文章编号:1004-0609(2013)08-2302-07

铝熔盐电解过程阳极电流非接触式测试方法

董 英1,周孑民1,李 茂1,周益文1, 2,詹水清1,杨建红2

(1. 中南大学 能源科学与工程学院,长沙 410083;

2. 中国铝业 郑州研究院,郑州 450041)

摘 要:针对铝电解槽电磁场的基本原理,提出一种阳极电流非接触式测试方法即多传感器测试方法。该方法是在每个阳极导杆附近,布置多个测试磁场的传感器,通过调节传感器的组合方式,得到测试点准确的磁场,进而反推得到各阳极导杆的电流分布。建立了铝电解槽的骨架模型,对多传感器测试方法进行验证并优化。结果表明:采用3个传感器的布置方案,阳极电流的测试误差减小,误差分布范围为0.35%~0.90%;在传感器1、2的间距为13 mm,传感器1、4的间距为5 mm的特定布置方案中,阳极电流的测试误差达到最小值,平均误差不超过±0.3%;并且该方法具有安装简单、操作方便、精度高以及可实现在线连续测量等特点。

关键词:铝电解槽;阳极电流;非接触式测试;磁场

中图分类号:TF821 文献标志码:A

Non-contacting measurement of individual anode current of alumina melts electrolysis

DONG Ying1, ZHOU Jie-min1, LI Mao1, ZHOU Yi-wen1, 2, ZHAN Shui-qing1, YANG Jian-hong2

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Zhengzhou Light Metals Research Institute of CHALCO, Zhengzhou 450041, China)

Abstract: Based on the principle of electromagnetic field in aluminum reduction cell, a new non-contacting measurement of individual anode current, i.e., multi-sensor method, was put forward, which was established by placing many magnetic field sensors near each anode rod to achieve the accurate individual anode current by means of adjusting the combination mode of these sensors. Thereby, the individual anode current or anode current distribution could be obtained from the measured magnetic field values. In addition, the skeleton structure model of aluminum reduction cell was also established, which was used for verification and optimization of the method. The results show that the relative errors of the combination mode of three sensors are reduced effectively and distribute between 0.35% and 0.90%. The relative errors of the combination mode of the 13 mm spacing between sensor 1 and sensor 2 and the 5 mm spacing between sensor 1 and sensor 4 are reduced significantly and evaluated to be within ±0.3%. The test method has characteristics of simple structure, easy operation, high precision and online continuous measurement.

Key words: aluminum reduction cell; anode current; non-contacting measurement; magnetic field

长期以来,铝电解槽的工艺参数在线连续检测问题一直是困扰铝电解工艺装备技术和自动控制技术更大发展的难题,电解槽日常生产操作都需要测定的阳极电流分布等工艺参数更是如此。多年以来,国内外铝电解槽的阳极电流分布测量一直是通过人工使用等距压降测定棒的落后方法进行测量,其耗时耗力,不能实现阳极电流分布的在线检测和监控,不利于改善生产操作和管理条件[1-3]。近年来,为了解决电解槽焙烧启动期间的阳极电流分布测量问题,龚文俊等[4]曾开发了采用裸露导线头通过螺母和螺栓固定在阳极铝导杆上进行阳极电流分布测定的装置。但换极时,这种装置需人工拆卸和重新安装,工作量大,操作安全系数低。席灿明[5]和李积刚等[6]研究设计出了阳极电流分布在线检测装置,可实现阳极电流的在线连续测量,但也存在换极时需要拆卸和重新安装的问题。另外,STEINGART等[7]、曾水平等[8-9]、李贺松等[10-12]在阳极电流测试方面做了很多研究。目前,URATA和EVANS等[13-14]提出了通过测量磁场来得到阳极电流分布的方法,实现了阳极电流的非接触式在线连续测量。然而,此方法一方面没有考虑对水平和垂直两个方向上测试磁场的修正,测量误差较大;另一方面,每根导杆电流值的计算方法与整个磁场的平均值相关联,由磁场到电流的推导过程中,若一个磁场值出错,将导致整个测试结果出错[15-16]。基于此,本文作者在对铝电解槽电磁场基本原理研究的基础上,提出了用多传感器的磁场测试值获取阳极电流分布的方法。该方法可以直接由测定的磁场值反推得到阳极电流分布,解耦了铝电解槽中磁场和电场相互耦合的关系,避免了因某一个磁场测试数据的出错或缺失,而造成整个测试结果的出错;测试精度高、稳定性好,并且可实现阳极电流的在线监测和控制。

