DOI: 10.11817/j.issn.1672-7207.2018.01.006

大直径AZ80镁合金热模锻有限元分析

李慧中1, 2, 3,刘超1,梁霄鹏1,吕凤1,齐叶龙1,朱泽晓1,黄琼1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 粉末冶金国家重点实验室,湖南 长沙,410083;

3. 中南大学 有色金属材料科学与工程教育部重点实验室,湖南 长沙,410083)

摘要:运用Pro/Engineer进行三维造型和建模,结合Deform-3D有限元软件对大直径764 mm AZ80镁合金锻件的热模锻过程进行模拟,分析模具温度对锻件的温度分布、等效应力分布以及上模载荷曲线的影响。根据模拟结果制备大尺寸AZ80镁合金锻件,并采用扫描电子显微镜(SEM)和力学性能测试,分析锻件不同部位的显微组织和力学性能。研究结果表明:当模具温度为350 ℃时,锻件的成形性最好;当模具温度为250 ℃和300 ℃时,锻件的等效应力和上模载荷较大;当模具温度为400 ℃和450 ℃时,锻件的局部温度将会超过400 ℃,容易产生过烧,均不利于加工;锻件中不同位置的流线方向与第2相分布方向一致;在损伤值较小的区域,合金具有更高的强度和伸长率。

关键词:Deform-3D有限元软件;模拟;热模锻;AZ80镁合金;显微组织

中图分类号:TG316 文献标志码:A 文章编号:1672-7207(2018)01-0039-08

Finite element analysis of hot die forging process for large size AZ80 magnesium alloy

LI Huizhong1, 2, 3, LIU Chao1, LIANG Xiaopeng1, 2, L Feng1, QI Yelong1, ZHU Zexiao1, HUANG Qiong1

Feng1, QI Yelong1, ZHU Zexiao1, HUANG Qiong1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

3. State Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,Central South University, Changsha 410083, China)

Abstract: The hot die forging process of  764 mm AZ80 magnesium alloy was simulated by Pro/engineer three-dimensional modeling and Deform-3D finite element software. The forging temperature, effective stress and load-stroke were analyzed under different mold temperatures. According to the simulation results, the large size of AZ80 magnesium alloy was obtained. The microstructures and mechanical properties of different parts of the forging were analyzed by scanning electron microscope(SEM) and mechanical property test. The results show that forging can be made when the mold temperature is 350 ℃. The effective stress value and load-stroke are greater when the mold temperatures are 250 ℃ and 300 ℃, respectively. The forging temperature is more than 400 ℃ when the mold temperatures are 400 ℃ and 450 ℃, respectively, which makes it easy to burn off. The streamline directions of the different positions in the forging are consistent with those of the distribution of the second phase. The alloy has higher strength and elongation rate when the damage value is less.

764 mm AZ80 magnesium alloy was simulated by Pro/engineer three-dimensional modeling and Deform-3D finite element software. The forging temperature, effective stress and load-stroke were analyzed under different mold temperatures. According to the simulation results, the large size of AZ80 magnesium alloy was obtained. The microstructures and mechanical properties of different parts of the forging were analyzed by scanning electron microscope(SEM) and mechanical property test. The results show that forging can be made when the mold temperature is 350 ℃. The effective stress value and load-stroke are greater when the mold temperatures are 250 ℃ and 300 ℃, respectively. The forging temperature is more than 400 ℃ when the mold temperatures are 400 ℃ and 450 ℃, respectively, which makes it easy to burn off. The streamline directions of the different positions in the forging are consistent with those of the distribution of the second phase. The alloy has higher strength and elongation rate when the damage value is less.

Key words: Deform-3D finite element software; simulation; hot die forging; AZ80 magnesium alloy; microstructure

