DOI:10.19476/j.ysxb.1004.0609.2017.07.18

铜镍氧硫混合矿焙烧-浸出过程铜、镍、铁的转化

崔富晖1,牟文宁2, 3,顾兴利1,许 茜4,翟玉春2, 3

(1. 东北大学 冶金学院,沈阳 110819;

2. 东北大学(秦皇岛分校) 资源与材料学院,秦皇岛 066004;

3. 秦皇岛市资源清洁转化与高效利用重点实验室,秦皇岛 066004;

4. 上海大学 材料科学与工程学院,上海 200072)

摘 要:随着硫化镍矿资源的日趋枯竭,铜镍氧硫混合矿的利用将会愈发受到关注。通过对原矿进行差热-热重、XRD以及热力学分析,揭示焙烧过程矿石矿相的转变历程,研究铜镍氧硫混合矿焙烧过程中矿物粒度、焙烧温度和焙烧时间对铜、镍、铁转化的影响,探索浸出过程中溶剂、液固比、浸出温度及浸出时间对铜、镍、铁浸出的影响。结果表明:矿物粒度为74~80 μm、焙烧温度为600 ℃、焙烧时间为2 h、选择水作为浸出溶剂、浸出温度为60 ℃、液固比为6:1、浸出时间2 h时,镍和铜的浸出率达到最高分别为46.25%和96.27%,铁的浸出率低于1%。

关键词:铜镍氧硫混合矿;焙烧;浸出;转化

文章编号:1004-0609(2017)-07-1471-08 中图分类号:TF815 文献标志码:A

全球镍矿资源主要有硫化镍矿和红土镍矿两种类型。截至2011年底,全球基础储量约为8000万t,我国已探明的镍矿有80余处,总储量为800万t,储量基础为1000万t,其中硫化镍矿约占总储量的87%,主要分布在甘肃、新疆、云南等地[1-4]。硫化镍矿资源品质高,伴生多种有价金属元素,一般采用火法冶炼,工艺成熟,附加值高,成本较低,多年来一直是世界镍冶炼的首选矿物[5-7]。但随着世界范围内镍消费的增加,高品位硫化镍矿储量日渐减少,一些较难处理的低品质硫化镍矿将成为镍冶金企业的重点开采对象[8-10]。

目前,低品位硫化镍矿仍主要采用选矿富集,后进行火法冶炼,但也有硫酸铵焙烧-水浸、细菌浸出的报道[11-13]。铜镍氧硫混合矿是原生硫化矿贫矿体与上部氧化带之间较厚的混合矿带,在我国新疆、甘肃等地均有广泛存在,约占镍资源总储量的2/3,且伴生大量的金属铜[14-15],这类矿石具有金属矿物含量少,碱性脉石含量高,有价金属赋存状态复杂的特点,且部分镍以硅酸镍形式存在,较难利用选矿工艺进行富集[16-17],而细菌浸出或采用传统硫化镍矿选矿→熔 炼→冰镍→转炉吹炼→高冰镍→电炉熔炼→粗镍[18-19]的火法冶炼工艺处理,有价金属回收率低,损失量大,经济效益不佳[20-23]。

硫酸化焙烧是有色金属冶炼常用的一种活法方法,其优点在于有价金属元素可转变的可溶性的金属硫酸盐,且可实现选择性硫酸化。低品位铜镍氧硫混合矿,因其高含硫量,可用空气作为氧化剂进行硫酸化焙烧,在合适的温度下,有价金属元素铜、镍可转化为金属硫酸盐,而硫酸铁因其低分解温度,在氧化性焙烧温度下已经分解为氧化铁,故可实现选择性焙烧。目前,我国对铜镍氧硫混合矿资源利用的相关研究不足,缺乏针对此类矿物的高效提取技术。因此,研究铜镍氧硫混合镍矿的处理新工艺和新技术具有重要的实际意义和广泛的应用价值。

本文作者将以铜镍氧硫混合矿为对象,在研究混合矿的特性基础上,采用焙烧-浸出法处理,探索焙烧时间、焙烧温度、矿物粒度、浸出溶剂、浸出温度、浸出时间及液固比等因素对镍、铜、铁等金属元素转化的影响,以期为铜镍氧硫混合矿的经济开发和综合利用提供技术指导。

1 实验

1.1 实验原料

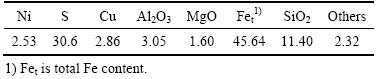

本研究所用铜镍氧硫混合矿来自新疆地区,经破碎、研磨、筛分、干燥后用于实验。采用日本理学公司S-max型XRF对矿石的化学组成进行测定,结果如表1所示。由表1可知,矿石属于高铁低镁型铜镍氧硫混合矿,镍和铜的含量分别为2.53%和2.86%,极具开采利用价值。