1 理论分析

电荷的定向移动形成电流,而运动的电流周围又会存在磁场。电流产生磁场的规律,可以由Biot-Savart定律和磁场叠加原理求出。依此原理,若能测得阳极导杆附近的磁场,则反推就可得到相应阳极导杆的电流分布[17-18]。

根据Biot-Savart定律,若将阳极导杆抽象成通电直导线,如图1所示,则阳极导杆周围的磁场(B)可表示为

(1)

(1)

式中: ,是真空的磁导率;I为导杆中的电流;r0为测试点到导杆的距离;

,是真空的磁导率;I为导杆中的电流;r0为测试点到导杆的距离; 、

、 为测试点到导杆两端的夹角。

为测试点到导杆两端的夹角。

然而实际工业中,铝电解槽阳极导杆有具体的长、宽和高,传感器安装位置与导杆间的距离又很小,因此,导杆形状对测点位置的磁场有着很大的影响,不能将导杆抽象成直导线,所以得到导杆周围磁场计算的积分式:

(2)

(2)

式中:b-a之差为导杆(或平衡母线、立柱)的宽度;d-c之差为导杆(或平衡母线、立柱)的厚度。

图1 阳极导杆周围磁场计算原理图

Fig. 1 Sketch of calculating magnetic fields near anode rod

为了计算方便,将式(2)中关于y的积分用N等份近似求和的形式代替,并且将磁场分解到铝电解槽长轴方向,则可得到Bx为

(3)

(3)

若令

(4)

(4)

则

(5)

(5)

因此,测得阳极导杆附近的磁场后,就可运用式(5)得到铝电解槽阳极电流分布。

2 测试方法

2.1 多传感器测试方法

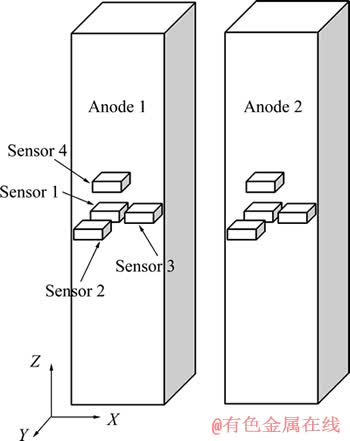

图2所示为只考虑两根导杆时多传感器测试磁场的原理图。从图2可以看出,每根导杆附近都装有4个传感器来测试该导杆附近的磁场。分析知,1号导杆中的电流在传感器1和2位置产生的磁场大小只与两个传感器到导杆的距离有关,因此是呈线性关系的。然而,与1号导杆毗邻的2号导杆产生的磁场会对传感器1、2的读数造成一定的影响,甚至其他导杆也会在一定程度上影响传感器1和2的读数。但是,与1号导杆对两个传感器读数影响相比,2号导杆的影响要小得多,并且,由于2号导杆距传感器1和2的距离很远,它对传感器1和2的影响几乎是相同的,所以,取传感器1和2的读数之差,就可消除2号导杆对传感器1在纵深方向上的影响。同理,取传感器1分别与传感器3和4之差,就可消除2号导杆在水平方向和竖直方向上对传感器1的影响。