镁合金作为一种密度低、比强度高、比刚度高、切削容易、减震和阻尼性能优良的轻质结构材料,在航空、航天、汽车、电子通讯等领域具有广阔的应用前景[1-4]。镁合金可以通过塑性变形的方式制备出各种规格的板材、棒材、管材、型材以及锻件等,从而满足多种结构件的需求[5-9]。锻造作为一种常见的镁合金塑性加工方法,在制备大尺寸镁合金零件中经常使用,其制得的锻件力学性能优良,稳定性好[10]。然而,当制备大尺寸形状复杂的镁合金模锻零件时,由尺寸效应带来的温度分布和应力分布不均匀等现象,会导致最终模锻成形困难,并且制备的模锻件存在组织和力学性能不均匀等缺点,如何避免这些缺点是目前大型镁合金锻件的研究热点。Deform有限元模拟作为一种重要的塑性变形数值模拟手段,可以直观地反映出合金塑性成形过程中的温度分布、应力分布、损伤现象等,是实际锻造时工艺选择的重要辅助手段[11]。许多零件在锻造时,均采用Deform有限元模拟的手段进行前期模拟研究。SATISHA等[12]采用Deform对前轴梁的成形过程进行数值模拟后,改变了衬垫最佳断面形状,有利于前轴梁的实际模锻成型;CHENG等[13]运用Deform-3D有限元软件模拟了5052铝合金多排链轮在冷半精锻成形过程中流动速度场的分布情况,发现切向速度是决定坯料流体能否充满凹模型腔的关键因素;JIANG等[14]结合Deform-3D有限元研究分析了AZ61镁合金角架触变成形的工艺路线;ZHANG等[15]采用Deform-3D有限元对AZ31镁合金板材冲压的成形过程进行数值模拟,为镁合金板材冲压成形工艺提供了依据;BAIA等[16]结合Deform-3D有限元研究了粉末高温合金的直接锻造工艺,为粉末直接锻造成形坯的几何尺寸和厚度提供了指导;张玉勋等[17]采用Deform对铝合金机轮轮毂在不同工艺参数下的锻造流线进行了仿真分析,发现适当增大坯料与模具之间的摩擦,可以减小流线与锻件表面夹角,从而避免流线露头。本文作者以AZ80为原料,基于刚塑形有限元方法,运用Pro/E与Deform软件对大尺寸形状复杂的AZ80镁合金热模锻过程进行模拟,分析模具温度对热模锻过程的影响。在模拟的基础上进行实际锻造,并对成形件的显微组织及力学性能进行分析。

1 模型的建立

图1所示为拟制备的大尺寸AZ80镁合金零件的结构图和三维图。进行模锻的坯料为经过自由锻获得的预锻坯,形状尺寸如图2所示。根据最终模锻件的形状,运用Pro/E设计出相应的模具,并将坯料与模具的几何模型导入Deform-3D有限元软件中,由于该锻件轴对称,模拟过程取其1/4进行模拟,热模锻的三维实体模型如图3所示。模拟时模具视为刚体,坯料定义为塑性体;根据本研究小组前期对于AZ80镁合金热变形行为的研究结果[18],利用其建立的本构方程,获得本模拟中所需的应力和应变。

在模拟过程中,设定下模固定,上模压下速度为1 mm/s,坯料温度为380 ℃,坯料和模具之间的摩擦因子为0.3,模具温度分别设定为250,300,350,400和450 ℃。

图1 大尺寸AZ80镁合金锻件示意图

Fig. 1 Schematic diagram of large-size AZ80 magnesium alloy forging

图2 模锻前坯料示意图

Fig. 2 Schematic diagram of billet before forging

图3 热模锻三维实体模型

Fig. 3 3D geometrical model for hot die forging

2 模拟结果和分析

2.1 模具温度的影响

图4所示为不同模具温度锻造后锻件的温度分布。从图4可以看出:由于各部位形状和尺寸不同,锻造后的锻件温度存在差异;当模具温度分别为250,300和350 ℃时,锻件较高的温度分布在中心凸起以及凸起与外廓之间的部位。这是因为:与其他部位相比,该区域的坯料变形量大,由变形与摩擦产生的热量多,导致温度高于其他区域的温度;当模具温度分别为400 ℃和450 ℃时,边沿上表面的接触摩擦作用大,产热多,因而较高的锻件温度分布在边沿上表面区域。从整体上看,锻造后锻件的平均温度随着模具温度升高而升高;当模具温度为250 ℃时,锻造后锻件的最低温度为277 ℃,大部分区域的温度在300~350 ℃之间;当模具温度升至450 ℃时,锻造后零件的最高温度达到432 ℃,大部分位置的温度在400~430 ℃之间,这是坯料与模具之间产生了热交换所致;当模具温度低于坯料温度时,坯料向模具传输热量,反之,模具向坯料传输热量。模具与坯料温差越大,热量传输速度越快。从图4还可以看出:当模具温度为350 ℃时,锻件不同位置的最高温度与最低温度相差最小,温度分布均匀。

