DOI: 10.11817/j.ysxb.1004.0609.2020-39653

水热反应温度对AZ31镁合金CaAl-LDH膜层结构及耐蚀性的影响

许恒旭1,孙俊丽1,李思远1,侯利锋1,杜华云1,刘宝胜1, 2,卫英慧1

(1. 太原理工大学 材料科学与工程学院,太原 030024;

2. 太原科技大学 材料科学与工程学院,太原 030024)

摘 要:采用一步水热法在AZ31镁合金表面上制得CaAl-LDH膜层,采用X射线衍射仪(XRD)、扫描电子显微镜(SEM)、能谱仪(EDS)、电化学阻抗测试(EIS)、极化曲线等手段研究水热反应温度对CaAl-LDH膜层形貌及性能的影响。结果表明:随着水热反应温度的升高,CaAl-LDH膜层的厚度随之增加,膜层LDH结构的尺寸增大,耐蚀性先增强后减弱;当水热反应温度为120 ℃时,CaAl-LDH膜层的表面最平整致密,层间阴离子为NO3-的加载量最大,离子交换作用最强,膜层的耐蚀性最佳。此时,膜层的电荷转移电阻Rct为9.933×106 Ω·cm2,腐蚀电流密度Jcorr为8.0×10-9 A/cm2。CaAl-LDH膜层的生长模式符合典型的Stranski-Krastanov生长模型。反应温度会影响LDH的结晶速度和生长过程,进而影响了CaAl-LDH膜层的结构和性能。在120 ℃下水热制备CaAl-LDH膜层是提高AZ31镁合金耐蚀性的有效方法。

关键词:AZ31镁合金;水热法;CaAl-LDH;耐蚀性;温度

文章编号:1004-0609(2021)-02-0298-12 中图分类号:TG174 文献标志码:A

引文格式:许恒旭, 孙俊丽, 李思远, 等. 水热反应温度对AZ31镁合金CaAl-LDH膜层结构及耐蚀性的影响[J]. 中国有色金属学报, 2021, 31(2): 298-309. DOI: 10.11817/j.ysxb.1004.0609.2020-39653

XU Heng-xu, SUN Jun-li, LI Si-yuan, et al. Effect of hydrothermal reaction temperature on structure and corrosion resistance of CaAl-LDH film on AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(2): 298-309. DOI: 10.11817/j.ysxb.1004.0609.2020-39653

镁合金具有很多优异的力学性能,如低密度、高比强度、良好的铸造加工性能等,而且作为一种工程材料,已在交通运输、航空航天、电子、医用材料等行业有所应用[1]。但是镁合金的耐蚀性较差,在实际工程应用中很容易被腐蚀侵蚀而导致镁合金的服役寿命缩短或终结。因此,为了保证镁合金的正常服役,改善镁合金的耐蚀性至关重要。

目前,改善镁合金耐蚀性的方法的方法众多,主要有合金化、缓蚀剂、表面涂层等[2]。合金化方法是指通过添加特定合金元素减少杂质元素的危害或改善微观结构从而提高镁合金的耐蚀性,但这种方法对镁合金耐蚀性的改善效果不明显[3]。缓蚀剂则通过在表面沉积成膜或吸附成膜,阻隔腐蚀介质与镁合金的接触,虽然缓蚀剂对耐蚀性的改善效果强于合金化,但是缓蚀剂的使用受到很多条件的限制,如服役环境等,因此不适合大范围的工程应用[4]。在镁合金的表面制备涂层可以有效阻隔镁合金与腐蚀介质的接触,同时表面膜层应用限制较少,更适合工业化推广。传统的表面涂层有铬酸盐转化膜、磷酸盐转化膜、电镀膜等,但是这些膜层的制备过程可能会污染环境,且膜层的保护性能单一[5]。近些年来,具有很多优异性能的智能涂层成为了新一代表面膜层的代表,其中作为纳米涂层代表的LDH膜层已被应用在镁合金表面[6]。

层状双金属氢氧化物(Layered double hydroxides, LDH)是一种典型的阴离子黏土,具有层状结构,主体层是带正电荷的金属氢氧化物,层间是带负电荷的阴离子和电中性的层间水。其化学通式为 ,M2+和M3+分别表示二价金属离子和三价金属离子,An-为n价阴离子,x为M3+/(M2++M3+)的摩尔比,m为层间水的数量[7]。LDH具有很多独特的性能,如离子交换性、层间距可调性、记忆效应、化学组成多样性等,在催化、离子吸附、药物载体等领域被广泛研究[8],而且其独特的性能也吸引了腐蚀防护研究人员的目光。WU等[9]通过原位水热法在阳极极化的镁合金上制备得到了MgAl-LDH膜层,并发现水热温度的改变会影响膜层的生长取向和致密度。HOU等[10]研究了硝酸根、钨酸根和甲硫氨酸离子交换后的MgAl-LDH膜层的耐蚀性能,结果表明钨酸根离子插入的LDH膜层的耐蚀性能显著提高。ZHOU等[11]采用水热法制备了ZnAl-LDH膜层,研究了加载氯离子和钒酸根离子的ZnAl-LDH膜层对AZ91镁合金耐蚀性的影响,其中加载钒酸根离子的ZnAl-LDH对耐蚀性的提高更为明显。YE等[12]研究发现,通过简单水热法制备的NiAl-LDH膜层可以显著提高镁合金的耐蚀性。CaAl-LDH除了与MgAl-LDH、ZnAl-LDH、NiAl-LDH具有相同的优异性能外,其对腐蚀性离子如氯离子(Cl-)的亲和度更高,而且对氯离子的亲和度与对碳酸根的相近[13-15]。这种独特性能使得CaAl-LDH可以捕捉更多的氯离子,又因为膜层对氯离子和碳酸根离子的亲和度相近,避免因碳酸根的交换而大量释放层间氯离子,从而防止局部氯离子浓度过高引起的膜层破坏。迄今为止,还未见到关于CaAl-LDH膜层的报道。此外,相较于其他原位生长法,水热合成法不仅制备工艺简单,膜层结合力好,片层尺寸可调控,而且可以在保证LDH良好结晶片层结构的前提下,缩短LDH的合成时间,提高膜层的制备效率[16-18]。

