文章编号:1004-0609(2014)12-2969-09

冷锻及再结晶退火对挤压态AZ31镁合金组织的影响

卢立伟1, 2,赵 俊1,刘龙飞1,王 尧1,刘天模3

(1. 湖南科技大学 机电工程学院,湘潭 411201;

2. 中南大学 材料科学与工程学院,长沙 410083;

3. 重庆大学 国家镁合金工程技术中心,重庆 400044)

摘 要:对挤压态AZ31镁合金试样沿挤压方向截取试样(0°试样)和垂直于挤压方向截取试样(90°试样),并分别进行变形量为12%的冷锻变形,在320 ℃下保温不同时间进行再结晶退火。利用金相显微镜和背散射电子衍射技术研究AZ31镁合金的微观组织演变。结果表明:经冷锻变形的0°试样,内部存在大量细小碎晶、{ }-{

}-{ }、{

}、{ }和{

}和{ }-{

}-{ }等孪晶,平均小角度取向差频率为0.031,硬度由57HV增至71.3HV,随后的再结晶退火可显著细化原始混晶组织;经冷锻变形的90°试样,内部含有少量的{

}等孪晶,平均小角度取向差频率为0.031,硬度由57HV增至71.3HV,随后的再结晶退火可显著细化原始混晶组织;经冷锻变形的90°试样,内部含有少量的{ }-{

}-{ }二次孪晶,平均小角度取向差频率为0.017,硬度由57HV增至69.3HV,再结晶退火时,与0°试样对比,静态再结晶开始及结束时间均被推迟。

}二次孪晶,平均小角度取向差频率为0.017,硬度由57HV增至69.3HV,再结晶退火时,与0°试样对比,静态再结晶开始及结束时间均被推迟。

关键词:AZ31镁合金;冷锻;静态再结晶;织构

中图分类号:TG146.2 文献标志码:A

Influence of cold forging and recrystallization annealing on microstructure of extruded AZ31 magnesium alloys

LU Li-wei1, 2, ZHAO Jun1, LIU Long-fei1, WANG Yao1, LIU Tian-mo3

(1. College of Electromechanical Engineering, Hunan University of Science and Technology, Xiangtan 411201, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

3. National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 400044, China)

Abstract: 0 ° and 90° samples of extruded AZ31 magnesium alloys were obtained from cutting along the extrusion direction and perpendicular to the extrusion direction, respectively, and 12% cold forging deformation was carried out on them, then recrystallization annealing tests were performed at 320℃ for different durations. The microstructure evolution of AZ31 magnesium alloys was investigated by metalloscopy and electron backscatter diffractometry. The results show that in 0° sample there are a large amount of tinny broken grains, { }-{

}-{ }, {

}, { } and {

} and { }-{

}-{ }, the average frequency of low angle grain boundary is 0.031, and the hardness increases from 57HV to 71.3HV. Besides, original mischcrystal structure can be refined obviously by subsequent recrystallization annealing. As for 90° sample, only a few of {

}, the average frequency of low angle grain boundary is 0.031, and the hardness increases from 57HV to 71.3HV. Besides, original mischcrystal structure can be refined obviously by subsequent recrystallization annealing. As for 90° sample, only a few of { }-{

}-{ } double twins come out, the average frequency of low angle grain boundary is 0.017, and the hardness increases from 57HV to 69.3HV. By comparison with that of 0° sample, the starting and ending times of static recrystallization for 90° sample are delayed during the recrystallization annealing process.

} double twins come out, the average frequency of low angle grain boundary is 0.017, and the hardness increases from 57HV to 69.3HV. By comparison with that of 0° sample, the starting and ending times of static recrystallization for 90° sample are delayed during the recrystallization annealing process.

Key words: AZ31 magnesium alloy; cold forging; static recrystallization; texture

镁合金具有密度低、比强度和比刚度高、弹性模量低以及易回收等一系列优点,是目前实际使用中最轻的金属结构材料,广泛应用于汽车、航空航天、通信等领域,被誉为“21世纪的绿色工程金属材料”[1-2]。大多数镁合金为密排六方结构(HCP)金属,对称性低,室温变形时缺少独立的滑移系,导致其塑性成形性能差,不易室温加工成型,在一定程度上限制了镁合金材料的大规模应用。镁合金的室温塑性变形机制主要有基面滑移和锥面孪晶,常见的孪生类型有3种[3]:{ }

} 拉伸孪晶、{

拉伸孪晶、{ }

} 压缩孪晶和{

压缩孪晶和{ }-{

}-{ }二次孪生。相关研究表明:镁合金中的孪生行为具有较强的极性,其中拉伸孪生,只有当晶粒c轴受到拉应力时才可发生,而压缩孪生是在晶粒c轴受到压应力时方可发生。此外,{

}二次孪生。相关研究表明:镁合金中的孪生行为具有较强的极性,其中拉伸孪生,只有当晶粒c轴受到拉应力时才可发生,而压缩孪生是在晶粒c轴受到压应力时方可发生。此外,{ }

