Nd添加对AZ80镁合金显微组织及力学性能的影响

来源期刊:中国有色金属学报(英文版)2012年第6期

论文作者:王亚霄 付俊伟 杨院生

文章页码:1322 - 1328

关键词:AZ80镁合金;Nd;显微组织;力学性能

Key words:AZ80 magnesium alloy; Nd; microstructure; mechanical properties

摘 要:研究添加稀土元素Nd对AZ80镁合金显微组织及力学性能的影响。结果表明:添加1.0% Nd元素可以有效地改善AZ80合金的铸态组织,其晶粒尺寸由448 μm细化至125 μm,凝固组织中出现条状的Al11Nd3相和块状的Al2Nd相,且β-Mg17Al12相显著细化,由连续网状变为不连续分布。时效过程中Nd元素的添加抑制了晶界处不连续析出相的出现,并推迟合金时效峰值的出现。在AZ80合金中添加1.0% Nd时,合金的综合力学性能最佳,屈服强度、抗拉强度和伸长率分别为103.7 MPa、224.0 MPa和8.4%。该合金T6态的屈服强度和抗拉强度分别达到141.1和231.1 MPa。

Abstract: The influence of Nd addition on the microstructures and mechanical properties of AZ80 magnesium alloys was investigated. The results show that the microstructure of as-cast AZ80 magnesium alloy is modified effectively with the addition of 1.0% Nd, the grain size is decreased from 448 to 125 μm, new rod-shaped Al11Nd3 phase and block-shaped Al2Nd phase are observed in the as-cast microstructure, and β-Mg17Al12 phases are refined and become discontinuous. The addition of Nd suppresses the discontinuous precipitations at grain boundaries during aging, and the time of reaching the peak hardness is delayed. With the addition of 1.0% Nd, the combined properties reach an optimum, the yield strength, tensile strength and elongation are 103.7 MPa, 224.0 MPa and 8.4%, respectively. After T6 heat treatment, the yield strength and tensile strength of the AZ80-1.0%Nd alloy are increased to 141.1 and 231.1 MPa, respectively.

![]()

Trans. Nonferrous Met. Soc. China 22(2012) 1322-1328

WANG Ya-xiao, FU Jun-wei, YANG Yuan-sheng

Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China

Received 20 July 2011; accepted 18 October 2011

Abstract: The influence of Nd addition on the microstructures and mechanical properties of AZ80 magnesium alloys was investigated. The results show that the microstructure of as-cast AZ80 magnesium alloy is modified effectively with the addition of 1.0% Nd, the grain size is decreased from 448 to 125 μm, new rod-shaped Al11Nd3 phase and block-shaped Al2Nd phase are observed in the as-cast microstructure, and β-Mg17Al12 phases are refined and become discontinuous. The addition of Nd suppresses the discontinuous precipitations at grain boundaries during aging, and the time of reaching the peak hardness is delayed. With the addition of 1.0% Nd, the combined properties reach an optimum, the yield strength, tensile strength and elongation are 103.7 MPa, 224.0 MPa and 8.4%, respectively. After T6 heat treatment, the yield strength and tensile strength of the AZ80-1.0%Nd alloy are increased to 141.1 and 231.1 MPa, respectively.

Key words: AZ80 magnesium alloy; Nd; microstructure; mechanical properties

1 Introduction

As the lightest structural alloys, magnesium alloys exhibit a good combination of superior castability and higher specific strength. During the last decade, great advances in magnesium alloys have been made due to the lightweight requirement in automotive and aerospace industries [1,2]. Mg-Al-Zn series alloys, as the most commonly used magnesium alloys, including AZ31, AZ80 and AZ91, display excellent castability and low cost. However, the application of these alloys on a large scale is limited by their poor room temperature mechanical properties [3-5]. To extend the application of magnesium alloys, further enhancement in the properties is in great need.

