铝电解槽改进型钢棒和绝缘挡板对铝液中水平电流的优化

李贺松1,陈桢1,田应甫2

(1. 中南大学 能源科学与工程学院,湖南 长沙,410083;

2. 重庆天泰铝业有限公司,重庆,401328)

摘要:为了减小传统铝电解槽内铝液中存在的较大水平电流,进一步提高铝电解槽电流效率,提出一种改进型阴极钢棒和在铝液中增加绝缘挡板的方案。以有限元软件ANSYS为平台,对175 kA预焙铝电解槽电场进行模拟分析,在此基础上通过改变阴极钢棒形状和在铝液层中增加绝缘挡板的方式,探讨不同方案对铝液层水平电流的优化作用。研究结果表明:改进型阴极钢棒可使阳极炭块下铝液中y向水平电流密度的最大值和平均值明显减小,绝缘挡板能有效抑制电流向阳极炭块侧部偏移,而通过改进型钢棒和绝缘挡板的结合,不仅能将铝液层电流控制在阳极炭块下,而且水平电流密度的大小和分布也能得到有效的控制,为铝电解实际生产提供理论依据。

关键词:铝电解槽;阴极钢棒;绝缘挡板;水平电流;优化

中图分类号:TF821 文献标志码:A 文章编号:1672-7207(2014)10-3351-07

Optimization of horizontal current in metal pad by using advanced collector bars and insulation boards in aluminum reduction cell

LI Hesong1, CHEN Zhen1, TIAN Yingfu2

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Chongqing Tiantai Aluminum Industry Co., Ltd., Chongqing 401328, China)

Abstract: Based on the target of reducing the large horizontal current in metal pad of aluminum reduction cells and improving current efficiency of aluminum reduction cells further more, a kind of advanced collector bars and insulation boards was improved. The software ANSYS was used to calculate the current distribution in the 175 kA prebake aluminum reduction cells. The effect of different conditions on current distribution in metal pad of aluminum reduction cells was talked about by changing the shape of collector bars and installing insulation boards in metal pad. The results show that advanced collector bars can significantly reduce the maximum and average values of horizontal current density along y axis in the metal pad under anode carbon block. Insulation boards can effectively restrain the current offset to the side of the anode carbon block. By combining advanced collector bars with insulation boards, it can not only control the current in metal pad under anode carbon block but the value and distribution of horizontal current density can also be controlled effectively. It provides theory basis for the actual production of aluminum reduction.

Key words: aluminum reduction cells; collector bar; insulation board; horizontal current; optimization

