DOI:10.19476/j.ysxb.1004.0609.2018.09.02

AZ31镁合金冷喷涂Al-Al2O3复合涂层组织及性能

陈金雄1,王 群1,罗丝丝1,谭兴龙2

(1. 湖南大学 材料科学与工程学院,长沙 410082;

2. 湖南顶立科技有限公司,长沙 410118)

摘 要:采用冷喷涂工艺在AZ31镁合金上制备纯Al涂层和Al-50%Al2O3复合涂层。通过扫描电镜(SEM)、能谱仪(EDS)、材料分析软件探讨Al2O3颗粒的加入对纯Al涂层显微组织的影响。用电化学工作站、显微硬度计和磨耗试验机来对涂层的性能进行表征,分析Al2O3颗粒的加入对纯Al涂层耐蚀性、显微硬度和磨损性能的影响。结果表明:与纯Al涂层相比,复合涂层组织更致密,孔隙率更低,硬度从51.2HV0.025提高到94.8HV0.025,滑动磨损率降低80.5%,磨粒磨损率降低40%。复合涂层的自腐蚀电流密度(2.36×10-7 A/cm2)和纯Al涂层的自腐蚀电流密度(1.19×10-7 A/cm2)相近,相对于镁合金的(2.56×10-4 A/cm2)降低3个数量级,可以大大提高镁合金的抗腐蚀 性能。

关键词:冷喷涂;AZ31镁合金;复合涂层;耐蚀性;耐磨性

文章编号:1004-0609(2018)-09-1720-10 中图分类号:TG174.44 文献标志码:A

镁合金由于其优异的物理和力学性能,例如低密度、高比强度、高比刚度和良好的加工性能,广泛应用于航空航天、汽车、电子等行业[1-4]。不幸的是镁的化学性质很活泼,导致镁合金耐腐蚀差,大大限制了镁合金应用范围,因此镁合金防护问题一直受到人们的重视。目前,镁合金常用表面防护技术有热喷涂、电镀、化学转化膜、有机涂层和阳极氧化等[5-8]。这些技术可使镁合金的防腐蚀特性在一定程度上得到提高,但都有自身的不足,如涂层不致密、降低疲劳寿命、效率低、污染大等。因此,开发高效、经济、环保且具有现场操作性的镁合金腐蚀防护工艺势在必行。

冷喷涂作为一种新型的表面处理技术,是在20世纪80年代中期由俄罗斯科学院新西伯利亚理论与应用力学研究所发明[9]。冷喷涂是一种在低于喷涂材料熔点的温度下,加速喷涂粉末撞击基体,通过剧烈的塑性变形与基体表面形成涂层的方法[10-12]。低温的特性避免了对喷涂材料和基体材料产生的热影响,高速粒子碰撞的喷丸效应,使得冷喷涂涂层与热喷涂相比具有低孔隙率的特征[13]。铝是低密度和高延展性的金属,具有优异的耐腐蚀性能且镁铝间的电偶腐蚀驱动力较小,这使铝成为冷喷涂原料的最佳选择。许多学者[14-18]在镁合金基体上采用冷喷涂技术制备了纯铝或铝合金涂层,发现涂层组织致密,孔隙率低,与镁合金基体相比,耐蚀性能显著提高,但冷喷涂铝涂层硬度和耐磨损性能偏低,在苛刻环境里保护性质是不够的。为此,本文作者将纯Al粉末和α-Al2O3粉末1:1进行机械混合,采用冷喷涂技术在AZ31镁合金表面制备铝基复合涂层。旨在通过观察复合涂层显微组织,测试其基本力学性能、耐腐蚀和磨损性能,并将其与纯Al涂层进行比较,探讨Al2O3颗粒的加入对纯Al涂层显微组织及性能的影响。

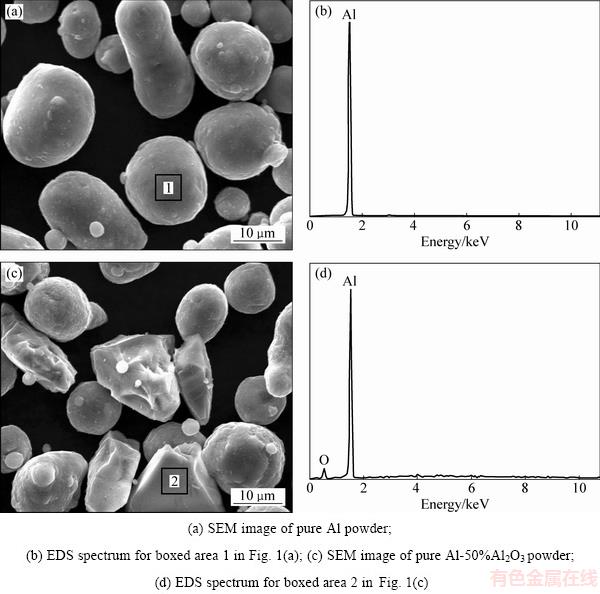

1 实验

冷喷涂粉末是选用气雾化法制备的纯Al粉末(99.5%,质量分数)和电炉重熔法制备的α-Al2O3粉末。纯Al颗粒以球形为主,兼有部分椭球形,表面略粗糙,粒度范围约为5~30 μm。α-Al2O3则是带棱角的不规则颗粒,平均粒度为5~30 μm。将纯Al粉末和Al2O3粉末按质量1:1进行机械混合,时间为8 h,纯Al粉末和纯Al-50%Al2O3粉末的宏观形貌和能谱分析如图1所示。

