DOI: 10.11817/j.ysxb.1004.0609.2021-36561

含钪钒钛磁铁矿尾矿焙烧-浸出提取分离钪

肖军辉1, 2, 3, 4,彭 杨1,陈 涛1,邹 凯1,丁 威1

(1. 西南科技大学 环境与资源学院,绵阳 621010;

2. 西南科技大学 四川省非金属矿粉体改性与高质化利用工程实验室,绵阳 621010;

3. 四川省钒钛资源综合利用重点实验室,攀枝花 617000;

4. 西南科技大学 固体废物处理与资源化利用教育部重点实验室,绵阳 621010)

摘 要:采用氯化焙烧和碱分解焙烧方法预先处理钪粗精矿(Sc2O3 44 g/t),强化载钪矿物晶体结构的转变,为焙烧渣进一步浸出分离钪创造有利条件。结果表明:在Na2CO3和钪粗精矿质量比为0.45、焙烧温度为900 ℃、焙烧时间为120 min、盐酸浸出液固质量比(mliquid:msolid) R=5:1、盐酸浓度为6 mol/L的条件下两段浸出240 min,钪的浸出率为84.32%,浸出渣中Sc2O3含量为8.67 g/t。浸出渣的XRD、SEM-EDS及化学成分分析结果表明:浸出后钪粗精矿中的辉石类、角闪石等硅铝酸盐矿物物相谱峰消失,出现NaCl、CaTiO3、Fe2O3的谱峰,未见明显金属钪的谱峰,也进一步验证碱分解焙烧能够有效地破坏载矿物的晶体结构;强化矿物层间结构中的钪离子被释放,有助于焙烧渣盐酸浸出生成ScCl3,显著提高钪的浸出率。

关键词:钪;含钪钒钛磁铁矿尾矿;焙烧;浸出

文章编号:1004-0609(2021)-06-1611-10 中图分类号:TD982 文献标志码:A

引文格式:肖军辉, 彭 杨, 陈 涛, 等. 含钪钒钛磁铁矿尾矿焙烧-浸出提取分离钪[J]. 中国有色金属学报, 2021, 31(6): 1611-1620. DOI: 10.11817/j.ysxb.1004.0609.2021-36561

XIAO Jun-hui, PENG Yang, CHEN Tao, et al. Extraction of scandium from Sc-bearing V-Ti magnetite tailings using roasting and leaching[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(6): 1611-1620. DOI: 10.11817/j.ysxb.1004.0609.2021-36561

钪属于广义的稀土元素,也是典型的稀散元 素[1]。全世界钪储量约为200万t,但是大部分的钪资源赋存于铝土矿、钛铁矿以及磷块岩中,可被开采利用的钪矿石较为罕见,并且含钪矿物成分复杂,钪含量低,分离、提取工艺复杂,导致钪产量低,价格高[2-3]。但钪及钪合金拥有高熔点、低密度等优良性能,在照明行业、合金工业、陶瓷行业、核能工业等国民生产生活中发挥出色的作用,科研工作者一直在探寻回收钪的工艺[4]。

自然界中含钪矿物种类多达上百种,但钪的独立矿物仅有钪钇矿、铍硅钪矿和水磷钪矿等少数几种,难以见到钪的独立矿床。面对日益增长的钪需求量,从含钪矿物如铝土矿、钨锡镍矿、钛冶金副产品、稀土、铀矿等资源中回收钪成为目前最优良的解决途径。由于钪在含钪原料中极其分散,并且原料组成复杂,钪在回收其他矿物过程中走向变化大,并不能高效地将钪富集起来,所以一般来说是通过化学方法将钪转化为可溶性化合物,从而达到回收钪的目的。例如铝土矿中钪的回收工艺可采用赤泥高温焙烧后的烧渣以酸浸出,浸出液即可进一步提纯回收钪;钨锡尾矿中的钪回收则是直接酸浸,浸出液再萃取、沉淀、煅烧即可获得高纯度的Sc2O3;钛冶金工艺中,钪主要存在于硫酸盐法生产钛白的废液中或者高钛渣氯化生产TiCl4时产生的氯化烟尘中,对于钛白废液中的钪回收目前有较为成熟的工艺,氯化烟尘中钪的回收采用水浸-萃取-除杂-煅烧工艺可以获得纯度为99%的氧化钪[4-8]。

对于钒钛磁铁矿尾矿中钪资源的回收利用国外还未见有报道,国内有学者采用硫酸化焙烧分解、酸浸萃取等方法处理钒钛磁铁矿含钪尾矿,取得了一定的成果,但是对于钪含量极低的矿石没有做过多的研究[9-11]。攀西地区钒钛磁铁矿尾矿经再次磁选后的尾矿中除了含有极少量的钛铁矿、磁赤铁矿外,其他主要矿物为钠长石、钙长石、辉石、绿泥石、云母等,其中含有44 g/t 的Sc2O3。目前对于该部分钪资源的回收研究不多,适合钪的回收方案更是少见。本研究综合考虑众多回收钪的工艺,借助现有资料,对比不同方案对钪的回收效果,总结出有利于从钪含量低的矿石中回收钪的工艺技术,为回收钒钛磁铁矿尾矿中的钪提供基本思路。