表1 原矿的化学组成

Table 1 Chemical composition of raw ore (mass fraction, %)

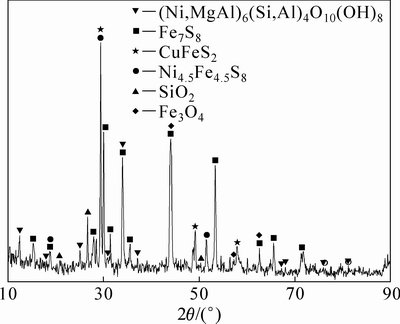

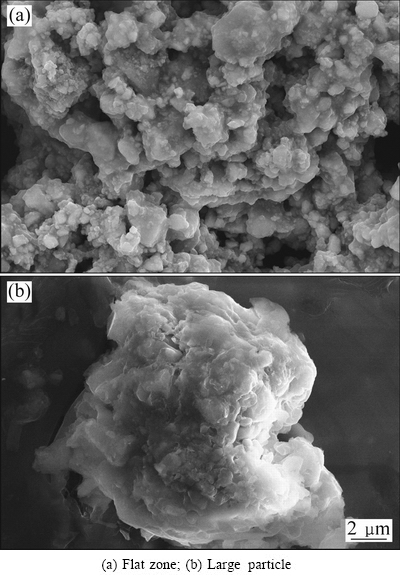

采用X'Pert型X射线仪(工作电压40 kV,工作电流250 mA,Cu Kα,扫描速度10 (°)/min,步长0.02)对铜镍氧硫混合矿进行衍射分析,结果如图1所示,由图1可知,矿石主要含有磁黄铁矿(Fe7S8)、黄铜矿(CuFeS2)、磁铁矿(Fe3O4)、石英(SiO2)、镍黄铁矿(Ni4.5Fe4.5S8)、镍绿泥石[(Ni,Mg,Al6(Si,Al)4O10(OH)8)]等矿物质,其中铁主要以磁黄铁矿、黄铜矿、磁铁矿形式存在,镍以镍黄铁矿、镍绿泥石形式存在,铜以黄铜矿形式存在。表2所列为用Jade6.5全谱拟合 Rietveld 法定量分析所得的矿石中各矿相的含量。

图1 原矿的XRD谱

Fig. 1 XRD pattern of raw ore

表2 原矿的矿相组成

Table 2 Mineral phase of raw ore (mass fraction, %)

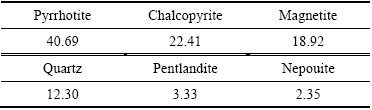

图2 原矿的SEM像

Fig. 2 SEM images of raw material

采用ZEISS SUPRA 55 SAPPHIRE型扫描电子显微镜对矿粉进行分析,结果如图2所示。由图2可知, 原矿颗粒大小不一,形状各异,小颗粒多镶嵌在大颗粒中,大颗粒表面多有突起且结构较为疏松。

1.2 试验方法

称取10 g矿粉于坩埚中,放入马弗炉,以10 ℃/min的速率加热到预定温度并恒温一段时间,自然冷却至室温,将焙烧熟料采用不同溶剂进行浸出,过滤,得到滤液和滤渣。利用双光束紫外可见分光光度计测定滤液中镍、铜的浓度,采用重铬酸钾滴定法测定溶液中铁的浓度,并按式(1)计算各金属元素的浸出率(ηi):

(1)

(1)

式中:ηi为金属元素浸出率,%;c为浸出液金属元素物质的量浓度,mol/L;M为元素摩尔质量,g/mol;V为浸出液体积,L;m为原矿质量,g;w为元素在原矿中质量分数,%。

