锌加压浸出渣浮选硫精矿汞硫分离富集研究

王子阳1, 2, 3,张泽彪1, 2, 3,刘能生1, 2, 3,彭金辉1, 2, 3,王万坤1, 2, 3,陈安然1, 2, 3

(1. 昆明理工大学 云南省复杂有色金属资源清洁利用国家重点实验室(培育基地),云南 昆明,650093;

2. 昆明理工大学 非常规冶金省部共建教育部重点实验室,云南 昆明,650093;

3. 昆明理工大学 云南省微波能应用及装备技术工程实验室,云南 昆明,650093)

摘要:对锌加压浸出渣经浮选后的硫精矿中的汞硫分离、富集以及硫磺回收进行研究,确定硫化铵溶液浸出过程汞硫分离和浸出母液热分解回收硫磺的最佳工艺条件。试验结果表明:在常温常压下,(NH4)2S浓度为2.5 mol/L、液固比6:1、时间10 min的浸出条件下,硫浸出率达98.66%,汞在渣中的富集率为93.8%,浸出渣中汞含量为原矿的6倍以上;浸出母液在热分解温度94 ℃、分解时间90 min的条件下,硫磺回收率在98%左右,硫磺纯度符合GB/T 2449—2006工业硫磺一等品标准;硫化铵试剂可循环利用,回收率为91.76%。

关键词:锌加压浸出渣;浮选硫精矿;汞硫分离;硫磺回收;硫化铵

中图分类号:TF111;TQ125.1+1 文献标志码:A 文章编号:1672-7207(2013)03-0901-06

Separation and enrichment of mercury and sulfur from flotation sulfur concentrate derived from zinc pressure leaching residue

WANG Ziyang1, 2, 3, ZHANG Zebiao1, 2, 3, LIU Nengsheng1, 2, 3, PENG Jinhui1, 2, 3, WANG Wankun1, 2, 3, CHEN Anran1, 2, 3

(1. State Key Laboratory of Complex Nonferrous Metal Resources Cleaning Utilization in

Yunnan Province (Breeding Base), Kunming University of Science and Technology, Kunming 650093, China;

2. Key Laboratory of Unconventional Metallurgy, Ministry of Education,

Kunming University of Science and Technology, Kunming 650093, China;

3. Yunnan Engineering Laboratory of Microwave Energy Application and Equipment Technology,

Kunming University of Science and Technology, Kunming 650093, China)

Abstract: The separation and enrichment of mercury and sulfur recovery from flotation sulfur concentrate derived from zinc pressure leaching residue were studied. The optimum procedure parameters were determinated for separation of mercury and elemental sulfur in flotation sulfur concentrate leaching with ammonium sulfide and the recovery of elemental sulfur in polysulfide solution by thermal decomposition. The results show that 98.66% of elemental sulfur is leached, and 93.8% mercury is enriched in residue at liquid/solid ratio of 6:1 with 2.5 mol/L ammonium sulfide concentration in 10 min at room temperature, and the content of mercury is enriched 6 times or more in leaching residue. About 98% sulfur is recovered in polysulfide solution thermal decomposing at 94 ℃ in 90 min,with a purity of sulfur in accordance with the GB/T 2449—2006 industrial first-rate product standard. Ammonium sulfide can be recycled back into process and the efficiency of ammonium sulfide recovery is 91.76%.

Key words: zinc pressure leaching residue; flotation sulfur concentrate; separation of mercury and elemental sulfur; sulfur recovery; ammonium sulfide