图1 纯Al粉末和Al-50%Al2O3粉末的SEM像和EDS谱

Fig. 1 SEM images ((a), (c)) of pure Al and Al-50%Al2O3 powders and EDS spectra ((b), (d))

根据材料供应商提供的数据,喷涂用的纯铝粉、用于对比的1060铝板以及基体材料AZ31镁合金的主要化学成分列于表1。

冷喷涂实验在中国科学院金属研究所自主研制的冷喷涂设备上进行,选择压缩空气为工作气体,喷涂前采用600~710um粒度刚玉对镁合金表面进行喷砂处理。根据前期的经验,相应的喷涂工艺参数如表2所列。

采用FEI-Quanta200型环境扫描电镜和JSM-6700F扫描电子显微镜观察粉末形貌、涂层截面组织和磨损表面形貌,结合EDAX 能谱仪分析元素种类及含量。涂层截面采用Kroll’s腐蚀剂(3 mL HF+6 mL HNO3+100 mL H2O),腐蚀时间约为12 s。采用日本理学RigakuD/max-2550 型X 射线衍射仪测试粉末和涂层的相结构。使用IQmaterials2软件分析涂层截面金相并测量其孔隙率,取10点平均值作为涂层的孔隙率。显微硬度测试采用泰明显微硬度计(HXD-1000TM),在涂层截面上测试硬度,硬度值取5次测量平均值,实验载荷质量为25 g,压力保持时间为15 s。

电化学测试在CHI600C电化学工作站上进行,采用三电极体系,样品作为工作电极,铂片作为辅助电极,饱和甘汞电极作为参比电极,常温下在3.5%NaCl (质量分数)溶液中进行测试。样品用树脂包封,样品工作面用砂纸逐级打磨后抛光,仅允许约2 cm2面积暴露于测试溶液中,浸泡时间为60 min,待体系稳定后进行极化曲线测量,从开路电位-500 mV向阳极方向扫描,扫描速度为1 mV/s。

干滑动摩擦磨损实验在中科凯华生产的CFT-1型材料表面性能综合测试仪上进行。采用球块式摩擦副,上摩擦副是直径为6 mm的GCr15钢球(硬度为HRC62),下摩擦副是尺寸为25 mm×25 mm×6 mm的块体,载荷为1.5 N,旋转速度200 r/min,旋转直径为6 mm,测试时间为60 min,实验温度为室温。根据块体上的磨痕截面积及其磨痕长度来计算器体积磨损量。磨粒磨损实验采用MLH-30型轮式磨耗试验机, 磨耗轮直径为50 mm,磨耗轮上粘有180号SiC砂纸,规格为12 mm×158 mm。实验载荷分别为3 N和29.8 N,被测试的块体材料尺寸为57 mm×25 mm×6 mm。块体材料做往复运动,块体材料每做一次往复运动,磨轮带动砂纸转动0.9°,即块体材料做400次往复运动,磨轮带动带动砂纸转动一周,完成一轮磨粒磨损实验,每个样块共进行4轮磨损测试。根据磨损前后的磨损质量损失与其密度比来计算其体积磨损量。

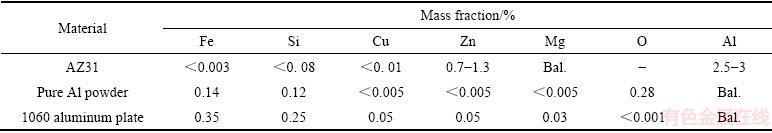

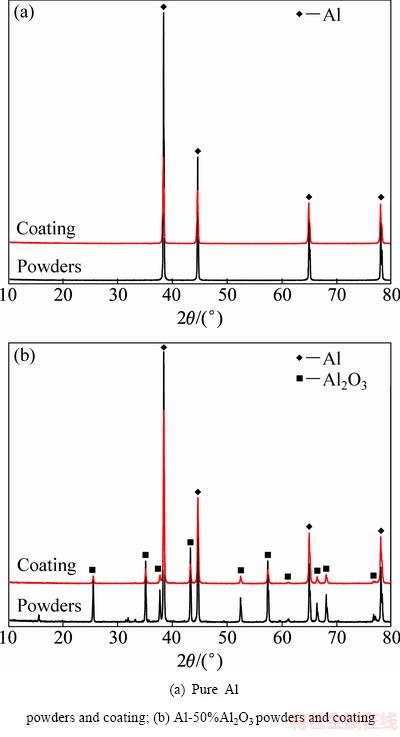

表1 AZ31镁合金、纯Al粉末和1060铝板的化学成分

Table 1 Chemical composition of AZ31 alloy, pure Al powders and 1060 aluminum plate

表2 涂层喷涂工艺参数

Table 2 Spraying parameters of coatings

2 结果与分析

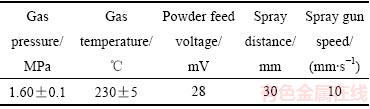

2.1 粉末和涂层相分析

图2所示为冷喷涂粉末和涂层的XRD谱。

由图2看出纯Al涂层和Al-50%Al2O3复合涂层XRD结果和各自粉末结果相似,主相都是Al相。另外两种涂层没有新峰出现,说明冷喷涂过程中对粉末的相结构几乎没有影响。