,M2+和M3+分别表示二价金属离子和三价金属离子,An-为n价阴离子,x为M3+/(M2++M3+)的摩尔比,m为层间水的数量[7]。LDH具有很多独特的性能,如离子交换性、层间距可调性、记忆效应、化学组成多样性等,在催化、离子吸附、药物载体等领域被广泛研究[8],而且其独特的性能也吸引了腐蚀防护研究人员的目光。WU等[9]通过原位水热法在阳极极化的镁合金上制备得到了MgAl-LDH膜层,并发现水热温度的改变会影响膜层的生长取向和致密度。HOU等[10]研究了硝酸根、钨酸根和甲硫氨酸离子交换后的MgAl-LDH膜层的耐蚀性能,结果表明钨酸根离子插入的LDH膜层的耐蚀性能显著提高。ZHOU等[11]采用水热法制备了ZnAl-LDH膜层,研究了加载氯离子和钒酸根离子的ZnAl-LDH膜层对AZ91镁合金耐蚀性的影响,其中加载钒酸根离子的ZnAl-LDH对耐蚀性的提高更为明显。YE等[12]研究发现,通过简单水热法制备的NiAl-LDH膜层可以显著提高镁合金的耐蚀性。CaAl-LDH除了与MgAl-LDH、ZnAl-LDH、NiAl-LDH具有相同的优异性能外,其对腐蚀性离子如氯离子(Cl-)的亲和度更高,而且对氯离子的亲和度与对碳酸根的相近[13-15]。这种独特性能使得CaAl-LDH可以捕捉更多的氯离子,又因为膜层对氯离子和碳酸根离子的亲和度相近,避免因碳酸根的交换而大量释放层间氯离子,从而防止局部氯离子浓度过高引起的膜层破坏。迄今为止,还未见到关于CaAl-LDH膜层的报道。此外,相较于其他原位生长法,水热合成法不仅制备工艺简单,膜层结合力好,片层尺寸可调控,而且可以在保证LDH良好结晶片层结构的前提下,缩短LDH的合成时间,提高膜层的制备效率[16-18]。

本文通过一步水热法在AZ31镁合金表面制备CaAl-LDH膜层,共选择7种水热反应温度。利用X射线衍射仪(XRD)、扫描电子显微镜(SEM)、能谱仪(EDS)、电化学阻抗(EIS)和极化测试等手段研究了水热反应温度对CaAl-LDH膜层结构和耐蚀性的影响,探讨了水热反应下CaAl-LDH膜层的生长机理。

1 实验

1.1 膜层制备

实验材料选用AZ31镁合金(元素成分(质量分数):Al 3.0%,Zn 0.9%,Mn 0.4%,Ca 0.04%,余量为Mg),切割成尺寸为30 mm×20 mm×5 mm的试样,试样的表面用砂纸逐级打磨至2000#,以去除试样表面的氧化层并保证表面粗糙度一致,在乙醇中超声清洗以去除油脂,再用去离子水冲洗,冷风吹干。

一步水热法制备CaAl-LDH膜层:用去离子水配制由0.04 mol/L的Ca(NO3)2和0.02 mol/L的Al(NO3)3组成的混合溶液,用2 mol/L的NaOH调节溶液pH至11,然后倒入水热反应釜中,垂直放入镁合金试样,密封反应釜,在恒定的水热温度下保持12 h,温度分别为90、100、110、120、130、140和150 ℃。待加热完成后,取出试样,再用去离子水冲洗,冷风吹干。

1.2 性能测试和形貌结构观察

CaAl-LDH膜层的物质结构用X射线衍射仪(XRD,TD-3500,China)进行表征,靶材为铜靶,射线波长为0.154 nm,衍射角度从5°到30°,步长0.02°。采用扫描电子显微镜(SEM,TESCAN VEGA3)对CaAl-LDH膜层的表面微观形貌和截面进行观察,同时用附带的能谱仪(EDS,Oxford instruments)对膜层的元素组成进行分析。

为了确定CaAl-LDH膜层的耐蚀性能,对试样进行电化学阻抗(EIS)和极化测试。这两种电化学测试都是在电化学工作站(SP-150,Biologic Science Instruments Co., Ltd., France)上完成。测试系统采用标准的三电极电解池,其中CaAl-LDH膜层试样作为工作电极,饱和甘汞电极(SCE)作为参比电极,铂网作为辅助电极,电解质溶液为3.5%的NaCl溶液,工作电极暴露面积1 cm2。在进行电化学测试前先要进行15 min的开路电位测试(OCP)。电化学阻抗谱测试的频率范围为10 mHz~100 kHz,以开路电位为基准,外加幅值为10 mV的正弦波扰动。极化测试的电位范围为腐蚀电位±500 mV,扫描速率为1 mV/s。为了保证电化学测试结果的可靠性,所有的电化学测试重复3次以上。

2 结果与分析

2.1 温度对CaAl-LDH膜层结构的影响

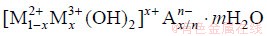

图1所示为不同水热反应温度下制备的CaAl-LDH膜层表面的SEM像。由图1可知,水热反应温度不同,CaAl-LDH膜层的表面形貌存在差异。当水热反应温度为90 ℃时,膜层表面较为平整,有一些细小的划痕、裂纹和剥落,组成膜层的LDH片层尺寸很小,大约为0.1 μm,片层的生长趋向随机。水热反应温度为100 ℃时,膜层的平整度较差,大量膜层剥落,片层的尺寸较小,大约为0.3 μm,一部分片层生长趋向平行于基体叠加生长。当水热反应温度为110 ℃时,膜层的平整度较差,出现很多条状起伏,剥落较少,片层的尺寸大约为0.2~0.5 μm,片层生长趋向垂直于基体交叉生长。水热反应温度为120 ℃时,膜层的平整度最好,没有出现明显的剥落,片层的尺寸约为0.5 μm,片层生长趋向于垂直于基体交叉生长,部分区域膜层表面较为致密。当水热反应温度为130 ℃时,膜层的平整度较差,出现大量大块膜层剥落,片层的尺寸约为0.5 μm,片层生长趋向于垂直于基体交叉生长。当水热反应温度为140 ℃时,膜层的平整度较差,剥落较少,条状起伏变宽,片层的尺寸约为0.8 μm,片层生长趋向于垂直于基体交叉生长。当水热反应温度为150 ℃时,膜层的平整度较差,没有明显的剥落,存在较宽的条状起伏,片层的尺寸约为0.8~1.0 μm,片层生长趋向于垂直于基体交叉生长,同时出现一些倾斜的LDH片层,在LDH片层的缝隙间有破碎的小片层。不同水热反应温度下制备的CaAl-LDH膜层的表面形貌符合典型的LDH片层形貌[19]。随着水热反应温度的升高,组成CaAl-LDH膜层的片层的尺寸逐渐增大。

