstructure transformation during homogenization treatment in as-cast GH742 alloy[J]. Chinese Journal of Materials Research, 2008, 22(6): 651?656.

[10] 马志新, 张家振, 李德富, 张 奎. 铸态Mg-Gd-Y-Zr镁合金均匀化工艺研究[J]. 特种铸造及有色合金, 2007, 27(9): 659?662.

MA Zhi-xin, ZHANG Jia-zhen, LI De-fu, ZHANG Kui. Homogenizing process for as-cast Mg-Gd-Y-Zr magnesium alloy[J]. Special Casting and Nonferrous Alloys, 2007, 27(9): 659?662.

[11] GAO Yan, WANG Qu-dong, GU Jin-hai, ZHAO Yang, TONG Yan. Behavior of Mg-15Gd-5Y-0.5Zr alloy during solution heat treatment from 500 to 540 ℃[J]. Mater Sci Eng A, 2007, 459: 117?123.

[12] 肖 阳, 张新明, 陈健美, 蒋 浩. Mg-9Gd-4Y-0.6Mn合金的微观组织与力学性能[J]. 材料热处理学报, 2007, 28(2): 44?48.

XIAO Yang, ZHANG Xin-ming, CHEN Jian-mei, JIANG Hao. Microstructure and mechanical properties of Mg-9Gd-4Y-0.6Mn alloy[J]. Transactions of Materials and Heat Treatment, 2007, 28(2): 44?48.

[13] WANG Tao, YIN Zhi-min, SUN Qiang. Effect of homogenization treatment on microstructure and hot workability of high strength 7B04 aluminum alloy[J]. Trans Nonferrous Met Soc China, 2007, 17(2): 335?339.

[14] FRIEDRICH H E, MORDIKE B L. Magnesium technology metallurgy, design data, applications[M]. New York: Springer Science+ Business Media, 2006: 81?82.

[15] 邓安华. 有色金属中的原子扩散[J]. 上海有色金属, 1999, 20(1): 36?41.

DENG An-hua. Atomic diffusion in nonferrous metals[J]. Shanghai Nonferrous Metals, 1999, 20(1): 36?41.

[16] HE S M, ZENG X Q, PENG L M, GAO X, NIE J F, DING W J. Precipitation in a Mg-10Gd-3Y-0.4Zr (wt.%) alloy during isothermal ageing at 250 ℃[J]. Journal of Alloys and Compounds, 2006, 421(1/2): 309?313.

[17] MA Ming-long, ZHANG Kui, LI Xing-gang, LI Yong-jun, ZHANG Kang. Hot deformation behavior of rare earth magnesium alloy without pre-homogenization treatment[J]. Trans Nonferrous Met Soc China, 2008, 18(s1): s132?s139.

[18] 余永宁. 材料科学基础[M]. 北京: 高等教育出版社, 2006: 742?743.

YU Yong-ning. Fundamentals of materials science[M]. Beijing: Higher Education Press, 2006: 742?743.

基金项目:国家重点基础研究发展计划资助项目(2007CB613704,2007CB613705)

收稿日期:2009-03-24;修订日期:2009-11-30

通信作者:张 奎,教授,博士;电话:010-82241168;E-mail: zhkui@grinm.com

(编辑 李艳红)