化石燃料燃烧和有色金属冶炼是世界上最重要的人为汞排放源[1],而金属锌冶炼被认为是人为汞排放最重要的来源之一[2]。1999年中国有色冶炼大气汞排放量占人为汞排放总量的45%,其中约28%来自金属锌冶炼[3]。发达国家不仅制定了强制的汞排放政策和有效的控制措施,而且一些锌冶炼厂从废弃物中回收汞作为副产品[4]。近年来,一些研究者开展炼锌过程大气汞排放因子及其对周围环境影响的研究[5-7],这将为我国工业化炼锌过程中汞污染控制和治理提供可靠的科学依据。在传统湿法炼锌过程中,硫化锌精矿在焙烧时产生SO2烟气,精矿中汞以汞蒸汽的形式随SO2烟气进入制酸系统,冶炼烟气制酸过程去除汞的应用方法有碘化钾法和氯化法[8-9]。工业上处理含汞废水的方法有生物制剂法[10]、化学沉淀法[11]、吸附法[12]等。在全湿法炼锌过程中,硫化锌精矿中的硫元素在加压浸出时主要以便于存储和运输的固态元素硫存在浸出渣中,汞主要以硫化汞形式进入浸出渣,含硫汞渣的大量堆积,既污染环境,又造成资源浪费。湿法冶金渣中回收元素硫的方法很多[13-14],主要有物理 法[15]和化学法[16-18]。硫化铵法回收元素硫具有工艺流程简单,硫磺回收率高和回收的硫磺纯度高等特点[19],并且硫化铵中硫离子与渣中易溶解的汞离子反应生成溶度积极小的硫化汞(硫化汞溶度积仅为4×10-53)。为此,本文作者采用硫化铵法对锌加压浸出渣经浮选后的硫精矿中元素硫的回收以及汞的分离和富集进行研究,在回收硫磺时,使汞在渣中富集,硫化铵试剂循环使用,使试剂消耗和生产成本大大降低,具有广阔的工业应用前景。

1 试验研究

1.1 试验原料

试验原料为锌加压浸出渣经浮选后的硫精矿,元素硫含量(质量分数)为84.980%,占总硫量的94.89%,汞含量为951.700 g/t,汞的主要存在形式为硫化汞,另外还有少量可溶的硫酸汞和氯化汞。浮选硫精矿的主要化学成分(质量分数)如表1所示。试验所用的硫化铵为分析纯。

1.2 基本原理

在一定条件下,元素硫与含有S2-的(NH4)2S溶液作用生成多硫化铵而溶解转入溶液中,反应式为:

(x-1)S0+(NH4)2S=(NH4)2Sx

溶硫过程中,pH在9~10缓慢变化时,溶液中Hg2+与S2-生成HgS沉淀而留在浸出渣中,反应式为:

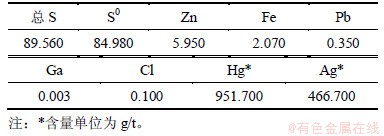

表1 浮选硫精矿化学分析结果

Table 1 Results of chemical analysis of flotation sulfur concentrate %

Hg2++S2-=HgS↓

矿石中元素硫被(NH4)2S溶解后,经过固液分离即可与不溶的浸出渣分离,之后将得到的多硫化铵母液在一定温度下加热分解,析出元素硫,反应式为:

(NH4)2Sx=H2S↑+2NH3↑+(x-1)S0

分解产生的气体产物H2S和NH3,首先通过冷凝后再将其导入水溶液中吸收可制得硫化铵溶液,再返回循环利用,分解析出的元素硫沉积在容器底部,反应结束后将溶液冷却并过滤出硫磺,风干后即得硫磺产品。

但是,在一定条件下,(NH4)2S溶液中过量的S2-还能和HgS继续反应,生成溶于水的汞络合阴离子而降低汞在渣中的富集率[12]。因此,需寻找合适的工艺条件,使浮选硫精矿中硫的浸出率最大,汞的浸出率最小,从而使汞富集在渣中。