2.2 涂层显微组织

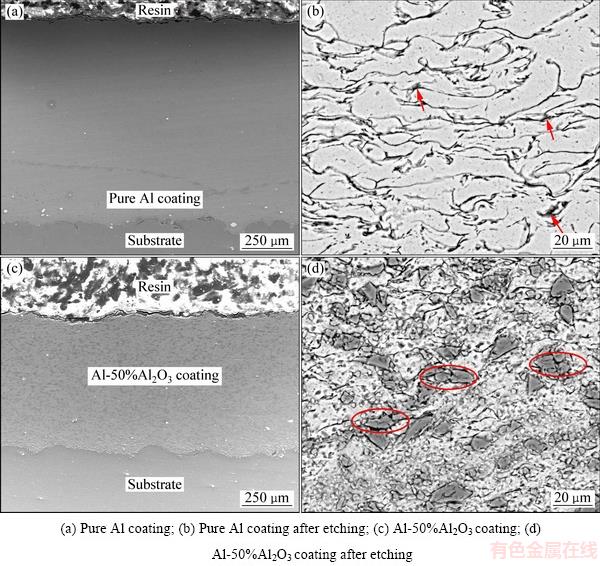

冷喷涂纯Al和Al-50%Al2O3涂层截面SEM像如图3所示。

由图3(a)和(c)可以两种涂层的低倍截面形貌可以看出,虽然纯Al涂层与基体的结合情况较好,但Al-50%Al2O3复合涂层与基体结合的更紧密。另外,在同样的喷涂条件下,纯Al涂层的厚度(约为970 μm)明显大于Al-50%Al2O3复合涂层的厚度(约为670 μm),添加硬质Al2O3会降低粉末的沉积率。由腐蚀后涂层的截面高倍形貌(见图3(b)和(d))可以看出,原始形状呈球形Al颗粒由于高速的撞击发生了充分的变形,形成扁平状的板条,水平分布的黑色曲线条纹即为Al板条的界面。在板条的交界和搭接处分布着少量的小尺寸不规则孔隙(见图3(b)箭头指示处)。

图2 粉末和涂层的XRD谱

Fig. 2 XRD patterns of powders and coatings

Al-50%Al2O3复合涂层中除了Al板条外,在板条的界面或内部处还弥散分布着尺寸不同的Al2O3颗粒,其中,小尺寸的Al2O3是由于复合粉末中Al2O3颗粒高速撞击时发生破裂而形成的。另外,相对于Al涂层,Al-50%Al2O3涂层中的板条界面不明显,且孔隙也相对较少,纯Al涂层孔隙率为1.5%,Al-50%Al2O3复合涂层孔隙率降低至0.3%。这是因为高硬度的Al2O3颗粒缺乏变形能力,撞击已沉积Al颗粒使之继续变形,进一步捣实形成致密组织(使Al-50%Al2O3复合涂层与基体的结合也更紧密)。对于冷喷涂涂层,剧烈塑性变形一般被认为是涂层结构致密的主要原因[19]。

图3 涂层截面SEM像

Fig. 3 Cross-sectional SEM images of coatings

2.3 电化学测试

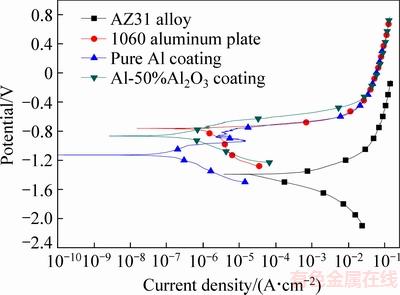

图4所示为AZ31镁合金、1060铝板、纯Al涂层和Al-50%Al2O3复合涂层在室温下置于3.5%NaCl溶液中浸泡60 min后测得的极化曲线。

图4 在3.5%NaCl溶液中浸泡60 min后样品的动电位极化曲线

Fig. 4 Potentiodynamic polarization curves of samples recorded after immersion in 3.5% NaCl solution for 60 min

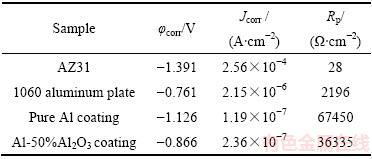

从图4中可以看出,纯Al涂层和Al-50%Al2O3复合涂层相对于基体自腐蚀电位明显正移,自腐蚀电流密度明显降低。几组样品的阳极极化曲线都出现自腐蚀电流迅速增大的点,表明发生了点蚀现象[20];不同的是各样品的自腐蚀电位差别较大,其中纯Al涂层出现明显的钝化区。对图4极化曲线进行Tafel拟合,得到自腐蚀电位(φcorr),自腐蚀电流密度(Jcorr)和极化电阻密度(Rp)数据,结果如表3所列。

由表3可以看出,纯Al涂层和Al-50%Al2O3复合涂层的自腐蚀电流密度分别为1.19×10-7 A/cm2和2.36×10-7 A/cm2比AZ31镁合金基体的2.56×10-4 A/cm2降低3个数量级,表明冷喷纯Al涂层和Al-50%Al2O3复合涂层较基体耐蚀性显著提高,且Al2O3颗粒的添加并没有明显降低纯Al涂层抗腐蚀能力。纯Al涂层的自腐蚀电流密度比1060铝板低了一个数量级,自腐蚀电位也低于1060铝板,这可能归因于1060铝板中有较高的Fe和Cu杂质(如表1所列),导致析氢反应大于纯Al涂层的[14, 21]。另外,冷喷涂纯Al涂层的晶粒尺寸比1060铝板板材更小,也可能是其耐蚀性更高的原因之一[22]。