图5所示为不同模具温度锻造后锻件中的等效应力分布。从图5可以看出:当模具温度为250 ℃时,锻件等效应力分布很不均匀;当模具温度为300 ℃时,较大的等效应力分布在锻件外围;而当模具温度分别为350,400和450 ℃时,锻件等效应力的分布情况大致相同,都是中心凸起区域的等效应力较大,外围边部区域的等效应力较小。从图5中各分图的右边状态栏不难看出:随着模具温度升高,锻造后锻件中的等效应力降低,分布愈均匀;当模具温度为250 ℃时,锻件的最大等效应力达294 MPa,等效应力主要分布在40~110 MPa之间;当模具温度为350 ℃时,锻件的最大等效应力为104 MPa,等效应力主要分布在40~70 MPa之间;而当模具温度升至450 ℃时,锻件的最大等效应力为85.5 MPa,等效应力主要分布在30~65 MPa之间。这种不同模具温度锻造后等效应力的差别与锻件的温度分布密切相关。当温度较高时,原子热运动剧烈,合金中具有明显扩散特性的塑形变形机构(晶间滑移机构、非晶机构)都发挥了作用,使应力降低。随着温度升高,在变形过程中还可能发生动态再结晶而使合金发生软化,两者共同作用使材料的变形抗力降低。

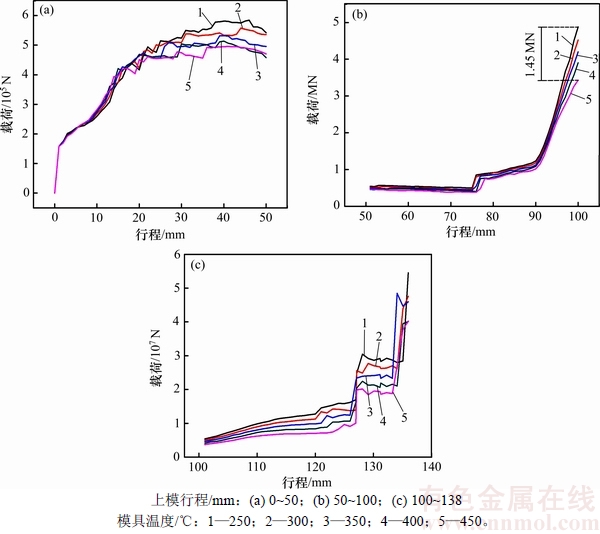

图6所示为不同模具温度下锻造过程中上模载荷的变化曲线。从图6可以看出:不同模具温度条件下的上模载荷曲线变化情况大致相同;模具温度越高,同一阶段对应的上模载荷越小。这是因为模具温度越高,对应的锻件温度越高,金属的流动性越好,变形抗力越小,在变形过程中发生了消除加工硬化的再结晶软化过程。当上模行程为0~50 mm时,锻件的变形量小,变形抗力较低;锻件与模具接触面积小,在变形过程中受到的摩擦阻力小,因而所需的载荷不大,不同模具温度下的上模载荷差距较小。从图6(b)可以看出:当上模行程在90 mm附近时,载荷曲线急剧升高,上模行至100 mm处,对应模具温度250 ℃的上模载荷比模具温度450 ℃的上模载荷高1.450 MN。产生这种现象的原因是:一方面,接触面积急剧增加,摩擦力显著增大,导致载荷增加;另一方面,随着变形进行,金属的加工硬化作用增强,当锻件继续变形时,需要更大的外界作用力。当上模行程为100~138 mm时,上模载荷比前2个阶段的大。这是因为随着模具型腔逐渐被金属填充,金属的流动性减弱,变形抗力增大;此外,接触面积增大也会导致摩擦阻力增大。

图4 不同模具温度锻造后锻件的温度分布

Fig. 4 Temperature distribution of forging after forging with different die temperatures

图5 不同模具温度锻造后锻件的等效应力分布

Fig. 5 Effective stress distributions of forging after forging with different mold temperatures

