文章编号:1004-0609(2014)11-2900-06

采用硫化铵去除冶炼烟气中的重金属

施 勇,王学谦,郭晓龙,马懿星,王郎郎,宁 平

(昆明理工大学 环境科学与工程学院,昆明 650500)

摘 要:以管式气氛炉作发生器,通过加热重金属氧化物,模拟冶炼厂重金属烟气。采用硫化铵沉淀化处理含铅、镉、汞的冶炼烟气,考察了硫化铵溶液的浓度、pH及SO2等条件对铝、镉、汞去除效果的影响。结果表明:硫化铵法吸收净化含铅、镉、汞烟气的最佳浓度分别为0.2、0.2和0.8 mol/L,最佳反应pH均为10。在最佳反应条件下,铅、镉、汞的净化效率可分别达到95.5%、93.2%、99.9%,烟气出口铅、镉、汞浓度均达到《大气污染物综合排放标准》(GB16297—1996)。此外,SO2对硫化铵吸收净化重金属有抑制作用。

关键词:硫化铵;重金属;净化效率

中图分类号:X51 文献标志码:A

Removal of heavy metals from smelting flue gas by ammonium sulfide

SHI Yong, WANG Xue-qian, GUO Xiao-long, MA Yi-xing, WANG Lang-lang, NING Ping

(Faculty of Environmental Science and Engineering,

Kunming University of Science and Technology, Kunming 650500, China)

Abstract: Tubular resistance furnace was used as a reactor to simulate smelter flue gas of heavy metals by heating heavy metal oxides. And the flue gas containing Pb, Cd and Hg was treated with ammonium sulfide solution. The experiment was conducted to investigate the effects of (NH4)2S concentration, pH value of solution and the existence of SO2 on removal efficiency. The results show that the optimal concentration of Pb, Cd and Hg absorbed by ammonium sulfide solutions are 0.2, 0.2 and 0.8 mol/L, respectively. And the optimal pH value is 10. Under the optimum conditions, the removal efficiency of Pb, Cd and Hg reach 95.5%, 93.2% and 99.9%, respectively. The emission concentration of Pb, Cd and Hg reach the requirements of Air Pollutant Emission Standard (GB16297-1996). In addition, SO2 can reduce the removal efficiency of heavy metals of smelter flue gas.

Key words: ammonium sulfide; heavy metal; removal efficiency

重金属污染主要集中在铜、铅、钴、锌、锑和汞等有色金属冶炼过程中,其中铅锌冶炼污染最为严重。铅锌冶炼生产过程中重金属污染物主要包括铅、镉、砷、汞等,污染范围包括水、大气和土壤[1-2]。

大气中铅污染主要是气态污染,以铅烟和铅尘形式存在,来源于采矿、锡焊、含铅汽油的燃烧、含铅产品的生产等过程[3-4]。高温条件下铅的挥发程度大, 所以火法熔炼过程中容易导致铅的挥发损失以及引起的环境污染。铅的氧化物形态多变,常见的如Pb3O4、PbO2以及PbO。常温多以Pb3O4存在,高温多以PbO存在。镉污染来自于铅锌矿冶炼、煤炭的燃烧和垃圾焚烧[5]。镉的毒性能持久地存在于环境和生物体内。大气中镉的形态有硫酸镉、硒硫化镉、硫化镉和氧化镉等,主要附着于固体颗粒物中。汞是一种具有持久性、生物累积性和生物扩大作用的有毒污染物,对人类健康和生态环境具有很大的负面影响。烟气中汞的存在形式主要有两种:气态汞(Hg2+、Hg0)和固态颗粒附着物。当温度高于800 ℃时,汞的化合物易分解成气态汞,气态汞的挥发性较高、水溶性较低,极难控制[6]。

目前,国内外对砷、汞重金属的研究居多,铅、镉相对较少。净化烟气中重金属主要采用吸附法[7-10]、催化氧化法[11-12]、化学沉淀法[13]。由于铅、镉的价态相对稳定,且以细小颗粒态存在,吸附法、催化氧化法等方法并不适用。而硫化法[14-16]属于化学沉淀法之一,在国内应用较为广泛,主要用于去除废水里面的重金属,而将其用于去除废气中重金属的研究和应用很少。本文作者重点研究硫化铵法吸收净化冶炼烟气中铅、镉、汞3种重金属及其主要的影响因素,该方法是基于硫化铵溶液中S2-与烟气中铅、镉、汞反应生成沉淀,达到净化目的,也有利于铅镉汞的回收利用,实现循环经济,为净化烟气中重金属的工程应用提供基础研究和理论依据。

