文章编号:1004-0609(2014)01-0239-07

铝电解槽电-热场强耦合建模计算方法

徐宇杰,李 劼,尹诚刚,杨 帅,张红亮,吕晓军

(中南大学 冶金与环境学院,长沙 410083)

摘 要:指出广泛使用的铝电解槽电-热场分离的计算方法和电-热场弱耦合计算方法的理论缺陷,提出一种电-热场强耦合计算模型。以某420 kA铝电解槽为对象,同时应用强耦合模型与传统的弱耦合模型对其电-热场进行计算,计算结果证明了在电-热场分析中采用强耦合模型的必要性。研究结果表明:不设定熔体温度是电场和热场实现强耦合的关键,对槽内各热源进行准确描述并引入计算模型中是获得可靠的铝电解槽电-热场分布的必要条件。

关键词:铝电解槽;电-热场;强耦合;热源分布

中图分类号:TF 821 文献标志码:A

Method of strongly coupled modeling and computing for thermal-electrical field in aluminium reduction cells

XU Yu-jie, LI Jie, YIN Cheng-gang, YANG Shuai, ZHANG Hong-liang,  Xiao-jun

Xiao-jun

(School of Metallurgy and Environment, Central South University, Changsha 410083, China)

Abstract: The theoretical defects of the widely adopted separation calculation method and weakly coupled calculation methods for the thermal-electrical field in aluminium reduction cells were pointed out, and a strongly coupled model of thermal-electrical field was presented. The thermal-electrical field of a 420 kA aluminium reduction cell was computed by using the strongly coupled model and the conventional weakly coupled model, respectively, and the results of this comparative computation prove that adopting the strongly coupled model is necessary. The results show that not setting the temperature of the melt is the key to realize the strong coupling of the electrical field and thermal field, and that introducing the each heat source, which are exactly described, into the calculation model is requirement for obtaining the reliable distribution of the thermal-electrical field.

Key words: aluminium reduction cell; thermal-electrical field; strong coupling; heat source distribution

铝电解槽是涉及质量、动量和热量传递过程的复杂熔盐电化学反应器,工业铝电解槽的工作性能受物理场的影响十分显著,合理的物理场分布是电解生产获得良好技术经济指标的关键。对于铝电解槽而言,电场是其运行的能量基础,电场分布不仅直接影响槽内的电化学反应过程,而且在较大程度上决定其他物理场的分布形态。电流通过有一定阻抗的电解槽产生焦耳热,进而形成热场,热场对铝电解生产的影响十分显著,在合理的热场下,铝液和电解质维持在适宜的温度,槽帮的厚度和形状适宜,槽膛内形稳定,而不合理的热场会导致熔体温度过高或过低、槽膛内形不规整且不稳定,从而直接影响电解生产稳定性和槽电压、电流效率等指标[1]。

鉴于电-热场对工业铝电解生产的重要性,长期以来国内外研究者对铝电解槽的电-热场计算方法开展了许多研究,并将其应用于工业铝电解槽的内衬结构设计和电解生产工艺改进中。但是,由于铝电解槽存在多种能量的生成、消耗以及传递途径,且含熔盐和槽帮之间的移动界面问题,其电-热场计算模型和计算方法至今未臻完善。更值得关注的是,有些早期电-热场计算方法仍在工程中大量应用,但其本身却在理论上缺乏论证甚至存在较明显的缺陷(尤其是在处理电场和热场的耦合关系方面存在缺陷),这势必造成研究结论与实际情况之间存在一定的偏差。鉴于该情况,本文作者将先对铝电解槽电-热场的各种计算方法进行分类,从理论上阐明某些计算方法所存在的问题,在此基础上,提出一种较为可靠的铝电解槽电-热场强耦合建模和计算方法,并给出该方法的应用实例。

1 铝电解槽电-热场计算方法分类

铝电解槽获得的能量来源于电流产生的焦耳热,电解槽内电流的非均匀分布及不同材料在导电性上的区别导致了产生热量的区域性差异,这种差异在很大程度上影响了电解槽的温度分布,于此同时,各种材料的电导率受温度的影响显著,电解槽的温度分布也会在一定程度上影响电流分布,由此可见,电场和热场的作用是相互的,即两者之间存在一种明确的强耦合关系。