1.3 工艺流程

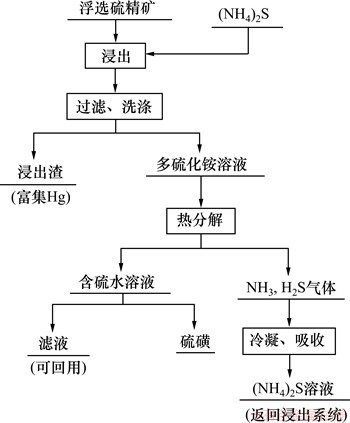

(NH4)2S法处理浮选硫精矿工艺流程如图1所示。

图1 (NH4)2S法处理浮选硫精矿工艺流程

Fig.1 Flowsheet of flotation sulfur concentrate treated by (NH4)2S method

2 试验结果和讨论

2.1 硫化铵溶液的浸出试验

2.1.1 (NH4)2S浓度对硫浸出率和汞富集率的影响

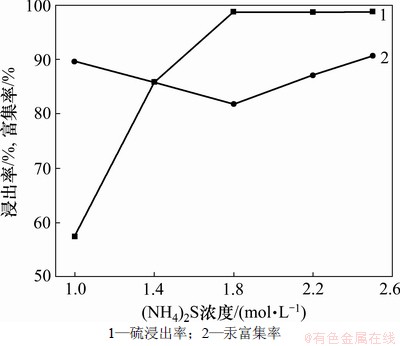

取浮选硫精矿50 g,液固比为6:1, 常温下浸出40 min,考察(NH4)2S浓度对硫浸出率和汞富集率的影响。试验结果如图2所示。

图2 (NH4)2S浓度对硫浸出率和汞富集率的影响

Fig.2 Effect of (NH4)2S concentration on sulfur leaching and mercury enrichment

从图2可以看出,随着(NH4)2S浓度从1.0 mol/L增加到1.8 mol/L时,元素硫浸出率急剧上升,溶液浓度达到1.8 mol/L后元素硫浸出率维持在98%以上。对汞元素来说,随着(NH4)2S浓度的增大,汞在渣中的富集率先减小后增大。元素硫浸出率较低时,对汞形成包裹,随着硫浸出率的提高,Hg2+逐渐被释放到溶液中,继续增加(NH4)2S浓度,多余的S2-与Hg2+形成HgS沉淀,汞在渣中的富集率明显提高。

2.1.2 液固比对硫浸出率和汞富集率的影响

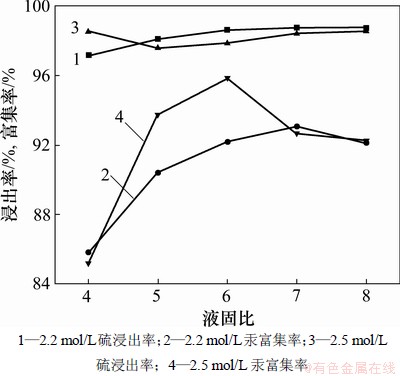

取浮选硫精矿50 g,在常温下,分别用浓度为2.2和2.5 mol/L硫化铵溶液浸出10 min,考察液固比对硫浸出率和汞富集率的影响。试验结果如图3所示。

从图3可以看出,在液固比为4:1~8:1的范围内,(NH4)2S浓度分别为2.2和2.5 mol/L时,元素硫浸出率变化不明显,维持在98%左右。在一定(NH4)2S浓度下,随着液固比的增大,汞在渣中的富集率先增大后减小,而且液固比对汞富集率的影响比对硫浸出率的影响更明显。提高硫化铵溶液的用量,有利于HgS沉淀,但过量的S2-能与HgS继续反应,生成可溶性络合阴离子[HgS2]2-,而降低汞的富集率。综合考虑硫的浸出率和汞的富集率,浸出试验选取在(NH4)2S浓度2.5 mol/L和液固比6:1条件下进行。

图3 不同浓度下液固比对硫浸出率和汞富集率的影响

Fig.3 Effect of liquid/solid ratio on sulfur leaching and mercury enrichment

2.1.3 浸出时间对硫浸出率和汞富集率的影响

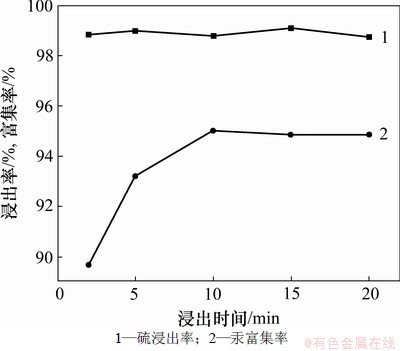

取浮选硫精矿50 g,在常温下,液固比为6:1,用浓度为2.5 mol/L的硫化铵溶液浸出,考察浸出时间对硫浸出率和汞富集率的影响。试验结果如图4所示。

图4 浸出时间对硫浸出率和汞富集率的影响

Fig.4 Effect of leaching time on sulfur leaching and mercury enrichment

从图4可以看出,浮选富集后的硫精矿用硫化铵溶液浸出时,溶硫效率很高,浸出时间为2 min时硫浸出率就达到98.5%以上,随着浸出时间的延长,浸出率已无明显变化。汞富集率在浸出时间2~10 min之内逐渐增加,10 min时达到最大值。