图6 不同模具温度锻造时的上模载荷分布

Fig. 6 Load-stroke curves under different mold temperatures during forging

从以上不同模具温度锻造的模拟结果可以看出:当模具温度为250 ℃和300 ℃时,锻件的平均温度较低,且温度分布不均匀,对应的等效应力和上模载荷均较大,不利于零件的锻造成形;当模具温度为400 ℃和450 ℃时,锻件的温度分布相对均匀,等效应力和上模载荷较小,但在模拟过程中,锻件局部的温度升至400 ℃以上,而AZ80镁合金在400 ℃以上变形时容易产生氧化腐蚀及过热过烧等现象。当模具温度为350 ℃,锻件温度分布在335~385 ℃,等效应力最大值为104 MPa时,上模载荷较小,有利于大直径AZ80镁合金热模锻成形。

2.2 锻造过程损伤模拟

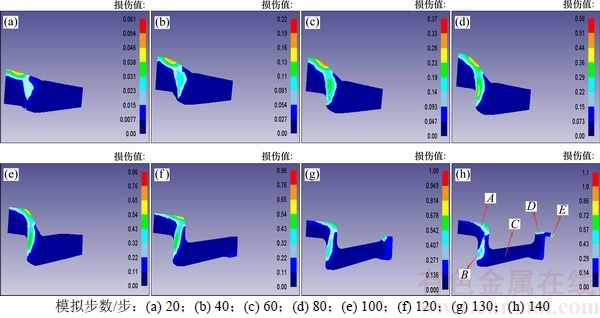

金属材料在伴有拉伸应力的塑性变形过程中存在损伤现象,据物理学观点,损伤可看作是由微空洞和微裂纹的形成和发展,最后成为宏观裂纹;据力学观点,损伤可看作是影响材料强度的状态变量[19]。在Deform-3D有限元软件分析结果的后处理模块中,损伤值能反映金属材料变形过程的这种损伤劣化情况,用于表征材料在加工过程中出现缺陷的难易程度,通常,损伤值越高的位置发生破坏的可能性就愈大。当模具温度为350 ℃,坯料温度为380 ℃,摩擦因子为0.3,上模速度为1 mm/s时,锻造过程中锻件不同时期损伤值分布见图7。从图7可以看出:随着变形进行,锻件的最大损伤值不断增大,从最初的0.061增加到1.100;在变形初期(模拟第20,40和60步),位于上模中心下的坯料损伤较大,这是因为该部分坯料在上模和下模的作用下被拉扯向下运动,变形量相对较大;此外,表面摩擦也起到促进作用;在变形中期(模拟第80,100和120步),中部凸起的损伤值较大,其他区域由于变形量较小,损伤并不明显;金属在上模与下模之间的型腔内流动,该部分的坯料变形量较大;随着接触面积增大,摩擦带来的影响越来越大。变形后期(模拟第130和140步),较大的损伤值分布在锻件的边沿和中央凸起部位。由图7可知:较大的损伤值分布在A,B,D和E区域, C区域的损伤较少。这是由于在相同的变形条件下,变形量大的部位,损伤较严重。