根据对铝电解槽电-热耦合关系的处理方式的不同,可将电-热场计算方法大致分成3种:电-热场分离计算方法;电-热场弱耦合计算方法;电-热场强耦合计算方法。第一种方法是指在铝电解槽电热场求解过程中有电、热分离计算步骤的方法,一种情况是在热场计算中不耦合电场[2-4];另一种情况是先应用热场模型计算槽帮形状,再根据所得槽帮形状进行电-热场计算[5-6]。显然,该计算方法与上述铝电解槽电热场耦合原理有相悖之处。第二种方法是指在铝电解槽电热场求解过程中虽未出现电、热分离计算步骤,但设定不适宜边界条件使得电-热场无法完全耦合的方法,该方法最显著的特征是计算设定熔体温度,即将熔体温度作为既定参数引入模型[7-10]。实际铝电解槽熔体温度由槽热平衡状态决定,并非设定技术参数,在环境温度已知且槽保温结构固定的情况下,获悉电解槽内的热源(包括产热源和吸热源)大小及分布,便可计算出热平衡条件下的熔体温度,而在设定熔体温度的情况下,热场计算无法完全耦合决定产热源分布的电场,进而无法实现真正的电-热耦合计算。第三种方法则是指完全依据上述电解槽电-热耦合原理进行建模计算的方法,该方法不设定熔体温度,在计算模型中需对各热源(包括产热源和吸热源)进行准确描述(第二种方法须设定熔体温度的原因正在于在其模型中未引入各热源,而将焦耳热作为唯一热源无法求得可靠槽温)。第三种方法正是本文作者所要提出并详细论述的方法。

2 电-热场强耦合模型

2.1 控制方程

对于铝电解槽电场,可根据稳恒电场的电流守恒定律和欧姆定律(微分形式)计算电压和电流分布:

(1)

(1)

(2)

(2)

式中:J为电流密度,A/m2;f为标量电位,V;σ为电导率,Ω-1·m-1。

须注意的是,对于电解槽内某些导电部件(如阴极碳块),其生产加工方式导致材料在各个方向上的不均匀性,使得其电导率呈现各向异性,此时, 应为张量,可表示为

应为张量,可表示为 。

。

此外,电接触现象在铝电解槽体系中广泛存在,尤其对于阳极部分和阴极部分而言,钢爪与碳素阳极连接处的接触压降以及钢棒与碳素阴极连接处的接触压降分别在阳极压降和阴极压降中占很大比例,在电场建模分析中应予以考虑。在不考虑电接触的情况下,接触压降这一槽电压的重要组成部分将被忽略,同时还可能导致计算结果的整体性偏差。

在铝电解槽电场建模中,可引入方程(3)对电接触进行描述:

(3)

(3)

式中:J为通过接触面的电流密度;σc为接触电导率;ft和fc分别为两个接触面对应的电势。

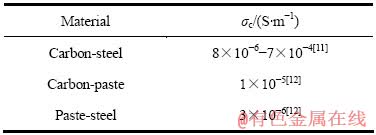

接触电导率σc与温度、压强、接触材料及其表面性质等多个因素有关,可通过实测获得,亦可通过相关理论或经验公式计算获得。表1中列出了相关文献报道的部分接触电导率数据。

在铝电解槽内部,除熔体区域存在热对流外,其他区域主要的传热方式是热传导,由于熔体作较为剧烈的湍流运动,故可将其近似视为等温体。在作此简化的基础上,铝电解槽热场计算的主要控制方程即为稳态热传导方程:

表1 不同材料间的接触电导率

Table 1 Contact conductivity between different materials

(4)

(4)

式中:kx、ky和kz为导热系数,W/(m·℃);t为温度,℃;qs为热源强度(单位体积热产生率),W/m3。

在电解槽的各个区域,主要存在以下热源(生成源或消耗源),须作为控制方程的源项引入模型中:

1) 导电区电流产生的焦耳热

(5)

(5)