2 结果与讨论

2.1 焙烧实验

2.1.1 焙烧过程热、物相及热力学分析

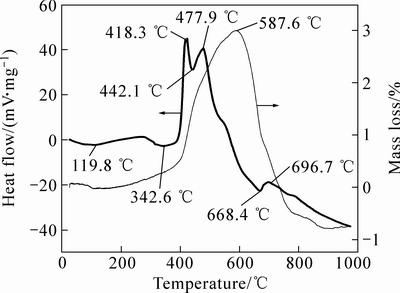

采用Diamond 6300型热重-差热综合热分析仪对原料进行分析,升温速率10 ℃/min,温度范围0~1000 ℃,结果如图3所示。

图3 空气状态下原矿的热重与差热分析

Fig. 3 TG-DTA curves of raw ore in air

由图3可知,DTA曲线上在0~400 ℃区间内无明显的吸放热峰,119.8 ℃时的吸热峰为矿石中吸附水的脱除,并伴随着0.66%的质量减少,342.6 ℃的吸热峰为镍绿石中结晶水的脱除反应。当温度高于400 ℃时,DTA曲线上存在418.3、477.9及696.7 ℃ 3个明显的放热峰,以及442.1 ℃、668.4 ℃两个明显的吸热峰。418 ℃时,磁黄铁矿(Fe7S8)、黄铜矿(CuFeS2)、镍黄铁矿(Ni4.5Fe4.5S8)与氧气反应生成氧化铁、氧化铜及氧化镍,并释放二氧化硫气体,部分金属硫化物将与二氧化硫、氧气反应生成金属硫酸盐,质量增加0.86%。442.1 ℃的吸热峰温度与硫单质的沸点为444.5 ℃相吻合,这是由于金属的高价硫化物在一定温度下分解生成低价金属硫化物与单质硫以及硫单质气化所致。477.9 ℃时,未反应完全的镍黄铁矿、磁黄铁矿及黄铜矿继续发生氧化反应和硫酸化反应。668.4 ℃时,未反应的磁黄铁矿脱硫生成低价态硫铁矿[24],696.7 ℃时,镍绿泥石发生相变反应[25]。随着矿石硫酸化反应的持续进行,587.6 ℃时体系质量增加达到最大值,为3.0%,之后质量一直损失,直到900 ℃达到平稳,与0 ℃相比失重为0.75%。

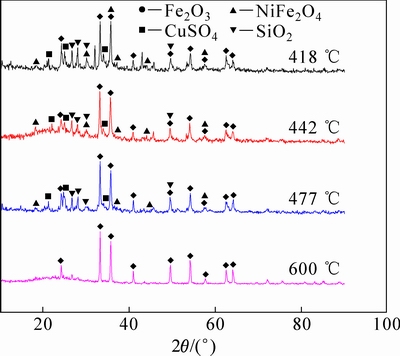

选取418、442、477、600 ℃ 4个温度进行矿样的焙烧实验,电炉升温速率10 ℃/min,恒温2 h。将不同焙烧温度下的熟料进行XRD分析,结果如图4所示。

图4 不同温度熟料的XRD谱

Fig. 4 XRD patterns of clinkers at different temperatures

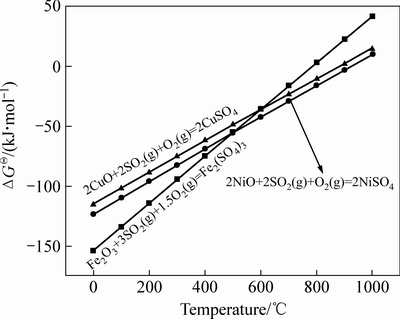

由图4可知,原矿经418 ℃焙烧,矿石中的磁黄铁矿(Fe7S8)、黄铜矿(CuFeS2)、镍黄铁矿(Ni4.5Fe4.5S8)转化成赤铁矿、硫酸铜、氧化镍铁,反应的方程式如式(2)~(8)所示。图5所示为原矿中金属硫化物氧化反应的标准吉布斯自由能。图6所示为金属氧化物硫酸化反应的标准吉布斯自由能。由图5和6的吉布斯自由能与温度的关系可知,金属硫化物氧化生成金属氧化物以及金属氧化物硫酸化转换为金属硫酸盐的标准吉布斯自由能均小于0,且氧化铜和氧化镍的硫酸化较氧化铁容易。在铁镍共生矿中,镍原子镶嵌在铁的晶格中[25],导致氧化过程中部分镍未转变为硫酸镍而生成氧化镍铁。因而氧化铜先于氧化镍被大量硫酸化,生成硫酸铜。

图5 原矿中金属硫化物氧化反应的标准吉布斯自由能

Fig. 5 Standard Gibbs free energy of metal sulfide oxidation reaction

图6 金属氧化物硫酸化反应的标准吉布斯自由能

Fig. 6 Standard Gibbs free energy of metal oxide sulfation reaction

焙烧温度升高,熟料的氧化铁衍射峰更为明显,硫酸铜、氧化镍铁及二氧化硅的衍射峰逐渐被氧化铁的衍射峰所掩盖。这是由于原矿中含铁矿物含量高,全铁含量约为铜、镍的20倍。另外,硫酸铁会480 ℃开始发生如式(9)的分解反应,生成氧化铁,其硫酸化较氧化铜和氧化镍困难,因此,熟料中的主要矿物为氧化铁。

(2)

(2)

(3)

(3)

(4)

(4)

(5)

(5)

(6)

(6)

(7)

(7)

(8)

(8)

(9)

(9)