} 拉伸孪晶和{

拉伸孪晶和{ }

} 压缩孪晶在变形过程中表现出来的晶界特性有着较大的差异,{

压缩孪晶在变形过程中表现出来的晶界特性有着较大的差异,{ }

} 压缩孪晶晶界比{

压缩孪晶晶界比{ }

} 拉伸孪晶晶界难以迁移,位错容易在其晶界处大量塞积而积聚较高的应变储能,在后续能量供应的条件下,{

拉伸孪晶晶界难以迁移,位错容易在其晶界处大量塞积而积聚较高的应变储能,在后续能量供应的条件下,{ }

} 压缩孪晶晶界处易产生无畸变的静态再结晶(SRX)晶核来释放应变储能,压缩孪晶晶界处更容易成为有效的形核区域,最终致使不同塑性变形模式下的动态和SRX行为产生较大的差异[4-7]。吴远志等[8]研究了AZ31镁合金多向锻造组织演变,发现组织演变主要分为两个阶段:孪晶再结晶的晶粒细化阶段和热激活长大的晶粒长大阶段。丁雪征等[9]发现锻造与压缩变形方式的变形速率不同导致铸态AZ31镁合金锻造和压缩变形产生孪生形貌明显不同,在退火时间相同时,锻造变形中的孪晶处比压缩变形孪晶处更易再结晶形核。CHAO等[10]发现随等温退火时间的延长,冷拉变形镁合金的再结晶晶粒组织逐渐长大且分布均匀。以往镁合金变形和再结晶的研究大多集中在热挤压、轧制和热锻变形中织构变化和动态再结晶晶粒细化等领域[11-13],然而,挤压镁合金往往具有强基面织构和挤压方向存在长条晶粒,对于挤压镁合金在冷锻塑性变形中不同初始取向和晶粒尺度如何协调塑形变形机制及后续的SRX行为影响机理仍缺少系统研究。

压缩孪晶晶界处易产生无畸变的静态再结晶(SRX)晶核来释放应变储能,压缩孪晶晶界处更容易成为有效的形核区域,最终致使不同塑性变形模式下的动态和SRX行为产生较大的差异[4-7]。吴远志等[8]研究了AZ31镁合金多向锻造组织演变,发现组织演变主要分为两个阶段:孪晶再结晶的晶粒细化阶段和热激活长大的晶粒长大阶段。丁雪征等[9]发现锻造与压缩变形方式的变形速率不同导致铸态AZ31镁合金锻造和压缩变形产生孪生形貌明显不同,在退火时间相同时,锻造变形中的孪晶处比压缩变形孪晶处更易再结晶形核。CHAO等[10]发现随等温退火时间的延长,冷拉变形镁合金的再结晶晶粒组织逐渐长大且分布均匀。以往镁合金变形和再结晶的研究大多集中在热挤压、轧制和热锻变形中织构变化和动态再结晶晶粒细化等领域[11-13],然而,挤压镁合金往往具有强基面织构和挤压方向存在长条晶粒,对于挤压镁合金在冷锻塑性变形中不同初始取向和晶粒尺度如何协调塑形变形机制及后续的SRX行为影响机理仍缺少系统研究。

为此,本文作者选择具有典型基面织构和混晶组织的挤压态AZ31镁合金,取0°和90°试样分别进行变形量为12%的冷锻变形,然后在320 ℃下进行不同保温时间的退火,采用光学显微镜和电子背散射衍射技术(EBSD)对冷锻变形和SRX行为进行分析,研究初始取向和混晶组织在冷锻变形中的协调塑性变形机理和再结晶退火组织演变行为,进一步完善挤压镁合金冷塑性变形理论及静态再结晶机理。

1 实验

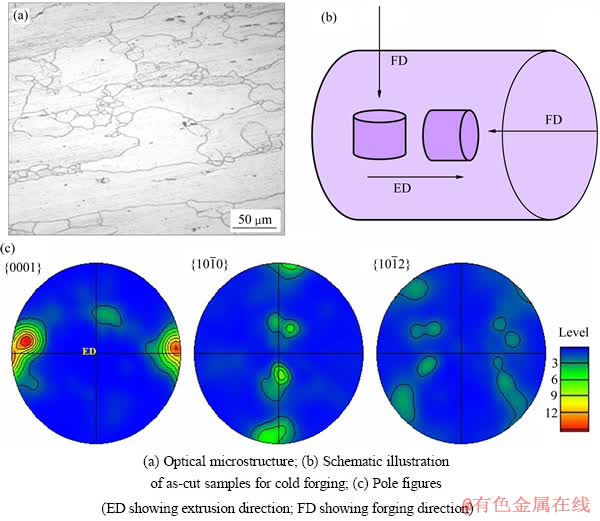

图1 原始挤压态AZ31镁合金组织结构和极图

Fig. 1 Microstructures and pole figures of original extruded AZ31 Mg alloys

实验材料为挤压态AZ31镁合金棒材,挤压比为4.5,挤压温度为400 ℃,名义化学成分(质量分数,% )为Mg-3Al-1Zn-0.4Mn。图1所示为原始挤压态AZ31镁合金组织结构和极图。如图1(a)所示,材料内部存在明显的混晶组织(如长条状晶粒、粗大晶粒和围绕着大晶粒分布的细小晶粒),粗晶晶粒尺寸约为120 μm,细晶晶粒尺寸仅为4 μm,这种混晶组织在以往的挤压镁合金研究中常有报道[14-16]。经极图分析,挤压棒材具有强烈的基面织构,即基面平行于挤压方向(ED),如图1(c)所示。实验冷锻试样截取如图1(b)所示,沿垂直和平行于ED分别截取尺寸为d 6 mm×5mm的圆柱试样(即0°和90°试样),0°试样中的大部分晶粒c轴平行锻造方向(FD),而90°试样大部分晶粒c轴垂直于FD。为了获得12%的冷锻变形量镁合金,将切割后的圆柱试样放入高度为4.4 mm的套筒来控制冷锻变形后的高度,冷锻结束后立即将试样浸入水中冷却,以减少变形热对组织的影响。将变形试样沿锻造轴向切开,经研磨和AC2电解抛光后在配备Nordlys II 探测器的JEOL JSM 7600场发射扫描电镜进行EBSD实验,并利用Channel 5.0软件对EBSD数据进行分析。对冷锻变形前后试样进行硬度测试,设备为DMH-1(Matsuzawa Seiki Co., Ltd.)数显硬度计,载荷为1 N,加载时间为8 s。最后,将不同锻造试样进行320 ℃保温时间分别为30、55、80、110、150和200 s的退火处理,并采用水冷以保留退火后的显微组织,经砂纸打磨和金相腐蚀处理后,在光学显微镜下观察其微观组织形貌。