1 实验

1.1 实验、仪器设备及试剂

实验所需设备主要有管式气氛炉;刚玉管;空气泵;质量流量计;PHS-3C酸度计;Z-2010偏振塞曼原子分光光度计;F-732冷原子吸收测汞仪。

实验所用药品主要有硫化铵((NH4)2S)、红色氧化铅(Pb3O4)、氧化镉(CdO)、氯化汞(HgCl2),均为分析纯,购于上海国药有限集团公司。

1.2 实验装置

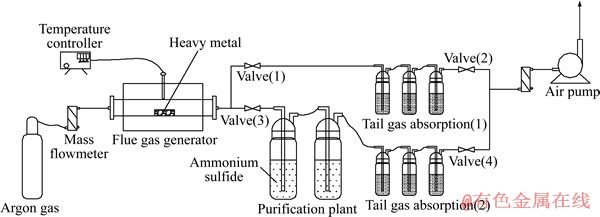

硫化铵法净化含重金属冶炼烟气的实验装置如图

1所示。氩气为载气,管式气氛炉为烟气模拟发生器,盛有硫化铵溶液的吸收瓶为净化装置。实验所模拟的烟气均为单一重金属烟气,实验过程中模拟含铅、镉、汞烟气采用的化合物分别为红色氧化铅(Pb3O4)、氧化镉(CdO)、氯化汞(HgCl2),相应的尾气吸收液为HNO3和H2O2混合液(V(HNO):V(H2O2)=1:1)、HNO3和H2O2混合液(V(HNO3):V(H2O2)=1:1)、酸性KMnO4溶液。实验过程中,重金属化合物(Pb3O4、CdO、HgCl2)在反应器中被高温加热成挥发态,与氩气混合形成模拟烟气。如图1所示,开启阀1、阀2,关闭阀3、阀4时,用尾气吸收装置1(根据美国环保总署EPA测定方法来确定模拟烟气中重金属的浓度)收集模拟烟气中重金属,时间为15 min,得到未经硫化铵溶液处理时模拟烟气中重金属的浓度C0;关闭阀1、阀2,开启阀3、阀4,用尾气吸收装置2收集经硫化铵溶液吸收后模拟烟气中重金属,时间为15 min,得到经硫化铵溶液处理后模拟烟气中重金属的浓度Cn,进而计算烟气中重金属的含量。

1.3 实验方法

冶炼烟气模拟实验。通过控制管式电阻炉加热温度、气体流量,得到固定浓度的重金属烟气。经过大量预实验,模拟铅、镉、汞烟气的最佳温度分别为900、1000和450 ℃,流量分别为200、200和150 mL/min,模拟烟气中铅、镉、汞的浓度可达到10~15、2~7和10~30 mg/m3,与冶炼厂实际状况相符。

硫化铵法吸收净化含铅、镉、汞的冶炼烟气,主要采用硫化铵作沉淀剂,使铅、镉、汞以PbS、CdS、HgS的形式沉淀下来,从而达到净化烟气的目的,化学反应如式(1)~(4)所示:

(1)

(1)

(2)

(2)

图1 实验装置图

Fig. 1 Schematic diagram of experimental apparatus

(3)

(3)

(4)

(4)

配制0~0.8 mol/L不同浓度硫化铵溶液,各取50mL用于吸收净化模拟烟气中Pb、Cd和Hg这3种重金属,考察浓度对其净化效率的影响,进而确定(NH4)2S溶液的最佳浓度。

配好实验已确定的最佳浓度的硫化铵溶液,通过1% NaOH与1%盐酸溶液调节其pH,制成不同pH的硫化铵溶液,再各取50 mL用于吸收净化Pb、Cd和Hg,考察pH对其净化效率的影响。

配好最佳浓度的硫化铵溶液,将二氧化硫持续通入硫化铵溶液,随着时间的增加,硫化铵溶液的pH会不断下降,在此过程中,各取50 mL不同pH的硫化铵溶液吸收净化Pb、Cd和Hg,考察二氧化硫对其净化效率的影响。

烟气中重金属的浓度(mg/m3)计算式如式(5)所示:

(5)

(5)

式中:ρL为尾气吸收液中重金属浓度,mg/L;VL为尾气吸收液体积,mL;Q为烟气流量,mL/min;t为烟气收集时间,min。

净化效率计算公式如式(6)所示:

(6)

(6)

式中:ρn为经硫化铵吸收后烟气中重金属的浓度;ρ0为未经硫化铵吸收时烟气中重金属的浓度,mg/L。

尾气吸收液中铅的浓度根据火焰原子吸收分光光度法(HJ538-2009)测定,尾气吸收液中镉的浓度火焰原子吸收分光光度法(HJ/T 64.1-2001)测定,尾气吸收液中汞的浓度冷原子吸收分光光度法(HJ542-2009)测定。

2 结果与讨论

2.1 沉淀的XRD分析

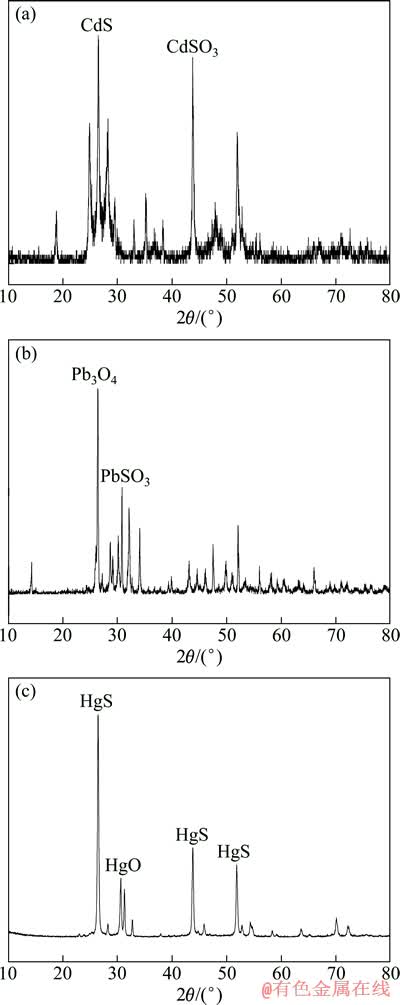

图2所示为重金属沉淀的XRD谱。由图2(a)可知,吸收含镉模拟烟气所产生的沉淀中主要以CdS和CdSO3为主,CdO含量很少。这充分说明硫化铵吸收含镉的重金属烟气主要以化学吸收为主。由图2(b)可知,吸收含铅模拟烟气所产生的沉淀主要以Pb3O4为主,PbSO4次之,PbS含量很少。由此可知,硫化铵吸收含铅的重金属烟气主要以物理吸收为主,少部分铅和硫化铵反应生成含铅的沉淀。图2(c)则是硫化铵吸收含汞烟气后产生的沉淀物的XRD分析,由图2(c)可知,沉淀中HgS为主要物相,所以硫化铵吸收含汞烟气主要是化学吸收作用。

图2 重金属沉淀的XRD谱

Fig. 2 XRD patterns of heavy metals precipitation containing Cd (a), Pb (b) and Hg (c)

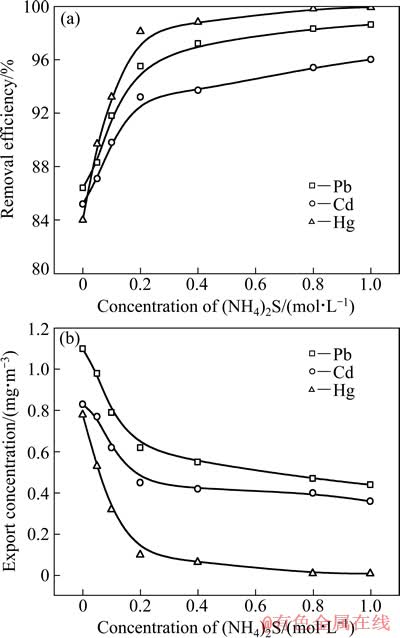

2.2 硫化铵浓度对烟气中铅、镉和汞净化效果的影响

硫化铵溶液的浓度是影响硫化铵法的净化效果和运行成本的重要参数。硫化铵溶液的浓度过高不仅会造成水中S2-浓度过高,而且会增加处理成本。硫化铵溶液的浓度过低也会使烟气中重金属净化效率降低,造成排放烟气中重金属超标。实验考查了硫化铵浓度对烟气中Pb、Cd和Hg净化效果的影响,其结果见图3。