图1 不同水热反应温度下制备的CaAl-LDH膜层表面的SEM像

Fig. 1 Surface SEM images of CaAl-LDH film prepared at different hydrothermal reaction temperatures

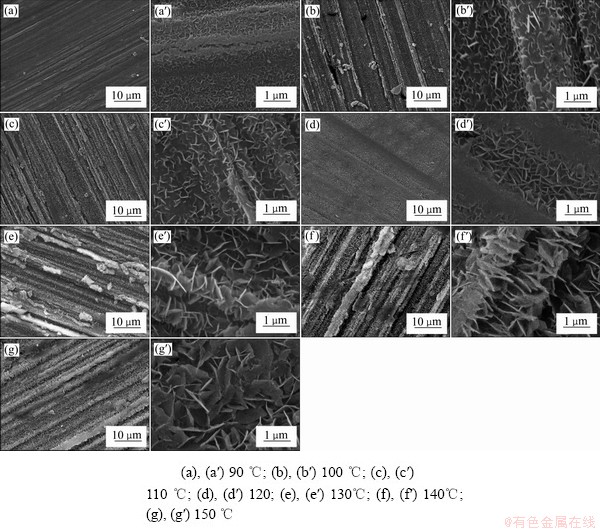

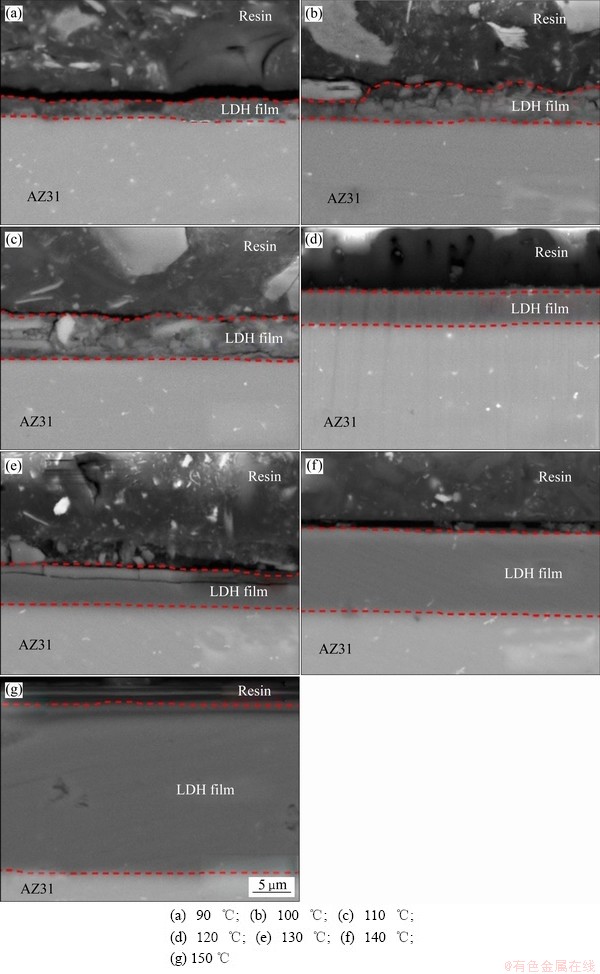

图2所示为不同水热反应温度制备的CaAl-LDH膜层截面的SEM像。图3所示为CaAl-LDH膜层的厚度随水热反应温度变化的折线图。当水热反应温度为90 ℃时,膜层的厚度较薄,约为4 μm,膜层的表面较平直,未观察到膜层剥落,膜层较疏松。当水热温度为100 ℃时,膜层的厚度变厚,约为5 μm,膜层的表面起伏幅度较大,观察到膜层剥落,膜层较90 ℃时的更加疏松,层间有很多细小的微裂纹。当水热反应温度为110 ℃时,膜层的厚度增加,约为7 μm,膜层表面有轻微的起伏,未观察到明显的膜层剥落,膜层疏松,除膜层间的裂纹外,与基体间出现细微的裂纹,说明于膜层的结合力下降。当水热反应温度为120 ℃时,膜层的厚度轻微下降,约为6 μm,膜层表面平直,无膜层剥落,膜层致密均一。当水热反应温度为130 ℃时,膜层的厚度增加,约为7 μm,膜层的顶部出现开裂,观察到膜层剥落,但是整体膜层致密。当水热反应温度为140 ℃时,膜层厚度增加,约为16 μm,膜层的表面平直,观察到一些剥落,膜层致密,无微裂纹。当水热反应温度为150 ℃时,膜层的厚度增加,约为32 μm,膜层的表面平直,未观察到剥落现象,膜层整体致密,但是存在一些孔隙。随着水热反应温度的升高,膜层的厚度逐渐增加,膜层的致密性先增加后减少。截面图中观察到的结果与图1结果一致。

图2 不同水热反应温度下制备的CaAl-LDH膜层截面的SEM像

Fig. 2 Section SEM images of CaAl-LDH films prepared at different hydrothermal reaction temperatures:

图3 不同水热反应温度下制备的CaAl-LDH膜层的厚度变化

Fig. 3 Variation in thickness of CaAl-LDH films prepared at different hydrothermal reaction temperatures