2 结果与讨论

2.1 冷锻试样显微组织分析

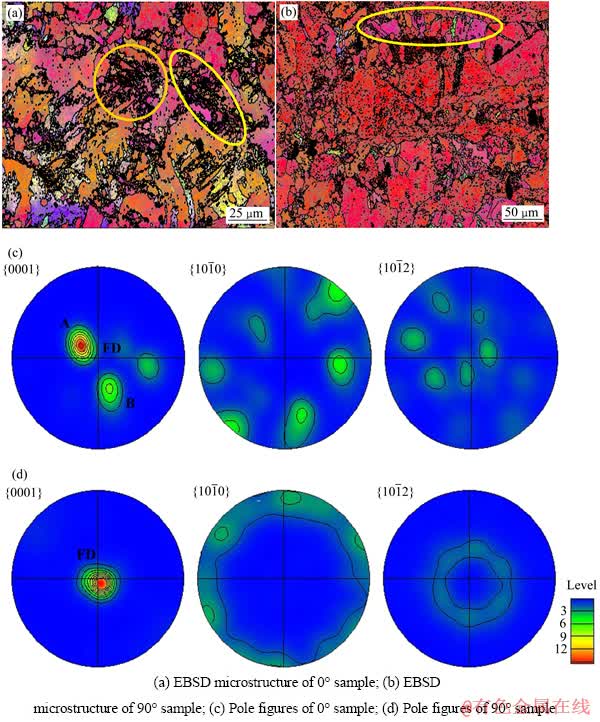

图2所示为冷锻变形12%的0°试样与90°试样的EBSD组织和极图。不同的颜色代表不同的晶体学取向,相近的颜色表明相近的晶粒取向。从图2(a)中可以看出,在冷锻变形的0°试样中,长条晶粒大都已被孪晶所分割,粗大晶粒和细小晶粒共存,晶粒组织中出现多种孪晶类型,孪晶相互交错,孪晶主要在较大的晶粒中存在,内部的孪晶类型主要有{ }、{

}、{ }-{

}-{ }、{

}、{ }-{

}-{ }、{

}、{ }- {

}- { }、{

}、{ }-{

}-{ }、{

}、{ }和{

}和{ }- {

}- { },冷锻变形中,受到锻造力的影响,晶界附近应力集中严重,由于长条晶粒和粗大晶粒内部位错滑移程大,也不易通过自身的转动来协调变形,因此,试样内部积聚大量位错,使滑移难以继续进行,致使长条晶粒晶界由平直变得弯曲,出现大量不连续的孪晶,且在粗大晶粒晶界处出现呈方向性排布的碎晶(见图2(a)),碎晶取向与原始晶粒取向发生了一定程度的改变,细晶内部位错滑移程小,也能通过非基面位错、晶界滑移以及其自身晶粒的转动来协调变形,这样,细晶内的滑移系比粗大晶内的更容易被开启,以达到释放应力集中来协调塑性变形的目的。此外,在绝大多数粗晶内部积聚着大量的小角度晶界,有关研究表明[17]:孪生一般不产生明显的小角度晶界,而滑移能产生明显的小角度晶界。表明在冷锻变形量为12%时,除孪生变形机制外也存在着滑移。由最终织构统计可见,如图2(c)所示,0°试样组织仍表现为强基面织构,但基面织构分散度增加,极图中呈现两个峰值A和B,晶粒的c轴与FD并不平行,而是大部分晶粒c轴与FD呈约15°角分布,少数晶粒的c轴与FD呈约25°角分布;由于冷锻变形速率快,0°试样的初始织构不利于大部分粗大晶粒的转动,晶界处应变协调能力差,应力容易发生高度集中,因此,在粗大晶粒晶界处产生了一些碎化细晶,且取向与原始晶粒发生了一定程度的变化,继而可以通过碎化晶粒的有利取向和自身的转动来继续协调变形。而对于90°试样,粗大晶粒内部的大多数{

},冷锻变形中,受到锻造力的影响,晶界附近应力集中严重,由于长条晶粒和粗大晶粒内部位错滑移程大,也不易通过自身的转动来协调变形,因此,试样内部积聚大量位错,使滑移难以继续进行,致使长条晶粒晶界由平直变得弯曲,出现大量不连续的孪晶,且在粗大晶粒晶界处出现呈方向性排布的碎晶(见图2(a)),碎晶取向与原始晶粒取向发生了一定程度的改变,细晶内部位错滑移程小,也能通过非基面位错、晶界滑移以及其自身晶粒的转动来协调变形,这样,细晶内的滑移系比粗大晶内的更容易被开启,以达到释放应力集中来协调塑性变形的目的。此外,在绝大多数粗晶内部积聚着大量的小角度晶界,有关研究表明[17]:孪生一般不产生明显的小角度晶界,而滑移能产生明显的小角度晶界。表明在冷锻变形量为12%时,除孪生变形机制外也存在着滑移。由最终织构统计可见,如图2(c)所示,0°试样组织仍表现为强基面织构,但基面织构分散度增加,极图中呈现两个峰值A和B,晶粒的c轴与FD并不平行,而是大部分晶粒c轴与FD呈约15°角分布,少数晶粒的c轴与FD呈约25°角分布;由于冷锻变形速率快,0°试样的初始织构不利于大部分粗大晶粒的转动,晶界处应变协调能力差,应力容易发生高度集中,因此,在粗大晶粒晶界处产生了一些碎化细晶,且取向与原始晶粒发生了一定程度的变化,继而可以通过碎化晶粒的有利取向和自身的转动来继续协调变形。而对于90°试样,粗大晶粒内部的大多数{ }拉伸孪晶已基本扩展完全,平直的长条晶粒晶界变为锯齿状,长条晶粒被分解成不同取向的块状晶,大应变量下晶粒趋于硬取向使晶粒碎化,但内部碎化的晶粒相对较少。观察发现,晶粒取向相近且存在一定的畸变程度,可推断出为原始晶粒或孪晶的碎化,如图2(b)所示,孪晶主要存在于粗大晶粒内,经鉴定内部的孪晶类型主要为{