随着计算机和数学的飞速发展,铝电解槽的物理场仿真与优化技术逐步精确。当今的铝电解工业正在向槽大容量、低电压方向发展。2010年以来,国内先后建设了400~500 kA大型电解槽,现有槽型电解槽电流也在不断强化,铝电解槽系列电流的增大会产生更强大的磁场,磁场与电解质及铝液中的电流相互作用产生强大的电磁力,使电解质和铝液发生循环流动、界面波动和隆起变形,这会造成槽稳定性降低,严重时甚至引起滚铝等极端现象[1-3]。熔体的不稳定性对铝电解槽的经济技术指标尤其是电流效率有着显著的影响,铝液波动引起铝的二次反应和溶解损失,造成电流效率的下降[4-6]。因此,如何尽量减少槽内熔体的水平电流,维持熔体的合理流动,已经成为铝电解槽设计和生产的核心之一。电磁力是引起电解槽内熔体波动的主要驱动力,在设计过程中,一般认为电解槽的垂直磁场与铝液中存在的水平电流作用产生的电磁力是引起电解槽不稳定性的重要影响因素之一[7-8]。在目前全球节能减排的大环境下,降极距、降电压已经成为未来铝电解发展的一个趋势,这对电解槽的稳定性提出了更高的要求。因此,从磁流体稳定性角度考虑,要从根本上解决铝液波动问题,主要在于优化铝液中存在的垂直磁场以及水平电流。考虑到电场是铝电解槽其他各物理场的根源,所以电场的优化就显得尤为重要。针对以上存在的问题,国内外的学者都做了许多的研究。一种用于电解系列最末端槽的母线补偿结构,已经运用于工业生产中[9]。最近新设计出的底部出电铝电解槽,不仅垂直磁场分布较为理想,而且铝液中的水平电流也相对较小[10]。以上的研究工作主要集中在优化电解槽的母线结构以及铝液层内垂直磁场两方面。在减小铝液水平电流方面,Moreau等[11]指出了减小铝液中水平电流对于加强磁流体稳定性的意义。Arita等[12-13]就侧部伸腿对铝液中电流分布的影响进行了计算,Fraser等[14-15]对不同伸腿长度下,不同铝液层的电流密度进行了模拟计算。Qi等[16]则通过计算阴极结构的电场,研究铝液高度以及伸腿长度对铝液中水平电流密度的影响,得出了铝液中水平电流的分布状况和铝液高度及伸腿长度对铝液层水平电流密度的影响规律。张艳芳等[17]对阴极炭块类型和钢棒类型以及钢棒高度及宽度变化对于铝液中水平电流的影响进行了分析。杨帅等[18]通过研究钢棒加高型阴极,对铝液中水平电流进行了优化。但以上大部分研究都建立在传统阴极结构上,而且由于铝液高度和伸腿长度受工艺条件的限制很难随意改变,而对于侧部炉帮铝液区存在的水平电流目前国内外还没有研究。本文作者以重庆天泰175 kA电解槽为例进行研究,通过模拟不同的阴极钢棒结构以及在侧部伸腿处铝液层增加绝缘挡板的方式,研究不同方案对铝液中水平电流的优化作用,已达到减小水平电流,提高电解槽熔体稳定性的目的。

1 铝电解槽电场模型的建立

1.1 模型的建立

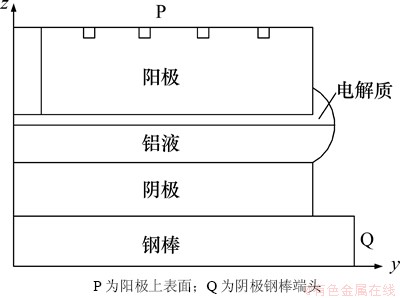

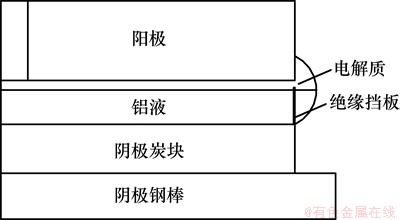

铝电解槽中电流的流动方向是从阳极流入槽内,经钢爪进入阳极炭块,电流均匀通过电解质层和铝液层,再由阴极钢棒横向导出,由于电流的流出方向和流入方向成90°角,电流必定会发生偏转。并且由于铝液的电阻率远远小于电解质的电阻率,所以电流转向绝大部分发生在铝液层,形成了铝液中的水平电流,水平电流与垂直磁场相互作用引起电解质-铝液界面的波动,从而影响到槽内磁流体的稳定性[11]。传统电解槽的结构如图1所示,由于其对称性,只取其1/4作为参考对象。

本文在建立的模型中,鉴于槽体系的复杂性,对所研究的导电部分阳极、电解质和铝液、阴极炭块做了如下假设[19]。

1) 铝电解槽解析域属于稳态场;2) 槽帮结壳、耐火保温材料看成绝缘体;3) 炉底无结壳,侧部伸腿长度为零;4) 铝液高度和电解质高度各处均匀;5) 阳极炭块下表面处于同一水平;6) 忽略碳钢接触压降;7) 阳极炭块、熔体、阴极炭块和钢棒电阻率在各区域为定值;8) 阳极上表面和阴极钢棒出口面视为等势面。在以上的假设基础上,同时,为了保持边界条件的连续性和准确性,本文将阳极、熔体、阴极作为一个整体进行计算。计算体系如图2所示。

1.2 边界条件及载荷

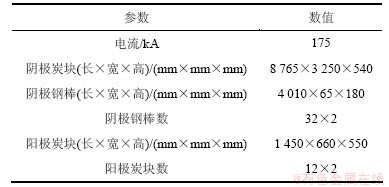

本文以重庆天泰175 kA预焙铝电解槽阴极作为研究对象,根据天泰铝业有限公司提供的参数,铝液层和电解质层的厚度分别为20.0 cm和20.5 cm。其他初始结构及工艺参数如表1所示。