Adding microcontent strengthening elements to the alloys is considered an important approach to improve the properties. Recently, it was reported that the addition of Ca, Sr, Sb and rare earth (RE) elements can improve the mechanical properties of Mg-Al-Zn series alloys effectively [6-11]. HIRAI et al [6] found that with the combined addition of 1.0% Ca and 0.5% Sr (mass fraction) to AZ91 alloy, the grain size was decreased to 20 μm, and the ultimate tensile strength was increased from 228 to 250 MPa. YUAN et al [7] reported that the Sb addition to AZ91 alloy caused some rod-shaped Mg3Sb2 precipitates which can strengthen both the matrix and grain boundaries effectively. The maximum of yield strength was obtained with 0.35% Sb (mass fraction) addition. Further increase of Sb addition results in a slight decrease in the yield strength. ZHAO et al [8] investigated the effect of Y addition on the microstructure and mechanical properties of AZ91 alloy. It was found that with 2.0% Y addition, the average grain size was decreased from 172 to 60 μm, and the ultimate tensile strength of the as-cast alloy was increased from 118 to 145 MPa. In addition, the coarse eutectic β-Mg17Al12 phase was refined, and rod-shaped Al2Y precipitate phase occurred in the microstructure.

Nd is proved to be an effective strengthening element for magnesium alloys, which can purify alloy melt, modify castability, refine the solidified microstructure and improve the mechanical properties and anti-oxidization properties [9]. ZHANG et al [10] investigated the effect of Nd on the microstructure and mechanical properties of Mg-4Al-based alloys. It was found that the grains could be refined, the Mg17Al12 phase was completely suppressed, and the tensile properties and corrosion resistance could also be improved substantially with proper content of Nd. XIE et al [11] reported that proper content of RE (Y and Nd) elements could dramatically refine the grains of AZ81 magnesium alloy, the amount of β-Mg17Al12 phase was reduced, and Al2Y and Al2Nd phases were formed. With the combined addition of 2.0% Nd and Y, the optimum of the ultimate tensile strength at room temperature and 150 ℃ was achieved. However, none of them have referred to the single application of Nd element on the AZ80 magnesium alloys. As the representative of AZ series alloys, AZ80 is mainly used in wheels of automotives after forging deformation. Direct application of as-cast AZ80 magnesium alloy to products can reduce the cost greatly, which is an interesting challenge and has great potentials. However, the mechanical properties of as-cast AZ80 magnesium alloy are too low to satisfy the requirement of wheels. Therefore, it is imperative to improve the mechanical properties of AZ80 magnesium alloy to achieve the aim. Herein, the influence of Nd on the microstructures and mechanical properties of as-cast AZ80 alloy was studied, and the mechanical inactivation mechanism was analyzed as well.

2 Experimental

Four alloys were prepared and the compositions are listed in Table 1. All the alloys were designed based on the AZ80 alloy (Al 8.21%, Zn 0.54%, Mn 0.23% and Mg Bal.) with 0-1.5% Nd addition (mass fraction). Nd was added in the form of Mg-21.26%Nd master alloy. The alloys were melted in a steel crucible in an electric resistance furnace under SF6 and CO2 mixed gas (mixing volume ratio was 1:200). The melt was held at 730 ℃ for 20 min after the alloying elements were dissolved, and then the melt was poured into a steel mold which was preheated to 250 ℃.

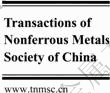

Table 1 Chemical compositions of experimental alloys (mass fraction, %)

The specimens cut from the ingots for uniform heat treatment were held at 415 ℃ for 18 h followed by water quenching in order to delineate the grain boundaries. T6 treatment for the specimens was performed at 200 ℃ for different time.

The tensile tests were carried out on cylindrical samples using an AG-100KNG electronic universal testing machine at a strain rate of 1 mm/min. The hardness of the alloys was measured by an AMH43 Vickers hardness tester under an indenter load of 0.196 N for a loading time of 15 s.

The microstructures were observed by optical microscopy (OM) and scanning electron microscopy (SEM) equipped with an energy dispersive X-ray spectrometer (EDS). The phase composition, structure and morphology were characterized by X-ray diffraction (XRD) and transmission electron microscopy (TEM). The as-cast microstructures for OM and SEM observation were revealed by 1% (volume fraction) ethanedioic acid in water. The samples after uniform heat treatment were etched in a solution of 70 mL ethanol, 6 g picric, 5 mL acetic acid and 70 mL water. Linear intercept method was used to determine the average grain size. The as-aged samples for OM and SEM observation were etched by 1.0% (volume fraction) nitric acid in alcohol. The TEM foils were prepared by twin-jet polishing in an electrolyte of 5% (volume fraction) perchloric acid in alcohol.