}拉伸孪晶已基本扩展完全,平直的长条晶粒晶界变为锯齿状,长条晶粒被分解成不同取向的块状晶,大应变量下晶粒趋于硬取向使晶粒碎化,但内部碎化的晶粒相对较少。观察发现,晶粒取向相近且存在一定的畸变程度,可推断出为原始晶粒或孪晶的碎化,如图2(b)所示,孪晶主要存在于粗大晶粒内,经鉴定内部的孪晶类型主要为{ }、{

}、{ }-{

}-{ }、{

}、{ }-{

}-{ }、{

}、{ }- {

}- { }和{

}和{ }-{

}-{ };在极图中表现为极强的峰值,晶粒的c轴与FD几乎完全平行,如图2(d)所示,这是由于90°试样初始状态时绝大部分晶粒c轴垂直于FD,在冷锻变形中受到拉应力的影响,晶粒取向有利于产生{

};在极图中表现为极强的峰值,晶粒的c轴与FD几乎完全平行,如图2(d)所示,这是由于90°试样初始状态时绝大部分晶粒c轴垂直于FD,在冷锻变形中受到拉应力的影响,晶粒取向有利于产生{ }拉伸孪晶,在更大的变形量下,{

}拉伸孪晶,在更大的变形量下,{ }拉伸孪晶能使基面旋转86°,致使晶粒c轴几乎完全平行于FD;{

}拉伸孪晶能使基面旋转86°,致使晶粒c轴几乎完全平行于FD;{ }拉伸孪晶界不易于应变积累,缓和了晶界间的应力集中,利于协调变形,有利于滑移的进行,这可能是内部碎化晶粒较少的原因,此外,在粗大晶粒内产生了较多的小角度晶界。

}拉伸孪晶界不易于应变积累,缓和了晶界间的应力集中,利于协调变形,有利于滑移的进行,这可能是内部碎化晶粒较少的原因,此外,在粗大晶粒内产生了较多的小角度晶界。

将挤压AZ31镁合金0°和90°试样冷锻变形12%前后的硬度进行对比,0°和90°试样的维氏硬度由57HV分别增至71.3HV和 69.3HV;两种试样的冷锻变形均出现明显的硬化现象,且0°试样比90°试样硬化更严重,这主要是由于在冷锻变形过程中,大量高位错密度在晶界和孪晶界积聚,宏观上表现为加工硬化,使得硬度增加,提高了材料的强度。0°试样的初始取向有利于产生压缩孪晶,但压缩孪晶界不易发生能量的迁移,造成形变不均匀,致使在晶界处出现应变能积累,应变能过大甚至会造成孪晶的碎化;而对于90°试样,其初始取向有利于{ }拉伸孪晶的产生,拉伸孪晶带宽,界面容易迁移,不易出现高形变储存能的界面。因此,压缩孪晶界处高位错密度积聚得更严重,试样内部积聚的存储能量就越高,在后续的退火过程中就越有利于SRX形核而均匀细化晶粒。

}拉伸孪晶的产生,拉伸孪晶带宽,界面容易迁移,不易出现高形变储存能的界面。因此,压缩孪晶界处高位错密度积聚得更严重,试样内部积聚的存储能量就越高,在后续的退火过程中就越有利于SRX形核而均匀细化晶粒。

图2 冷锻12% 的AZ31镁合金的EBSD组织和极图

Fig. 2 EBSD maps and pole figures of 12% cold forged AZ31 magnesium alloys

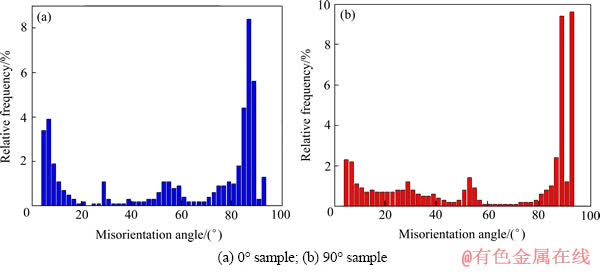

为了更深入地研究冷锻变形后晶界的特性,对两种冷锻试样内部的晶界取向差分布进行统计分析,结果如图3所示。由图3可见,0°和90°试样的变形组织中大部分晶界主要呈现大角度晶界分布(>15°),取向差角分布最大值均出现在86°附近,与{ }拉伸孪晶相对应,且由于冷锻速率快,{

}拉伸孪晶相对应,且由于冷锻速率快,{ }孪晶界发生了一定程度的扩展。此外,取向差为56°附近存在较小的峰值,符合{

}孪晶界发生了一定程度的扩展。此外,取向差为56°附近存在较小的峰值,符合{ }压缩孪晶的取向关系。小角度晶界主要存在于粗大晶粒和长条晶内,小角度晶界的多少可反映位错数量的多少,因此,可以由小角度晶界的含量直观地反映金属内部储存能的相对大小[4],通过图3的量化计算得出0°和90°冷锻试样的平均小角度取向差(<10°)频率分别为0.031和0.017,0°试样中小角度晶界明显比90°试样中的多,其内部的变形储存能也相对大得多,可为后续的静态再结晶提供能量条件(320 ℃退火),晶粒组织中的高密度小角度晶界可不断吸收位错而逐步转变为大角度晶界,改善其内部组织结构。

}压缩孪晶的取向关系。小角度晶界主要存在于粗大晶粒和长条晶内,小角度晶界的多少可反映位错数量的多少,因此,可以由小角度晶界的含量直观地反映金属内部储存能的相对大小[4],通过图3的量化计算得出0°和90°冷锻试样的平均小角度取向差(<10°)频率分别为0.031和0.017,0°试样中小角度晶界明显比90°试样中的多,其内部的变形储存能也相对大得多,可为后续的静态再结晶提供能量条件(320 ℃退火),晶粒组织中的高密度小角度晶界可不断吸收位错而逐步转变为大角度晶界,改善其内部组织结构。