式中:σ为电导率,S/m;f为电势,V。

2) 反应区内电化学反应吸收的热量

槽内发生的主体电化学反应(Al2O3(s)+1.5C(s)= 2Al(l)+1.5CO2(g))是吸热反应(反应需要的能量一部分来自以反应电势表征的电能,一部分来自周围环境提供的热能),设通过该反应生成1 mol Al需要向环境吸热ΔH0(CO2的温度取其离开电解槽时的温度,其他反应物及生成物温度取电解温度),则该项单位体积热吸收率为

(6)

(6)

式中:I为通过电解槽的电流强度,A;F为法拉第常数,C/mol;η为电流效率;Vr为反应吸热区域的体积,m3。

3) 电解质区加热物料消耗的热量

加热的物料主要为参与反应的氧化铝和碳,设定氧化铝及碳由室温(25 ℃)加热到电解温度,热焓分别增加ΔH1(J/mol)和ΔH2(J/mol),则生产1 mol铝,加热物料需要的热量为(0.5ΔH1+0.75ΔH2)(J),在考虑电流损失主要通过反应2Al+3CO2=Al2O3+3CO发生的情况下,该项单位体积热消耗率可表示为

(7)

(7)

式中:Vh为物料加热区域的体积,m3。

查阅相关热力学数据手册可知,在900~1 000 ℃的范围内,铝电解主体反应的焓变约为1 094 kJ/mol,折合电能消耗为约5.63 kW·h(每千克Al)。另外,反应物加热所需热量折合为电能约为0.7 kW·h(每公斤 Al) [13]。因此,对于电流为I的电解槽单位时间内加热原料与发生反应总耗能Qr约为

(8)

(8)

除去电化学反应消耗的电能以及阳极气膜阻抗产生的焦耳热,单位时间内尚需从熔体中吸收的热量 Qa为

(9)

(9)

式中:E为反应电势,V;Vg为阳极底掌下的气膜层电压,V。

2.2 边界条件

铝电解槽外表面与周围环境的换热有热对流和热辐射两种方式。对流热损失Qc(J/(m2·s))的计算公式为

(10)

(10)

式中:αc为对流换热系数,J/(m2·s·℃);t1为槽外壁温度,℃;t0为环境温度,℃;A为散热面积,m2。

对流换热系数ac的取值与周围空气的温度、流动状态及槽壁的配置形状有关,可以由无量纲准数努塞尔数Nu表征:

(11)

(11)

式中:k为流体的导热系数;L为表面区域的特征尺寸;努塞尔数Nu 的计算方法可参看文献[14]。

槽表面辐射热损失Qr(J/(m2·s))计算式如下:

(12)

(12)

式中:ε为辐射物体的黑度; 为斯蒂芬-玻尔兹曼常数,5.67×10-8 W/(m2·K4);φ为辐射表面与相邻表面相互辐射角度系数;t1和t0分别为辐射物体壁面温度和周围环境温度,℃;A为辐射物体的辐射表面积,m2。

为斯蒂芬-玻尔兹曼常数,5.67×10-8 W/(m2·K4);φ为辐射表面与相邻表面相互辐射角度系数;t1和t0分别为辐射物体壁面温度和周围环境温度,℃;A为辐射物体的辐射表面积,m2。

对于铝电解槽,在计算辐射热损失时,较为困难的是确定ε和φ值。黑度值ε与物体的性质、表面状况和温度等因素有关,是物体本身的固有特性,与外界环境情况无关,对铝电解槽表面,槽壳为粗糙且已氧化的钢,黑度可取0.8,槽体上部覆盖料的黑度可取0.4,铝导杆的黑度取0.07。对于角度系数的确定,在最简单情况下,即一壁向无限大的空间进行热辐射时,角度系数取1,针对铝电解槽,有的可以近似按此处理,如阳极上盖板的辐射角度系数,而有些则不可。文献[15]中有角度系数取值的报道:上部氧化铝面取0.45,而其他部位简化均取值为0.5。

将辐射散热等效为对流换热,其等效换热系数为

(13)

(13)

槽外综合换热系数αs为

(14)

(14)