3 Results and discussion

3.1 Microstructure

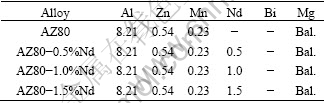

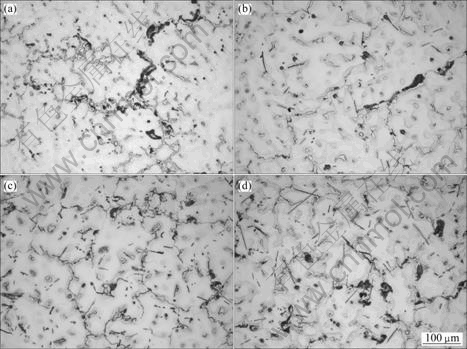

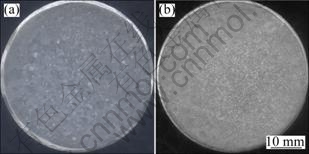

The as-cast microstructures of the experimental alloys are shown in Fig. 1. The as-cast microstructure of AZ80 alloy consists of primary α-Mg matrix, divorced eutectic β-Mg17Al12 phase and secondary precipitated β phase. The eutectic β-Mg17Al12 phase appears in the form of network at grain boundaries, as shown in Fig. 1(a). With the addition of Nd, coarse eutectic β-Mg17Al12 phase is refined and becomes discontinuous, and a new rod-shaped phase occurs, as shown in Figs. 1(b), (c) and (d). With the increase of Nd content, the grain size decreases gradually and reaches a minimum when the content of Nd is 1.0%, as shown in Fig. 2. Figure 3 shows the macrographs of AZ80 and AZ80-1.0%Nd alloy, it can be seen that the grain size is much smaller with 1.0% Nd addition. However, when the content of Nd rises to 1.5%, the rod-shaped phase becomes coarser, as shown in Fig. 1 (d).

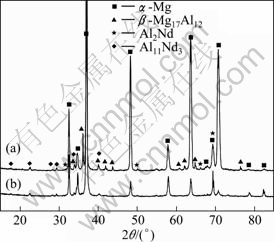

The XRD patterns of AZ80-1.0%Nd magnesium alloy under as-cast and as-solution treated conditions are shown in Fig. 4. It is confirmed that the as-cast microstructure of this alloy consists of α-Mg, β-Mg17Al12, Al2Nd and Al11Nd3 phases [10,12]. After solution treatment, no β-Mg17Al12 phase is found in the XRD pattern, which maybe dissolves into the matrix. Al2Nd and Al11Nd3 phases remain their diffraction peak because of the high melting points of Al2Nd and Al11Nd3 (![]() =1205 ℃ and

=1205 ℃ and ![]() =1235 ℃) [13].

=1235 ℃) [13].

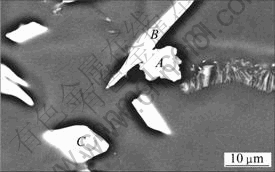

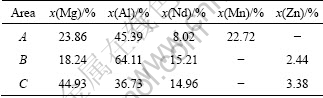

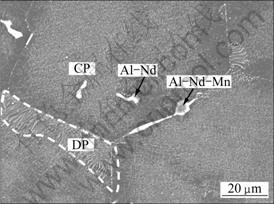

To determine the formation of new phases, SEM and EDS analyses of AZ80-1.0%Nd alloy were carried out, as shown in Fig. 5 and Table 2, respectively. The EDS analysis indicates that both the rod-shaped phase (area B) and block-shaped phase (area C) in Fig. 5 contain Nd element. Combined the XRD pattern (Fig. 4), it can be determined that the rod-shaped phase of area B and the block-shaped phase of area C are Al11Nd3 or Al2Nd. It should be mentioned that the mole fraction of Al and Nd could not be estimated exactly because of the great influence of matrix and β-Mg17Al12 nearby. The rosette-shaped phase (area A), containing Mg, Al, Nd and Mn, is confirmed to be Al-Nd-Mn phase. Al-Nd-Mn phase is not found in the XRD pattern because of the low volume fraction. ZHENG et al [14] studied the microstructure of AZ91 magnesium alloy with the addition of misch metal (MM). It was found that RE can not only form Al-RE phase with Al, but also act with Al and Mn to form Al-RE-Mn phase. The Al-RE-Mn phase is very complicated, and further work should be done to identify its composition and structure.