1 实验

1.1 矿石性质

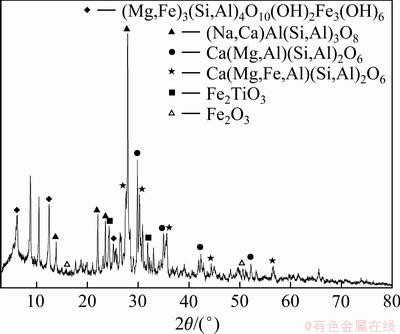

本研究所用矿石为攀西地区某钒钛磁铁选矿厂选铁选钛后产生的尾矿,该尾矿在实验室经过再次磁选选别铁和钛后的磁选矿作为提钪原矿(钪粗精矿),钪粗精矿的主要化学成分分析结果见表1,钪粗精矿的X射线衍射(XRD)分析结果见图1。

钪粗精矿中含Fe2O3 11.84%、TiO2 4.36%、Sc2O3 44 g/t,X射线衍射分析表明钪粗精矿除了含有极少量的钛铁矿、磁赤铁矿外,其他主要矿物为钠长石、钙长石、辉石、绿泥石、云母等。查阅文献[12-13]可知,金属钪在钒钛磁铁矿尾矿中赋存不明显,主要集中在辉石类、长石类、角闪石和云母等矿石中。对钪粗精矿进行富集钪探索试验,但富集效果并不明显,并且容易造成钪损失,由此确定采用强磁选铁钛的磁选尾矿直接作为提钪原矿。

图1 钪粗精矿的XRD谱

Fig. 1 XRD pattern of coarse scandium concentrate

1.2 试验方法

现有研究[12-13]表明,钪粗精矿中金属钪主要存在于辉石类、长石类矿物中,钪极易取代铁、铝等主要元素,即金属钪是以类质同象的形式存在于辉石类矿物中,这就造成采用传统的选矿方法无法高效率富集钪。本文作者欲采用焙烧的方法,在焙烧助剂与高温的双重作用下破坏辉石类、长石类矿物结构,使得矿物层间结构中的金属钪被释放出来,采用酸浸工艺进一步处理焙烧后,钪转变为Sc3+进入浸化液,以达到分离提取钪的目的。具体试验流程为:将钪粗精矿与焙烧助剂充分混合均匀后加水制粒再干燥,干燥后的矿粒进行焙烧,烧渣再以酸液浸出,得到浸出液与浸出渣,通过分析浸出液中的钪含量来表征钪粗精矿中钪的浸出率,由此确定试验条件。

试验过程中使用的主要仪器设备为:荷兰PANalytical公司产Axios X射线荧光光谱仪与X Pert pro X射线衍射仪、英国Thermo Fisher Scientific公司产ICAP6500电感耦合等离子发射光谱仪、德国Carl zeissNTS GmbH公司产UItra55高分辨冷场发射扫描显微镜分析系统、上海实研电炉有限公司产SXW-8-16型程控电炉(≤1200 ℃)、邦西仪器科技(上海)有限公司产SHZ-D(Ⅲ)型循环水真空泵、黄石市恒丰医疗器械有限公司产8FG-01B型电热恒温鼓风干燥箱。

表1 钪粗精矿主要化学成分分析结果

Table 1 Main chemical composition analysis results of coarse scandium concentrate (mass fraction, %)

2 结果与讨论

2.1 氯化焙烧

已有研究表明[14-16],对于白云鄂博稀选尾矿和包头稀土尾矿中的钪资源,采用添加氯化剂在一定条件下焙烧,焙烧矿在酸性条件下浸出,可以获得较高的钪浸出率。本文作者将此法运用至本试验中,探索钒钛磁铁矿尾矿中钪资源的提取回收工艺条件。

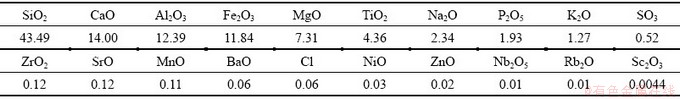

以NaCl、CaCl2、KCl、MgCl2作为氯化剂,探究氯化剂种类、用量、焙烧温度、焙烧时间等因素对钪浸出的影响。

2.1.1 氯化剂种类与焙烧温度对钪浸出的影响

氯化焙烧即以氯化剂提供氯离子,在高温条件下,Sc2O3与氯离子结合生成ScCl3[10]。每种氯化剂因物化性质不同,氯化焙烧造成的结果必定也有所区别。氯化焙烧试验流程:钪粗精矿与氯化剂(氯化剂用量均为10%)混合均匀,加水制粒烘干后焙烧90 min,烧渣用6 mol/L盐酸、在液固质量比R=5:1、水浴80 ℃保温的条件下浸出120 min,试验结果见图2。