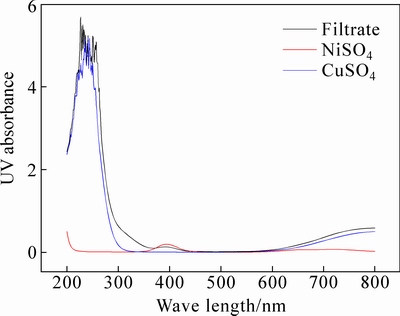

2.1.2 光谱分析

由于在XRD谱中未能发现硫酸镍特征峰,现采用紫外分光光度仪对滤液进行光谱分析,定性的分析滤液的化学成分。将焙烧熟料水浸后过滤,得到浸出渣及滤液。对滤液进行光谱分析。

配制1%(质量分数)硫酸镍标准溶液及1%(质量分数)硫酸铜标准溶液。采用TU-1901型号紫外分光光度仪,分别对1%(质量分数)硫酸镍标准溶液、1%(质量分数)硫酸铜标准溶液和滤液进行光谱分析,结果如图7所示。

图7 滤波在不同波长处的吸光度

Fig. 7 UV absorbance of filtrate at different wave lengths

由图7可知,硫酸镍溶液在波长为395 nm处有明显特征峰,硫酸铜溶液在波长200~300 nm之间有多个特征峰,经与硫酸镍和硫酸铜标准溶液的吸收峰对比,滤液的特征峰能够很好的和标准溶液特征峰相吻合,这表明原矿在600 ℃焙烧过程中生成了硫酸镍和硫酸铜。

2.1.3 粒度对浸出率的影响

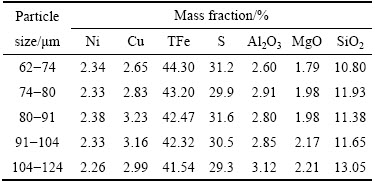

矿粉的氧化焙烧属于气-固反应,矿粉的比表面积不同,扩散作用对反应的影响也不同。采用筛分机将矿粉粒度分级为62~74 μm、74~80 μm、80~91 μm、91~104 μm、104~124 μm,并对不同粒度下的原料进行定量分析,结果如表3所示。

表3 不同粒度矿粉的元素定量分析

Table 3 Element content of ore powder with different particle size

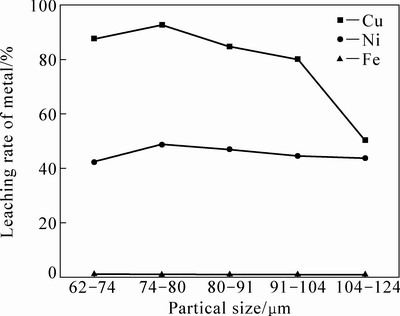

在焙烧温度600 ℃、焙烧时间2 h的条件下对不同粒度的矿粉进行焙烧,考察粒度对镍、铁、铜浸出的影响。焙烧熟料采用水浸出,浸出条件如下:液固比6:1,温度60 ℃,时间2 h,结果如图8所示。

图8 矿粉粒度对金属元素浸出率的影响

Fig. 8 Effect of particle size of ore powder on leaching rate of metal

由图8可知,矿粉粒度对铜、镍的浸出影响显著。矿粉粒度为62~74 μm时,颗粒间接触紧密,阻碍氧气、二氧化硫向矿粉内部的扩散,致使镍、铁、铜反应程度较低。当矿粉粒度为74~80 μm时,铜和镍的浸出率达到最大值,分别为92.68%和48.75%,之后随着矿粉粒度的增加,镍、铜浸出率均呈现降低趋势。矿粉粒度增大,比表面积减小,气-固反应界面缩小,导致镍、铜元素的硫酸化反应率降低。矿粉粒度对铁的浸出率无明显影响,随着矿粉粒度的减小,铁的浸出率均为1%左右,主要原因为在焙烧为600 ℃的条件下,硫酸铁已发生式(9)的分解反应,生成氧化铁留在渣中,这有利于滤液中金属元素的后续分离。

2.1.4 焙烧温度对浸出率影响

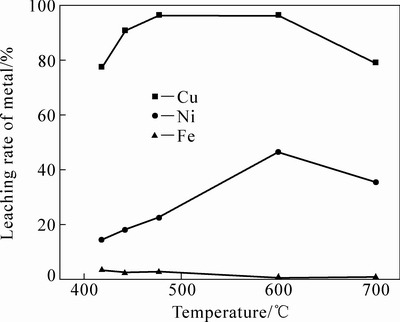

将粒度为74~80 μm的矿粉在418、442、477、600、700 ℃的条件下焙烧2 h,考察焙烧温度对镍、铁、铜浸出的影响。焙烧熟料水浸出的条件如下:液固比6:1、温度60 ℃、时间2 h,实验结果如图9所示。