Fig. 1 OM images of AZ80 (a), AZ80-0.5%Nd (b), AZ80-1.0%Nd (c), AZ80-1.5%Nd (d) alloys

Fig. 2 Average grain size of experimental alloys

Fig. 3 Macrographs of AZ80 (a) and AZ80-1.0%Nd (b) magnesium alloys

Fig. 4 XRD patterns of AZ80-1.0%Nd magnesium alloy under as-cast (a) and as-solution treated (b) condition

Fig. 5 SEM image showing precipitated phases in AZ80- 1.0%Nd magnesium alloy

Table 2 EDS analysis of areas A, B and C in Fig. 4

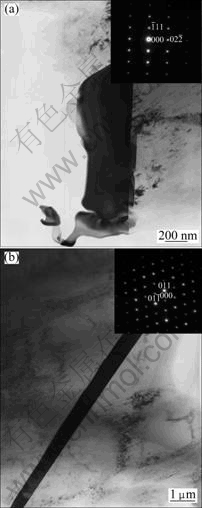

The TEM images and the corresponding selected area electron diffraction (SAED) patterns further confirm that the block-shaped phase (Fig. 6(a)) is Al2Nd (face-centered cubic structure, a=0.8000 nm [15]) and the rod-shaped phase (Fig. 6(b)) is Al11Nd3 (body-centered orthorhombic structure, a=0.4359 nm, b=1.2924 nm, c=1.0017 nm [15]).

Fig. 6 TEM images and SAED patterns along zone axis [211] of Al2Nd phase (a) and [100] of Al11Nd3 phase (b)

The possibility of forming compound between different elements can be examined by the electronegativity difference. The electronegativity differences between Nd and Al, Nd and Mn are 0.47 and 0.41, respectively [16], which are larger than that between Nd and Mg (0.17). Thus, Nd is prone to form compounds with Al and Mn in AZ series alloys. Meanwhile, it can be noticed that the electronegativity difference between Nd and Al is larger than that between Al and Mg (0.30). The addition of Nd can limit the formation of Mg17Al12, which is consistent with the microstructure shown in Fig. 1.

It was reported that [10,17] normal segregation of Nd occurred during non-equilibrium solidification, and Nd would enrich in the liquid ahead of the growing interface. During the solidification, addition of Nd element is expected to generate a constitutional undercooling in the diffusion layer, which can hinder the diffusion of Mg and Al atoms. In addition, further nucleation events can occur when the constitutional undercooling (ΔTc) reaches the undercooling required for nucleation (ΔTn) of α-Mg [18]. Furthermore, the formation of Al2Nd and Al11Nd3 would consume more Al, which reduces the amount of Al solute required for forming β-Mg17Al12. Therefore, with the Nd addition, the grains get refined and the β-Mg17Al12 phases become discontinuous.

3.2 Aging behavior

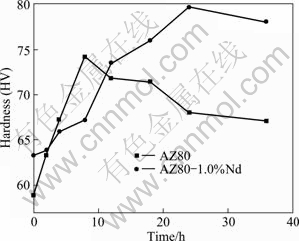

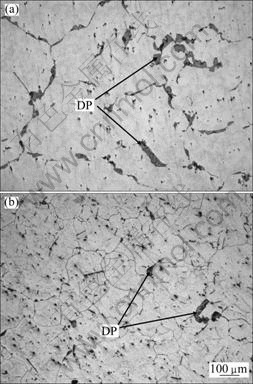

The age-hardening curves of AZ80 and AZ80- 1.0%Nd alloys aged at 200 ℃ are shown in Fig. 7. It can be observed that 8 h is required to reach the peak hardness for AZ80. With the addition of Nd, the increase rate of hardness is slower than that of AZ80 alloy, and the peak hardness appears at 24 h for AZ80-1.0% Nd alloy. This demonstrates that with the addition of Nd, the aging behavior is lagged, and the time of reaching the peak hardness is delayed. The microstructures aged at 200 ℃ for 2 h are shown in Fig. 8. It can be seen that the discontinuous precipitations (DPs) of β-Mg17Al12 phase at the grain boundaries of AZ80-1.0%Nd alloy decreases apparently. This indicates that the addition of Nd depresses the precipitation of discontinuous β-Mg17Al12 phase.