根据图2中的数据可知,添加氯化剂后钪的浸出率均超过30%,并且随着焙烧温度的提高,钪浸出率有所增加。但当焙烧温度超过900 ℃后,浸出率反而下降,这是因为温度过高导致过烧,烧渣形成难以破碎的块状体甚至玻璃体。以MgCl2做氯化剂的实验组浸出率相对较高,并且在焙烧温度900 ℃时达到最高,浸出率为43.32%,浸出渣钪含量为19.37 g/t,推测认为高温条件下MgCl2中Mg2+可以和粗精矿矿中的镁一同与矿石发生反应,降低粗精矿的熔融温度,由此导致该试验组释放出更多的钪,所以浸出率略高于其他试验组[10]。综合考虑选择MgCl2作为焙烧选钪粗精矿的氯化剂。

图2 氯化剂种类与焙烧温度对钪浸出的影响

Fig. 2 Effect of chlorination agent and roasting temperature on scandium leaching

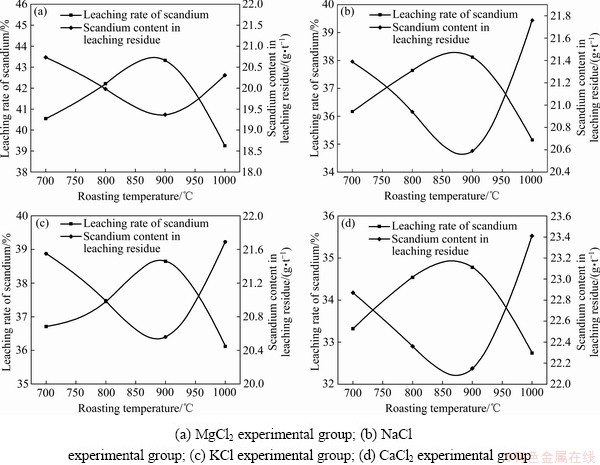

2.1.2 氯化镁用量对钪浸出的影响

由于精矿矿中含有Ca2+、Al3+、Na+等可被氯化的金属离子,若是氯化剂用量过少,那么ScCl3的产量也会相应减少,导致浸出率过低;但用量过大,又会造成药剂浪费,增加成本,因此,有必要分析氯化剂用量对钪浸出过程的影响。

进行相关试验分析氯化镁用量对钪浸出的影响,具体试验流程为:将MgCl2与钪粗精矿混合均匀加水制粒烘干后,在900 ℃条件下焙烧90 min,烧渣用6 mol/L盐酸,在液固质量比R=5:1、水浴80 ℃保温的条件下浸出150 min,测定钪浸出率,分析MgCl2用量对钪浸出率的影响,试验结果见图3。

图3 氯化镁用量对钪浸出的影响

Fig. 3 Effect of magnesium chloride content on scandium leaching

根据图3可知,随着氯化镁用量增加,钪的浸出率也随之增加,但当氯化镁用量超过15%后,钪浸出率开始下降。由此确定氯化焙烧浸出钪氯化镁最佳用量为15%,此时钪浸出率为43.79%,浸出渣钪含量为19.21 g/t。

由此可以得出,采用氯化焙烧浸出钪的方案难以将尾矿中的钪浸出,此法对于稀土尾矿效果明显,但针对钒钛磁铁矿钪粗精矿选钪却有所限制。究其原因,本试验所使用的钪粗精矿中钪含量相对稀土尾矿更低,在氯化钪的同时将钠、镁、铝、钙等也一并氯化,从而导致浸出作业时其余氯盐包覆于烧渣表面,阻碍钪的浸出[19-20]。

2.2 碱分解焙烧

文献[11, 13, 21]表明钒钛磁铁矿尾矿中的钪存在于脉石层间架构中,为提高钪浸出率,首先需要破坏硅酸盐的稳定结构。由此,本文作者采用Na2CO3与尾矿混合焙烧,利用其强碱性在高温条件下与硅铝酸盐矿物反应,以达到破坏矿石结构的目的。