计算时假定24组阳极平均分配全部系列电流,并假定每组阳极上4个钢爪平均分担每组阳极的电流强度。阳极上表面(P面)假设为电压等势面,分别加载相应的载荷电流,P面4个钢爪电流密度相同。同时为建模的方便以及计算效率,假定每块阴极上通过的电流为总电流在所有阴极上的平均值。全槽模型的计算体系如图2所示,电解槽槽的电流为175 kA,每块阳极上通过的电流为总电流在所有阳极上的平均值,即175/24=7.29 kA;阴极钢棒出口处(Q面)视为电压零势面,在出口面上设零电势边界,Q面上每个节点电流密度相同。

图1 铝电解槽几何模型

Fig. 1 Aluminum reduction cell geometrical model

图2 计算体系示意图

Fig. 2 Schematic diagram of calculation system

表1 电解槽初始导电结构及工艺参数

Table 1 Initial conductive structure parameters of aluminum electrolytic cell

1.3 控制方程

铝电解槽导电部分的导电微分方程可表示为拉普拉斯方程,即:

(1)

(1)

(2)

(2)

式中:V为标量电位;I为电流;R为电阻;σ为电导率。

2 计算结果及分析

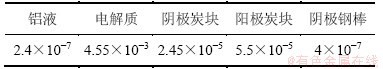

坐标原点选在阴极碳块底部槽中心点。x向为阳极宽度方向,y向为阳极长度方向,即系列电流方向,z向为垂直方向。x,y,z符合右手定则。刘业翔等[10]研究得出:当阴极炭块和阴极钢棒组合在一起时,两者的电阻率差别越大,其在阴极产生的电势梯度等势线越趋于水平,同时在铝液中产生的水平电流会越小一些。所以,本文建模时,采用石墨化阴极与低电阻率钢棒。计算中所需的材料属性见表2。

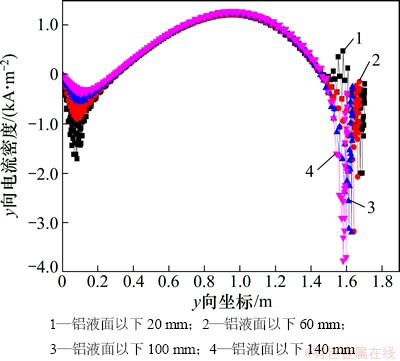

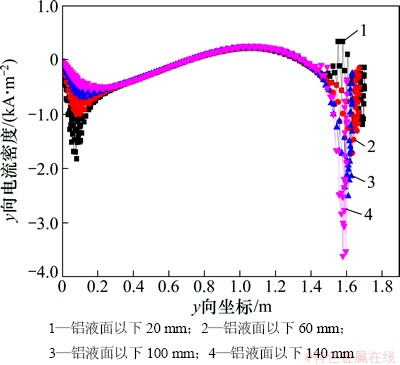

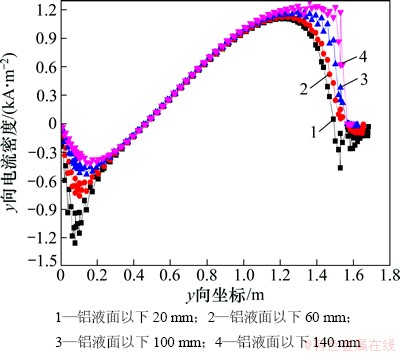

图3所示为理想炉帮情况下,电解槽不同铝液层水平电流密度分布。

表2 导电材料的电阻率

Table 2 Electrical resistivity of conductive materials Ω·m

图3 理想炉帮情况下铝液层内水平电流密度 (阳极y向尺寸:0.10~1.55 m)

Fig. 3 Horizontal current density in metal pad with ideal ledge

由图3可以看出:在铝液层内,靠近槽中心位置,出现了负值电流密度,这表明电流有向槽中心流动的分量,而且随着铝液高度的降低,此处的负值电流密度逐渐减小,这表明水平电流逐步转为向槽侧部的正方向流动。