Fig. 7 Age-hardening curves of experimental alloys aged at 200 ℃

Fig. 8 SEM images of AZ80 (a) and AZ80-1.0%Nd (b) alloys aged at 200 ℃ for 2 h

Figure 9 shows the microstructure of AZ80- 1.0%Nd after aging at 200 ℃ for 24 h. The DPs at grain boundaries are increased. Continuous precipitates (CP) are distributed within the grains and some coarse flaky Al-Nd phases and rosette-shaped Al-Nd-Mn phases are studded at the grain boundaries. The Al-Nd and Al-Nd-Mn phases with high melting point remain the initial as-cast morphology after heat treatment because they cannot be dissolved into the matrix during solution treatment.

Fig. 9 SEM image of AZ80-1%Nd alloy aged at 200 ℃ for 24 h

The nucleation and growth of β-Mg17Al12 phase from the supersaturated solid solution appear during the aging of AZ series magnesium alloys. This procedure is controlled by the diffusivity of Al and Mg atoms [19-21]. First, the atomic radius of Nd is larger than those of Mg and Al. Thus, Nd which dissolves in the matrix can impede the diffusivity of Al and Mg. In addition, during aging, Al-Nd phases occupy some crystal defects where it is beneficial to the nucleation for β-Mg17Al12 phase at the grain boundaries, restraining the nucleation of β-Mg17Al12 phase. Therefore, during aging, Nd can hinder the discontinuous precipitations at grain boundaries of AZ80-1.0%Nd alloy to delay the aging process.

3.3 Mechanical properties

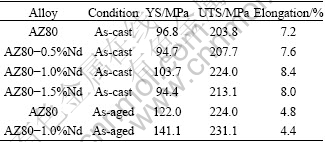

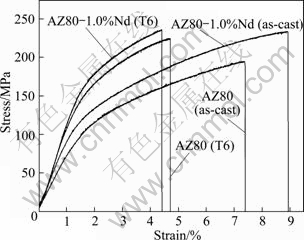

The tensile properties of the alloys, including 0.2% yield strength (YS), ultimate tensile strength (UTS) and elongation are listed in Table 3. It is shown that under as-cast conditions, Nd addition improves the tensile properties compared with AZ80-base alloy. When the content of Nd is 1.0%, the combination properties reach an optimum, in which the YS, UTS and elongation are increased to 103.7 MPa, 224.0 MPa and 8.4%, respectively. However, further increase in Nd amount from 1.0% to 1.5% impairs the tensile properties. After aging treatment, the YS and UTS are increased to 141.1 and 231.1 MPa, respectively, with the addition of 1.0% Nd, while the elongation is decreased compared with the as-cast alloys. The stress—strain curves of the as-cast and as-aged AZ80 and AZ80-1.0%Nd alloys are depicted in Fig. 10. It can be inferred that the combination properties of the AZ80-1.0%Nd alloy reaches an optimum under both as-cast and T6 condition.

Tabel 3 Mechanical properties of experimental alloys

It is well known that fine grains are generally beneficial to the tensile properties of engineering alloys. When 1.0% Nd is added, the grain size is refined from 448 to 125 μm, as shown in Fig. 2. According to Hall-Petch relationship [22], the refinement of grain size would improve the yield strength of the alloy. The maximum solubility of Nd in α-Mg matrix is 3.6%, and the diameter of Nd is larger than that of Mg, so Nd atoms can cause distortion of lattice, hindering the dislocation motion to achieve the solution strengthening. Moreover, the modification of β-Mg17Al12 phase from continuous to discontinuous precipitate and the fine Al2Nd and Al11Nd3 phases can also improve the tensile properties of AZ80 magnesium alloy. However, further increase of Nd leads to the occurrence of coarse Al-Nd phase which splits the α-Mg matrix and is detrimental to the mechanical properties.

Fig. 10 Stress—strain curves of AZ80-1.0%Nd alloy under as-cast (a) and T6 (b) conditions

After T6 heat treatment, the strength of as-aged AZ80-1.0%Nd alloy is improved compared with the as-cast alloy because of the CP of Mg17Al12, as shown in Fig. 8. Furthermore, the dispersion strengthening by Al-Nd phase with high melting point and the decrease of discontinuous Mg17Al12 phase can improve the strength as well.