图9 焙烧温度金属元素浸出率的影响

Fig. 9 Effect of roasting temperature on leaching rate of metal

由图9可知,当温度低于477 ℃时,随着焙烧温度的升高,镍、铜的浸出率均逐渐增大。当焙烧温度为600 ℃时,镍、铜浸出率均达到最大值,分别为96.27%、46.25%。焙烧温度高于600 ℃,铜、镍浸出率均随温度的升高而大幅降低。铁的浸出率随着焙烧温度的升高而降低,418 ℃时最大约为3%。

温度升高,物质的反应活性提高,铜、镍氧化物硫酸化速率提高,时间一定的条件下,铜、镍的浸出率也随之提高。但氧化反应和金属氧化物的硫酸化反应皆属于放热反应,当焙烧温度高于600 ℃,不利于向正向进行,导致铜、镍浸出率均有所降低。

2.1.5 焙烧时间的影响

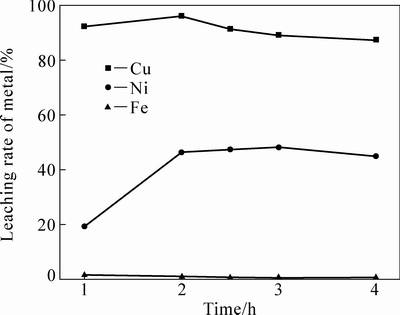

将粒度为74~80 μm的矿粉在600 ℃下焙烧1~4 h,考察焙烧时间对镍、铁、铜浸出的影响。焙烧熟料水浸出的条件为:液固比6:1,温度60 ℃,时间2 h。结果如图10所示。

图10 焙烧时间对金属元素浸出率的影响

Fig. 10 Effect of roasting time on leaching rate of metal

由图10可知,铁、铜的浸出率随焙烧时间的增加变化不明显,铜的浸出率在焙烧时间为2 h时达到最高值,96.27%。当焙烧时间小于2 h时,镍的浸出率随着时间的增加显著提高,当时间为2 h时镍的浸出率达到最高值为48.35%,之后随着时间的延长无明显变化。随着焙烧时间的增加,镍、铜的硫酸化反应更充分,浸出率也随之提高。当焙烧时间超过2 h后,因形成化合物氧化镍铁,致使嵌在铁氧化合物晶格中的镍被包裹起来,阻碍了硫酸化反应的进行,导致镍浸出率无明显变化。

2.2 浸出实验

2.2.1 浸出溶剂对有价组元提取率的影响

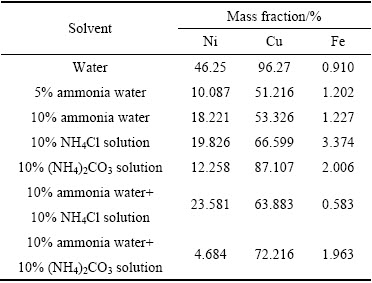

新疆铜镍氧硫混合矿中有价组元镍、铜一部分已硫化物形式存在,一部分以氧化物形式存在,硫酸化焙烧后,考虑到仍有部分有价组元仍以氧化物形式存在,而氧化镍、氧化铜与铵根有很强的络合能力,且氨水及铵盐类浸出剂可循环利用,故选取水、氨水、铵盐、以及铵盐组合作为浸出剂进行考虑。将粒度为74~80 μm的矿粉在焙烧温度600 ℃、焙烧时间2 h的条件下焙烧,焙烧熟料采用不同的溶剂进行浸出,考察不同溶剂对镍、铜、铁浸出的影响。浸出条件如下:液固比为6:1、温度为60 ℃、时间为2 h的试验条件下,结果如表4所示(表中溶剂含量均为质量分数)。

表4 不同溶剂条件下铜铁镍的浸出率

Table 4 The leaching ratio in different solvents

由表4可知,水作为溶剂进行浸出时,Cu、Ni的浸出率均可达到最大值,铁的浸出率低于1%。金属元素在氨水、铵盐和氨水-铵盐中浸出机理为金属离子与铵根络合生成相应的络合物,从而实现浸出。在本研究中,采用低浓度的氨水浸出时,铜、镍浸出率均较低,有关实验表明[4],氨水以及氨水-铵盐体系中铵根离子浓度越高,镍、铜的浸出率也越高,但考虑到成本因素,故不适宜作为浸出溶剂。采用氯化铵、碳酸铵进行浸出时,由于铵根的水解,溶液呈弱酸性,抑制了Ni2+和Cu2+的浸出。综上所述,本研究中选择水作为焙烧熟料的浸出溶剂。

2.2.2 液固比的影响

将粒度为74~80 μm的矿粉在600 ℃焙烧2 h,焙烧熟料水浸,考察液固比分别为3:1~7:1时对镍、铁、铜浸出的影响。水浸出条件如下:温度60 ℃,时间2 h,实验结果如图11所示。