在阳极底部(y向坐标为0.900~1.565 m),不同铝液层面内,电流密度的变化趋势非常相似,其变化特征是,在y向坐标1 m(自里向外约第三个钢爪)之前,水平电流密度逐步增加,此后再逐渐减小,最后恢复到零,其原因是阳极投影下铝液层电流不断向阴极钢棒出口端汇集,导致水平电流分量逐渐增大,在到达第三个钢爪位置后,其受到由侧部炉帮导致的负向水平电流的影响越来越大,导致绝对值下降。水平电流密度的正向最大值大约出现在阳极下y向坐标1 m处。同时,最大值随着铝液层面的降低有略微减小的趋势,但变化很小。也就是说,阳极下铝液层中的水平电流密度几乎不受铝液高度的影响。

阳极侧部炉帮处出现了较大的负向水平电流分量,并且,随着铝液层面的降低,出现的规律是:负向水平电流密度逐渐增大;存在水平电流的区域逐渐减少。这是由炉帮的形状和本身绝缘的性质决定的,因为随着层面的降低,相应铝液层面对应的侧部结壳位置与伸腿最顶端的水平距离越来越小。

3 钢棒结构优化及其结果与分析

电解槽系列由于系列电流及其导电母线的存在,产生的电磁力,对电解槽槽内流场、能量平衡及电流分布产生影响。在电解槽设计时,可通过优化母线结构和体系内电流来削弱这部分影响。水平电流主要是由铝电解槽的几何结构、导电方式和它复杂的工艺条件共同决定的。从图3可以看出:铝液层水平电流有2种存在形式:第一种是在熔体边缘区有从外围向中间的水平电流产生,这部分水平电流主要是受电解槽几何结构影响产生的;第二种存在于阳极投影下,从槽中心向外的水平电流,这部分水平电流受阴极炭块和钢棒的物理属性影响,占据铝液层绝大部分区域。所以,分别对阴极钢棒进行优化和在侧部伸腿处增加绝缘挡板,模拟不同的优化结构下熔体中水平电流的变化,以供电解槽设计时参考。

3.1 钢棒结构优化与结果分析

3.1.1 钢棒模型模拟方案

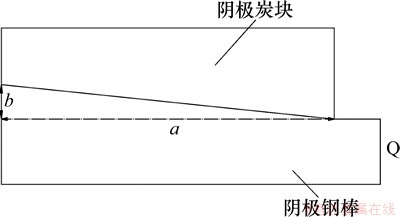

电流经熔体区由阴极钢棒导出这段区间,由于受到其固有导电方式的影响,必定会向钢棒出口端偏移。要减少电流的水平偏移分量,必须要改变其原有的导电结构。其理论依据是钢棒的导电性远远优于阴极炭块的导电性,所以钢棒结构的改变对于整个阴极部分的电场分布会产生影响,进而改变铝液中的电流分布。本文通过对嵌入阴极炭块内的钢棒结构做出改进,伸出炭块的钢棒保持不变,以考察各种情况下熔体区水平电流分布情况。2种改进后的阴极结构剖面图分别如图4和图5所示。图中:A=B=C=1/3a;D=E=1/2b=3 cm,通过表2提供的导电材料的电阻率参数。

方案一的阴极结构剖面图如图4所示。方案二的阴极结构示意图如图5所示。

图4 方案一阴极结构剖面图(A=B=C;D=E)

Fig. 4 Schematic diagram of cathode structure with the first program

图5 方案二阴极结构示意图(a=3A;b=2D=3 cm)