表3 样品动电位极化结果

Table 3 Resluts of potentiodynamic polarization of samples

2.4 涂层的硬度和磨损性能

2.4.1 硬度

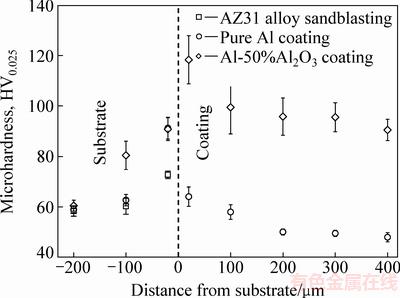

AZ31镁合金喷砂、纯Al涂层和Al-50%Al2O3复合涂层显微硬度与涂层/基体界面距离关系如图5所示。

图5 AZ31镁合金喷砂、纯Al涂层和Al-50%Al2O3复合涂层显微硬度与涂层/基体界面距离关系

Fig. 5 Microhardness of AZ31 alloy sandblasting, pure Al coating and Al-50%Al2O3 coating as function of distance from substrate/coating interface

由图5可见,Al-50%Al2O3复合涂层平均硬度(94.8HV0.025)高于纯Al涂层平均硬度(51.2HV0.025),这是由于弥散分布的高硬度Al2O3颗粒提高了Al-50%Al2O3复合涂层的硬度[23-25]。Al-50%Al2O3复合涂层各点硬度平均偏差较纯Al涂层的大,这归因于Al2O3颗粒不均匀分布影响测量结果。涂层的硬度从涂层/基体界面向涂层表面的方向逐渐降低,镁合金基体的硬度也是从涂层/基体界面向处向内部逐渐降低。这两种硬度呈梯度的变化的主要是由于冷喷涂颗粒冲击而引起加工硬化造成的[26]。对于涂层而言,越靠近涂层/基体界面处的涂层受到后续喷涂粒子的连续撞击的时间越长,加工硬化越明显,同时涂层的致密度的也越高,从而导致较高的硬度;而越靠近涂层表层的部分则受到的冲击作用较小,加工硬化程度轻,涂层的致密度较低,从而其硬度也较低[23, 27-28]。对于镁合金基体来说,喷砂使基体表面硬度增加[29],但喷涂纯Al和Al-50%Al2O3粉末都能对镁合金基体造成加工硬化现象,但是,由后者造成加工硬化现象明显高于前者。这主要由于Al-50%Al2O3粉末中含有Al2O3颗粒造成的,一方面Al2O3具有更高密度,另一方面Al2O3颗粒在撞击时不像纯铝粉末那样发生塑形变形,这两方面的原因使得冷喷涂Al-50%Al2O3比纯铝对镁合金基体造成的冲击能量更大,从而表现出更显著的加工硬化现象。

2.4.2 滑动摩擦性能

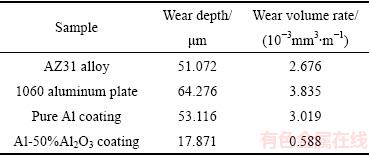

表4所列为AZ31镁合金、1060铝板、纯Al涂层和Al-50%Al2O3复合涂层滑动摩擦试验结果。

表4 滑动摩擦试验结果

Table 4 Experimental results of sliding wear

如表4所示,1060铝板和纯Al涂层的滑动磨损率分别比AZ31镁合金的高43.3%和12.8%,而Al-50%Al2O3复合涂层的滑动磨损率比AZ31镁合金和纯Al涂层的分别降低约77%和80%。