2.2 温度对CaAl-LDH膜层成分的影响

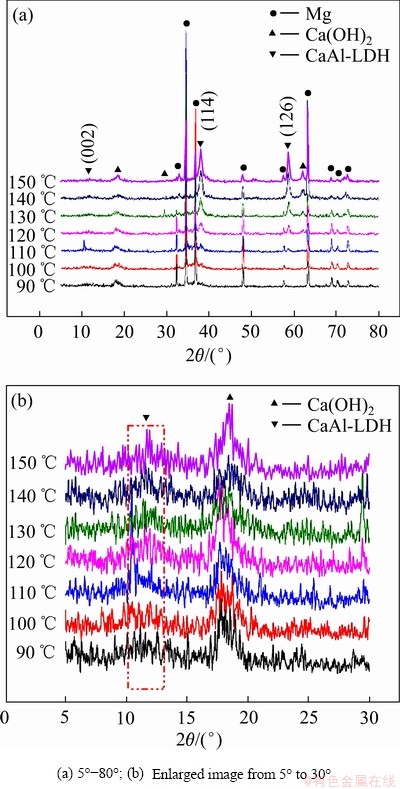

图4所示为不同水热反应温度制备的CaAl-LDH膜层的XRD谱。结果显示所有水热反应温度下都检测到很强的Mg峰,由于X射线穿透膜层抵达镁合金基体(PDF#89-5003),并检测到Ca(OH)2峰,说明在膜层中存在氢氧化钙(PDF# 84-1274)。随着水热反应温度的升高,在37.6°和58.6°的CaAl-LDH特征峰(114)和(126)显著增强,说明随着水热反应温度的提高,CaAl-NO3-LDH的结晶度增加(PDF#89-6723)。对5°~30°范围的XRD谱进行放大于图4(b)中,在11°左右的峰为CaAl- NO3-LDH的(002)特征峰,不同水热反应温度的特征峰强度差别不大,层间距则有所不同,90 ℃时为0.794 nm,100 ℃时为0.802 nm,110 ℃时为0.846 nm,120 ℃时为0.776 nm,130 ℃时为0.765 nm,140 ℃时为0.764 nm,150 ℃时为0.758 nm (PDF# 89-6723)。随着水热反应温度的升高,层间距先增大,后减少。金属氢氧化物主体层的厚度为0.48 nm,而NO3-的离子大小为0.2 nm,所以层间有足够的空间插入NO3-[20]。

图4 不同水热反应温度下制备的CaAl-LDH膜层的XRD谱

Fig. 4 XRD patterns of CaAl-LDH films prepared at different hydrothermal reaction temperatures

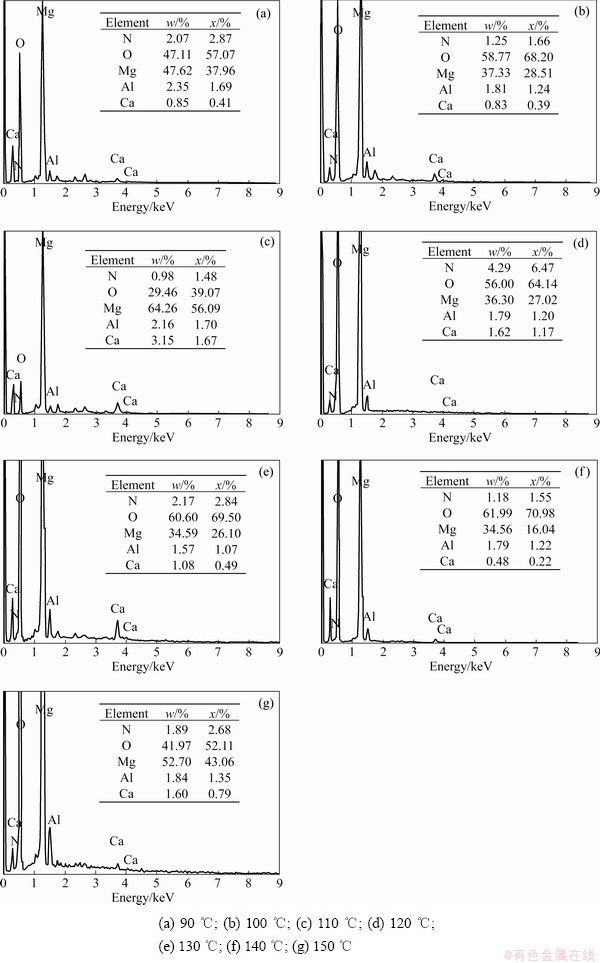

图5所示为不同水热反应温度制备的CaAl-LDH膜层的EDS分析结果。其中,检测到Ca、Al和O元素,说明生成的膜层为CaAl-LDH膜层。Al元素的含量高于Ca元素是因为在检测时射线可能穿透膜层打到镁合金基体上,从而检测到镁基体中的元素,这也是Mg含量很高的原因。检测到N元素,说明CaAl-LDH的层间离子为NO3-离子。而且N元素的含量在温度为120 ℃时最大,说明此温度下制备的CaAl-LDH膜层加载的硝酸根离子的量最多。EDS的检测结果证明镁合金表面制备得到的膜层为CaAl-LDH膜层,与XRD的结果一致。

图5 不同水热反应温度下制备的CaAl-LDH膜层的EDS谱

Fig. 5 EDS spectra of LDH films prepared at different hydrothermal reaction temperatures