2.2 再结晶退火试样的显微组织分析

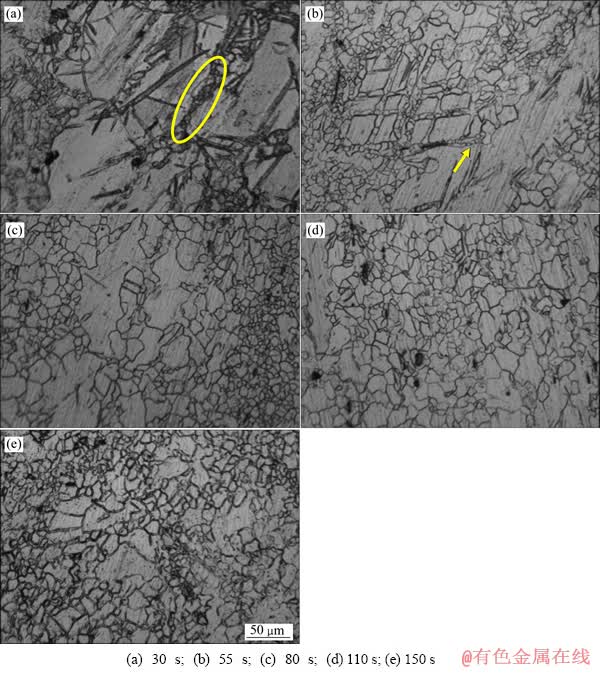

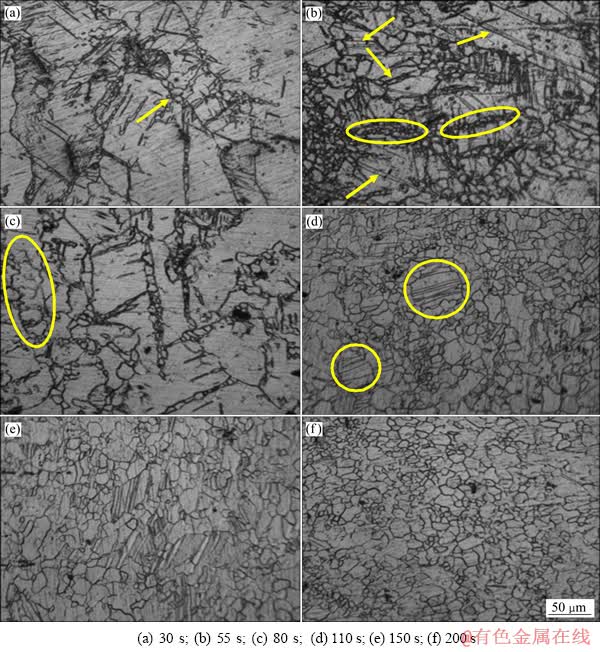

图4所示为0°试样冷锻变形12%后在320 ℃下保温不同时间退火后的光学显微组织。退火30 s后,试样内部粗大晶粒晶界处已开始发生SRX,在晶界处出现条“项链状”细小的SRX晶粒(见图4(a)),且SRX晶粒优先在原始晶界尤其是三叉角处形核。退火55 s后,试样大部分区域发生了SRX,但依然存在明显的长条晶粒,长条晶粒晶界处无明显的形核,一般认为在孪晶交叉处形变更复杂,畸变程度大,亚晶取向较大的偏转,因此,大量的SRX晶粒主要在交错的孪晶内和孪晶界处形核,此外,在粗大晶粒晶界处也有形核(见图4(b)箭头处),SRX未发生充分;退火80 s后,试样大部分已完全SRX,SRX晶粒极其不均匀,粗大晶粒和细小晶粒分布区域明显不同,粗大晶粒尺寸可达100 μm,细小晶粒尺寸为2~3 μm,主要是因为在冷锻变形中,原始不同尺度的晶粒协调应变能力存在差异,各晶粒的转动不一致,在长条晶和粗大晶界处能积累较大的应力,不同晶粒晶界处形变储存能不同,因此,发生再结晶的速率相应地也会存在差异。通过大量金相组织观察发现,实验中的再结晶晶粒均比较细小,即使在320 ℃保温时间达到200 s时,几乎所有的再结晶晶粒依然小于10 μm。为了方便统计分析,本文作者将尺寸小于10 μm的无畸变晶粒视为SRX晶粒。经统计分析得出SRX晶粒的体积分数约为76%;退火时间110 s时,内部的混晶组织已几乎完全发生SRX,组织趋于均匀细化,其平均尺寸约为7 μm,试样的SRX晶粒体积分数达到95%;继续延长保温时 间至150 s,局部细小的SRX晶粒开始出现长大,发现有异常长大的二次再结晶组织。

图3 12%冷锻AZ31镁合金的取向差角分布

Fig. 3 Misorientation angle distribution of 12% cold forged samples

图4 0°冷锻试样在320 ℃退火不同时间的光学显微组织

Fig. 4 Optical micrographs of cold forged 0° samples annealed at 320 ℃ for different durations