由图11可知,在实验范围内,液固比对镍、铁、铜的浸出率影响较小,随着液固比增加,镍、铁、铜的浸出率均略有提高。由于硫酸铜和硫酸镍在水中的溶解度都很大,故水量的增加对镍、铁、铜浸出率的提高意义不大。

2.2.3 浸出温度的影响

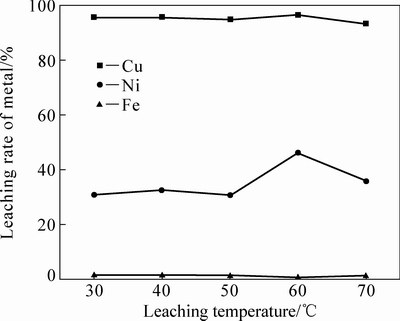

将粒度为74~80 μm的矿粉在600 ℃下焙烧2 h,焙烧熟料水浸,考察浸出温度分别为30~70 ℃时对镍、铁、铜浸出的影响。水浸出条件如下:液固比6:1,时间为2 h,结果如图12所示。

图11 液固比对镍铁铜浸出率的影响

Fig. 11 Effect of liquid-solid rate on leaching rate of Ni, Fe and Cu

图12 浸出温度对镍铁铜浸出率的影响

Fig. 12 Effect of leaching temperature of solvent on leaching rate of Ni, Fe and Cu

由图12可知,浸出温度对铜的浸出率影响不大。镍的浸出率在30~50 ℃段略有波动,在浸出温度为60 ℃时达到最大值,为46.25%,温度继续升高,镍浸出率降低。铁的浸出率很低,稳定在1%左右。

2.2.4 浸出时间的影响

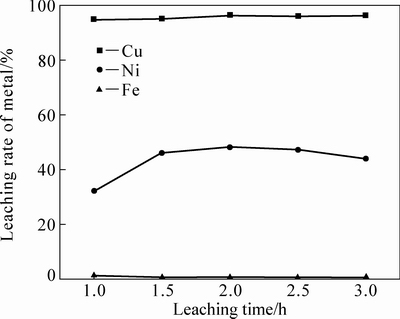

将粒度为74~80 μm的矿粉在600 ℃下焙烧2 h,焙烧熟料水浸,考察浸出时间分别为1~3 h时对镍、铁、铜浸出的影响。水浸出条件如下:液固比6:1,温度60 ℃,结果如图13所示。

由图13可知,浸出时间对铜的浸出率影响不明显,稳定在96%左右,镍的浸出率随着浸出时间由1 h增加到1.5 h时,提高较为明显,之后延长浸出时间对浸出影响不大。铁的浸出率很低,在0.8%左右。

图13 浸出时间对金属浸出率的影响

Fig. 13 Effect of leaching time on leaching rate of metal

3 结论

1) 铜镍氧硫混合矿在焙烧过程中金属硫化物转化成金属硫酸盐,但硫酸铁在温度较高时不稳定,以氧化铁的形式存在。

2) 矿粉粒度对铜的浸出影响较大,随矿粉粒度的增大铜浸出率呈先增大后减小趋势。焙烧温度对铜、镍浸出影响显著,均呈随焙烧温度升高而增大。焙烧时间对镍的浸出影响明显,随焙烧时间的增加镍浸出率先显著增大后维持不变。铜镍氧硫混合矿氧化焙烧的适宜条件如下:矿粉粒度74~80 μm,焙烧温度600 ℃,焙烧时间2 h。

3) 水作为浸出溶剂,对焙烧熟料中铜、镍、铁浸出效果较好。液固比对铜、镍浸出影响不明显;浸出温度对影响显著,随浸出温度升高镍的浸出率呈先不变、显著增加后降低的趋势。镍的浸出受浸出时间的影响较大,随焙烧时间的增加先升高,后保持稳定。焙烧熟料水浸出的适宜条件如下:液固比6:1,浸出温度60 ℃,浸出时间2 h。

REFERENCES

[1] 汤中立. 中国的小岩体岩浆矿床[J]. 中国工程科学, 2002(6): 9-12.

TANG Zhong-li. Little rock the magmatic deposit of small rock body in China[J]. China Engineering Science, 2002(6): 9-12.

[2] 罗立群, 李金良, 曹佳宏. 哈密铜镍矿工艺矿物学特性与影响选矿的因素[J]. 中国有色金属学报, 2014, 24(7): 1846-1855.

LUO Li-qun, LI Jin-liang, CAO Jia-hong. Process mineralogy and factors affecting mineral processing for copper-nickel ore in Hami[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(7): 1846-1855.

[3] 刘欣伟, 胡文韬, 李浩然, 冯雅丽. 高镁型低品位硫化镍矿浸出工艺及机理[J]. 中国有色金属学报, 2014, 24(6): 1599-1606.