从图3可看出,铅、镉、汞净化效率均随硫化铵吸收液浓度的升高而升高。硫化铵浓度从0到0.2 mol/L,铅、镉净化效率升高非常明显,铅的净化效率从86.4%提高到95.5%,镉的净化效率从85.2%提高到93.2%,同时,汞的净化效率从82.3%提高到98.1%。硫化铵浓度为0.2 mol/L时,出口烟气中铅、镉的浓度分别为0.65和0.45 mg/m3,均已达到大气污染物综合排放标准(GB16297-1996),而汞的浓度为0.1 mg/m3,未能达标。当浓度大于0.2 mol/L时,铅、镉和汞的净化效率均可达到95%以上,但提高趋势均较平缓。继续提高硫化铵浓度至0.8 mol/L时,汞的净化效率达到99.9%,出口烟气中汞的浓度<0.01 mg/L,达到大气污染物的综合排放标准。在同一浓度下,3种重金属的净化效率由大到小的顺序依次为Hg、Pb、Cd,说明硫化铵更易和Hg反应生成沉淀,这3种金属的Ksp由小到大的顺序依次为HgS、PbS、CdS。硫化铵净化烟气中铅、镉和汞均效果较好,结合净化效率和经济效益考虑,硫化铵吸收液净化含铅、镉和汞烟气的最佳浓度分别为0.2、0.2和0.8 mol/L。

图3 硫化铵浓度对烟气中Pb、Cd和Hg去除的影响

Fig. 3 Influence of (NH4)2S concentration on removal of Pb , Cd and Hg from flue gas

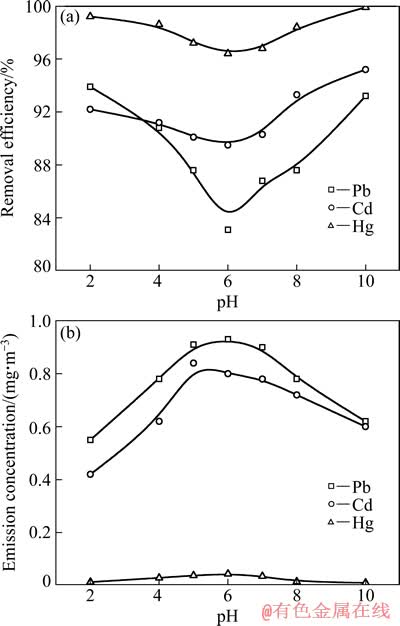

2.3 反应pH对烟气中铅、镉、汞净化效果的影响

硫化铵与烟气中重金属反应时,溶液pH也是影响硫化铵法对烟气中重金属去除率的重要因素。S2-在水中的存在形态与溶液中H+结合形成HS-与H2S,化学反应如式(7)~(8)所示[17]:

,

, ,

, (7)

(7)

,

, ,

, (8)

(8)

H+与S2-的结合降低了S2-的使用效率。实验考察了pH对烟气中Pb、Cd、Hg净化效果的影响,实验结果见图4。从图4可知,在pH为2~10的条件下,重金属净化效率随pH的升高在式(2)~(6)呈现下降趋势,在式(6)~(10)中呈现上升的趋势。Pb的波动区间为89.5%~95.5%,Cd为83.1%~93.2%,Hg为96.4%~ 99.9%,其中,当pH为6~7时,净化效率最低。在酸性很强时,气态重金属被分解成离子态,离子态铅镉与硫离子反应生成的硫化铅和硫化镉沉淀又迅速被分解,所以重金属大部分以离子态铅镉被捕集留在水中;而在碱性很强时,气态铅镉汞一部分与硫离子反应生成重金属硫化物沉淀而被捕集,一部分因降温实现固气分离,直接停留在水中。pH=10时,Pb、Cd和Hg的净化效率均在92%以上,且出口烟气中铅、镉、汞的浓度分别为0.65、0.45和<0.01 mg/m3,均符合大气污染物综合排放标准(GB16297-1996)。考虑到离子态的重金属仍需进一步处理,碱性条件更适合铅镉烟气的净化。因此,硫化铵吸收液净化含铅、镉、汞烟气的最佳pH均为10。