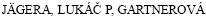

图5所示为90°试样冷锻12%后在320 ℃下不同时间退火的光学显微组织。退火30 s后,试样内部只有少量SRX晶粒在晶界处出现,对比0°试样,90°试样的SRX形核区域较少,说明开始发生SRX时间被推迟的现象,此外,SRX优先形核点主要集中在晶粒的三叉晶界处;退火55 s后,内部的SRX晶粒数目明显增加,沿粗大晶粒晶界处出现多条“项链状”的细小SRX晶粒,但内部仍存在大量拉伸孪晶(见图5(b)箭头处),同一晶粒内孪晶呈平行分布,且孪晶界无明显的再结晶形核;退火80 s后,部分拉伸孪晶开始发生明显的再结晶形核,孪晶被细小的再结晶晶粒所分割,粗大晶粒晶界处出现大量SRX晶粒,但内部依然仍存在着大量未发生SRX区域,长条晶粒晶界处无明显的SRX形核(见图5(c)),组织极其不均匀;退火110 s后,发生了明显的SRX,大量长条晶粒和粗大晶粒已被SRX晶粒所替代,但局部粗大晶粒中依然有少量相互平行的拉伸孪晶存在(见图5(d)),这也说明了拉伸孪晶不利于SRX形核,SRX晶粒体积分数为78%;继续延长保温退火时间至150 s,混晶组织逐渐均匀化,周围SRX晶粒的不断长大慢慢吞噬残余的拉伸孪晶,SRX晶粒体积分数达83%,发生完全SRX时间有所延长,这主要是因为挤压镁合金不同取向的冷锻变形,变形机制的不同导致其内部储存能比0°试样的低,而充分发生SRX形核需要提供更多的能量;继续延长保温退火时间至200 s,内部的拉伸孪晶已完全被SRX晶粒替代,已经基本完成再结晶,SRX晶粒体积分数高达96%,原始的混晶组织得到明显均匀细化,晶粒呈等轴状分布,其平均晶粒尺寸约为8 μm。

图5 90°冷锻试样在320 ℃退火不同时间的光学显微组织

Fig. 5 Optical micrographs of cold forged 90° samples annealed at 320 ℃ for different durations

SRX是一个新的无畸变晶粒形成和核心长大过程,驱动力来自于变形金属中的形变储存能[18]。SRX的形核也需要一个孕育过程,在320 ℃保温30 s的条件下提供了较为充分的形核孕育期,随着退火时间逐渐延长至200 s,SRX晶粒的体积分数逐渐增加,晶粒尺寸由先发生完全SRX而细化再随能量的供应发生晶粒长大。晶粒长大属于热激活过程,在退火温度T下,平均晶粒尺寸 随着时间t的延长可用式(1)表示[19]:

随着时间t的延长可用式(1)表示[19]:

(1)

(1)

式中: 为原始晶粒尺寸;k和m为材料常数;R为摩尔气体常数;T为退火温度;Q为晶界移动激活能。退火温度对SRX的发生起重要作用,退火温度越低,SRX形核越不易发生,SRX持续时间越长;随着退火温度升高,组织中原子的热振动和扩散速率增加,晶界更容易发生迁移。

为原始晶粒尺寸;k和m为材料常数;R为摩尔气体常数;T为退火温度;Q为晶界移动激活能。退火温度对SRX的发生起重要作用,退火温度越低,SRX形核越不易发生,SRX持续时间越长;随着退火温度升高,组织中原子的热振动和扩散速率增加,晶界更容易发生迁移。 等[20]发现:温度在100 ℃以下退火时,随退火时间的延长,试样显微组织无明显改变;而随着退火温度的升高,内部显微组织变化得非常迅速,300 ℃以上退火时,完全SRX时间大大缩短,SRX晶粒优先在孪晶界处形核。在本实验中选择320 ℃进行不同时间的退火,可大大缩短完全SRX时间,有利于更全面地分析孪晶组织对SRX行为的影响。

等[20]发现:温度在100 ℃以下退火时,随退火时间的延长,试样显微组织无明显改变;而随着退火温度的升高,内部显微组织变化得非常迅速,300 ℃以上退火时,完全SRX时间大大缩短,SRX晶粒优先在孪晶界处形核。在本实验中选择320 ℃进行不同时间的退火,可大大缩短完全SRX时间,有利于更全面地分析孪晶组织对SRX行为的影响。

对于挤压镁合金,由于其典型的各向异性,不同的初始取向对冷锻变形机制影响很大,因此,在相同的冷锻应变下形变储存能存在较大的差异,继而影响后续的SRX行为。0°试样比90°试样冷锻变形储存能高,所以,在相同的退火条件下,SRX开始和结束时间均被提前。对本实验中的0°试样冷锻变形,初始阶段以基面滑移为主,当变形量增加至12%时,出现了大量的{ }压缩孪晶和{

}压缩孪晶和{ }-{

}-{ }二次孪晶,分别使晶粒c轴转动64°和38°,致使晶粒取向更有利于滑移的进行,大量的小角度晶界在粗大晶粒内产生,平均小角度取向差(<10°)的频率为0.031。而对于90°试样,冷锻变形初期主要以{

}二次孪晶,分别使晶粒c轴转动64°和38°,致使晶粒取向更有利于滑移的进行,大量的小角度晶界在粗大晶粒内产生,平均小角度取向差(<10°)的频率为0.031。而对于90°试样,冷锻变形初期主要以{ }拉伸孪晶为主,且伴随有基面滑移,当变形量12%时,产生大量的{

}拉伸孪晶为主,且伴随有基面滑移,当变形量12%时,产生大量的{ }拉伸孪晶导致晶体取向旋转86°,使大多数的晶体c轴与FD平行,晶粒取向不利于滑移的进行[9],而少量{

}拉伸孪晶导致晶体取向旋转86°,使大多数的晶体c轴与FD平行,晶粒取向不利于滑移的进行[9],而少量{ }压缩孪晶及{

}压缩孪晶及{ }-{

}-{ }二次孪晶的产生使得部分晶粒处于有利于滑移的取向,在粗晶内部形成一定量的小角度晶界(<10°),其出现的平均频率为0.017。黄洪涛等[21]对不同取向样品在150 ℃压缩15%后进行退火处理,对比研究发现,样品的不同初始取向导致不同的压缩变形机制,因此,90°试样的SRX开始及结束时间均被推迟,与本研究结果相吻合。变形镁合金中80%~90%的SRX储能以孪晶的形式保留下来[22],不同孪生类型的储能能力存在差异,由于冷锻变形12%的90°试样中拉伸孪晶界面相比0°试样中的多,拉伸孪晶界比压缩孪晶及二次孪生扩展能力强,容易发生应变迁移,不易在晶界处造成应力集中,所以试样内部形变储存能较低,难以成为有效的SRX形核点[7],而压缩孪晶及二次孪晶界能积聚较高的变形储存能,诱发大量的SRX形核。冷锻变形中产生的孪晶类型差异导致0°试样的SRX形核区域较多,SRX形核和充分再结晶时间提前,晶粒细化更为有效。在本实验的等温退火过程中,冷锻变形量高达12%,使得试样内部植入大量缺陷,尤其是粗大晶粒和长条晶晶界处的位错密度急剧增加,具备了较高的变形储存能,因此,等温退火过程中SRX晶粒容易在粗大晶粒和长条晶晶界处形核,并通过不断的长大逐渐吞并晶界易于扩展的拉伸孪晶,最终发生完全SRX,达到细化晶粒的目的。