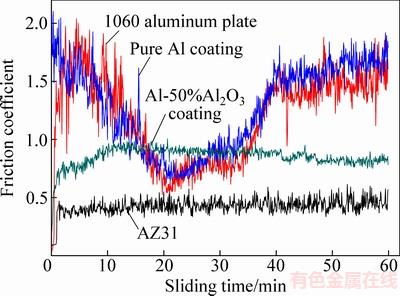

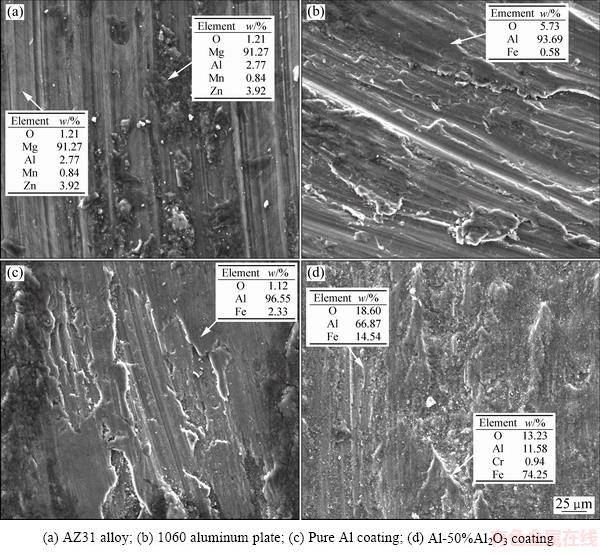

各材料摩擦因数系数曲线和磨痕微观形貌及典型选取能谱分析如图6和7所示。

图6 不同样品的摩擦因数与摩擦时间的变化关系

Fig. 6 Friction coefficient versus wear time for different samples

图7 样品磨损表面的SEM像及EDS结果

Fig. 7 SEM images and EDS results of worn surface of samples

由图6可以看出,1060铝板和冷喷涂纯Al涂层摩擦曲线非常类似,都呈现出快速上升,然后逐渐下降,然后再逐渐上升的过程,表现出类似的滑动磨损机制。硬度较高的铬钢球压在较软的1060铝板和冷喷涂纯Al涂层表面时,由于球块接触面积小,使得铬钢球会压入这两种材料表面一定的深度形成凹坑。当球块发生相对滑动时,塑形很好的铝板和铝涂层沿铬钢球运动前方的凹坑壁会发生宏观塑形变形。此时,铬钢球除了要克服球块之间的常规摩擦力外,还要克服1060铝板或冷喷涂纯Al涂层发生宏观塑形变形的力。此时,球块之间的摩擦力很大,超过正压力,相应的摩擦因数也大于1。在随后的摩擦过程中,铬钢球会使与其配合的摩擦副发生塑形变形,同时其表面的微凸部分对铝材作用以“犁沟”为主,摩擦副间强烈的摩擦产热量会使摩擦副间产生部分粘着磨损。由图7(b)和(c)所示的摩擦膜能谱分析结果来看,材料转移主要是从软的纯铝转移到较硬的GCr15钢球表面,而钢球表面的材料仅发生少量的转移。在随后磨损过程中粘着的材料被剪切,发生层状剥落或压入磨痕中的摩擦膜中。由于磨痕中的铝材反复塑形变形引起的疲劳断裂、微切削产生的切屑以及粘着造成的材料脱落都会形成磨屑颗粒,这些颗粒在较高的摩擦热作用下氧化形成摩擦膜,从而使得摩擦力逐渐降低(相应的摩擦因数也降低)。随着摩擦的继续进行,生成的氧化膜越来越厚,硬度较高的氧化膜一方面会对铬钢球表面产生切削作用,另一方面钢球表面也会在与摩擦副反复作用的过程中发生疲劳破坏。这两方面的原因会导致铬钢球表面的磨疤粗糙度升高,粗糙的磨疤也会对摩擦膜表面产生连续的冲击作用。在铬钢球的反复作用下,这种较厚且脆性较大的摩擦膜会发生开裂,破裂的摩擦膜一部分会脱落,被推向磨痕边缘,少部分碎屑又会留在磨痕中。这样由于摩擦膜的脱落而暴露出新的铝基体表面除了会发生犁沟和塑形变形外,还会受到被碾碎的的摩擦膜产生碎屑的作用,呈现出部分三种磨粒磨损的磨损机制。由于摩擦副间的摩擦膜的破坏,相应的摩擦因数又继续升高。文献[30]也报道了这种摩擦因数先快速升高,再降低,然后又升高的变化趋势。可以推测,随着磨擦过程的继续进行,这种摩擦膜反复形成和破裂而导致的摩擦因数的变化过程会周而复始的进行。

铬钢球与镁合金以及Al-50%Al2O3复合涂层摩擦因数曲线类似,都是先上升然后保持比较平稳的趋势。由于镁合金的塑形较差,不易发生塑形变形,镁合金磨损失效机制主要以铬钢球表面的微凸起对镁合金的微切削作用,大部分碎屑被推向磨痕边缘,小部分碎屑留在磨痕中。由留在磨痕中碎屑的主要成分为AZ31的合金中的元素和少量的氧,未发现Fe元素(见图7(a)),说明铬钢球基本未和镁合金发生粘着磨损。另外,磨痕中除了有一些切削下来的碎屑外,无明显的摩擦膜产生(见图7(a)),这使得AZ31镁合金与钢球间的摩擦过程较为平稳,获得了较为稳定的摩擦因数。铬钢球与冷喷涂Al-50%Al2O3复合涂层磨擦可以分为两个方面,一方面铬钢球上的微凸起会对Al-50%Al2O3复合涂层中的Al产生犁沟和挤压作用,另一方面随着较软的Al被去除后,突出的高硬度Al2O3颗粒也会对铬钢球表面产生切削作用,由于铬钢球的强度高于镁合金,因此,铬钢球与Al-50%Al2O3复合涂层之间的摩擦因数比其与AZ31间的摩擦因数要高。另外,由于Al-50%Al2O3复合涂层中凸起的Al2O3对铬钢球的支撑和切削作用,大量Fe元素残留在凸起Al2O3区域(见图7(d)),使得铬钢球对Al的切削减少,从而降使得Al-50%Al2O3涂层的磨损量相对较低。当复合涂层中铝基体对Al2O3颗粒约束力小于摩擦力时,Al2O3颗粒就会发生位移、松动甚至脱落,脱落的Al2O3颗粒在涂层表面和摩擦副表面之间滚动和滑动表现出一定的三体磨损形式[31]。这种相互切削并伴随一定形式的磨粒磨损的方式使得铬钢球和Al-50%Al2O3复合涂层之间的摩擦因数也基本保持稳定状态。