图 7 热模锻过程中的损伤值分布

Fig. 7 Distributions of damage value under hot die forging

3 模锻成形试验验证

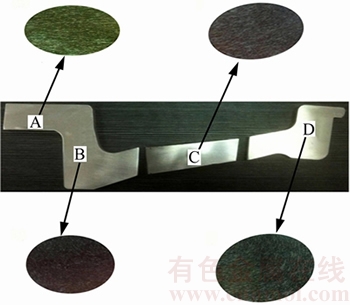

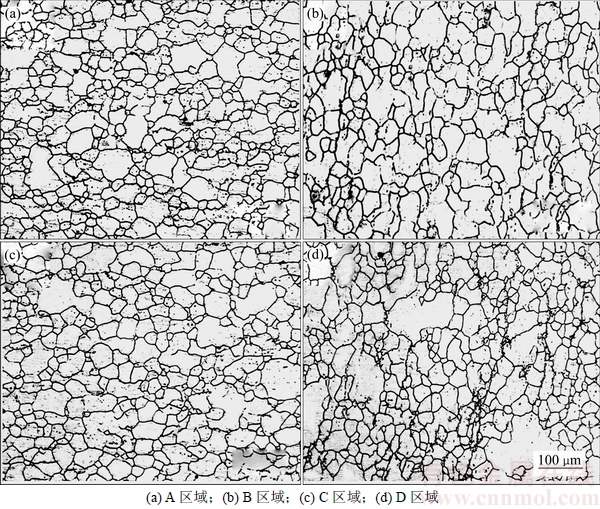

从数值模拟结果可知,当模具温度为350 ℃时,坯料具有较好的模锻成形性。因此,在此条件下对大尺寸AZ80镁合金锻件进行模锻成形试验,获得成形零件。零件表面质量良好,未发现开裂等缺陷。图8所示为模锻件不同位置的宏观流线分布图(腐蚀液为 4%硝酸+96%酒精,体积分数),宏观流线反映了变形过程中的金属流动情况,也是判断锻件成形好坏的重要指标。从图8可以看出:模具型腔内的金属在外力的作用下呈现出不同的流动情况;A区域和C区域的流线呈现水平分布,B区域和D区域的流线呈现出圆弧状。锻件不同位置的金相显微组织见图9。从图9可见:锻件的晶粒分布与宏观流线分布基本相同。

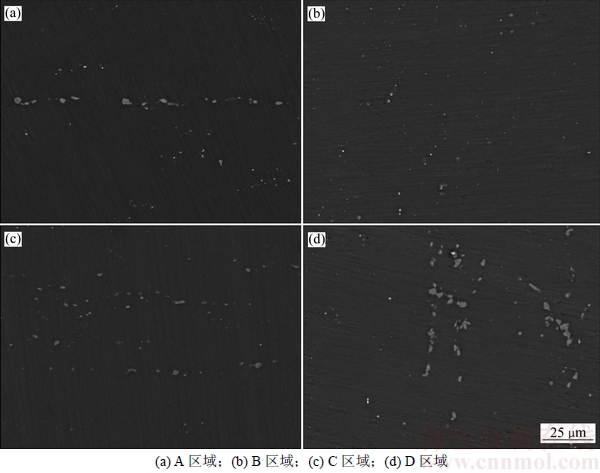

图10所示为锻件不同区域(图8中A,B,C和D)的SEM形貌分布图。从图10可以看出:在不同的变形条件下,对应的第2相粒子分布情况不同;A区域和C区域的第二相粒子呈水平分布;B区域和D区域的第2相粒子呈垂直分布;D区域的第二相粒子分布不均匀,尺寸较大;A,B和C区域的第2相粒子尺寸较小,且分布较均匀。

图8 锻件不同部位的宏观流线

Fig. 8 Flow line distributions of different positions on component

图9 锻件不同位置的金相显微组织

Fig. 9 Metallographic microstructures of different locations on component

图10 锻件不同区域的第2相形貌

Fig.10 The second phase morphology of different locations on component

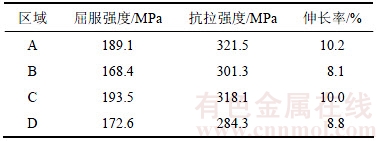

锻件不同位置的力学性能如表1所示。试样的取样区域为图8中A,B,C和D共4处,取样平面垂直于横截面。从表1可见:A区域和C区域的屈服强度、抗拉强度和伸长率均比B区域和D区域的高,这是A区域和C区域的损伤较少、第二相粒子分布较均匀所致。

表1 室温下锻件的力学性能

Table 1 Mechanical properties of forging at room temperature

4 结论

1) 在热模锻过程中,随着模具温度升高,AZ80镁合金锻件整体温度升高,最大等效应力和上模载荷降低。当大尺寸AZ80镁合金热模锻坯料温度为380 ℃时,最佳模具温度为350 ℃。

2) 在大尺寸AZ80镁合金模锻件中,锻件不同部位的宏观流线运动方向与金属粒子分布方向保持一致。

3) 损伤值反映了锻件不同部位的力学性能,损伤值较小的区域对应的屈服强度、抗拉强度和伸长率均比损伤值较大区域的高。

参考文献:

[1] MORDIKE B L, EBERT T. Magnesium: properties- applications-potential[J]. Materials Science and Engineering A, 2001, 302(1): 37-45.

[2] OH-ISHI K, MENDIS C L, HOMMA T, et al. Bimodally grained microstructure development during hot extrusion of Mg-2.4 Zn-0.1 Ag-0.1 Ca-0.16 Zr(at%) alloys[J]. Acta Materialia, 2009, 57(18): 5593-5604.

[3] HERRERA-SOLAZ V, LLORCA J, DOGAN E, et al. An inverse optimization strategy to determine single crystal mechanical behavior from polycrystal test: application to AZ31 Mg alloys[J]. International Journal of Plasticity, 2014, 57(2): 1-15.