图2 多传感器测试导杆附近磁场原理图

Fig. 2 Sketch of measuring magnetic fields by multi-sensor method

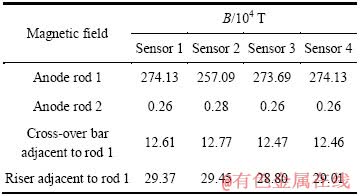

表1所列为分别给图2中各部件供电,从而得到的各部件对导杆1附近磁场的影响值。从表1可以看出,导杆1对传感器1、2的影响相当显著,而与导杆1相比,导杆2的影响要小得多,并且,在这两个传感器上的差别(0.26-0.28=-0.02)几乎可以忽略;导杆1附近的平衡母线与立柱尽管对这两个传感器的影响都不是很小,但是其在这两个传感器上的影响差别(12.61-12.77=-0.16×104 T和29.37-29.45=-0.08×104 T)是非常小的;再将传感器1的值分别与传感器3、4的值作比较不难发现:1号导杆和2号导杆对传感器1、3和4的影响几乎是相同的,只是平衡母线和立柱对这3个传感器的影响有差别,这样,再用传感器3和传感器4的读数对传感器1和2的差值进行修正,就可以消除其他导杆以及平衡母线、立柱在X、Y、Z 3个方向上的影响。另外,表1中数值均是以槽子的长并且水平方向为基准,而阳极连接母线正好处在这个方向上,因此,阳极连接母线中的电流不会对传感器有影响。

表1 各部件对导杆1附近磁场传感器的贡献

Table 1 Various component contributions to magnetic fields at four sensors near anode rod 1

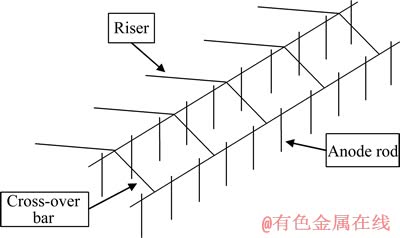

2.2 建立铝电解槽骨架模型

为了验证前文提出的多传感器测试铝电解槽阳极电流方法的准确度,本文作者建立了如图3所示的铝电解槽骨架模型,从图3可以看出,模型包括阳极导杆、平衡母线和立柱3个部分,由于阳极炭块、电解质及电解质以下的部分对传感器读数的影响十分微弱,因此,在骨架模型中它们被忽略。另外,阳极连接母线也没有建立在骨架模型之内,因为阳极连接母线正好处在传感器被安装的槽子的长轴水平方向,因此不会对传感器的读数有影响。

图3 铝电解槽骨架模型示意图

Fig. 3 Schematic diagram of skeleton structure model

3 结果与分析

以某电解铝厂300 kA系列电解槽为研究对象,采用前文提出的多传感器阳极电流测试方法,并结合图3中建立的铝电解槽骨架模型,对其阳极电流进行计算。图4所示为骨架模型中阳极导杆的分布。

图4 骨架模型中阳极导杆的分布图

Fig. 4 Numbering system of anodes used in skeleton model

3.1 不同传感器组合方式对结果的影响

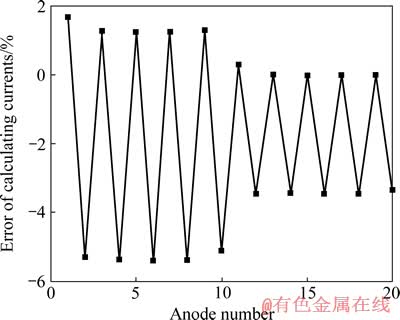

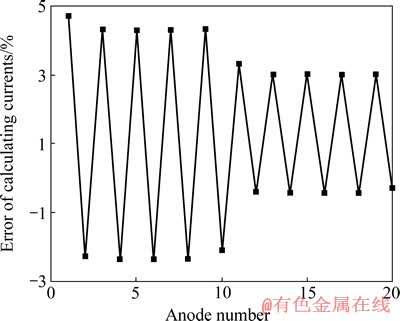

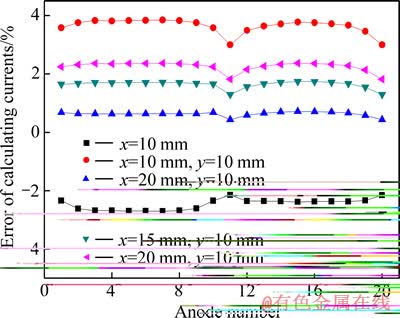

不同的传感器组合方式肯定会对计算电流的误差产生不同的影响,基于前文提出的多传感器测试方法,在此,选取4种不同的组合方式,讨论分析它们的电流误差分布,图5~8所示为不同组合方式下计算电流误差的分布图。