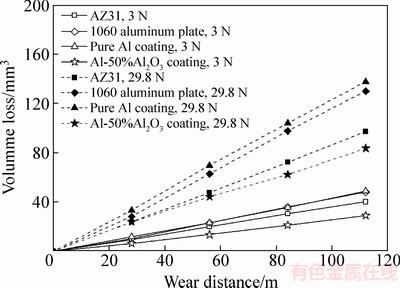

2.4.3 磨粒磨损性能

AZ31镁合金、1060铝板、冷喷涂纯Al涂层和Al-50%Al2O3复合涂层与SiC砂纸在不同载荷累计磨损量如图8所示。

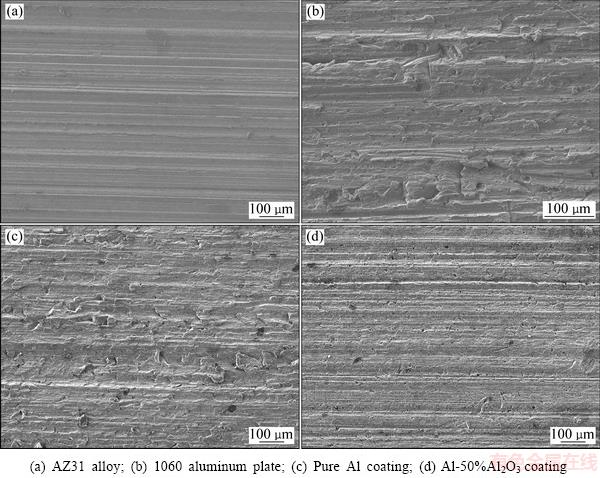

由图8看出4种被测试材料的体积磨损量随着载荷的增加而增加。其中,1060铝板和纯Al涂层在两种载荷下的磨损量相当,但都比AZ31镁合金的高。Al-50%Al2O3复合涂层磨损量最低,较纯Al涂层降低约40%左右,表明添加Al2O3能提高纯Al涂层抗磨粒磨损性能。图9所示为AZ31镁合金、1060铝板、纯Al涂层和Al-50%Al2O3复合涂层在载荷为3 N下磨粒磨损表面的SEM像。

如图9所示,纯Al涂层和Al-50%Al2O3复合涂层磨损表面都出现明显划痕和犁沟,纯Al涂层的磨痕宽而深,复合涂层的磨痕浅而窄。纯Al涂层的犁沟中存在大片的金属层片残留,并且层片相对摩擦面翘起,这种翘起造成磨痕的不连续,但在复合涂层中金属层片较少。磨粒磨损过程中,固定在砂纸上的尖锐的SiC粒子很容易压入纯Al涂层表层,当二者发生相对运动时,SiC粒子将会对Al涂层产生严重的犁沟磨损。犁沟两侧隆起的材料被切削和碾压,从而造成纯铝涂层磨痕表面呈现出明显的犁沟和被碾压的金属Al残片。对于Al-50%Al2O3复合涂层中,由于高硬度的Al2O3颗粒的存在,可以部分减小SiC粒子刺入涂层的深度,因此,SiC粒子将会对Al-50%Al2O3复合涂层造成的犁沟磨损程度要轻一些。在磨损起始阶段,由于Al-50%Al2O3涂层中的Al2O3颗粒受到Al的包裹和固定,当SiC粒子作用在尺寸较大的Al2O3颗粒上时,Al2O3颗粒可能由于撞击发生破裂而部分脱落或者沿SiC粒子运动的方向被压入涂层中。随着磨粒磨损的进行,砂纸上的SiC粒子将复合涂层中的纯Al相不断切削掉,使部分Al2O3颗粒凸出,失去粘结金属Al相包裹和固定的Al2O3颗粒很容易发生脱落。那些尺寸较小的Al2O3颗粒无论是在磨损的起始阶段还是过程中,均会被粒度较大的SiC粒子连同粘结Al相一同切削掉。可见,Al-50%Al2O3复合涂层中的小颗粒Al2O3对提高涂层的抗磨粒磨损性能十分有限,而尺寸较大的Al2O3颗粒在冷喷涂的过程中由于强烈的冲击作用,内部也出现裂纹(见图3(d)中的椭圆圈处)或破碎,在SiC粒子的不断作用下容易脱落,最终使得Al2O3颗粒的添加对提高纯铝涂层的抗磨粒磨损效果不是十分显著。

图8 样品在不同载荷下的体积磨损量

Fig. 8 Volume loss of samples under different loads

图9 样品磨粒磨损表面的SEM像

Fig. 9 SEM images of abrasive worn surface of samples

3 结论

1) 采用冷喷涂技术AZ31镁合金基体上制备了Al-50%Al2O3复合涂层,由于Al2O3颗粒对已沉积的Al进一步捣实,复合涂层较纯Al涂层更致密,孔隙率更低。

2) Al-50%Al2O3复合涂层的自腐蚀电流密度(2.36×10-7 A/cm2)和纯Al涂层的自腐蚀电流密度(1.19×10-7 A/cm2)相差不大,说明添加Al2O3并不会降低纯Al涂层的抗腐蚀能力。而相对于镁合金基体(2.56×10-4 A/cm2),复合涂层及纯Al涂层的自腐蚀电流密度降低了3个数量级,耐蚀性显著提高。

3) 纯Al涂层的滑动磨损率比镁合金高43.3%,Al-50%Al2O3复合涂层的滑动磨损率比AZ31镁合金和纯Al涂层的分别降低约77%和80%,Al2O3颗粒的加入可显著提高纯Al涂层的抗滑动磨损性能。

4) Al-50%Al2O3复合涂层的磨粒磨损率较纯Al涂层的降低约40%左右,Al2O3颗粒的添加不能显著提高纯Al涂层的抗磨粒磨损性能。

REFERENCES

[1] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[2] LUO A A. Magnesium casting technology for structural applications[J]. Journal of Magnesium and Alloys, 2013, 1(1): 2-22.