Fig. 5 Schematic diagram of cathode structure with the second program

3.1.2 结果与分析

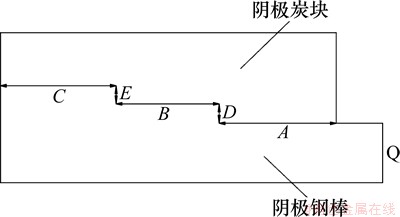

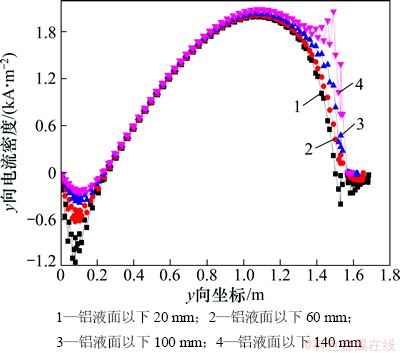

各方案铝液层电流密度分布图见图6~8。

由图6可以看出:方案一情况下,在铝液层内,靠近槽中心位置和侧部炉帮处,均出现了负值电流密度,所不同的是,随着铝液层面的降低,靠近槽中心位置处的水平电流密度绝对值逐渐减小,反之,在侧部炉帮处则是逐渐增加的。同时,可以看出侧部炉帮处水平电流密度最大值要远大于靠近槽中心位置处的水平电流密度最大值。而在阳极正投影下区域,水平电流密度则呈波浪形分布,大部分区域为负值,但其变化幅度和整体绝对值均较小,并且,其变化规律几乎不随铝液高度的变化而变化。

图6 方案一铝液层内水平电流密度

Fig. 6 Horizontal current density in metal pad with the first program

图7 方案二铝液层内水平电流密度

Fig. 7 Horizontal current density in metal pad with the second program

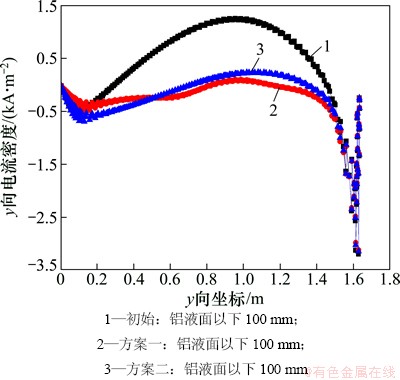

图8 各方案铝液层内水平电流密度对比

Fig. 8 Comparison of horizontal current density in metal pad with each program

由图7可以看出:方案二情况下,类似于方案一,在铝液层内靠近槽中心位置和侧部炉帮处,电流也有向槽中心流动的分量,且其变化规律也和方案一相同。在阳极正投影下区域,则呈现出先负向再正向的变化趋势,而且随着铝液层面的降低,其大小和变化规律几乎没有变化。变化幅度和整体绝对值均较小。

从图8可以看出:通过对阴极钢棒进行改进后,铝液中间层的水平电流密度在靠近槽中心位置和侧部炉帮处无论是大小还是变化规律都与初始钢棒下的情况几乎相同。这说明,这2个区域的水平电流密度未受钢棒形状改变的影响。而阳极投影下区域的水平电流密度比初始情况的大幅度减小,可见,水平电流密度无论是最大值还是变化幅度均有了很大程度的降低,分布更加均匀,其值稳定在-0.50~0.25 kA/m2。这对于控制铝液稳定,减小铝液的波动有着重要意义。

3.2 增加绝缘挡板对铝液中水平电流的影响

电解槽由于受到其固有几何结构的限制,在熔体边缘区会有从外围向中间的较大水平电流产生。这部分水平电流的特点是:区域相对偏小,但绝对值很大,这和铝电解槽电磁力在四周分布偏大相对应。由于四周较大水平电流的存在,造成铝液波动厉害,槽内磁流体的极度不稳定。所以,如何减小这部分水平电流,对铝电解生产具有十分重要的意义。

3.2.1 方案模型结构简介

由于炉帮形状的不能随意更改性,在炉底阳极右端边缘处加一块绝缘挡板,并使其固定于阴极炭块上,挡板最上沿位于电解质层内2 cm,各挡板长度为阳极炭块宽度,挡板下沿处于理想情况下炉底伸腿处。其结构简图如图9所示。