LIU Xin-wei, HU Wen-tao, LI Hao-ran, FENG Ya-li. The leaching process and mechanism of high magnesium low grade nickel sulphide ore[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(6): 1599-1606.

[4] 王 娟. 碱性脉石低品位镍矿氨-铵盐体系浸出的研究[D]. 长沙: 中南大学, 2009.

WANG Juan. Study on ammonia-ammonium leaching of low grade nickel ore with high alkali gangue content[D]. Changsha: Central South University, 2009.

[5] 燕凌羽, 王安建. 全球镍资源供需格局浅析[J]. 中国矿业, 2016(4): 1-5.

YAN Ling-yu. WANG An-jian. Analysis of global nickel supply and demand patterns[J]. Chin Mining Magazine, 2016(04): 1-5.

[6] SIMATE G S, NDLOUU S, WALUBITA L F. The fungal and chemolithotrophic leaching of nickel laterites—Challenges and opportunities[J]. Hydrometallurgy, 2010, 103(1): 150-157.

[7] JOSE P M S, JORDI C, SALVADOR G, WILLIAMS M, ARMANDO R, JOSE E. Composition and dissolution kinetics of garnierite from the Loma de Hierro Ni laterite deposit Venezuela[J]. Chemical Geology, 2008, 249(1): 191-202.

[8] SMILIE J W, YIP S H. The outlook for nickel[J]. Metall, 1998, 52(6): 346-349. (in Germany)

[9] 王瑞廷, 毛景文, 柯 洪, 王东生. 我国西部地区镍矿资源分布规律、成矿特征及勘查方向[J]. 矿产与地质, 2003(1): 266-269.

WANG Rui-ting, MAO Jing-wen, KE Hong, WANG Dong-sheng. The region distribution, metallogenic features and exploration direction of nickel ore resources in Chinese western area[J]. Mineral Resources and Geology, 2003(1): 266-269.

[10] 孙 涛, 王登红, 钱壮志, 付 勇, 陈郑辉, 娄德波. 中国镍矿成矿规律初探[J]. 地质学报, 2014(12): 2227-2251.

SUN Tao, WANG Deng-hong, QIAN Zhuang-zhi, FU Yong, CHEN Zheng-hui, LOU De-bo. Summary of metallogenic regularity for the nickel deposite, China[J]. Acta Geologica Sinica, 2014(12): 2227-2251.

[11] NORGATE T, JAHANSHAHI S. Low grade ores-Smelt, leach or concentrate?[J]. Minerals Engineering, 2010, 23(2): 65-73.

[12] LIU Xin-wei, FENG Ya-li, LI Hao-ran, YANG Zhi-chao, CAI Zhen-lei. Recovery of valuable metals from a low-grade nickel ore using an ammonium sulfate roasting-leaching process[J]. International Journal of Minerals, Metallurgy and Materials, 2012, 19(5): 377-383.

[13] YANG Cong-ren, QIN Wen-qing, LAI Shao-shi, WANG Jun, ZHANG Yan-sheng, JIAO Fen, REN Liu-yi, ZHUANG Tian, CHANG Zi-yong. Bioleaching of a low grade nickel-copper- cobalt sulfide ore[J]. Hydrometallurgy, 2011, 106(1): 32-37.

[14] MU Wen-ning, ZHAI Yu-chun, LIU Yan. Leaching of magnesium from desiliconization slag of nickel laterite ores by carbonation process[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(5): 87-91.

[15] CHEN Tao, LEI Chang, YAN Bo, XIAO Xian-min. Metal recovery from the copper sulfide tailing with leaching and fractional precipitation technology[J]. Hydrometallurgy, 2014, 147(8): 178-182.

[16] 周贺鹏, 李运强, 雷梅芬, 徐 晶, 王鹏程, 翁存建. 某难选微细粒铜镍硫化矿选矿新工艺研究[J]. 矿冶工程, 2015(1): 35-38.

ZHOU He-peng, LI Yun-qiang, LEI Mei-fen, XU Jing, WANG Peng-cheng, WEN Cun-jian. A new beneficiation technology to choose some microgranular copper and nickel sulfide ore[J]. Mining and Metallurgical Engineering, 2015(1): 35-38.

[17] FENG Bo, LUO Xian-ping, XU Jing, WENG Cun-jian. Elimination of the adverse effect of cement filling on the flotation of a nickel ore[J]. Minerals Engineering, 2014, 69: 13-14.

[18] 马 琼, 盂建荣, 侯 伟. 我国镍闪速熔炼技术的发展[J]. 中国有色冶金, 2012, 41(4): 31-33.