铝电解槽环境温度为车间实际温度,上部氧化铝覆盖料的环境温度为烟气温度,均为可测定的值。槽各部位的综合换热系数均与槽壁表面温度t1有关,根据式(10)~(14)可以计算出不同槽表面温度下的综合换热系数。根据综合换热系数和环境温度,可确立槽表面处的热边界条件。

在电场方面,边界条件通常设定如下:在进电端设定进电量,在出电端设定零电位(或者在进电端设定零电位,在出电端设定出电量),其余表面均为绝缘面。

2.3 槽帮形状计算方法

准确计算并获得电解槽内的槽帮形状是电-热场分析的核心内容之一。槽帮对电解槽的热平衡起调节作用,当槽温升高,槽帮表面熔化从而减弱对槽膛的保温,当槽温降低,槽帮表面电解质凝固(槽帮增厚)从而加强对槽膛的保温,当电解槽处于热平衡时,槽帮形状达到稳定。槽帮形状由电解槽的热平衡状态决定,热平衡状态与电场相关,同时,熔体-槽帮界面分布又是电热场计算不可或缺的边界条件,所以槽帮形状计算必须在电-热耦合模型中进行,而槽帮表面温度是否恰为电解质初晶度是判断计算是否获得电解槽热平衡态的主要依据。

在实际计算中,通过反复修正槽帮形状并进行电-热耦合迭代计算,求得槽帮表面各点温度恰为电解质初晶度的热平衡态解,从而在确立槽帮形状的同时获悉电解槽的电场和热场分布。此方法需定义熔体与槽帮之间的对流传热系数hE(J/(m2·s·℃))来描述单位时间单位界面上的换热量Qint(J/(m2·s)):

(15)

(15)

式中:tL和tS分别为槽帮-熔体界面附近熔体和槽帮的温度。

对流传热系数hE与熔体热容、槽帮表面附近熔体流速、流体边界层厚度等因素存在关联,其取值或计算方法可参看文献[16-17]。对于不同容量的铝电解槽,该系数有较大变化,通常情况下,随着电解槽容量增大,槽内熔体流速会相应增大,槽帮和熔体间的对流换热系数也会有所增大。

3 应用实例

本文作者应用上述电-热强耦合计算模型在ANSYS平台上对某420 kA铝电解槽进行电-热场有限元计算,将其计算结果与采用前文所述的第二种方法所得结果进行比较,论证了本模型的可靠性以及弱耦合模型的不准确性。

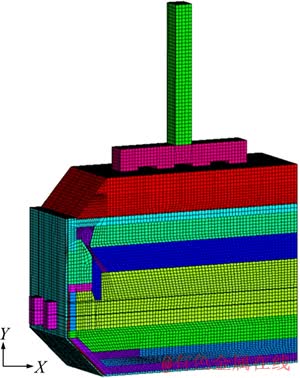

计算采用可表征电解槽电-热场整体状况的大面单阳极模型,其有限元模型如图1所示。所采用的主要工艺条件参数如表2所列,另外,电流效率设定为93%(工业常规值)。根据电解质组成获悉电解质初晶温度约为942 ℃,根据阳极电流密度等参数计算获得反电动势约为1.66 V,阳极气膜压降约为0.17 V。作为热场的边界条件,环境温度设定如下(经现场测定):槽底环境温度为38 ℃,槽周环境温度为40 ℃,上部烟气温度为160 ℃。槽热平衡态及对应槽帮形状通过电-热场迭代计算获得,在制定迭代目标条件时,槽帮表面各点温度与初晶温度间的允许偏差值定为±1 ℃(当槽帮表面各点的温度都在(942±1) ℃范围内时,认为获得平衡态解)。

图1 420 kA槽电-热场计算有限元模型

Fig. 1 Finite element model of thermal-electrical field computation for 420 kA cell