2.3 CaAl-LDH膜层的电化学性能

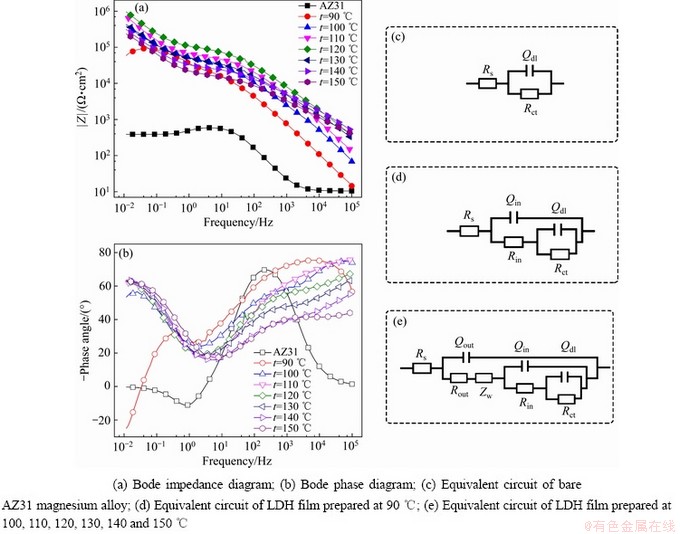

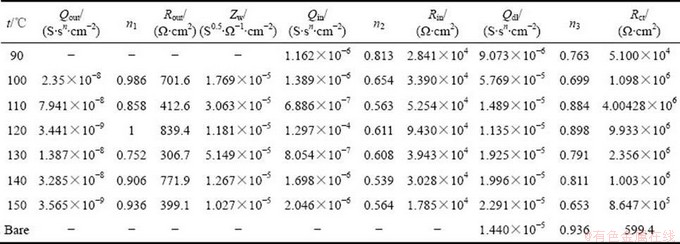

图6所示为不同水热反应温度下制备的CaAl- LDH膜层的电化学阻抗谱(见图6(a)和(b))和拟合所用的等效电路图(见图6(c)、(d)和(e))。低频区的阻抗可以反映一个腐蚀体系的耐蚀性能[21-22]。图6(a)中,在低频区,与裸样AZ31镁合金相比,CaAl-LDH膜层的阻抗曲线高出2至3个数量级,对应的阻抗曲线由上到下反应温度分别是120、110、130、100、140、150和90 ℃。为了量化CaAl-LDH膜层对镁合金耐蚀性的改善效果,选择3个等效电路对裸样AZ31镁合金和7种水热反应温度下制备的CaAl-LDH膜层的电化学阻抗结果进行拟合,拟合参数如表1所示。Rs是溶液电阻,Qdl是双电层电容,Rct是电荷转移电阻,Qin和Qout是内部膜层和外部膜层的电容,Rin和Rout是内部膜层和外部膜层的电阻,Zw是扩散阻抗。水热反应温度为90 ℃时,拟合结果中没有代表外部膜层的时间常数Rout和Qout。不同的水热反应温度制备的CaAl-LDH膜层的Rin有一定的规律性,表现为随温度的升高先增加后减少,在温度为120 ℃时,膜层的Rin最大。参数Rct可以反应一个体系的耐蚀性能[23]。裸样AZ31镁合金的Rct较小。CaAl-LDH膜层的Rct在104~106数量级,较AZ31镁合金提高了2~4个数量级。不同水热反应温度下制备的CaAl-LDH膜层的Rct存在规律性。随温度的升高,Rct先增加后减少,温度为120 ℃时,Rct最大。

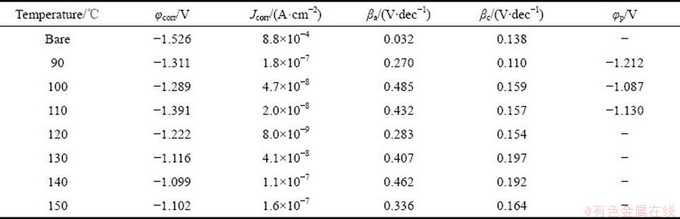

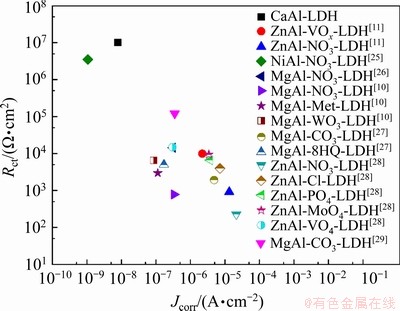

为了进一步确定CaAl-LDH膜层对AZ31耐蚀性的改善效果以及水热反应温度对膜层耐蚀性能的影响,对裸样AZ31镁合金及CaAl-LDH膜层试样进行极化测试,极化曲线如图7所示。与裸样AZ31镁合金相比,不同水热反应温度下制备的CaAl-LDH膜层的极化曲线向电位更正、电流密度更小的方向移动。可以观察到水热反应温度为90、100和110℃时,极化曲线的阳极分支出现击穿现象。为了量化膜层的耐蚀性,对极化曲线采用Tafel外推法,得到的极化参数列在表2中。腐蚀电位越正,腐蚀倾向越小;腐蚀电流密度越小,耐蚀性越好[24]。在表2中,不同水热反应温度下制备的CaAl-LDH膜层的腐蚀电位φcorr均正于裸样AZ31镁合金,约差0.2~0.4 V,说明CaAl-LDH膜层比裸样AZ31镁合金的腐蚀倾向小。不同水热反应温度下制备的CaAl-LDH膜层的腐蚀电流密度Jcorr均小于裸样AZ31镁合金的,约差3~5个数量级,说明CaAl-LDH膜层的耐蚀性要好于裸样AZ31的。

图6 不同水热反应温度下制备的CaAl-LDH膜层与裸样AZ31镁合金的Bode图和等效电路图

Fig. 6 Bode diagrams of CaAl-LDH films and bare AZ31 magnesium alloy prepared at different hydrothermal reaction temperatures and equivalent circuit

表1 裸样AZ31镁合金及不同水热反应温度制备的CaAl-LDH膜的电化学阻抗拟合数据

Table 1 Fitting data of electrochemical impedance of bare AZ31 magnesium alloy and CaAl-LDH films prepared at different hydrothermal reaction temperatures

表2 裸样AZ31镁合金及不同水热反应温度制备的CaAl-LDH膜的极化参数

Table 2 Polarization parameters of bare AZ31 magnesium alloy and CaAl-LDH films prepared at different hydrothermal reaction temperatures

图7 不同水热反应温度制备的CaAl-LDH膜层和裸样AZ31镁合金的极化曲线

Fig. 7 Polarization curves of CaAl-LDH films and bare AZ31 magnesium alloy prepared at different hydrothermal reaction temperatures

不同水热反应温度制备的CaAl-LDH膜层的Jcorr有一定的规律,随温度的升高,Jcorr先减小后增大,说明膜层的耐蚀性先增大后减小。在水热反应温度为120 ℃时,制备的CaAl-LDH膜层的Jcorr最小,说明此膜层的耐蚀性最好。极化曲线的分析结果与电化学阻抗的结果一致。