对比图5和图6可见,当在原来传感器1和2的基础上,再增加传感器4对测试磁场进行修正时,计算电流的误差得到了大幅度的改善,最大误差从原来的-2.7%减小到了0.9%,并且各导杆误差主要集中在0.35%和0.7%之间。但是,比较图5和图7发现,当在原来传感器1和2的基础上,再增加传感器3对测试磁场进行修正时,计算电流的误差不仅没能得到改善,反而被大幅度地放大,最大误差由原来的-2.7%增大到了-5.5%,而且误差的分布出现了强烈波动,误差分布范围从原来的-2.1%~2.7%变化为-5.5%~ 2%。从图8中可以发现,当同时增加传感器3和传感器4时,计算电流时虽在图7的基础上稍有改变,然而改变的幅度相当有限,与图6比较可见,图8中的误差不仅没得到有效改善,而且还被大幅度地放大,并且与图7相似,也出现了大幅度的波动。

当传感器4存在时,计算电流的误差得到了良好改善,然而当增加传感器3修正时,计算电流的误差被大幅度地放大,而且还出现了剧烈的波动;分析可知,立柱和平衡母线对相邻传感器有着显著的影响,并且对与传感器之间的距离敏感,而新增传感器3没能安装在相邻平衡母线和立柱的中间位置,这导致了与相邻平衡母线和立柱间出现了明显的距离不相等,因此,当增加传感器3后,计算电流的误差出现了剧烈波动,而增加传感器4不会存在这样的问题。

综上所述,为修正测量磁场、改善计算电流误差,应采用传感器1,2和4的组合方式。

图5 传感器1和2组合时计算电流误差分布曲线

Fig. 5 Error distribution curves of calculating currents with sensors 1 and 2

图6 传感器1、2和4组合时计算电流误差分布曲线

Fig. 6 Error distribution curves of calculating currents with sensors 1, 2 and 4

图7 传感器1、2和3组合时计算电流误差分布曲线

Fig. 7 Error distribution curves of calculating currents with sensors 1, 2 and 3

图8 传感器1、2、3以及4组合时计算电流误差分布曲线

Fig. 8 Error distribution curves of calculating currents with sensors 1, 2, 3 and 4

3.2 测试方法的优化

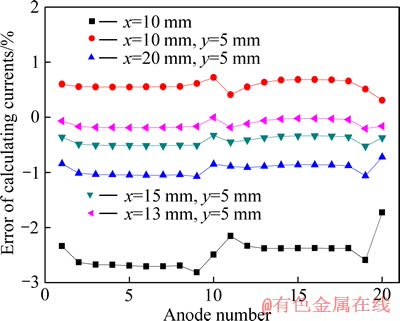

基于传感器1、2和4组合方式测试铝电解槽阳极电流的方法,选取4种传感器1、2间距和2种传感器1、4间距的组合方案,通过磁场计算了各导杆的阳极电流,图9~14所示为不同方案下计算电流误差的分布曲线。图中,x代表传感器1、2的间距,y代表传感器1、4的间距。

图9和10所示为导杆电流均匀分布时阳极电流的误差分布曲线。从图9可见,增加传感器4修正可以改善计算电流的误差,且传感器不同间距的搭配对计算电流的误差有着显著的影响。当传感器1、2间距为20 mm、传感器1、4间距为10 mm时,计算电流的误差减小到0.6%左右,而且几乎没有波动,分布平稳。再与图10比较可以发现,当将传感器1、4的距离减小到5 mm时,计算电流的误差得到了更好的改善,最大误差不超过±1%,而对于传感器1、2间距13 mm、传感器1、4间距5 mm的情况,计算电流的误差达到最小值,不超过±0.3%。

图11和12所示为20号导杆电流超载时阳极电流的误差分布曲线。从图中可见,有传感器1、4修正的计算电流误差同样得到了明显的改善,误差也没有较大的波动,分布平稳。还可以看出,当传感器1、4间距10 mm时,而传感器1、2间距20 mm时,计算电流的误差最小,只有0.8%左右;在5 mm修正中,传感器1、2间距13 mm修正中,计算电流的误差只有±0.2%。再与图9和10比较可以发现,由于20号导杆电流过载,20号导杆的计算电流误差在不同传感器组合下变化最大,但随着修正电流误差的迅速减小,在误差最小的传感器1、2间距13 mm、传感器1、4间距5 mm组合中误差只有-0.16%。