图9 绝缘挡板安装简图

Fig. 9 Schematic diagram of insulation board installation

3.2.2 结果与分析

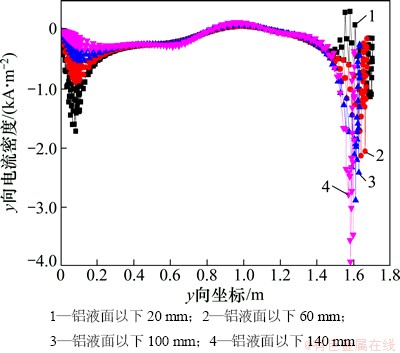

图10和图11所示分别为初始钢棒结构和方案二结合绝缘挡板2种情况下铝液层内的水平电流密度 分布。

由图10可以看出:通过增加绝缘挡板,阳极右侧铝液层内的水平电流有了大幅度减少,而且随着铝液层面的降低水平电流已基本消失;阳极左侧靠近槽中心处水平电流几乎没有变化;阳极正投影下区域铝液层内水平电流变化规律与初始情况基本类似,电流密度先是逐步增加,当达到某一位置后再逐渐减小。所不同的是,水平电流密度最大值有所增大,而且最大值出现位置更加靠近钢棒出口端,这是合理的,因为在总电流一定的前提下,阳极右侧铝液区水平电流消失,必然会导致阳极正投影下铝液区域电流密度增大。同样,侧部的负向水平电流的减小也会削弱其对阳极底部正向水平电流的影响,导致最大值往钢棒出口端偏移。

图10 初始钢棒下加挡板时液层内水平电流密度

Fig. 10 Horizontal current density in metal pad with initial collector bar and insulation board

图11 方案二情况下加挡板液层内水平电流密度

Fig. 11 Horizontal current density in metal pad with the second program and insulation board

由图11可以看出:通过改变阴极钢棒形状和增加绝缘挡板2种方法相结合,既可以消除阳极侧部铝液层内存在的较大水平电流,又降低了阳极底部铝液中的水平电流。

4 结论

1) 传统电解槽在靠近电解质的铝液层内,在靠近槽中心位置,有负值电流密度,而且随着铝液层面的降低,负值电流密度逐渐消失;在阳极底部,水平电流密度先是逐渐增大,达到某一最大值后再快速下降,而且其变化规律和值几乎不随铝液高度的变化而变化;在阳极侧部靠近炉帮区域出现较大的负向电流密度,铝液层面越低,水平电流密度梯度越大,但有负向电流密度的铝液面宽度变窄。

2) 2种钢棒改进模型对于减小阳极底部铝液中的水平电流以及优化其分布有积极的效果。水平电流密度由初始钢棒下的-0.50~1.30 kA/m2减小为-0.50~0.25 kA/m2。水平电流密度无论是最大值还是平均值都有着明显的减小,分布更加均匀。

3) 在阳极右侧伸腿处的铝液层内增加绝缘挡板对于阳极侧部靠近炉帮区域存在的较大负向水平电流优化效果明显。通过增加绝缘挡板,该铝液区域电流的水平分量已基本消失,这对于减小铝电解槽四周电磁力,优化磁流体稳定性,有十分重要的意义。

参考文献:

[1] 邱竹贤. 预焙槽炼铝[M]. 北京: 冶金工业出版社, 2005: 158-160.

QIU Zhuxian. Prebaked pot for aluminum smelting[M]. Beijing: Metallurgical Industry Press, 2005: 158-160.

[2] LI Xiangpeng, LI Jie, LAI Yanqing, et al. Mathematical simulation of gas induced bath flow in drained aluminum reduction cell[J]. Transactions of Nonferrous Metals Society of China, 2004, 14(6): 1221-1226.

[3] 李劼, 徐宇杰, 刘伟, 等. 基于波动模态耦合的铝电解槽磁流体稳定性傅立叶级数法分析[J]. 计算力学学报, 2010, 27(2): 213-217.

LI Jie, XU Yujie, LIU Wei, et al. Aspect ratio research based on magneto-hydrodynamic stability in aluminum reduction cells[J]. Chinese Journal of Computational Mechanics, 2010, 27(2): 213-217.

[4] 刘业翔, 李劼. 现代铝电解[M]. 北京:冶金工业出版社, 2008: 81-83.

LIU Yexiang, LI Jie. Modern aluminum electrolysis[M]. Beijing: Metallurgical Industry Press, 2008: 81-83.