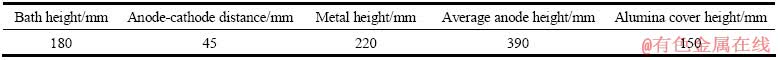

表2 420 kA槽主要工艺参数

Table 2 Main technical parameters of 420 kA cell

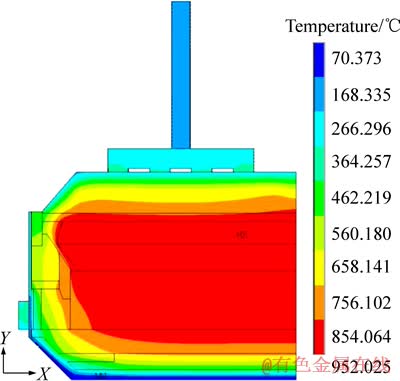

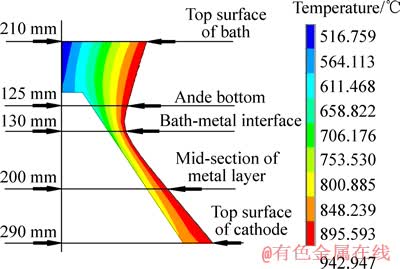

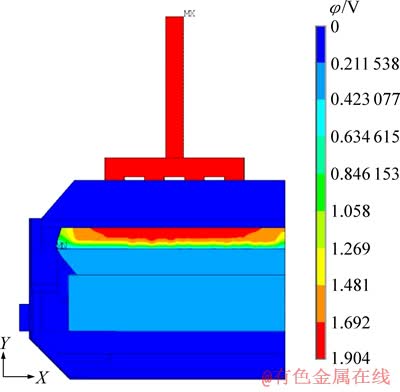

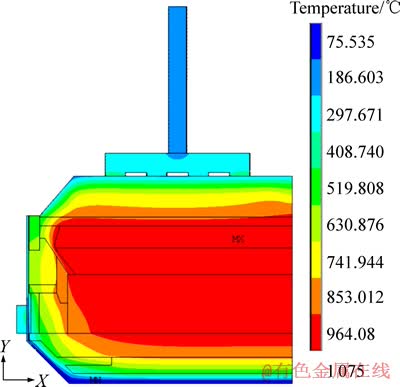

应用本文作者提出的电-热强耦合模型进行迭代计算,所得该420 kA槽温度分布以及槽帮形状分布分别如图2和3所示。由图2可知,槽内最高温度为952 ℃,出现在电解质区(以“MX”标识),这是因为电解质电阻率高,为槽内最大产热体,热量由该区向外传递,最后经槽表面进入环境。由图3可知,该槽的槽帮厚度较为适宜,形状较为规整,未见伸腿肥大等现象,可满足电解生产要求。此外,计算所得槽欧姆压降分布如图4所示,槽体总欧姆压降为1.9 V,属于该型号槽欧姆压降的正常范围。计算未对熔体温度进行设定,且槽帮形状基于热平衡条件通过电-热耦合迭代计算获得,故而图2所示槽温分布及图3所示槽帮分布是该槽在热平衡状态下自然形成,由该槽的保温结构、电场分布、电解质组成及环境温度等因素共同决定。

图2 电-热场强耦合模型计算所得420 kA槽温度分布

Fig. 2 Temperature distribution of 420 kA cell computed with strongly coupled model of thermal-electrical field

图3 电-热场强耦合模型计算所得420 kA槽槽帮形状

Fig. 3 Ledge shape of 420 kA cell computed with strongly coupled model of thermal-electrical field

图4 电-热场强耦合模型计算所得420 kA槽欧姆压降分布

Fig. 4 Ohmic voltage distribution of 420 kA cell computed with strongly coupled model of thermal-electrical field

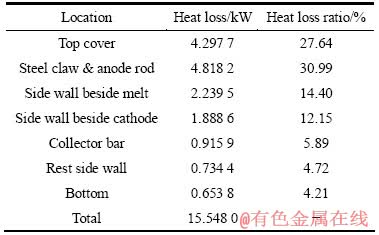

计算所得该电解槽槽表面各区域的散热量分布如表3所列。其中,上部散热量占槽总散热量的58.6%,侧部散热量占总散热量的37.2%,底部散热量占总散热量的4.2%,该散热比例较为适宜,可使电解槽对热平衡的波动具有一定调节空间。