图9 均匀电流下传感器1、4间距10 mm修正误差分布曲线

Fig. 9 Error distribution curves of sensors 1 and 4 with 10 mm spacing at uniform anode rods current currents

图10 均匀电流下传感器1、4间距5 mm修正误差分布曲线

Fig. 10 Error distribution curves of sensors 1 and 4 with 5 mm spacing at uniform anode rods current

图11 20号导杆电流超载时传感器1、4间距10 mm方案误差分布曲线

Fig. 11 Error distribution curves of sensors 1 and 4 with 10 mm spacing except for anode 20 currents being uniform

图12 20号导杆电流超载时传感器1、4间距5 mm方案误差分布曲线

Fig. 12 Error distribution curves of sensors 1 and 4 with 5 mm spacing except for anode 20 currents being uniform

图13 5号导杆电流超载时传感器1、4间距10 mm方案误差分布曲线

Fig. 13 Error distribution curves of sensors 1 and 4 with 10 mm spacing except for anode 5 currents being uniform

图14 5号导杆电流超载时传感器1、4间距5 mm方案误差分布曲线

Fig. 14 Error distribution curves of sensors 1 and 4 with 5 mm spacing except for anode 5 currents being uniform

图13和14所示为5号导杆电流超载时,阳极电流的误差分布曲线。从图中可见,与图11、图12相似,有传感器4修正的计算电流误差得到了显著改善,在传感器1、4间距5 mm修正中,传感器1、2间距为13 mm时,电流误差最小,只有-0.2%。与图9、图10比较可以发现,5号导杆的电流误差变化最大,从-2%到3%,这是因为5号导杆的电流超载。当增加传感器4,计算电流的误差迅速减小,在传感器1、2间距13 mm、传感器1、4间距5 mm组合的方案中,误差变化范围只有-0.25%~0。

综上所述,在传感器1、2间距为13 mm、传感器1、4间距为5 mm的组合中,各种工况下阳极导杆电流误差均达到最小值,误差不超过±0.3%。

4 结论

1) 通过对铝电解槽电磁场理论的研究,提出了直接由测定的磁场反推阳极电流的计算方法,解耦了铝电解槽中磁场和电场相互耦合的关系,避免了因某一个磁场测试数据的出错或缺失,而造成整个测试结果的出错。

2) 通过多方案对比分析,提出了采用3个传感器的特定布置方案,消除了阳极导杆前后和上下4个方向上的测量误差,明显地提高了阳极电流的测量精度,平均误差仅为±0.3%。

3) 利用霍尔效应原理,实现了铝电解槽阳极电流的非接触式测量,测量过程不会因更换阳极而中断,可实现在线连续测量,能够不间断地监视实际工业生产中阳极电流的实时变化,及时预警阳极效应,以及减少阳极脱落等操作问题的发生,提高电流效率。

REFERENCES

[1] YUE Qiang, WANG He-ming, LU Zhong-wu. Quantitative estimation of social stock for metals Al and Cu in China[J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1744-1752.

[2] EVANS J W. The evolution of technology for light metals over the last 50 years: Al, Mg and Li[J]. JOM, 2007, 59(2): 30-38.

[3] AMPHLETT J C, PEPPLEY B A, HALLIOP E, SADIQ A. The effect of anode flow characteristics and temperature on the performance of a direct methanol fuel cell[J]. Journal of Power Sources, 2001, 96(1): 204-213.

[4] 龚文俊, 裴朝阳, 罗以民, 聂 英. 便携式阳极电流测试仪: 中国, 200920230039[P]. 2010-09-29.

GONG Wen-jun, PEI Zhao-yang, LUO Yi-min, NIE Ying. Portable anode current meter: China, 200920230039[P]. 2010-09-29.

[5] 席灿明. 阳极电流分布在线监测装置: 中国, 200610200170[P]. 2007-03-07.

XI Can-ming. Online monitoring device of anode current distribution: China, 200610200170[P]. 2007-03-07.