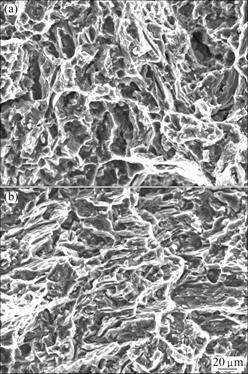

The SEM fractographs of the as-cast AZ80 and AZ80-1.0%Nd alloys are shown in Fig. 11. It can be seen that the addition of 1.0% Nd to AZ80 alloy does not significantly change the fracture pattern of the alloy. The fractograph consists of cleavage planes and some tear ridges. Some secondary cracks are also observed on the fracture surface, as shown in Fig. 11(a). This indicates that the fracture mechanism of AZ80-Nd alloy is quasi-cleavage crack. With the addition of Nd, the fractograph becomes smoother, and the rear ridges tend to be denser, as shown in Fig. 11(b).

Fig. 11 SEM fractographs of as-cast AZ80 (a) and AZ80- 1.0%Nd (b) alloys

For AZ80-1.5%Nd alloy, a large quantity of rod-shaped and block-shaped Al-Nd phases (marked by arrow A, Al2Nd or Al11Nd3) are observed on the fracture surface, as shown in the backscattered image (Fig. 12(b)). The broken phases (marked by arrows B and C) are the crack-initiation, which is identified as Al-Nd phase. Thus, when the content of Nd element exceeds a certain value, the coarse Al-Nd phases are broken first, as the origin of the rupture.

Fig. 12 Fractographs of as-cast AZ80-1.5%Nd magnesium alloy: (a) Second electron image; (b) Backscattered electron image

4 Conclusions

1) With the addition of 1.0% Nd to AZ80 magnesium alloy, the microstructure of as-cast AZ80 magnesium alloy is modified effectively. The grain size is decreased from 448 to 125 μm. The morphology of the primary a-Mg in AZ80D alloy is changed from dendrite to rosette. The coarse eutectic β-Mg17Al12 phase is refined and becomes discontinuous. Rod-shaped Al11Nd3 phase and block-shaped Al2Nd phase occur in the microstructure.

2) The addition of Nd depresses the discontinuous precipitations of β-Mg17Al12 at grain boundaries during aging, and the occurrence of the peak hardness is delayed.

3) Under as-cast condition, Nd addition improves the tensile properties compared with AZ80-base alloy. With the addition of 1.0% Nd, the combined properties reach an optimum, the yield strength, ultimate tensile strength and elongation are 103.7 MPa, 224.0 MPa and 8.4%, respectively. After T6 heat treatment, the yield strength and ultimate tensile strength of AZ80-1.0%Nd are increased to 141.1 MPa and 231.1 MPa, respectively.

References

[1] Mordike B L, Elbert T. Magnesium: Properties-applications- potential [J]. Materials Science and Engineering A, 2001, 302: 37-45.

[2] Song W Q, BEGGS P, EASTON M. Compressive strain-rate sensitivity of magnesium-aluminum die casting alloys [J]. Materials & Design, 2009, 30: 642-648.

[3] MAHMUDI R, KABIRIAN F, NEMATOLLAHI Z. Microstructural stability and high-temperature mechanical properties of AZ91 and AZ91+2RE magnesium alloys [J]. Materials & Design, 2011, 32: 2583-2589.

[4] YAKUBTSOV I A, DIAK B J, SAGER C A, BHATTACHARYA B, MACDONALD W D, NIEWCZAS M. Effects of heat treatment on microstructure and tensile deformation of Mg AZ80 alloy at room temperature [J]. Materials Science and Engineering A, 2008, 496: 247-255.

[5] TANG Wei, HAN En-hou, XU Yong-bo, LIU Lu. Precipitation behavior and effect of new precipitated β phase in AZ80 magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(s3): s1725-s1728.

[6] HIRAI K J, SOMEKAWA H S, TAKIGAWA Y B, HIGASHI K J. Effects of Ca and Sr addition on mechanical properties of a cast AZ91 magnesium alloy at room and elevated temperature [J]. Materials Science and Engineering A, 2005, 403: 276-280.

[7] YUAN Guang-yin, SUN Yang-shan, DING Wen-jiang. Effects of Sb addition on the microstructure and mechanical properties of AZ91 magnesium alloy [J]. Scripta Materialia, 2000, 43: 1009-1013.

[8] ZHAO Zu-de, CHEN Qiang, WANG Yan-bin, SHU Da-yu. Microstructures and mechanical properties of AZ91D alloys with Y addition [J]. Materials Science and Engineering A, 2009, 515: 152-161.

[9] WANG Ying-xin, GUAN Shao-kang, ZENG Xiao-qin, DING Wen-jiang. Effects of RE on the microstructure and mechanical properties of Mg-8Zn-4Al magnesium alloy [J]. Materials Science and Engineering A, 2006, 416: 109-118.