表3 420 kA槽表面各区域散热量分布

Table 3 Heat loss from different surfaces of 420 kA cell

上述强耦合模型在热场计算中除了考虑由电场决定的焦耳热外,还引入电化学反应等吸热源,若只耦合电场结果,即将焦耳热作为唯一热源,则所得电解槽温度场分布如图5所示(假定槽帮厚度不变)。由图5可知,此计算方案下所得槽熔体温度已在1 000 ℃以上,与完整的强耦合模型计算所得结果有较大差别。由此可见,准确描述槽内各热源分布并将其引入计算模型是获得可靠的热场分布的必要条件。

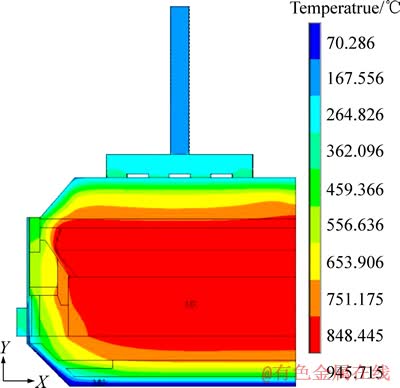

为进行对比,本文作者同时应用电-热弱耦合模型(第二类计算方法)对该420 kA槽在相同保温条件下的热场进行计算。在设定熔体温度为945 ℃的情况下,计算所得的槽温分布如图6所示。显然,945 ℃非该槽在热平衡条件下的实际槽温,但此计算仍可获得收敛解。值得注意的是,计算所得最高温度出现在阴极区域(以“MX”标识,具体位于阴极钢棒与阴极炭糊的接触处,由高接触压降引起),而非熔体区,这是因为熔体温度已设为定值,无法根据该区域实际产热量进行计算(不能耦合电场结果)。此计算结果显然与电解槽的实际热场分布不符,进而证明了第二类计算方法的缺陷。鉴于非强耦合模型的不准确和不可靠性,应尽量避免其在工程计算中应用。

图5 仅考虑焦耳热的电-热场强耦合模型计算所得420 kA槽温度分布

Fig. 5 Temperature distribution of 420 kA cell computed with strongly coupled model of thermal-electrical field merely considering Joule heat

图6 电-热场弱耦合模型计算所得420 kA槽温度分布

Fig. 6 Temperature distribution of 420 kA cell computed with weakly coupled model of thermal-electrical field

4 结论

1) 对铝电解槽电-热场计算方法进行分类,基于铝电解槽电场和热场耦合机理指出电-热场分离计算方法和电-热场弱耦合计算方法存在的理论缺陷。

2) 提出一种铝电解槽电-热场强耦合计算模型,系统论述了电、热边界条件及槽内各热源(包括产热源和吸热源)的数学描述方法,指出不设定熔体温度是电场和热场实现强耦合的关键,而在模型中准确引入各热源是获得可靠热场分布所必须。

3) 应用本研究建立的铝电解槽电-热场强耦合模型对某420 kA槽进行分析,获得该槽全面的与实际相符的电热场分布信息,采用电-热场弱耦合模型分析同一电解槽得到偏离实际的计算结果,进一步论证非强耦合模型的不可靠性。

REFERENCE

[1] 刘业翔, 李 劼. 现代铝电解[M]. 北京: 冶金工业出版社, 2008: 310-312.

LIU Ye-xiang, LI Jie. Modern aluminum electrolysis[M]. Beijing: Metallurgical Industry Press, 2008: 310-312.

[2] BRUGGEMAN J N, DANKA D J. Two-dimensional thermal modeling of the Hall-Héroult cell[C]//BLCKERT C M. Light Metals 1990. Anaheim, CA: TMS, 1990: 203-209.

[3] TOMASINO T, MARTIN C, WAZ E, RENAUDIER S. Numerical modeling of heat transfer around an aluminum reduction pot shell[C]//TABEREAUX A T. Light Metals 2004. Carlotte, NC: TMS, 2004: 433-438.

[4] KISS L I, DASSYLVA-RAYMOND V. Freeze thickness in the aluminum electrolysis cells[C]//DEYOUNG D H. Light Metals 2008. New Orleans, LA: TMS, 2008: 431-436.