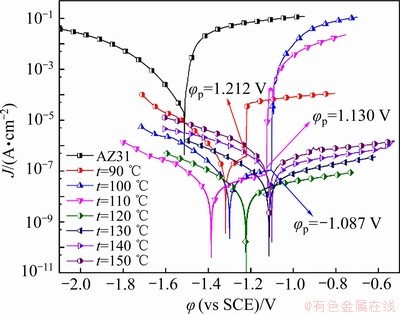

为了突出CaAl-LDH膜层优势,把120 ℃制备的CaAl-LDH膜层的耐蚀性能与其他LDH膜层研究的结果进行比较,如图8所示。膜层的耐蚀性通过电化学参数中的电荷转移电阻Rct和腐蚀电流密度Jcorr反映出来,Rct越大,Jcorr越小,膜层的耐蚀性越好[25-26]。图8中,膜层的电化学参数位点越靠近图的左上方,反映出膜层的耐蚀性越好;电化学参数位点越靠近图的右下方,膜层的耐蚀性越差。与其他LDH膜层相比,CaAl-LDH膜层的电化学参数位点更加靠近图的左上方,耐蚀性要明显好于其他层间离子为硝酸根的LDH膜层,甚至好于层间离子为缓蚀性阴离子的LDH膜层。

图8 不同LDH膜层的耐蚀性比较

Fig. 8 Comparison of corrosion resistance of different LDH films

2.4 膜层的生长机制

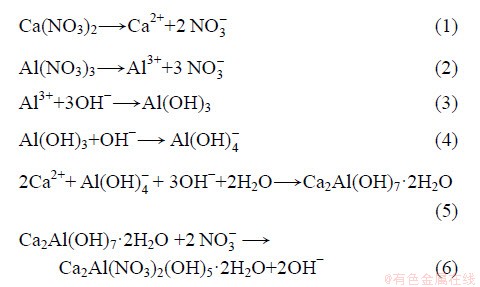

在密封的水热反应釜中,反应溶液(pH≈11)中的Ca(NO3)2和Al(NO3)3先发生反应,生成大量的CaAl-LDH晶胚,反应如式(1)~(6)[27-28]:

CaAl-LDH晶胚会沉积吸附在镁合金的表面,形成CaAl-LDH膜层的初始生长位点。在一定水热反应温度下,晶胚发展成晶核,随后晶核逐渐长大成为片层。但是镁合金表面的空间有限,当CaAl-LDH片层长大到一定的尺寸,有限的生长空间使得片层交叉生长在一起,岛状分布的LDH片层联结成的网状结构。片层间互相挤压,产生破碎的小片层。这些小片层会填充在片层间的孔隙和网状结构的孔隙中。这样经过填充致密后,形成了一个完整的表面LDH层。随后在这个膜层上又开始新一轮的沉积、成核和生长。这种膜层的生长模式符合典型的Stranski-Krastanov生长模型[24-25]。

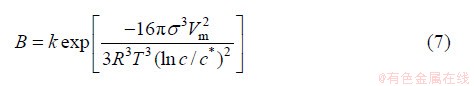

由XRD谱和SEM像的结果可知,水热反应温度的不同,影响了CaAl-LDH晶核的形成和长大。根据形核近似公式,如式(7)所示:

式中:B为成核速度;k为比例常数;Vm为体积分数;R为摩尔气体常数;T为温度;σ为表面张力;c为溶液浓度;c*为临界浓度。式(7)证明,成核速度与反应温度呈正相关,即温度越高,形核速度越快[30-31]。

在水热反应温度较低时,由晶胚到晶核的孕育期较长,晶核的长大较为缓慢。这就导致在相同的时间内,镁合金表面可以沉积更多的CaAl-LDH晶胚。由这些晶胚成核生长成的LDH片层的生长程度较低,所以片层的尺寸较小。因此,经过12 h的反应后,90 ℃下制备的CaAl-LDH的结晶度低,片层尺寸小。随水热反应温度升高,CaAl-LDH的结晶度逐渐增加,片层尺寸逐渐增大。所以,不同水热反应温度下制备的CaAl-LDH膜层的表面形貌会出现较大差异。当水热反应结束时,CaAl-LDH膜层的生长停止,膜层的最终结构由内部的较为致密层和外部的疏松层构成。其中外部疏松层主要是还未致密化的交叉生长的LDH片层,内部致密层是经过一系列生长过程的LDH层,如连结、挤压、破碎、填充和致密。在水热反应温度为90、100和110 ℃时,由于温度较低,LDH片层的生长速度较小,整体内部膜层的这一系列过程进行不充分,导致整体密层致密度较差。随着水热反应温度的升高,LDH片层的生长速度加快,膜层的致密过程进行的更充分。但是水热反应温度过高时,LDH片层的生长速度过快,膜层的致密过程的时间缩短,过快的致密过程导致一些缺陷,如被倾斜生长的LDH片层覆盖的孔隙保留下来,导致整体膜层的致密度下降。

LDH膜层对基体金属的保护由物理阻挡作用和离子交换作用共同贡献[22]。由实验结果可知,在温度为120 ℃时,膜层的致密性较高,可以提供有效的阻挡保护。由于温度120 ℃时CaAl-LDH膜层的硝酸根的加载量最大,表明膜层的离子交换作用更强。因此,温度120 ℃下制得的CaAl-LDH膜层可以通过离子交换捕获更多的Cl-,同时释放更多的NO3-,形成阴离子缓冲层,延缓腐蚀的进行[22]。所以,温度120 ℃制得的膜层耐蚀性最佳。当水热反应温度为90 ℃时,LDH的片层尺寸过小,外部疏松层的厚度较薄,不能在电化学阻抗中反映出来。所以该温度下制备的CaAl-LDH膜层的电化学阻抗结果中代表膜层的时间常数只有一组:Rin和Qin。其他水热反应温度制备的CaAl-LDH膜层的电化学阻抗结果中代表膜层的时间常数有两组:Rout和Qout、Rin和Qin。

3 结论

1) 通过一步水热法,在AZ31镁合金上制备得到CaAl-LDH膜层,有效改善了镁合金的耐蚀性能。当水热反应温度为120 ℃时,制备的CaAl-LDH膜层表面最平整,结构最致密,耐蚀性的改善效果最明显。