2.2.1 碳酸钠用量与焙烧温度对钪浸出的影响

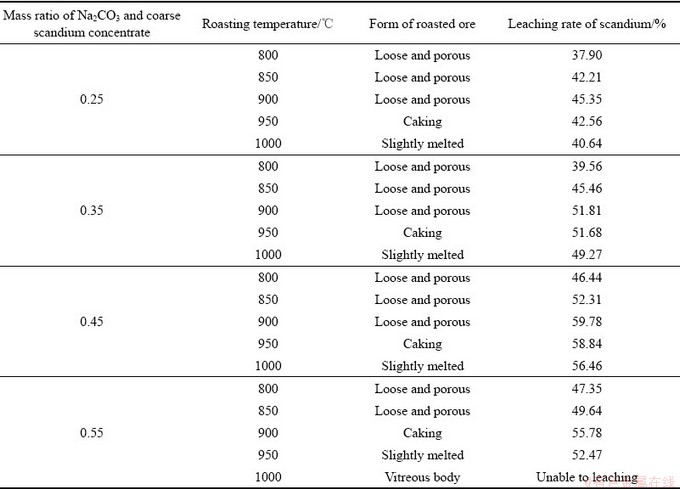

碳酸钠用量与钪粗精矿质量的比值(以下称碱矿比)。该组试验的试验流程为:在钪粗精矿中混入不同配比的碳酸钠,磨细后加水制粒烘干,在不同温度下焙烧120 min,烧渣采用6 mol/L盐酸、在液固质量比R=5:1的条件下浸出90 min,测定钪浸出率,试验结果见表2。

由表2可知,同一焙烧温度条件下,随着碳酸钠用量的增加,钪浸出率也增加,但碳酸钠用量过多,反而出现了浸出率下降的现象。综合分析了焙烧温度与碱矿比之间的关系,发现碱矿比为0.45时对焙烧浸出钪较为有利。固定碱用量,在不同温度下焙烧浸出,可知在一定温度范围内,随着焙烧温度的升高,钪浸出率也随之增加,当温度达到1000 ℃时,钪浸出率快速下降。分析认为,随着碱用量的增加,选钪钪粗精矿中的辉石等脉石矿物被破坏的量也有所增加,把更多的钪从矿物层间结构中释放出来,并且随着焙烧温度的升高,脉石矿物的结构也越容易被破坏,从而钪浸出率也提高;但当用碱过量时,易造成烧渣在较低温度即出现熔融现象。同时,焙烧温度过高容易导致脉石矿物转化为玻璃体物质,焙烧渣破碎和磨矿的难度提高,物料之间的包覆现象严重,不利于钪的选择性浸出,进而降低钪的浸出率。因此,确定碱矿比为0.45,焙烧温度为900 ℃,此时钪浸出率为59.78%。

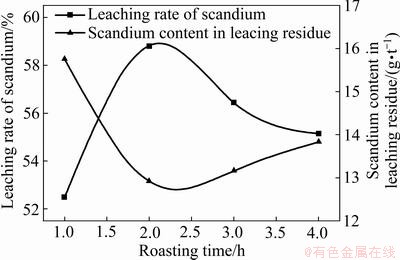

2.2.2 焙烧时间对钪浸出率的影响

焙烧时间同样也会影响碱分解效果,焙烧时间对钪浸出影响的试验流程为:在碱矿比为0.45时将两者混合均匀,加水制粒烘干,在焙烧温度900 ℃,盐酸浓度为6 mol/L、在液固比R=5:1的条件下浸出90 min,测定钪浸出率及浸出渣钪含量,试验结果见图4。

据图4可知,合理的焙烧时间对于钪浸出至关重要,焙烧时间为2 h时,钪的浸出率达到最大,浸出率为59.81%,浸出渣中钪含量12.92 g/t。这说明碱分解焙烧在1~2 h内基本完成,过长的焙烧时间使得矿粒出现熔融现象,反而钪的浸出率会降低。因此,确定碱焙烧时间为2 h。

表2 Na2CO3用量与焙烧温度对钪浸出的影响

Table 2 Effect of Na2CO3 dosage and roasting temperature on scandium leaching

图4 焙烧时间对钪浸出的影响

Fig. 4 Effect of roasting time on scandium leaching

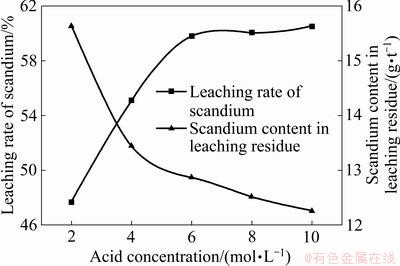

2.2.3 浸出酸浓度对钪浸出率的影响

酸用量对钪浸出率有较大影响,分析酸用量对钪浸出影响的试验流程为:在碱矿比0.45时将两者混合均匀,加水制粒烘干后,于焙烧温度900 ℃条件下焙烧2 h,烧渣用不同浓度盐酸在液固比R=5:1的条件下浸出90 min,测定钪浸出率及浸出渣钪含量,试验结果见图5。

图5 酸浓度对钪浸出的影响

Fig. 5 Effect of acid concentration on scandium leaching

由图5结果可以看出,浸出过程对酸浓度的依赖性较大,一定范围内增加浸出酸浓度,可大幅提高钪浸出率。当酸浓度超过6 mol/L后,继续提高酸浓度,钪浸出率小幅增加。考虑到经济性问题,确定浸出酸浓度为6 mol/L,此时钪浸出率为59.79%,浸出渣钪含量为12.87 g/t。