[5] 李相鹏. 75 kA导流型铝电解槽物理场仿真与优化[D]. 长沙: 中南大学, 2004: 56-83.

LI Xiang-peng. Physical fields simulation and optimization of the 75 kA drained aluminum reduction cells[D]. Changsha: Central South University, 2004: 56-83.

[6] 李 劼, 王志刚, 张红亮, 赖延清, 徐宇杰. 5 kA级惰性阳极铝电解槽热平衡仿真[J]. 中国有色金属学报, 2009, 19(2): 339-345.

LI Jie, WANG Zhi-gang, ZHANG Hong-liang, LAI Yan-qing, XU Yu-jie. Simulation of heat balance in 5 kA grade aluminum reduction cell with inert anodes[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(2): 339-345.

[7] DUPUIS M. Computation of aluminum reduction cell energy balance using ANSYS finite element models[C]//WELCH B J. Light Metals 1998. San Antonio, TX: TMS, 1998: 409-417.

[8] 李 劼, 邓星球, 赖延清, 刘凤琴,刘业翔. 160 kA预焙铝电解槽在低分子比和低温条件下的三维电热场[J]. 中南大学学报: 自然科学版, 2004, 35(6): 875-879.

LI Jie, DENG Xing-qiu, LAI Yan-qing, LIU Feng-qin, LIU Ye-xiang. 3D thermo-electric of 160 kA prebaked aluminum reduction cell at low cryolitic ratio and temperature[J]. Journal of Central South University: Science and Technology, 2004, 35(6): 875-879.

[9] 崔青玲, 喻海良, 田庭辽, 刘相华, 王国栋. 铝电解槽三维电热场耦合分析[J]. 有色金属: 冶炼部分, 2005(4): 28-30.

CUI Qin-ling, YU Hai-liang, TIAN Ting-liao, LIU Xiang-hua, WANG Guo-dong. 3D thermo-electric coupling analysis of aluminum reduction cell[J]. Nonferrous Metals: Extractive Metallurgy, 2005(4): 28-30.

[10] LU Ding-xiong, MAO Ji-hong, BAN Yun-gang, QI Xi-quan, YANG qing-chen, DONG Hui. Development of NEUI500kA family high energy efficiency aluminum reduction pot(HEEP) technology[C]//LINDSAY J. Light Metals 2011. San Diego, CA: TMS, 2011: 455-460.

[11] HAUPIN W E. Cathode voltage loss in aluminum smelting cells[C]//LOURIE D. Light Metals 1975. New York, NY: Metall Soc of AIME, 1975: 339-349.

[12] 李景江, 邱竹贤. 铝电解槽阴极电场的计算机仿真[J]. 东北工学院学报, 1989, 10(6): 591-597.

LI Jing-jiang, QIU Zhu-xian. Computer simulation of electric field for cathode of aluminium electrolysis cell[J]. Journal of Northeast University of Technology, 1989, 10(6): 591-597.

[13] 杨重愚. 轻金属冶金学[M]. 北京: 冶金工业出版社, 1991.

YANG Zhong-yu. Metallurgy of the light metals[M]. Beijing: Metallurgical Industry Press, 1991.

[14] MCADAMS W H. Heat transmission[M]. New York: McGraw-Hill, 1954.

[15] 邱竹贤. 铝电解[M]. 北京: 冶金工业出版社, 1995: 332-333.

QIU Zhu-xian. Aluminum electrolysis[M]. Beijing: Metallurgical Industry Press, 1995: 332-333.

[16] SOLHEIM A. Some aspects of heat transfer between bath and sideledge in aluminum reduction cells[C]//LINDSAY J. Light Metals 2011. San Diego, CA: TMS, 2011: 381-386.

[17] SEVERO D S, GUSBERTI V. A modeling approach to estimate bath and metal heat transfer coefficients[C]//BEARNE G. Light Metals 2009. San Francisco, CA: TMS, 2009: 557-562.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51274241,51104187);湖南省博士生科研创新项目(CX2011B105)

收稿日期:2013-03-25;修订日期:2013-09-15

通信作者:李 劼,教授,博士;电话:0731-88876454;E-mail:13808488404@163.com