[5] 冯乃祥. 铝电解[M]. 北京: 化学工业出版社, 2006: 103-113.

FENG Naixiang. Aluminum electrolysis[M]. Beijing: Chemical Industry Press, 2006: 103-113.

[6] 田应甫. 大型预焙铝电解槽生产实践[M]. 长沙: 中南大学出版社, 2005: 154-159.

TIAN Yingfu. Production practive of large pre-baked aluminum electrolytic cell[M]. Changsha: Central South University Press, 2005: 154-159.

[7] Lindsay R I, Davidson P A. Stability of interfacial waves in aluminum reduction cell[J]. J Fluid Mech, 1998, 362: 327-331.

[8] Bojarevics V, Romerio M V. Long waves instability of liquid metal-electrolyte interface in aluminum electrolysis cells: A generalization of Sele’s criteria[J]. European Journal of Mechanics B, 1994, 13: 33-56.

[9] Ziegler D P, Ruan Y M. Busbar arrangement optimization for end cells[C]//Light Metals. Warrendale, PA, USA: TMS, 2009: 535-538.

[10] 刘业翔, 梁学民, 李劼, 等. 底部出电型铝电解槽母线结构与电磁流场仿真优化[J]. 中国有色金属学报, 2011, 21(7): 1688-1695.

LIU Yexiang, LIANG Xuemin, LI Jie. Simulation and optimization of bus structure and electro-magneto-flow field of aluminum reduction cells with vertical bottom bars[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(7): 1688-1695.

[11] Moreau R J, Ziegler D. Stability of aluminium cells: A new approach[C]//Light Metals. New Orleans, LA: TMS, 1986: 359-364.

[12] Arita Y, Ikeuchi H. Numerical calculation of bath and metal convection patterns and their interface profile in Al reduction cells[C]//Light Metals. Warrendale, PA, USA: TMS, 1981: 357-363.

[13] Robl R F. Metal flow dependence on ledging in Hall-Heroult cells[C]//Light Metals. Warrendale, PA, USA: TMS, 1983: 449-454.

[14] Fraser K J, Billnghurst D, Chen K L, et al. Some applications of mathematical modeling of electric current distributions in Hall-Heroult cells[C]//Light Metals. Warrendale, PA, USA: TMS, 1989: 219-226.

[15] El-Demerdash M F, Khali E E, Ahmed H A, et a1. Modeling of metal topography and flow regimes in working pmbaked aluminum pot[C]//Light Metals. Warrendale, PA, USA: TMS, 1993: 369-374.

[16] QI Xiquan, LU Dingxiong, MA Shaoxian, et al. Study of current distribution in the metal pad of aluminum reduction cells[C]// Light Metals. Warrendale, PA, USA: TMS, 2009: 575-580.

[17] 张艳芳, 赵庆云, 刘吉波, 等. 铝电解槽阴极对水平电流影响的模拟与分析[C]//2007中国国际铝冶金技术论坛论文集. 北京: 冶金工业出版社, 2007: 540-543.

ZHANG Yanfang, ZHAO Qingyun, LIU Jibo, et al. The simulation and analysis of the affection of the cathode to the horizontal current in the aluminum reduction cell[C]//Proceedings of 2007 China International Conference on Aluminum Metallurgy. Beijing: Metallurgical Industry Press, 2007: 540-543.

[18] 杨帅, 李劼, 徐宇杰, 等. 铝电解槽钢棒加高型阴极对铝液中水平电流的优化[J]. 中国有色金属学报, 2012, 22(10): 2951-2959.

YANG Shuai, LI Jie, XU Yujie, et al. Optimization of horizontal current in metal pad by using cathode with heightened collector bars in aluminum reduction cell[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(10): 2951-2959.

[19] 姜昌伟. 预焙阳极铝电解槽电场、磁场、流场的耦合仿真方法及应用研究[D]. 长沙: 中南大学能源科学与工程学院, 2003: 15-16.

JIANG Changwei. Study on electric field, magnetic field and flow field coupling simulation method and its application in the prebaked aluminum reduction cell[D]. Changsha: Central South University. School of Energy Science and Engineering, 2003: 15-16.

(编辑 杨幼平)