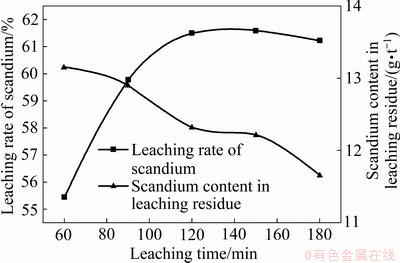

2.2.4 浸出时间对钪浸出率的影响

加碱高温焙烧使得大部分钪从辉石层间结构中释放出来,再以盐酸浸出,即可将钪转化为可溶性氯盐ScCl3进入溶液中,浸出时间将在一定程度上影响钪的转化量。

试验流程:在碱矿比0.45的比例下将两者混合均匀,加水制粒烘干后,于焙烧温度900 ℃条件下焙烧2 h,烧渣用6 mol/L盐酸、在液固质量比R=5:1的条件下浸出不同时间,测定钪浸出率及浸出渣钪含量,试验结果见图6。

据图6可知,在将钪从辉石类、长石类矿物结构中释放出来的前提下,适当延长浸出时间,可以提高钪浸出率,当浸出时间为120 min时,钪浸出率为61.48%,浸出渣钪含量为12.32 g/t,浸出时间为150 min时,钪浸出率为61.59%,浸出渣钪含量12.32 g/t,二者差距较小,浸出时间达到180 min后,钪浸出率反而有所下降。这是由于整个浸出环境为强酸性,该条件下会溶解部分矿粒表面,随着浸出时间的加长,被溶解的矿粒增多,使得浸出液浓度增加,溶解下来的部分矿渣将会附着于矿粒表面,阻碍酸液与矿粒内部的反应;且溶解下来的细小矿粒极易发生团聚,将部分浸出液包裹住,这便使得部分浸出液难以从浸出渣中冲洗下来,从而导致浸出时间增加,钪的浸出率反而减小。由此可以确定,浸出时间为120 min较为合适。

图6 浸出时间对钪浸出的影响

Fig. 6 Effect of leaching time on scandium leaching

2.2.5 浸出液固比对钪浸出率的影响

浸出过程中,矿浆液固比的大小将直接影响矿物颗粒表面与酸接触面积,合理的液固比也是高浸出率的影响因素之一。

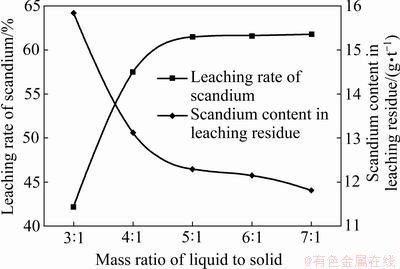

试验流程:在碱矿比0.45的比例下将两者混合均匀,加水制粒烘干后,于焙烧温度900 ℃条件下焙烧2 h,烧渣用6 mol/L盐酸、在不同液固比的条件下浸出120 min,测定钪浸出率及浸出渣钪含量,试验结果见图7。

试验过程中发现,较低的液固比将导致矿浆呈现出胶状,失去流动性,无法进行浸出作业。据图7可知,增加液固比,可显著提高钪浸出率,但当液固质量比超过5:1后,浸出率变化不大,此因素不再是影响浸出率的关键因素,由此确定浸出作业液固比为5:1,此时钪浸出率为61.5%,浸出渣钪含量为12.29 g/t。为提高浸出率,将一次浸出渣在相同条件下再次浸出,计算综合浸出成果。

图7 浸出液液固比对钪浸出的影响

Fig. 7 Effect of mass ratio of liquid to solid of leachate on scandium leaching

2.2.6 碱分解焙烧-浸出提取钪综合试验

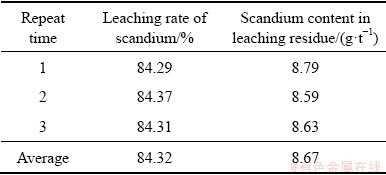

本文探索了碱分解焙烧-二次浸出钒钛磁铁矿尾矿中的钪资源,得到了提取过程中的主要工艺参数,为验证分离指标的稳定性,在碱矿比0.45,焙烧温度900 ℃条件下焙烧2 h,烧渣用6 mol/L盐酸、在液固质量比为R=5:1的条件下两段浸出240 min,重复3次,测定钪浸出率及浸出渣钪含量,结果见表3所示。

由表3可知,3次试验的钪浸出率与浸出渣中钪含量变化较小,即碱分解焙烧-浸出综合条件较为稳定。3次作业钪浸出率平均值为84.32%,浸出渣钪含量为8.67 g/t。