[3] HIRSCH J, AL-SAMMAN T. Superior light metals by texture engineering: Optimized aluminum and magnesium alloys for automotive applications[J]. Acta Materialia, 2013, 61(3): 818-843.

[4] ABBOTT T B. Magnesium: Industrial and research developments over the last 15 years[J]. Corrosion, 2015, 71(2): 120-127.

[5] 余 刚, 刘跃龙, 李 瑛, 叶立元, 郭小华, 赵 亮. Mg 合金的腐蚀与防护[J]. 中国有色金属学报, 2002, 12(6): 1087-1098.

YU Gang, LIU Yue-long, LI Ying, YE Li-yuan, GUO Xiao-hua, ZHAO Liang. Corrosion and protection of magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1087-1098.

[6] GRAY J E, LUAN B. Protective coatings on magnesium and its alloys-a critical review[J]. Journal of Alloys and Compounds, 2002, 336(1/2): 88-113.

[7] WU Li-ping, ZHAO Jing-jing, XIE Yong-ping, YANG Zhong-dong. Progress of electroplating and electroless plating on magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(2): 630-637.

[8] SONG Guang-ling, SHI Zhiming. Corrosion mechanism and evaluation of anodized magnesium alloys[J]. Corrosion Science, 2014, 85: 126-140.

[9] ALKHIMOV A P, KOSAREV V F, PAPYRIN A N. A method of cold gas-dynamic spraying[J]. Doklady Akademii Nauk SSSR, 1990, 315(5): 1062-1065.

[10] 李文亚, 李长久. 冷喷涂特性[J]. 中国表面工程, 2002, 15(1): 12-16.

LI Wen-ya, LI Chang-jiu. Characteristics of cold spray process[J]. China Surface Engineering, 2002, 15(1): 12-16.

[11] BALA N, SINGH H, KARTHIKEYAN J, PRAKASH S. Cold spray coating process for corrosion protection: A review[J]. Surface Engineering, 2014, 30(6): 414-421.

[12] ASSADI H, KREYE H, GARTNER F, KLASSEN T. Cold spraying–a materials perspective[J]. Acta Materialia, 2016, 116: 382-407.

[13] STOLTENHOFF T, BORCHERS C, GARTNER F, KREYE H. Microstructures and key properties of cold-sprayed and thermally sprayed copper coatings[J]. Surface and Coatings Technology, 2006, 200(16): 4947-4960.

[14] TAO Yong-shang, XIONG Tian-ying, SUN Chao, KONG Ling-yan, CUI Xing-yu, LI Tie-fan, SONG Ling-guang. Microstructure and corrosion performance of a cold sprayed aluminium coating on AZ91D magnesium alloy[J]. Corrosion Science, 2010, 52(10): 3191-3197.

[15] DEFORCE B S, EDEN T J, POTTER J K. Cold spray Al-5% Mg coatings for the corrosion protection of magnesium alloys[J]. Journal of Thermal Spray Technology, 2011, 20(6): 1352-1358.

[16] 刘德鑫, 石仲川, 张晓云, 陆 峰, 孙志华, 汤智慧. ZM6镁合金冷喷涂Al涂层结构与耐蚀性研究[J]. 材料工程, 2012(12): 50-54.

LIU De-xin, SHI Zhong-chuan, ZHANG Xiao-yun, LU Feng, SUN Zhi-hua, TANG Zhi-hui. Structure and anti-corrosion properties of cold sprayed Al coatings on ZM6 magnesium alloy[J]. Journal of Materials Engineering, 2012(12): 50-54.

[17] ROKNI M R, WIDENER C A, CRAWFORD G A, WEST M K. An investigation into microstructure and mechanical properties of cold sprayed 7075 Al deposition[J]. Materials Science & Engineering A, 2015, 625: 19-27.

[18] 贾 利, 崔 烺, 刘 光, 郑子云. 冷喷涂铝涂层及其耐磨性能研究[J]. 兵器材料科学与工程, 2017, 40(3): 78-80.

JIA Li, CUI Lang, LIU Guang, ZHENG Zi-yun. Wear property of cold sprayed Al coating[J]. Ordnance Material Science and Engineering, 2017, 40(3): 78-80.

[19] STEENKISTE T H, SMITH J R, TEETS R E. Aluminum coatings via kinetic spray with relatively large powder particles[J]. Surface and Coatings Technology, 2002, 154(2/3): 237-252.

[20] SZKLARSKA-SMIALOWSKA Z. Pitting corrosion of aluminum[J]. Corrosion Science, 1999, 41(9): 1743-1767.