[4] BLAWERT C, HORT N, KAINER K U. Automotive applications of magnesium and its alloys[J]. Transactions of the Indian Institute of Metals, 2006, 57(4): 397-408.

[5] XU S W, MATSUMOTO N, KAMADO S, et al. Dynamic microstructural changes in Mg-9Al-1Zn alloy during hot compression[J]. Scripta Materialia, 2009, 61(3): 249-252.

[6] JAIN A, DUYGULU O, BROWN D W, et al. Grain size effects on the tensile properties and deformation mechanisms of a magnesium alloy AZ31B sheet[J]. Materials Science and Engineering A, 2008, 486(1/2): 545-555.

[7] XU S W, KAMADO S, HONMA T. Effect of homogenization on microstructures and mechanical properties of hot compressed Mg-9Al-1Zn alloy[J]. Materials Science and Engineering A, 2011, 528(6): 2385-2393.

[8] LOU Yan, LI Luoxing, ZHOU Jia, et al. Deformation behavior of Mg-8Al magnesium alloy compressed at medium and high temperatures[J]. Materials Characterization, 2011, 62(3): 346-353.

[9] 黎文献. 镁及镁合金[M]. 长沙: 中南大学出版社, 2005: 119.

LI Wenxian. Magnesium and magnesium alloy[M]. Changsha: Central South University Press, 2005: 119.

[10] 吴远志, 严红革, 朱素琴, 等. 锻造方式对 ZK21 镁合金显微组织和力学性能的影响[J]. 中南大学学报(自然科学版), 2015, 46(2): 444-451.

WU Yuanzhi, YAN Hongge, ZHU Suqin, et al.Effects of forging technique on microstructure and mechanical properties of ZK21 magnesium alloy[J]. Journal of Central South University (Science and Technology), 2015, 46(2): 444-451.

[11] 张莉, 李升军. DEFORM在金属塑性成形中的应用[M]. 北京: 机械工业出版社, 2009: 6-10.

ZHANG Li, LI Shengjun. DEFORM in the application of metal plastic forming[M]. Beijing: China Machine Press, 2009: 6-10.

[12] SATISHA G D, SINGHB N K, OHDARB R K. Preform optimization of pad section of front axle beam using DEFORM[J]. Journal of Materials Processing Technology, 2008, 203(1/2/3): 102-106.

[13] CHENG Wangjun, CHI Chengzhong, WANG Yongzhen, et al. 3D FEM simulation of flow velocity field for 5052 aluminum alloy multi-row sprocket in cold semi-precision forging process[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(3): 926-935.

[14] JIANG Jufu, WANG Ying, QU Jianjun, et al. Numerical simulation and experiment validation of thixoforming angle frame of AZ61 magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S3): s888-s892.

[15] ZHANG Shihong, SUN Cheng, WANG Zhongtang. Finite element simulation on press forging of magnesium alloy AZ31 sheets[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(1): 269-272.

[16] BAIA Q, LINA J, JIANGA J, et al. A study of direct forging process for powder superalloys[J]. Materials Science and Engineering A, 2015, 621: 68-75.

[17] 张玉勋, 易幼平, 李云, 等. 铝合金机轮轮毂锻造流线仿真与实验研究[J]. 中南大学学报(自然科学版), 2011, 42(7): 1967-1972.

ZHANG Yuxun, YI Youping, LI Yun, et al. Simulation and experiment research on forging flow lines for aluminum alloy wheel-hub[J]. Journal of Central South University (Science and Technology), 2011, 42(7): 1967-1972.

[18] LI Huizhong, WEI Xiaoyan, OUYANG Jie, et al. Hot deformation behavior of extruded AZ80 magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(11): 3180-3185.

[19] 曹乃光. 金属塑形加工原理[M]. 北京: 冶金工业出社, 1983: 69-75.

CAO Naiguang. Principle of plastic deformation in metals processing[M]. Beijing: Metallurgical Industry Press, 1983: 69-75.

(编辑 陈灿华)

收稿日期:2017-01-29;修回日期:2017-03-26

基金项目(Foundation item):国家自然科学基金面上资助项目(51074186) (Project(51074186) supported by the National Natural Science Foundation of China)

通信作者:梁霄鹏,副教授,从事钛铝金属间化合物,铝合金以及镁合金塑性变形研究;E-mail: mselxp@163.com