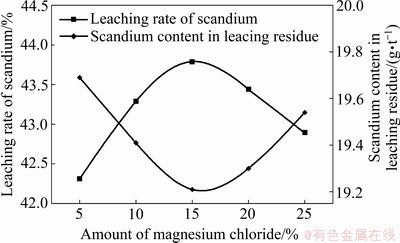

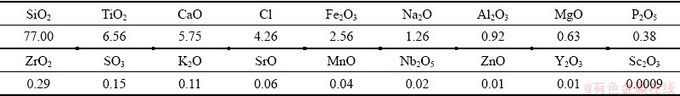

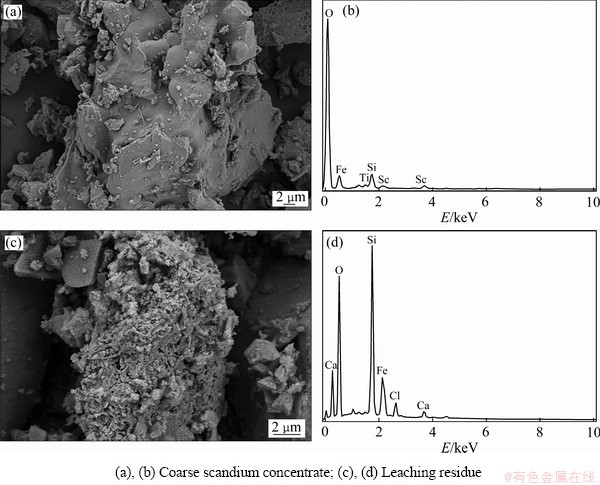

2.2.7 浸出渣分析

钪粗精矿经碱分解焙烧-浸出工艺,可将钪粗精矿中大部分的钪转移到液相中。为了解浸出渣中化学组成与矿物形态,分析了浸出渣的化学成分,结果见表4;浸出渣的X射线衍射分析结果见图8;钪粗精矿与浸出渣的扫描电镜图、能谱分析结果如图9所示。

表3 综合条件试验

Table 3 Comprehensive condition test

图8 浸出渣的XRD谱

Fig. 8 XRD pattern of leaching residue

表4 浸出渣化学成分分析

Table 4 Chemical composition analysis of leaching residue (mass fraction, %)

图9 钪粗精矿与浸出渣的SEM像与EDS谱分析结果

Fig. 9 SEM images((a), (c)) and EDS spectra analysis results((b), (d)) of coarse scandium concentrate and leaching residue

对比钪粗精矿与浸出渣的化学成分变化,可以得出矿物中硅含量基本不变,钙、铝、铁、镁、钛等金属离子有不同程度的减少,Sc2O3含量也明显减少。浸出渣的X射线衍射分析结果表明,图谱中存在NaCl、CaTiO3、Fe2O3的谱峰,而钪粗精矿中的长石类、辉石类、角闪石等硅铝酸盐矿物物象谱峰消失,由此可以说明钪粗精矿中存在的载钪矿物物相已被破坏,存在于矿物层间结构中的钪离子被释放出来,具备了与酸液反应生成ScCl3的条件。对比钪粗精矿与浸出渣的扫描电镜图可以明显看出,钪粗精矿表面较为光滑平整,而浸出渣颗粒已经严重腐蚀,矿物结构已被破坏,这与浸出渣的X射线衍射分析结果相吻合。钪粗精矿的能谱分析中能够清楚见到金属钪的谱峰,而浸出渣的能谱分析却难以找到金属钪的谱峰,由此说明钪粗精矿经碱分解焙烧-浸出后,大部分的金属钪已经从矿石结构中转移至浸出液内,验证了碱分解焙烧-浸出工艺提钪方案的可行性。

3 结论

1) 攀西地区含钒钛磁铁矿经过磁选进一步脱除铁钛后,获得Sc2O3含量为44 g/t的钪粗精矿,钪粗精矿中除了少量的钛铁矿与磁赤铁矿以外,主要成分为钠长石、钙长石、辉石、绿泥石、云母等。采用氯化焙烧-浸出与碱分解焙烧-浸出两种工艺对钪粗精矿进行提钪,结果发现两种方法均能一定程度浸出钪,但后者效果较好。

2) 通过条件试验得出,碱分解焙烧-浸出具体工艺条件为:在碱矿比为0.45、焙烧温度为900 ℃条件下焙烧2 h,烧渣用6 mol/L盐酸在液固比为5:1的条件下两段浸出,每段浸出120 min,总共可获得钪浸出率为84.32%,浸出渣钪含量为8.67 g/t的钪分离提取指标。

3) 浸出渣的XRD、SEM-EDS及化学成分分析结果表明,钪粗精矿中的金属元素有不同程度的溶解,但浸渣中硅含量基本不变。物相分析表明,浸出渣中未出现长石类、辉石类等矿物的特征峰,说明经碱分解焙烧-浸出工艺,可以破坏钪粗精矿中硅酸盐的晶型结构,钪从载钪矿物层间结构被释放出来,为盐酸浸出分离钪和提高钪的浸出率提供有利条件。

REFERENCES

[1] 汪镜亮. 钪的提取和回收[J]. 矿产综合利用, 1995(3): 35-42.

WANG Jing-liang. Extraction and recovery of scandium[J]. Multipurpose Utilization of Mineral Resources, 1995(3): 35-42.

[2] 郑明贵, 陈艳红. 世界稀土资源供需现状与中国产业政策研究[J]. 有色金属科学与工程, 2012, 3(4): 70-74.