图4 pH对烟气中Pb、Cd和Hg去除的影响

Fig. 4 Influence of pH on removal of Pb , Cd and Hg from flue gas

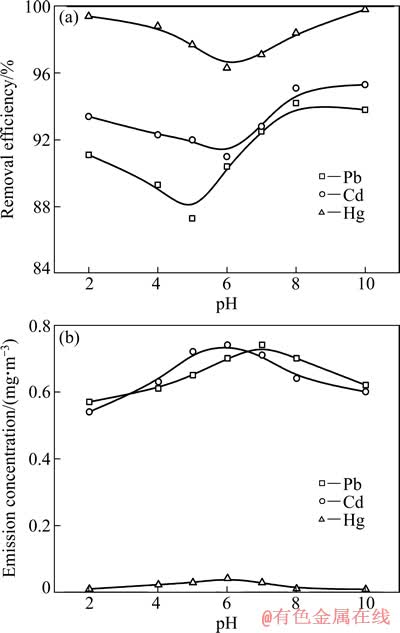

2.4 SO2对烟气中铅镉汞净化效果的影响

铅锌冶炼的原料有原矿和精矿,原矿石中所含矿物种类可分为硫化矿和氧化矿。自然界中铅锌矿石还是硫化矿最多,其中硫含量高达27%~32%[18],冶炼过程中会产生大量的SO2,因此,SO2也是影响烟气净化重金属的重要因素。

图5 SO2对烟气中Pb、Cd和Hg去除的影响

Fig. 5 Influence of SO2 on removal of Pb , Cd and Hg from flue gas

实验考察了SO2对Pb、Cd、Hg净化效果的影响,实验过程中通入不同时间的SO2,随着SO2与硫化铵反应,溶液中S2-逐渐减少而S2O32-等酸性离子逐渐增加(见式(9))。这样,硫化铵的pH就会逐渐下降,就可以制得不同PH的硫化铵溶液,结果见图5。由图5可知,在pH为2~10条件下,重金属去除率随pH升高,先降低再升高。由式(9)和(10)可知,这一过程中,硫化铵易与SO2反应,消耗了溶液中的S2-,从而抑制了S2-与重金属反应。随着SO2持续通入,溶液由碱性渐渐变成酸性,气态重金属被分解成离子态,捕集于溶液中。当pH为5~6时,Hg去除率从99.9%降低到96.4%,Pb净化效率从95.2%降低到93.2%,Cd净化效率从93.7%降低到91.7%。因此,SO2对烟气重金属净化效果有一定的抑制作用。

(9)

(9)

(10)

(10)

3 结论

1) 结合净化效率和经济效益考虑,硫化铵吸收液净化铅、镉、汞烟气的最佳浓度分别为0.2、0.2和0.8 mol/L。且同一反应条件下,3种重金属的净化效率由大到小的顺序依次为Hg、Pb、Cd。

2) 硫化铵吸收净化重金属效率随pH的升高呈现下降趋势,在呈现上升的趋势。pH=6时,3种重金属去除率均降至最低,碱性条件下,Pb、Cd、Hg均能以其硫化物沉淀的方式实现分离。因此,硫化铵法吸收净化重金属的最佳pH为10。

3) 在上述最佳反应条件下,铅、镉、汞的出口浓度分别为0.65、0.45、<0.01 mg/m3,均已达到《大气污染物综合排放标准》(GB16297-1996)。

4) 在硫化铵吸收净化冶炼烟气中重金属的过程中,SO2的存在会消耗硫化铵溶液中硫离子,从而降低重金属的去除效率。

REFERENCES

[1] 林星杰. 铅冶炼行业重金属污染现状及防治对策[J]. 有色金属工程, 2011, 1(4): 23-27.

LIN Xing-jie. Present situation and control methods of heavy metals pollution from lead smelting industry[J]. Nonferrous Metallurgical Engineering, 2011, 1(4): 23-27.

[2] 林世英. 有色冶金环境工程学[M]. 长沙: 中南工业大学出版社, 1992: 34-39.

LIN Shi-ying. Environmental engineering for nonferrous metallurgy[M]. Changsha: Central South Industry University Press, 1992: 34-39.

[3] 吴忠标. 大气污染控制工程[M]. 北京: 科学出版社, 2002: 54-55.

WU Zhong-biao. Engineering for air pollution control [M]. Beijing: Science Press, 2002: 54-55.

[4] 黄 萍. 大气中铅烟及铅尘的污染及研究现状[J]. 科技创新导报, 2009, 3(8): 109-110.

HUANG Ping. Current situation of pollution and research on lead smoke and lead dust in the atmosphere[J]. Science and Technology Innovation Herald, 2009, 3(8): 109-110.

[5] 周 琳. 成都经济区大气降尘中铅、镉的环境化学行为研究[D]. 成都: 成都理工大学, 2006: 2-5.