2) 水热反应温度会影响CaAl-LDH膜层的结构。较低的水热反应温度下,CaAl-LDH的结晶速度和生长较慢,形成的膜层疏松,厚度薄,片层尺寸小。随着温度的升高,结晶速度和生长变快,膜层厚度变厚,致密度先增加后下降,片层尺寸增加,片层方向趋向于垂直于基体。

3) 水热反应温度会影响CaAl-LDH膜层的耐蚀性。较低水热反应温度制得的膜层疏松,导致膜层阻挡作用弱,耐蚀性差。随水热反应温度升高,膜层变得致密,阻隔作用增强,耐蚀性提高。当温度为120 ℃时,CaAl-LDH膜层加载的阴离子NO3-的量最多,离子交换能力最强。因此,温度120 ℃时,CaAl-LDH膜层具有最大的Rct和最小的Jcorr,耐蚀性能表现最佳。

REFERENCES

[1] 张高会, 张平则, 潘俊德. 镁及镁合金的研究现状与进 展[J]. 世界科技研究与进展, 2003, 25(1): 72-78.

ZHANG Gao-hui, ZHANG Ping-ze, PAN Jun-de. Research and developments of magnesium and magnesium alloys[J]. World Sci-Tech R&D, 2003, 25(1): 72-78.

[2] 高志恒. 镁合金的腐蚀特性及防护技术[J]. 表面技术, 2016, 45(3): 169-177.

GAO Zhi-heng. Corrosion characteristics and protection techniques for Mg alloys[J]. Surface Technology, 2016, 45(3): 169-177.

[3] 张景怀, 唐定骧, 张洪杰, 等. 稀土元素在镁合金中的作用及其应用[J]. 稀有金属, 2008, 32(5): 659-667.

ZHANG Jing-huai, TANG Ding-xiang, ZHANG Hong-jie, et al. Effect and application of rare earth in magesium alloys[J]. Chinese Journal of Rare Metals, 2008, 32(5): 659-667.

[4] 周 娜. NaCl溶液中AZ31镁合金缓蚀剂的研究[D]. 太原: 太原理工大学, 2014.

ZHOU Na. Study on corrosion inhibitors for AZ31 magnesium in NaCl solution[D]. Taiyuan: Taiyuan University of Technology, 2014.

[5] 林 锐, 刘朝辉, 王 飞, 等. 镁合金表面改性技术现状研究[J]. 表面技术, 2016, 45(4): 124-131.

LIN Rui, LIU Zhao-hui, WANG Fei, et al. Development of corrosion surface modification technology for magnesium alloys[J]. Surface Technology, 2016, 45(4): 124-131.

[6] 李 健, 王 颖. 智能涂层及其研究现状[J]. 表面工程与再制造, 2006, 6(1): 5-6.

LI Jian, WANG Ying. Intelligent coating and its research status[J]. Surface Engineering & Remanufacturing, 2006, 6(1): 5-6.

[7] 贺学智. 层状双金属氢氧化物Zn(Cu)/Al(Ti)-LDHs的制备及其光催化转化CO2-H 2O的研究[D]. 上海: 上海交通大学, 2013.

HE Xue-zhi. The preparation of layered double hydroxides Zn(Cu)/Al(Ti)-LDHs and research on the photo-conversion of CO 2-H2O with LDHs[D]. Shanghai: Shanghai Jiao Tong University, 2013.

[8] LI Feng, DUAN Xue. Applications of layered double hydroxides[J]. Cheminform, 2006, 37(24): 193-223.

[9] WU Liang, ZHENG Zhi-cheng, PAN Fu-sheng, et al. Influence of reaction temperature on the controlled growth of Mg-Al LDH film[J]. International Journal of Electrochemical Science, 2017, 12(7): 6352-6364.

[10] HOU Li-feng, LI Yu-lin, SUN Jun-li, et al. Enhancement corrosion resistance of Mg-Al layered double hydroxides films by anion-exchange mechanism on magnesium alloys[J]. Applied Surface Science, 2019, 487: 101-108.

[11] ZHOU Meng, YAN Lu-chun, LING Hao, et al. Design and fabrication of enhance corrosion resistance Zn-Al layered double hydroxides films based anion-exchange mechanism on magnesium alloys[J]. Applied Surface Science, 2017, 404(1): 246-253.

[12] YE Xin, JIANG Zi-min, LI Lin-xin, et al. In-situ growth of NiAl-layered double hydroxide on AZ31 Mg alloy towards enhanced corrosion protection[J]. Nanomaterials, 2018, 8(6): 411-420.

[13] CHEN Yu-xuan, SHUI Zhong-he, CHEN Wei, et al. Chloride binding of synthetic Ca-Al-NO3 LDHs in hardened cement paste[J]. Construction and Building Materials, 2015, 93: 1051-1058.

[14] FAHAMI A, DURAIA E S M, BEALL G W, et al. Facile synthesis and structural insight of chloride intercalated Ca/Al layered double hydroxide nanopowders[J]. Journal of Alloys and Compounds, 2017, 727: 970-977.

[15] CHI Lin, WANG Zheng, ZHOU You-fang, et al. Layered double hydroxides precursor as chloride inhibitor: Synthesis, characterization, assessment of chloride adsorption performance[J]. Materials, 2018, 11(12): 2537-2547.

[16] 谢 晖, 矫庆泽, 段 雪. 镁铝型水滑石水热合成[J]. 应用化学, 2001, 18(1): 70-72.

XIE Hui, JIAO Qing-ze, DUAN Xue. Synthesis of hydrotalcite by hydrothermal method[J]. Chinese Journal of Applied Chemistry, 2001, 18(1): 70-72.

[17] 王永在. 纳米晶Mg-Al水滑石的水热合成及合成机理[J]. 无机材料学报, 2008, 23(1): 93-98.

WANG Yong-zai. Hydrothermal synthesis nano Mg-Al LDHs and its formation mechanism[J]. Journal of Inorganic Materials, 2008, 23(1): 93-98.

[18] GUO Lian, WU Wei, ZHOU Yong-feng, et al. Layered double hydroxide coatings on magnesium alloys: A review[J]. Journal of Materials Science & Technology, 2018, 34: 1455-1466.