ZHENG Ming-gui, CHEN Yan-hong. Supply and demand of global rare earth resources and China’s rare earth industry policy[J]. Nonferrous Metals Science and Engineering 2012, 3(4):70-74.

[3] 王普蓉, 戴惠新, 高利坤, 等. 钪的回收及提取现状[J]. 稀有金属, 2012, 36(3): 501-506.

WANG Pu-rong, DAI Hui-xin, GAO Li-kun, et al. Status of scandium recovery and extraction[J]. Chinese Journal of Rare Metals, 2012, 36(3): 501-506.

[4] 陈哲海. 钒钛磁铁矿中微量钪的测定[J]. 矿冶工程, 1990(3): 54-56.

CHEN Zhe-hai. The determination of microamounts of scandium in vanadous titanomagnetite[J]. Mining and Metallurgical Engineering, 1990(3): 54-56.

[5] 柯家骏. 湿法冶金提钪的进展[J]. 稀有金属, 1987(5): 372-376.

KE Jia-jun. Progress in extracting scandium by hydrometallurgy[J]. Chinese Journal of Rare Metals, 1987(5): 372-376.

[6] 刘召波. 高铁赤泥中钪钠选择性分离提取工艺基础研究[D]. 北京: 北京科技大学, 2017.

LIU Zhao-bo. Metallurgical process for selective leaching and extraction of scandium and sodium from iron rich bauxite residue[D]. Beijing: University of Science & Technology Beijing, 2017.

[7] 张邦安. 从钨、锡、铀、钛、铝、锆等矿物原料中提取钪(综述)[J]. 湿法冶金, 1989(3): 38-41.

ZHANG Bang-an. Extracting scandium from minerals such as tungsten, tin, uranium, titanium, aluminum, and zirconium (review) [J]. Hydrometallurgy of China, 1989(3): 38-41.

[8] 柯家骏, 陆正亚, 涂桃枝, 等. 从钛氯化烟尘中提取氧化钪的研究[J]. 稀有金属, 1983(2): 1-6.

KE Jia-jun, LU Zheng-ya, TU Tao-zhi, et al. Study on extracting scandium oxide from titanium chloride fume[J]. Chinese Journal of Rare Metals, 1983(2): 1-6.

[9] WNAG Wei-wei, PRANOLO Y, CHENG Chu-yong. Metallurgical processes for scandium recovery from various resources: A review[J]. Hydrometallurgy, 2011, 108(1): 100-108.

[10] 肖军辉, 施哲, 陈金花. 含钪钛矿石氯化焙烧-浸出分离钪研究[J]. 稀土, 2015, 36(2): 21-28.

XIAO Jun-hui, SHI Zhe, CHEN Jin-hua. Study on separation of scandium from scandium-containing titanium ore by chlorination roasting-leaching[J]. Chinese Rare Earths, 2015, 36(2): 21-28.

[11] 佘宗华, 毛建军, 徐 舜. 攀枝花含钪钛尾矿分解试验研究[J]. 矿冶, 1999(1): 54-57.

SHE Zong-hua, MAO Jian-jun, XU Shun. Study on decomposition of Panzhihua electrostatic separation tailings of V-Ti-Sc magnetite tailings[J]. Mining and Metallurgy, 1999(1): 54-57.

[12] 黄霞光, 罗国清, 李亚平. 攀西钒钛磁铁矿中钪的赋存状态研究[J]. 有色金属(选矿部分), 2016(6): 1-4.

HUANG Xia-guang, LUO Guo-qing, LI Ya-ping. Study on the occurrence state of scandium in Panxi vanadium-titanium magnetite[J]. Nonferrous Metals(Mineral Processing Section) , 2016(6): 1-4.

[13] 张宗华, 张桂芳. 选钛尾矿分选钪实验研究[J]. 中国矿业, 2003(11): 36-38.

ZHANG Zong-hua, ZHANG Gui-fang. Study on test of separating scandium from tailing of titanium separation[J]. China Mining Magazine, 2003(11): 36-38.

[14] 马升峰. 白云鄂博稀选尾矿中钪的提取工艺研究[D]. 呼和浩特: 内蒙古大学, 2012.

MA Sheng-feng. Study on extraction technology of scandium form the Bayanobo tailings[D]. Huhhot: Inner Mongolia University, 2012.

[15] 魏彤彤. 从包头稀土尾矿中提取有价组分钪的研究[D]. 沈阳: 东北大学, 2017.

WEI Tong-tong. Extraction of valuable scandium component from Baotou rare earth tailings[D]. Shenyang: Northeastern University, 2017.

[16] 李 梅, 耿金龙, 高 凯, 等. 白云鄂博尾矿中钪的浸出及铌富集物制备工艺研究[J]. 稀土, 2017, 38(5): 111-119.

LI Mei, GENG Jin-long, GAO Kai, et al. Study on technology for leaching of scandium and preparation of niobium[J]. Chinese Rare Earths, 2017, 38(5): 111-119.