ZHOU Lin. Environmental chemical behavior research of lead and cadmium in atmospheric dust from Chengdu economic zone[D]. Chengdu: Chengdu University of Technology, 2006: 2-5.

[6] 崔 夏, 马丽萍, 邓春玲, 许文娟, 毛 宇. 燃煤烟气中汞去除的研究进展[J]. 化工进展, 2011, 30(7): 1607-1613.

CUI Xia, MA Li-ping, DENG Chun-ling, XU Wen-juan, MAO Yu. Research progress of removing mercury from coal-fired flue gas[J]. Chemical Industry and Engineering Progress, 2011, 30(7): 1607-1613.

[7] MERCEDES D S, ROSA M T. High-temperature removal of cadmium from a gasification flue gas using solid sorbents[J]. Fuel, 2005, 84: 717-721.

[8] THOMAS K, ISABEL M L. Feasibility of mercury removal from simulated flue gas by activated chars made from poultry manures[J]. Journal of Environmental Management, 2010, 91: 2466-2470.

[9] JOST O L, WENDT, SUNG J L. High-temperature sorbents for Hg, Cd, Pb and other trace metals: Mechanisms and applications[J]. Fuel, 2010, 89: 894-903.

[10] YANG X F, SHEN Z G. Silica nanoparticles capture atmospheric lead: Implications in the treatment of environmental heavy metal pollution[J]. Chemosphere, 2013, 90: 653-656.

[11] 张 郃, 赵建涛, 房倚天, 王 洋. 活性炭催化氧化脱除单质汞的研究[J]. 燃料化学学报, 2011, 39(5): 373-377.

ZHANG He, ZHAO Jian-tao, FANG Yi-tian, WANG Yang. Stabilized oxidation and adsorption of elemental mercury by activated carbon[J]. Journal of Fuel Chemistry and Technology, 2011, 39(5): 373-377.

[12] FANG P, CEN C P, WANG X M. Simultaneous removal of SO2, NO and Hg0 by wet scrubbing using urea KMnO4 solution[J]. Fuel Processing Technology, 2013, 106: 645-653.

[13] 李洪桂. 稀有金属冶金学[M]. 北京: 冶金工业出版社, 1990: 55-56.

LI Hong gui. Rare metals metallurgy[M]. Beijing: Metallurgical Industry Press, 1990: 55-56.

[14] BJORGE D, JOEL H. Removal of heavy metals occurring in the washing water of flue gas purification[J]. Chemical Engineering Journal, 2009, 150: 196-203.

[15] 谭浩强, 何文杰, 韩宏大, 郑成志, 马 越, 陈玉琢, 卜建伟. 化学沉淀法强化常规工艺应急去除水中的镉[J]. 环境工程学报, 2013, 7(3): 848-852.

TAN Hao-qiang, HE Wen-jie, HAN Hong-da, ZHENG Cheng-zhi, MA Yue, CHEN Yu-zhuo, PU Jian-wei. Cadmium removal in water emergency treatment of conventional process enhanced by chemical precipitation[J]. Chinese Journal of Environmental Engineering, 2013, 7(3): 848-852.

[16] 谢 昊, 赵中伟, 曹才放, 梁 勇, 李江涛. 硫化法除钼过程中杂质砷的行为[J]. 中南大学学报: 自然科学版, 2012, 43(2): 435-439.

XIE Hao, ZHAO Zhong wei, CAO Cai fang, LIANG Yong, LI Jiang-tao. Behavior of arsenic in process of removing molybdenum by sulfide method[J]. Journal of Central South University: Science and Technology, 2012, 43(2): 435-439.

[17] PEKKA S, WILLIS F. Precipitation of lead sulfide for surface chemical studies[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2000, 172: 17-31.

[18] 魏 昶, 李存兄. 锌提炼冶金学[M]. 北京: 冶金工业出版社, 2013: 6-7.

WEI Chang, LI Cun-xiong. Zinc extractive metallurgy[M]. Beijing: Metallurgical Industry Press, 2013: 6-7.

(编辑 李艳红)

基金项目:国家高技术研究发展计划资助项目(2012AA062504);国家自然科学基金资助项目(U1137603,51268021,51368026)

收稿日期:2014-03-04;修订日期:2014-07-30

通信作者:王学谦,教授,博士;电话:13888183303;E-mail:wxqian3000@aliyun.com