[19] PHILLIPS J D, VANDEPERRE L J. Anion capture with calcium, aluminium and iron containing layered double hydroxides[J]. Journal of Nuclear Materials, 2011, 416(1/2): 225-229.

[20] YAO Qing-song, ZHANG Fen, SONG Liang, et al. Corrosion resistance of a ceria/polymethyltrimethoxy silane modified Mg-Al-layered double hydroxide on AZ31 magnesium alloy[J]. Journal of Alloys and Compounds, 2018, 764: 913-928.

[21] WANG Li-da, ZONG Qiu-feng, SUN Wen, et al. Chemical modification of hydrotalcite coating for enhanced corrosion resistance[J]. Corrosion Science, 2015, 93: 256-266.

[22] ZHANG Gen, WU Liang, TNG Ai-tao, et al. Active corrosion protection by a smart coating based on a MgAl-layered double hydroxide on a cerium-modified plasma electrolytic oxidation coating on Mg alloy AZ31[J]. Corrosion Science, 2018, 139: 370-382.

[23] ZHANG You, LIU Jian-hua, LI Ying-dong, et al. Fabrication of inhibitor anion-intercalated layered double hydroxide host films on aluminum alloy 2024 and their anticorrosion properties[J]. Journal of Coatings Technology and Research, 2015, 12(2): 293-302.

[24] ZHANG Gen, WU Liang, TANG Ai-tao, et al. Growth behavior of MgAl-layered double hydroxide films by conversion of anodic films on magnesium alloy AZ31 and their corrosion protection[J]. Applied Surface Science, 2018, 456: 419-429.

[25] CHEN Jun, SONG Ying-wei, SHAN Da-yong, et al. In situ growth process of Mg-Al hydrotalcite conversion film on AZ31 Mg alloy[J]. Journal of Materials Science & Technology, 2015, 31: 384-390.

[26] WANG Xin, JING Chuan, CHEN Yu-xiang, et al. Active corrosion protection of super-hydrophobic corrosion inhibitor intercalated Mg-Al layered double hydroxide coating on AZ31 magnesium alloy[J]. Journal of Magnesium and Alloys, 2020, 8(1): 291-300.

[27] MUHAMMAD J A, ZHAO Jing-mao, VAHDAT Z A, et al. In-situ intercalation of 8-hydroxyquinoline in Mg-Al LDH coating to improve the corrosion resistance of AZ31[J]. Corrosion Science, 2019, 157: 1-10.

[28] TANG Yan, WU Fang, FANG Liang, et al. A comparative study and optimization of corrosion resistance of ZnAl layered double hydroxides films intercalated with different anions on AZ31 Mg alloys[J]. Surface and Coatings Technology, 2019, 358: 594-603.

[29] ZHANG Gen, WU Liang, TANG Ai-tao, et al. Sealing of anodized magnesium alloy AZ31 with MgAl layered double hydroxides layers[J]. RSC Advances, 2018, 8: 2248-2259.

[30] 李志强, 杨立斌, 沙作良, 等. 氯化钾间歇冷却结晶生长规律及粒度控制实验研究[J].无机盐工业, 2019, 51(8): 33-36.

LI Zhi-qiang, YANG Li-bin, SHA Zuo-liang, et al. Experimental research on growth and crystal size control of potassium chloride in batch cooling crystallization[J]. Inorganic Chemicals Industry, 2019, 51(8): 33-36.

[31] 丁绪淮, 谈 遒. 工业结晶[M]. 北京: 化学工业出版社, 1985: 74.

DING Xu-huai, TAN Qiu. Industrial crystallization[M]. Beijing: Chemical Industry Press, 1985: 74.

Effect of hydrothermal reaction temperature on structure and corrosion resistance of CaAl-LDH film on AZ31 magnesium alloy

XU Heng-xu1, SUN Jun-li1, LI Si-yuan1, HOU Li-feng1, DU Hua-yun1, LIU Bao-sheng1, 2, WEI Ying-hui1, 2

(1. College of Materials Science and Engineering, Taiyuan University of Technology, Taiyuan 030024, China;

2. College of Materials Science and Engineering, Taiyuan University of Science and Technology, Taiyuan 030024, China)

Abstract: A one-step hydrothermal method was used to prepare a CaAl-LDH film on the AZ31 magnesium alloy. X-ray diffractometer (XRD), scanning electron microscope (SEM), energy spectrometer (EDS), electrochemical impedance test (EIS) and polarization curve were used to study the effects of the hydrothermal reaction temperature on the morphology, chemical composition and corrosion resistance of the CaAl-LDH film. The results show that as the hydrothermal reaction temperature increases, the thickness and density of the CaAl-LDH film increase, the sheet size increases, and the corrosion resistance increases first and then decreases. When the hydrothermal reaction temperature is 120 ℃, the surface of the CaAl-LDH film is the most flat and dense, and the loading of anion NO3- between layers is the largest, which indicates that the LDH film has the strongest ion exchange effect. So the corrosion resistance of the CaAl-LDH film prepared at 120 ℃ is the best, which charge transfer resistance Rct is 9.933×106 Ω·cm2, corrosion current density Jcorr is 8.0×10-9 A/cm2. The growth mode of CaAl-LDH film conforms to the typical Stranski-Krastanov growth model. The reaction temperature will affect the crystallization speed and growth process of LDH, which in turn affects the structure and performance of CaAl-LDH film. Hydrothermal preparation of CaAl-LDH film at 120 ℃ is an effective method to improve the corrosion resistance of AZ31 magnesium alloy.

Key words: AZ31 magnesium alloy; hydrothermal method; CaAl-LDH; corrosion resistance; temperature

Foundation item: Project(52071227) supported by the National Natural Science Foundation of China; Project (201805D121003) supported by Platform Base Construction of Shanxi Province, China

Received date: 2020-01-20; Accepted date: 2020-05-25

Corresponding author: HOU Li-feng, Tel: +86-351-6018683; E-mail: houlifeng78@126.com

(编辑 龙怀中)

基金项目:国家自然科学基金(52071227);山西平台基地建设项目(201805D121003)

收稿日期:2020-01-20;修订日期:2020-05-25

通信作者:侯利锋,教授,博士;电话:0351-6018683;E-mail:houlifeng78@126.com