2.1.4 浸出温度对硫浸出率和汞富集率的影响

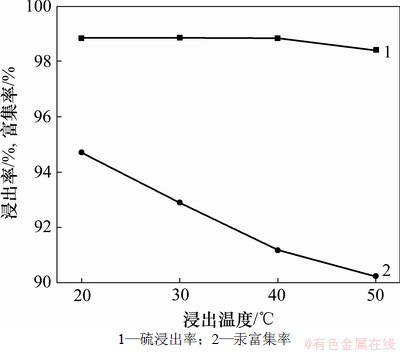

取浮选硫精矿50 g,液固比为6:1,用浓度为2.5 mol/L的硫化铵溶液浸出10 min,考察浸出温度对硫浸出率和汞富集率的影响。试验结果如图5所示。

图5 浸出温度对硫浸出率和汞富集率的影响

Fig.5 Effect of leaching temperature on sulfur leaching and mercury enrichment

从图5可以看出,硫化铵溶液溶硫过程中,温度对硫浸出率影响很小,在20~25℃均能获得很高的硫浸出率。然而随着浸出温度的升高,汞的富集率明显降低。浸出温度过高会造成硫化铵试剂的挥发和分解等损耗,减少溶液中S2-浓度,不利于HgS沉淀形成,降低汞在渣中的富集率。

2.2 多硫化铵母液的热分解试验

来自浸出过程所得到的含多硫离子的多硫化铵浸出母液,由于 的稳定性较差,在酸性或加热的条件下可被分解而析出元素硫,本试验采用蒸馏热分解方法回收硫磺。

的稳定性较差,在酸性或加热的条件下可被分解而析出元素硫,本试验采用蒸馏热分解方法回收硫磺。

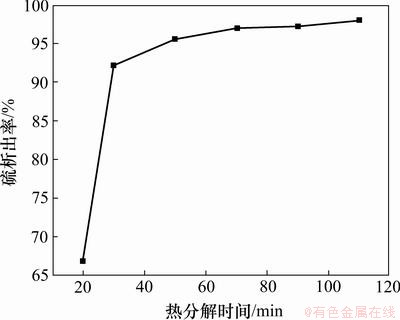

2.2.1 热分解时间对硫析出率的影响

在热分解温度90 ℃条件下,不同热分解时间对硫析出率的影响,结果如图6所示。

从图6可以看出,随着热分解时间的延长,浸出母液中硫析出率逐渐增加。分解时间30 min内硫析出率显著增加,此后随着时间的延长,硫析出率增加趋势变缓,90 min时硫析出率达到97%以上。试验发现,母液分解110 min后的残液颜色略带淡黄色,表明分解不彻底。蒸馏后期只延长热分解时间没有太大意义,应适当提高热分解温度加快气体产物的分解和逸出。

图6 热分解时间对硫析出率的影响

Fig.6 Effect of time of thermal decomposition on recovery of elemental sulfur

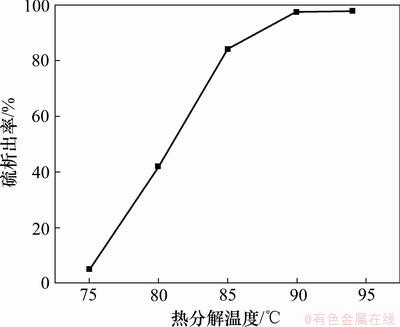

2.2.2 热分解温度对硫析出率的影响

热分解时间90 min,热分解温度在75~94 ℃(已沸腾)范围内对硫析出率的影响,结果如图7所示。

图7 热分解温度对硫析出率的影响

Fig.7 Effect of temperature of thermal decomposition on recovery of elemental sulfur

从图7可以看出,热分解温度对硫析出率的影响很大,90 ℃之前硫析出率随着温度的升高上升显著,继续升高温度到94 ℃,硫析出率虽然趋于平缓,但分解结束后残液颜色为无色,表明分解很彻底,这样有利于蒸馏残液的处理和利用。