}二次孪晶的产生使得部分晶粒处于有利于滑移的取向,在粗晶内部形成一定量的小角度晶界(<10°),其出现的平均频率为0.017。黄洪涛等[21]对不同取向样品在150 ℃压缩15%后进行退火处理,对比研究发现,样品的不同初始取向导致不同的压缩变形机制,因此,90°试样的SRX开始及结束时间均被推迟,与本研究结果相吻合。变形镁合金中80%~90%的SRX储能以孪晶的形式保留下来[22],不同孪生类型的储能能力存在差异,由于冷锻变形12%的90°试样中拉伸孪晶界面相比0°试样中的多,拉伸孪晶界比压缩孪晶及二次孪生扩展能力强,容易发生应变迁移,不易在晶界处造成应力集中,所以试样内部形变储存能较低,难以成为有效的SRX形核点[7],而压缩孪晶及二次孪晶界能积聚较高的变形储存能,诱发大量的SRX形核。冷锻变形中产生的孪晶类型差异导致0°试样的SRX形核区域较多,SRX形核和充分再结晶时间提前,晶粒细化更为有效。在本实验的等温退火过程中,冷锻变形量高达12%,使得试样内部植入大量缺陷,尤其是粗大晶粒和长条晶晶界处的位错密度急剧增加,具备了较高的变形储存能,因此,等温退火过程中SRX晶粒容易在粗大晶粒和长条晶晶界处形核,并通过不断的长大逐渐吞并晶界易于扩展的拉伸孪晶,最终发生完全SRX,达到细化晶粒的目的。

3 结论

1) 当冷锻变形量为12%时,0°试样中长条晶粒晶界由平直变得弯曲,粗大晶粒晶界处出现了取向发生倾转的大量细小碎晶,晶粒c轴主要与FD呈15°和25°角分布;而90°试样中碎化晶粒相对较少,平直的长条晶粒晶界变为锯齿状,形成基面几乎完全与FD相垂直的织构。

2) 在冷锻变形过程中,由于内部出现{ }、{

}、{ }-{

}-{ }和{

}和{ }-

}- }等不同类型的孪晶和滑移系的开启,导致0°试样比90°试样具有更明显的加工硬化、更高频率的小角度取向差和更高的畸变存储能。

}等不同类型的孪晶和滑移系的开启,导致0°试样比90°试样具有更明显的加工硬化、更高频率的小角度取向差和更高的畸变存储能。

3) SRX形核点优先集中在三叉晶界处,沿着粗大晶界形成“项链状”细晶,{ }和{

}和{ }压缩孪晶及其二次孪晶可有效地促进SRX形核,SRX晶粒长大可吞并{

}压缩孪晶及其二次孪晶可有效地促进SRX形核,SRX晶粒长大可吞并{ }拉伸孪晶晶界。

}拉伸孪晶晶界。

4) 再结晶退火时,0°试样比90°试样更易发生SRX;通过SRX形核和长大可显著细化内部的粗晶组织和长条晶组织,粗晶组织细化速率较快,最终可获得均匀的细晶组织,0°试样和90°试样的平均尺寸分别约为7和8 μm。

REFERENCES

[1] 王 斌, 易丹青, 方西亚, 刘会群, 吴春萍. ZK60镁合金高温动态再结晶行为的研究[J]. 材料工程, 2009, 11: 45-50.

WANG Bin, YI Dan-qin, FANG Xi-ya, LIU Hui-qun, WU Chun-ping. Thermal simulation on hot deformation behavior of ZK60 magnesium alloy[J]. Material Engineering, 2009, 11: 45-50.

[2] 张晓华, 姜巨福, 罗守靖. AZ91D镁合金的热压缩变形行为[J]. 中国有色金属学报, 2009, 19(10): 1720-1725.

ZHANG Xiao-hua, JIANG Ju-fu, LUO Shou-jing. Compression deformation behavior of AZ91D magnesium alloy at elevated temperature[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(10): 1720-1725.

[3] 陈振华, 杨春花, 黄长清, 夏伟军, 严红革. 镁合金塑性变形中孪生的研究[J]. 材料导报, 2006, 20(8): 107-113.

CHEN Zhen-hua, YANG Chun-hua, HUANG Chang-qing, XIA Wei-jun, YAN Hong-ge. Investigation of the twinning in plastic deformation of magnesium alloy[J]. Materials Review, 2006, 20(8): 107-113.

[4] WANG M Y, XIN R L, WANG B S, LIU Q. Effect of initial texture on dynamic recrystallization of AZ31 Mg alloy during hot rolling[J]. Materials Science and Engineering A, 2011, 528(6): 2941-2951.

[5] HUMPHEYS F J, HATHERLY M. Recrystallization and related annealing phenomena[M]. 2nd ed. Oxford: Pergamon Press, 2004: 222.

[6] LI X, YANG P, WANG L N, CUI F. Orientational analysis of static recrystallization at compression twins in a magnesium alloy AZ31[J]. Materials Science and Engineering A, 2009, 517(1/2): 160-169.

[7] 李 萧, 杨 平, 孟 利, 崔凤娥. AZ31镁合金中拉伸孪晶静态再结晶的分析[J]. 金属学报, 2010, 46(2): 147-154.