[21] KANG Ju, FU Rui-dong, LUAN Guo-hong, DONG Chun-lin, HE Miao. In-situ investigation on the pitting corrosion behavior of friction stir welded joint of AA2024-T3 aluminium alloy[J]. Corrosion Science, 2010, 52(2): 620-626.

[22] MENG Guo-zhe, WEI Li-yan, ZHANG Tao, SHAO Ya-wei, WANG Fu-hui, DONG Chao-fang, LI Xiao-gang. Effect of microcrystallization on pitting corrosion of pure aluminium[J]. Corrosion Science, 2009, 51(9): 2151-2157.

[23] TAO Yong-shang, XIONG Tian-ying, SUN Chao, JIN Hua-zi, DU Hao, LI Tie-fan. Effect of α-Al2O3 on the properties of cold sprayed Al/α-Al2O3 composite coatings on AZ91D magnesium alloy[J]. Applied Surface Science, 2009, 256(1): 261-266.

[24] SPENCER K, FABIJANIC D M, ZHANG Ming-xing. The use of Al–Al2O3 cold spray coatings to improve the surface properties of magnesium alloys[J]. Surface and Coatings Technology, 2009, 204(3): 336-344.

[25] XIONG Yu-ming, Zhang Ming-xing. The effect of cold sprayed coatings on the mechanical properties of AZ91D magnesium alloys[J]. Surface & Coatings Technology, 2014, 253(9): 89-95.

[26] ZHANG P, LINDEMANN J. Influence of shot peening on high cycle fatigue properties of the high-strength wrought magnesium alloy AZ80[J]. Scripta Materialia, 2005, 52(6): 485-490.

[27] GHELICHI R, Macdonald D, BAGHERIFARD S, JAHED H, GUAGLIANO M, JODOIN B. Microstructure and fatigue behavior of cold spray coated Al5052[J]. Acta Materialia, 2012, 60(19): 6555-6561.

[28] DIAB M, PANG X, JAHED H. The effect of pure aluminum cold spray coating on corrosion and corrosion fatigue of magnesium (3% Al-1% Zn) extrusion[J]. Surface and Coatings Technology, 2017, 309: 423-435.

[29] 高 阳, 代明江, 向兴华, 韦春贝. 表面处理对AZ91D镁合金性能的影响[J]. 热加工工艺, 2011, 40(2): 121-124.

GAO Yang, DAI Ming-jiang, XIANG Xing-hua, WEI Chun-bei. Effect of surface treatment on performance of AZ91D magnesium alloy[J]. Hot Working Technology, 2011, 40(2): 121-124.

[30] 刘彦学, 袁晓光, 吕 楠, 黄宏军, 赵 惠. 镁合金表面锌铝合金冷喷涂层的磨损行为[J]. 沈阳工业大学学报, 2005, 27(4): 385-388.

LIU Yan-xue, YUAN Xiao-guang, Lü Nan, HUANG Hong-jun, ZHAO Hui. Wear behavior of cold spray Zn-Al alloy coating on magnesium alloy[J]. Journal of Shenyang University of Technology, 2005, 27(4): 385-388.

[31] PRAMANIK A. Effects of reinforcement on wear resistance of aluminum matrix composites[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(2): 348-358.

Microstructure and properties of cold sprayed Al-Al2O3 coating on AZ31 magnesium alloy

CHEN Jin-xiong1, WANG Qun1, LUO Si-si1, TAN Xiong-long2

(1. College of Materials Science and Engineering, Hunan University, Changsha 410082, China;

2. Advanced Corporation for Materials & Equipments Co., Ltd., Changsha 410118, China)

Abstract: The pure Al coating and Al-50% Al2O3 composite coating were deposited on AZ31 magnesium alloy by cold spraying. The effect of addition Al2O3 particles on morphology of the pure Al coating was analyzed by scanning electron microscopes(SEM), energy dispersive spectroscopy(EDS) and material analysis software. The effects of Al2O3 particles adding on corrosion resistance, micro-hardness and wear properties of the pure Al coating were studied by using electrochemical workstation, microhardness tester, abrasion tester to evaluate the properties of coatings. The results show that the composite coating possessed higher density, lower porosity, the microhardness increases from 51.2 HV0.025 to 94.8 HV0.025, the sliding wear rate decreases by 80.5% and the abrasive wear rate reduces by 40% in comparison to the pure Al coating. The corrosion current densities of the composite coating (2.36×10-7 A/cm2) and the pure Al coating(1.19×10-7 A/cm2) show the same level, but they are about 3 orders of magnitudes low compared with that of magnesium alloys substrate(2.56×10-4 A/cm2), which can significantly improve the corrosion resistance of magnesium alloys.

Key words: cold spray; AZ31 magnesium alloy; composite coating; corrosion resistance; wear resistance

Foundation item: Project(2013WK3027) supported by Hunan Province Science and Technology Program, China; Project(521298863) supported by Young Backbone Teacher Project of Hunan Province, China

Received date: 2017-11-21; Accepted date: 2018-03-23

Corresponding author: WANG Qun; Tel: +86-13787113453; E-mail: 13787113453@163.com

(编辑 王 超)

基金项目:湖南省科学计划资助项目(2013WK3027);湖南省青年骨干教师项目(521298863)

收稿日期:2017-11-21;修订日期:2018-03-23

通信作者:王 群,副教授,博士;电话:13787113453;E-mail:13787113453@163.com