2.3 硫化铵溶液的循环利用

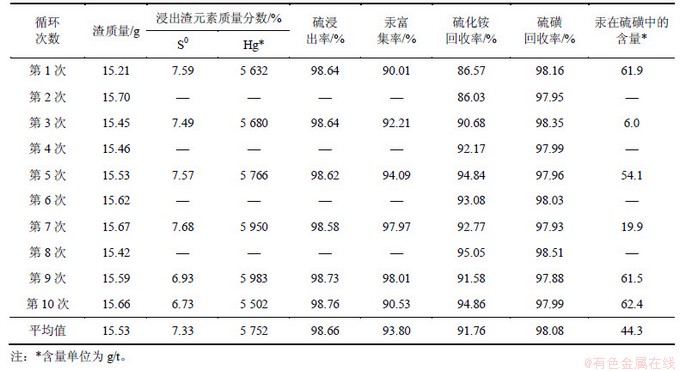

综合以上影响因素,确定最佳浸出条件为:常温下、(NH4)2S浓度2.5 mol/L、液固比6:1、浸出时间10 min;热分解条件为:热分解时间90 min、温度94 ℃。每次取浮选硫精矿100 g,用硫化铵溶液循环浸出10次,蒸馏回收的硫化铵溶液再返回下一次使用。试验结果见表2。

表2 硫化铵循环利用试验结果

Table 2 Results of recycling of ammonium sulfide

由表2可知,硫化铵溶液浸出浮选硫精矿后,减渣效果明显,100 g矿石浸出的渣质量平均为15.53 g,渣中元素硫含量(质量分数)在7%左右,平均硫浸出率为98.66%。硫化铵溶液多次循环利用时,对硫磺的回收基本没有影响,硫磺的回收率在98%左右。经分析,析出的硫磺纯度为99.54%,符合GB/T 2449—2006工业硫磺一等品标准。

汞在渣中的平均含量为5 752 g/t,与原矿石中的汞含量相比富集了6倍以上,平均富集率为93.8%,此含汞渣可成为品位较高的汞精矿进一步回收汞。汞在硫磺中的含量比较低,最高为62.4 g/t,对蒸馏残液中汞作检测,其质量浓度为0.021 mg/L,低于国家工业废水中汞的排放标准(0.05 mg/L)。

硫化铵的平均回收率为91.76%。第1次和第2次试验时硫化铵回收率较低,是因为洗涤浸出渣用水量较少,渣中残留有较多的浸出母液,因此减少溶液在渣中的残留和过程中的挥发,以及充分吸收气体都可以进一步提高硫化铵的回收率。

3 结论

(1) 使用硫化铵溶液处理含汞锌加压浸出渣浮选硫精矿的工艺流程简单,易于控制。汞硫分离效果好,平均硫浸出率为98.66%,硫磺回收率在98%左右,汞在渣中的平均富集率为93.8%,与原矿石中的汞含量相比富集了6倍以上。

(2) 回收的硫磺产品纯度高,达到99.5%以上,符合GB/T 2449—2006工业硫磺一等品标准。

(3) 硫化铵溶液可循环利用,试剂损耗较小,平均回收率为91.76%,大大降低生产成本。整个工艺过程基本采用全闭路循环操作,对环境不会产生新的污染,具有广阔的工业应用前景。

参考文献:

[1] Pacyna E G, Pacyna J M, Sundseth K, et al. Global emission of mercury to the atmosphere from anthropogenic sources in 2005 and projections to 2020[J]. Atmospheric Environment, 2010, 44: 2487-2499.

[2] Nriagu J O, Pacyna J M. Quantitative assessment of worldwide contamination of air, water and soil by trace metals[J]. Nature, 1988, 333: 134-139.

[3] Streets D G, HAO Jiming, WU Ye, et al. Anthropogenic mercury emissions in China[J]. Atmospheric Environment, 2005, 39: 7789-7806.

[4] Mukherjee A B, Melanen U M, Ekqvist M, et al. Assessment of atmospheric mercury emissions in Finland[J]. Science of the Total Environment, 2000, 259: 73-83.

[5] FENG Xinbin, QIU Guangle. Mercury pollution in Guizhou, Southwestern China-An overview[J]. Science of the Total Environment, 2008, 400: 227-237.

[6] LI Guanghui, FENG Xinbin, LI Zhonggen, et al. Mercury emission to atmosphere from primary Zn production in China[J]. Science of the Total Environment, 2010, 408: 4607-4612.

[7] WANG Shuxiao, SONG Jingxiang, LI Guanghui, et al. Estimating mercury emissions from a zinc smelter in relation to China’s mercury control policies[J]. Environmental Pollution, 2010, 158: 3347-3353.