[10] ZHANG Jing-huai, WANG Jun, QIU Xin, ZHANG De-ping, TIAN Zheng, NIU Xiao-dong, TANG Ding-xiang, MENG Jian. Effect of Nd on the microstructure, mechanical properties and corrosion behaviors of die-cast Mg-4Al-based alloy [J]. Journal of Alloys and Compounds, 2008, 464: 556-564.

[11] XIE Jian-chang, LI Quan-an, WANG Xiao-qiang, LI Jian-hong. Microstructure and mechanical properties of AZ81 magnesium alloy with Y and Nd elements [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(2): 303-308.

[12] WANG Jian-li, DONG Han-wu, WANG Li-dong, WU Yao-ming, WANG Li-min. Effect of hot rolling on the microstructure and mechanical properties of Mg-5Al-0.3Mn-2Nd alloy [J]. Journal of Alloys and Compounds, 2010, 507: 178-183.

[13] MASSALSKI T B, OKAMOTO H, SUBRAMANIAN P R, KACPRZAK L. Binary alloy phase diagrams [M]. Materials Park, Ohio: ASM International, 1990: 180.

[14] ZHENG Wei-chao, LI Shuang-shou, TANG Bin, ZENG Da-ben. Effects of mischmetal on microstructure and mechanical properties of AZ91D magnesium alloy [J]. Acta Metallurgica Sinica, 2006, 42: 835-842.

[15] VILLARS P. Pearson’s handbook of crystallographic data for intermetallic phase (desk edition) [M]. Materials Park, Ohio: ASM International, 1997: 170-171.

[16] YAO Yun-bin. Handbook of physical chemistry [M]. Shanghai: Shanghai Scientific and Technical Publishers, 1985: 11. (in Chinese)

[17] AGHAYANI M K, NIROUMAND B. Effects of ultrasonic treatment on microstructure and tensile strength of AZ91 magnesium alloy [J]. Journal of Alloys and Compounds, 2011, 509: 114-122.

[18] LEE Y C, DAHLE A K, St JOHN D H. The role of solute in grain refinement of magnesium [J]. Metallurgical and Materials Transactions A, 2000, 31: 2895-2906.

[19] BRASZCZY?SKA-MARK K N. Discontinuous and continuous precipitation in magnesium-aluminum type alloys [J]. Journal of Alloys and Compounds, 2009, 477: 870-876.

[20] DULY D, SIMON J P, BRECHET Y. On the competition between continuous and discontinuous precipitations in binary Mg-Al alloys [J]. Acta Metallurgica Materialia, 1995, 43: 101-106.

[21] BALASUBRAMANI N, SRINIVASAN A, PILLAI U T S, PAI B C. Effect of Pb and Sb additions on the precipitation kinetics of AZ91 magnesium alloy [J]. Materials Science and Engineering A, 2007, 457: 275-281.

[22] AAKELAND D R, PHUL? P P. Essentials of materials science and engineering [M]. Beijing: Tsinghua University Press, 2005: 103. (in Chinese)

王亚霄,付俊伟,杨院生

中国科学院 金属研究所, 沈阳 110016

摘 要:研究添加稀土元素Nd对AZ80镁合金显微组织及力学性能的影响。结果表明:添加1.0% Nd元素可以有效地改善AZ80合金的铸态组织,其晶粒尺寸由448 μm细化至125 μm,凝固组织中出现条状的Al11Nd3相和块状的Al2Nd相,且β-Mg17Al12相显著细化,由连续网状变为不连续分布。时效过程中Nd元素的添加抑制了晶界处不连续析出相的出现,并推迟合金时效峰值的出现。在AZ80合金中添加1.0% Nd时,合金的综合力学性能最佳,屈服强度、抗拉强度和伸长率分别为103.7 MPa、224.0 MPa和8.4%。该合金T6态的屈服强度和抗拉强度分别达到141.1和231.1 MPa。

关键词:AZ80镁合金;Nd;显微组织;力学性能

(Edited by FANG Jing-hua)

Foundation item: Project (2011BAE22E01-1) supported by the National Key Technology R&D Program of China

Corresponding author: YANG Yuan-sheng; Tel: +86-24-23971728; Fax: +86-24-23844528; E-mail: ysyang@imr.ac.cn

DOI: 10.1016/S1003-6326(11)61321-6