MA Qiong, MENG Jian-rong, HOU Wei. The development of nickel flash smelting technology in China[J]. China Nonferrous Metallurgy, 2012, 41(4): 31-33.

[19] 刘树峰. 闪速熔炼技术发展趋势[J]. 铜业工程, 2013(5): 8-11.

LIU Shu-feng. The development trend of flash smelting technology[J]. Copper Engineering, 2013(5): 8-11.

[20] LI Y J, PEREDERIY I, PAPANGELAKIS V G. Cleaning of waste smelter slags and recovery of valuable metals by pressure oxidative leaching[J]. Journal of Hazardous Materials, 2008, 152(2): 607-615.

[21] KOPKOVA E K, GROMOV P B, SHCHELOKOVA E A. Decomposition of converter copper-nickel slag in solutions of sulfuric acid[J]. Theoretical Foundations of Chemical Engineering, 2011, 45(4): 505-510.

[22] YU Guo-lin, ZHANG Ying, ZHENG Shi-li, ZOU Xing, WANG Xiao-hui, ZHANG Yi. Extraction of arsenic from arsenic-containing cobalt and nickel slag and preparation of arsenic-bearing compounds[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(6): 1918-1927.

[23] 陈国玺. 我国某矿田硫化物和硫盐类矿物差热失重分析的研究[J]. 地球化学, 1976(3): 201-212.

CHEN Guo-xi. A research using thermo-gravimetric to analyse sulfide and sulfur saline minerals differential analysis in one of mine field in our country[J]. Geochimica, 1976(3): 201-212.

[24] 周传华, 胡 沁, 李国勋, 郁 强. 水淬对金精矿焙砂中磁黄铁矿性质的影响[J]. 有色金属, 1998(4): 82-84, 81.

ZHOU Chuan-hua, HU Qin, LI Guo-xun, YU Qiang. The effect about pyrrhotite properties in the gold concentrate calcine using water quenching[J]. Nonferrous Metals, 1998(4): 82-84, 81.

[25] SWAMY Y V, KAR B B, MOHANTY J K. Physico-chemical characterization and sulphatization roasting of low-grade nickeliferous laterites[J]. Hydrometallurgy, 2003, 69(1/3): 89-98.

Transformation of cooper, nickel and iron of oxide-sulfide mixed copper-nickel ore during roasting-leaching process

CUI Fu-hui1, MU Wen-ning2, 3, GU Xing-li1, XU Qian4, ZHAI Yu-chun2, 3

(1. School of Material and Metallurgy, Northeastern University, Shenyang 110819, China;

2. School of Resources and Materials, Northeastern University at Qinhuangdao, Qinhuangdao 066004, China;

3. Key laboratory of Clean Conversion and Efficient Utilization to Resource in Qinhuangdao, Qinhuangdao 066004, China;

4. School of Materials Science and Engineering, Shanghai University, Shanghai 200072, China)

Abstract: With the resource shortage of nickel sulfide ore, the new process is needed to treat the oxide-sulfide mixed copper-nickel mixed ore. DTA-TG and XRD of ore at different roasting temperatures and thermodynamic analysis were used to reveal the phase transition at the roasting stage. The influences of mineral particle size, roasting temperature and roasting time on the element transformation of copper, nickel and iron were studied at the roasting process of oxide-sulfide mixed copper-nickel ore. The influences of different leaching solvents, liquid-solid ratio, leaching temperature and leaching time on the leaching of copper, nickel and iron were studied during leaching process. The results show that when the particle size of mineral powder is 74-80 μm, the roasting temperature is 600 ℃, roasting time is 2 h, using water as solvent, leaching temperature is 60 ℃, liquid-solid ratio is 6:1 and leaching time is 2 h, the leaching ratios of copper and nickel reach the maximum, 46.25% and 96.27%, respectively.

Key words: oxide-sulfide mixed copper-nickel ore; roasting; leaching; transformation

Foundation item: Project (2014CB643405) supported by the Natural Program on Key Basic Research of China; Project (51204036) supported by the National Natural Science Foundation of China; Project (BJ201604) supported by Hebei College Youth Top-notch Talent, China; Project (152304010) supported by Basic Research Expenses of Central University, China

Received date: 2015-12-15; Accepted date: 2016-12-06

Corresponding author: MU Wen-ning; Tel: +86-335-8071038; E-mail: muwn@neuq.edu.cn

(编辑 李艳红)

基金项目:国家重点基础研究发展计划资助项目(2014CB643405);国家自然科学基金资助项目(51204036);河北省高等学校青年拔尖人才项目(BJ201604);中央高校基本科研业务费资助项目(N152304010)

收稿日期:2015-12-15;修订日期:2016-12-06

通信作者:牟文宁,副教授,博士;电话:0335-8071038;E-mail:muwn@neuq.edu.cn