[8] 孟昭华. 冶炼烟气制酸的除汞技术[J]. 硫酸工业, 1986(2): 12-16.

MENG Zhaohua. Technologies of mercury removal from roasting exhaust gas in making acid[J]. Sulphuric Acid Industry, 1986(2): 12-16.

[9] 董四禄. 西北铅锌冶炼厂除汞技术[J]. 硫酸工业, 1997(5): 28-30.

DONG Silu. Technologies of mercury removal at Northwest lead and zinc smelter[J]. Sulphuric Acid Industry, 1997(5): 28-30.

[10] 王庆伟, 柴立元, 王云燕, 等. 锌冶炼含汞污酸生物制剂处理新技术[J]. 中国有色金属学报, 2008, 18(1): s416-s421.

WANG Qingwei, CHAI Liyuan, WANG Yunyan, et al. Novel technology for treatment of acidic wastewater containing Hg by biologics in zinc smelter[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(1): s416-s421.

[11] Hutchison A, Atwood D Q, Santilliann-Jiminez E. The removal of mercury from water by open chain ligands containing multiple sulfurs[J]. Journal of Hazardous Materials, 2008, 156: 458-465.

[12] 黄美荣, 王琳, 易辉, 等. 废水中汞离子去除方法的研究进展[J]. 化工环保, 2007, 27(2): 135-138.

HUANG Meirong, WANG Lin, YI Hui, et al. Progresses in research on removing mercury ion from wastewater[J]. Environmental Protection of Chemical Industry, 2007, 27(2): 135-138.

[13] 周勤俭. 湿法冶金渣中元素硫的回收方法[J]. 湿法冶金, 1997(3): 50-54.

ZHOU Qinjian. Method of reclaim elemental sulfur from hydrometallurgical slag[J]. Hydrometallurgy of China, 1997(3): 50-54.

[14] Halfyard J E, Hawboldt K. Separation of elemental sulfur from hydrometallurgical residue: A review[J]. Hydrometallurgy, 2011, 109: 80-89.

[15] Fujita T, Shibayama A, Miyazaki T, et al. Sulfur recovery from the leached residue produced in the direct leaching of zinc concentrates[C]//Mishra B, Yamauchi C. Second International Conference on Processing Materials for Properties. USA: Minerals, Met & Mat Soc, 2000: 689-692.

[16] 孙培梅, 魏岱金, 李洪桂, 等. 铜渣氯浸渣中有价元索分离富集工艺[J]. 中南大学学报, 2005, 36(1): 38-43.

SUN Peimei, WEI Daijin, LI Honggui, et al. Separation and enrichment of valuable elements from copper residue leached by chlorine[J]. Journal of Central South University, 2005, 36(1): 38-43.

[17] 李竟菲, 王宝璐, 徐敏, 等. 含铜金精矿中单质硫的煤油浸取回收工艺[J]. 化学工程, 2009, 37(8): 75-78.

LI Jingfei, WANG Baolu, XU Min, et al. Process technology on recovery of sulphur from copper-bearing gold concentrate by using kerosene method[J]. Chemical Engineering(China), 2009, 37(8): 75-78.

[18] PENG Peng, XIE Huiqin, LU Lizhu. Leaching of a sphalerite concentrate with H2SO4-HNO3 solutions in the presence of C2Cl4[J]. Hydrometallurgy, 2005, 80: 265-271.

[19] 邓日章, 赵天从, 钟竹前, 等. 从含硫浸出渣中回收元素硫的研究[J]. 中南矿冶学院学报, 1992, 23(3): 287-291.

DENG Rizhang, ZHAO Tiancong, ZHONG Zhuqian, et al. Investigation on recovery of elemental sulphur from leach residue containing sulphur[J]. Journal of Central South Institute of Mining and Metallurgy, 1992, 23(3): 287-291.

(编辑 赵俊)

收稿日期:2012-05-25;修回日期:2012-08-10

基金项目:昆明理工大学分析测试基金资助项目(2011196)

通信作者:张泽彪(1954-),男,湖南湘西人,高级工程师,从事金银提取、固体废弃物处理等研究;电话:15987126280;E-mail: zebiaozhang@yahoo.com.cn