[17] 高 峰, 马永静. Mg2+和Na+对高熔点煤灰熔融性的影响[J]. 燃料化学学报, 2012, 40(10): 1161-1166.

GAO Feng, MA Yong-jing. Study on the effect of Mg2+ and Na+ on the fusibility of coal ash with high ash fusion point[J]. Journal of Fuel Chemistry and Technology, 2012, 40(10): 1161-1166.

[18] 范浩杰, 何柯佳, 刘俊杰, 等. 镁基助熔剂对高灰熔点煤灰熔融影响的机理[J]. 动力工程学报, 2015, 35(1): 19-24.

FAN Hao-jie, HE Ke-jia, LIU Jun-jie, et al. Mechanism study on the effect of magnesium-based flux on the fusibility of coal ash with high fusion point[J]. Chinese Journal of Power Engineering, 2015, 35(1): 19-24.

[19] 毛建军, 范剑琴, 佘宗华. 攀枝花选钛尾矿提钪工艺的研究[J]. 矿冶工程, 1996(4): 48-52.

MAO Jian-jun, FAN Jian-qin, SHE Zong-hua. Scandium extraction from Panzhihua titanium tailing[J]. Mining and Metallurgical Engineering, 1996(4): 48-52.

[20] 林维聪, 温 涛, 刘起明, 等. 从广西某钒钛磁铁矿选钛尾矿中回收钪的试验研究[J]. 矿产综合利用, 1986(2): 16-19.

LIN Weri-cong, WEN Tao, LIU Qi-ming, et al. Experimental research on recovery of scandium from titanium tailings of a vanadium-timagnetite mine in Guangxi[J]. Multipurpose Utilization of Mineral Resources, 1986(2): 16-19.

[21] 张宗华, 庄故章. 用萃取法从攀枝花选钛尾矿中提钪[J]. 稀土, 1999(3): 25-28.

ZHANG Zong-hua, ZHUANG Gu-zhang. Extracting Sc2O3 from tails of separating Ti in Panzhihua[J]. Chinese Rare Earths, 1999(3): 25-28.

Extraction of scandium from Sc-bearing V-Ti magnetite tailings using roasting and leaching

XIAO Jun-hui1, 2, 3, 4, PENG Yang1, CHEN Tao1, ZOU Kai1, DING Wei1

(1. School of Environment and Resources, Southwest University of Science and Technology, Mianyang 621010, China;

2. Sichuan Provincial Engineering Laboratory of Non-Metallic Mineral Powder Modification and High-Value Utilization, Southwest University of Science and Technology, Mianyang 621010, China;

3. Key Laboratory of Sichuan Province for Comprehensive Utilization of Vanadium and Titanium Resources, Panzhihua 617000, China;

4. Key Laboratory of Ministry of Education for Solid Waste Treatment and Resource Recycle, Southwest University of Science and Technology, Miangyang 621010, China)

Abstract: The chlorination roasting and alkali decomposition roasting were used to pre-treat coarse scandium concentrate (Sc2O3 content of 44 g/t) to strengthen the transformation of crystal structure of scandium-bearing minerals and create favorable conditions for further leaching scandium from roasting slag. The results show that scandium leaching efficiency of 84.32% is obtained, and the content of Sc2O3 in the leaching residue is 8.67 g/t under the compressive conditions of alkali decomposition roasting-leaching process as follows: mass ratio of Na2CO3 to coarse of 0.45, roasting temperature of 900 ℃, roasting time of 120 min, hydrochloric acid mass ratio of leaching liquid to solid ratio (R) 5:1, hydrochloric acid concentration of 6 mol/L, two-stage leaching for 240 min. XRD, SEM-EDS and chemical composition analysis results of the leaching residue show that, after leaching, the physical image spectral peaks of pyroxene, hornblende and other aluminate minerals in scandium coarse concentrate disappear, and the spectral peaks of NaCl, CaTiO3 and Fe2O3 appear, and there is no obvious spectral peak of scandium metal. It is also further verified that the alkali decomposition roasting can effectively destroy the crystal structure of the mineral, and the scandium ion in the enhanced interlayer structure of the mineral is released. It is helpful for hydrochloric acid leaching of roasting slag to produce SCCl3 and improve the leaching rate of scandium obviously.

Key words: Sc; Sc-bearing V-Ti magnetite tailings; roasting; leaching

Foundation item: Project (2018FZ0092) supported by Sichuan Science and Technology Program, China

Received date: 2020-06-10; Accepted date: 2020-11-30

Corresponding author: XIAO Jun-hui; Tel: +86-13990190544; E-mail: xiaojunhui33@163.com

(编辑 李艳红)

基金项目:四川省科技计划资助项目(2018FZ0092)

收稿日期:2020-06-10;修订日期:2020-11-30

通信作者:肖军辉,副教授,博士;电话:13990190544;E-mail:xiaojunhui33@163.com