LI Xiao, YANG Ping, MENG Li, CUI Feng-e. Analysis of the static recrystallization at tension twins in AZ31 magnesium alloy[J]. ActaMetallurgica Sinica, 2010, 46(2): 147-154.

[8] 吴远志, 严红革, 陈吉华, 朱素琴, 薄红伟, 王林伟. AZ31镁合金高应变速率多向锻造组织演变及力学性能[J]. 中国有色金属学报, 2012, 22(11): 3000-3005.

WU Yuan-zhi, YAN Hong-ge, CHEN Ji-hua, ZHU Su-qin, BO Hong-wei, WANG Lin-wei. Microstructure evolution and mechanical properties of AZ31 magnesium alloy fabricated by high strain rate triaxial-forging[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 3000-3005.

[9] 丁雪征, 刘天模, 陈 建, 张 喑, 卢立伟. 孪晶界对AZ31镁合金静态再结晶的影响[J]. 中国有色金属学报, 2013, 23(1): 1-8.

DING Xue-zheng, LIU Tian-mo, CHEN Jian, ZHANG Yin, LU Li-wei. Effect of twin boundary on static recrystallization of AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 1-8.

[10] CHAO H Y, YANG Y, WANG X, WANG E D. Effect of grain size distribution and texture on the cold extrusion behavior and mechanical properties of AZ31 Mg alloy[J]. Materials Science and Engineering A, 2011, 528: 3428-3434.

[11] LU L W, LIU T M, JIANG S, PAN F S, LIU Q, WANG Z C. Microstructure and mechanical property of dual-directional- extruded Mg alloy AZ31[J]. Materials Science and Engineering A, 2010, 527: 4050-4055.

[12] HUANG X S, SUZUKI K, CHINO Y. Different annealing behaviours of warm rolled Mg-3Al-1Zn alloy sheets with dynamic recrystallized microstructure and deformation microstructure[J].Materials Science and Engineering A, 2013, 560: 232-240.

[13] 简炜炜, 康志新, 李元元. 多向锻造ME20M 镁合金的组织演化与力学性能[J]. 中国有色金属学报, 2008, 18(6): 1005-1011.

JIAN Wei-wei, KANG Zhi-xin, LI Yuan-yuan. Microstructural evolution and mechanical property of ME20M magnesium alloy processed by multidirectional forging[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(6): 1005-1011.

[14] WU B L, WAN G, ZHANG Y D, ESLING C. Twinning characteristics in textured AZ31 alloy under impact loading along specified direction[J]. Materials Letters, 2010, 64: 636-639.

[15] LEVINSON A, MISHRA R K, DOHERTY R D, KALIDINDI S R. Influence of deformation twinning on static annealing of AZ31 Mg alloy[J]. Acta Materialia, 2013, 61: 5966-5978.

[16] 毛萍莉, 于金程, 刘 正, 董 阳, 席 通. 挤压态Mg-Gd-Y镁合金动态压缩力学性能与失效行为[J]. 中国有色金属学报, 2013, 23(4): 889-897.

MAO Ping-li, YU Jin-cheng, LIU Zheng, DONG Yang, XI Tong. Dynamic mechanical property and failure behavior of extruded Mg-Gd-Y alloy under high strain rate compression[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 889-897.

[17] 黄宏涛, 刘 伟, GODFREY A,唐瑞鹤, 刘 庆. AZ31镁合金单轴压缩中的孪生行为[J]. 金属学报, 2012, 48(3): 357-362.

HUANGHong tao, LIUWei, GODFREY A, TANGRui he, LIU Qing. Study of twin behavior during uniaxial compression of AZ31 magnesiumalloy[J]. ActaMetallurgica Sinica, 2012, 48(3): 357-362.

[18] LIU J Z, LIU T M, YUAN H Q. Effect of cold forging and static recrystallization on microstructure and mechanical property of magnesium alloy AZ31[J]. Materials Transactions, 2010, 51(2): 341-346.

[19] ZHANG J, LI W G, GUO Z X. Static recrystallization and grain growth during annealing of an extruded Mg-Zn-Zr-Er magnesium alloy[J]. Journal of Magnesium and Alloys, 2013, 1(1): 31-38.

[20]  V, HALODA J, DOPITA M. Influence of annealing on the microstructure of commercial Mg alloy AZ31 after mechanical forming[J]. Materials Science and Engineering A, 2006, 432: 20-25.

V, HALODA J, DOPITA M. Influence of annealing on the microstructure of commercial Mg alloy AZ31 after mechanical forming[J]. Materials Science and Engineering A, 2006, 432: 20-25.

[21] 黄洪涛, GODFREY A, 刘 伟, 唐瑞鹤, 刘 庆. 样品取向对AZ31镁合金静态再结晶行为的影响[J]. 金属学报, 2012, 48(8): 915-921.

HUANG Hong-tao, GODFREY A, LIU Wei, TANG Rui-he, LIU Qing. Effect of sample orientation on static recrystallization of AZ31 magnesium alloy[J]. ActaMetallurgica Sinica, 2012, 48(8): 915-921.

[22] 刘 宇, 刘天模, 肖 盼. AZ31镁合金冷压缩变形再结晶的研究[J]. 材料导报, 2007, 21(5): 370-371.

LIU Yu, LIU Tian-mo, XIAO Pan. The investigation of AZ31 magnesium alloy cold compression deformation recrystallization [J]. Materials Review, 2007, 21(5): 370-371.

(编辑 陈卫萍)

基金项目:湖南省自然科学基金资助项目(14JJ3111);湖南科技大学科学研究基金资助项目(E51353);湖南省自然科学湘潭联合基金资助项目(13JJ8017)

收稿日期:2014-04-01;修订日期:2014-06-15

通信作者:卢立伟,博士;电话:0731-58290047;E-mail: cqulqyz@126.com