[6] KAR P, EVANS J W. A model for the electrochemical reduction of metal oxides in molten salt electrolytes[J]. Electrochimica Acta, 2008, 54(2): 835-843

[7] STEINGART D A, EVANS J W, WRIGHT P K, ZIEGLER D. Experiments on wireless measurement of anode currents in hall cells[C]// HALVOR K. Light Metals 2005. San Francisco, CA, USA:TMS, 2005: 333-338.

[8] 曾水平, 张秋萍. 预焙铝电解槽电流效率与阳极电流分布的数学模型[J]. 中国有色金属学报, 2004, 14(4): 681-685.

ZENG Shui-ping, ZHANG Qiu-ping. Mathematical model of current efficiency with anode current distribution in aluminum production[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(4): 681-685

[9] 李春艳, 曾水平. 铝电解槽阳极工作状态故障诊断系统研究[J]. 自动化技术与应用, 2004, 23(7): 49-51.

LI Chun-yan, ZENG Shui-ping. Research fill fault diagnosis system for the operating mode of the anode of the aluminum reduction cell[J]. Techniques of Automation and Applications, 2004, 23(7): 49-51.

[10] LI He-song, MEI Chi, ZHOU Nai-jun, TANG Qian, HUANG Yong-bo. Diagnosis of working conditions of an aluminum reduction cell based on wavelet packets and fuzzy neural network[J]. Chemical Engineering and Processing: Process Intensification, 2006, 45(12): 1074-1080.

[11] 李贺松, 殷小宝, 韦隆和, 黄涌波, 唐 骞, 单 峰. 不同槽况下160 kA 铝电解槽阳极电流的频谱分析[J]. 中国有色金属学报, 2010, 20(5): 999-1005.

LI He-song, YIN Xiao-bao, WEI Long-he, HUANG Yong-bo, TANG Qian, SHAN Feng. Spectral analysis of anode current for 160 kA aluminum reduction cells in different states[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 999-1005.

[12] 李贺松, 殷小宝, 黄涌波, 丁立伟, 姜昌伟. 基于阳极电流波动的铝电解槽槽况诊断系统[J]. 化工学报, 2011, 62(6): 1770-1777.

LI He-song, YIN Xiao-bao, HUANG Yong-bo, DING Li-wei, JIANG Chang-wei. Diagnosis system of different status of aluminum reduction cells based on anode current fluctuation[J]. CIESC Journal, 2011, 62(6): 1770-1777.

[13] EVANS J W, URATA N. Wireless and non-contacting measurement of individual anode currents in Hall-Héroult pots; experience and benefits[C]// CARLOS E. Light Metals 2012. Orlando, FL, USA: TMS, 2012: 939-942.

[14] URATA N, EVANS J W. The determination of pot current distribution by measuring magnetic fields[C]// JOHN A J. Light Metals 2010. Seattle, WA, USA: TMS, 2010: 473-478.

[15] TARCY G, TABEREAUX A. The initiation, propagation and termination of anode effects in hall-heroult cells[C]// LINDSAY S. Light Metals 2011. Warrendale, PA, USA: TMS, 2011: 473-478.

[16] STEINGART D A, EVANS J W. Determining electrical current using at least two sensors at a known distance from each other: USA, 8125241B1[P]. 2012-02-28.

[17] 袁国胜, 刘浙华. 霍尔效应测量大电流的理论探讨[J]. 中国测试技术, 2005, 31(2): 15-18.

YUAN Guo-sheng, LIU Zhe-hua. Measuring the big-electric current with hall effect[J]. China Measurement Technology, 2005, 31(2): 15-18.

[18] 李 劼, 张红亮, 徐宇杰. 现代大型铝电解槽内复杂物理场的仿真计算与优化[J]. 中国有色金属学报, 2011, 21(10): 2594-2606.

LI Jie, ZHANG Hong-liang, XU Yu-jie. Simulated computation and optimization of comprehensive physical fields in modern large-scale aluminium reduction cells[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2594-2606.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(50876116,50974127);中南大学中央高校基本科研业务费专项资金项目(2013zzts038)

收稿日期:2012-10-05;修订日期:2013-01-23

通信作者:李 茂,副教授,博士;电话:13055169363;E-mail: limao89@163.com