文章编号:1004-0609(2011)12-2979-08

高低温处理条件下AZ31镁合金的力学性能与微观组织

张学锋1, 2,吴国华1, 2,丁文江1, 2

(1. 上海交通大学 轻合金精密成型国家工程研究中心,上海 200030;

2. 上海交通大学 金属基复合材料国家重点实验室,上海 200030)

摘 要:针对月球环境温度变化情形,研究了长时间低温浸泡(-196 ℃)和多次高低温交变循环处理(-196~200 ℃)对挤压态AZ31镁合金在20 ℃下的力学性能、显微组织以及断口形貌的影响。研究表明:AZ31镁合金经过长时间液氮浸泡和高低温交变循环处理后,力学性能无明显变化;室温态合金的σb和δ分别为288 MPa和18.3%,经过10 d低温浸泡后σb和δ分别为292 MPa和18.7%,经过10次高低温循环后合金的σb和δ分别为294 MPa和16.9%;低温和高低温交变处理对断口形貌和相组成没有明显影响,均为准解理断裂。

关键词:AZ31镁合金;月球环境温度;力学性能;微观组织

中图分类号:TG146.2 文献标志码:A

Mechanical properties and microstructures of AZ31 magnesium alloy after high and low temperature treatment

ZHANG Xue-feng1, 2 , WU Guo-hua1, 2, DING Wen-jiang1, 2

(1. National Engineering Research Center of Light Alloy Net Forming, Shanghai Jiao Tong University, Shanghai 200240, China;

2. State Key Laboratory of Metal Matrix Composites, Shanghai Jiao Tong University, Shanghai 200240, China)

Abstract: In view of the lunar environment temperature change situation, the influence of long time low temperature immersion (-196 ℃) and high-low temperature alternation processing (-196-200 ℃) on the mechanical properties, microstructures and fracture surfaces of AZ31 magnesium alloy at 20 ℃ was studied. The results indicate that there are no significant changes on the mechanical properties of AZ31 magnesium alloy after liquid nitrogen immersion or temperature alternation cycle treatment. The σb and δ of AZ31 magnesium alloy at room temperature are 288 MPa and 18.3%, respectively, after 10 d cryogenic processing, they will reach 292 MPa and 18.7%, respectively. σb and δ after 10 times high-low temperature alternation processing are 294 MPa and 16.9%, individually. SEM observation and XRD results show that the fracture surface and phase constitutions do not change obviously after low temperature or high-low temperature alternation processing. And the fractures are both quasi-cleavage crack.

Key words: AZ31 magnesium alloy; lunar environment temperature; mechanical properties; microstructures

镁在地球上储量非常丰富,约占地壳总质量的2%。镁合金是最轻的工程结构材料,密度低、比强度和比刚度高,且易于成型,导热性好、减震性好、有电磁屏蔽效应。此外,还具有易回收、有利于环保的优点,被称为21世纪最有发展前途的“绿色”工程材料[1-4]。当前,国内外关于镁合金的研究主要集中在高 性能镁合金的开发以及镁合金产品成型技术与工艺研究等方面[5-7],而由于镁及其合金的优点,在大飞机、探月工程等航空航天以及太空探索事业中有着广泛的应用前景,但是关于这方面的研究很少。

AZ31变形镁合金是目前商业化应用最广泛的变形镁合金,它具有较高的室温强度,良好的延展性以及优良的抗大气腐蚀能力,而且价格便宜。对AZ31镁合金的研究主要集中于高温和室温方面,关于其低温性能方面的研究则鲜见报道。为了探讨AZ31镁合金在月球环境温度下的应用可行性,本文作者将模拟月球的温度变化情形,期望能够弄清AZ31镁合金在长时间低温和高低温交变环境中的性能与组织变化规律。以往一些学者[8-11]在研究轻质合金低温性能时大多是在低温环境下(如液氮、液氢中)进行原位拉伸或是较短时间深冷处理后拉伸[12-13],本文作者充分考虑到月球的环境温度要求[14](在月球一个自转周期内,极限温度可以达到150 ℃及-180 ℃),对AZ31镁合金试样先进行长时间液氮浸泡或高低温交变循环处理,而后在20 ℃下进行力学性能测试,这也是本研究与以往研究的不同之处。通过与室温态试样对照,探明低温和高低温交替环境中,AZ31镁合金成分、力学性能以及组织的变化规律,探讨其应用可行性,为AZ31镁合金在太空探索事业中的广泛应用提供理论依据。

1 实验

1.1 实验材料

试验所用材料为d 20 mm的工业挤压态棒状AZ31变形镁合金,其成分如表1所列;用线切割数控加工机床从中心部位沿平行于挤压方向切割拉伸试样,尺寸如图1所示。

表1 AZ31的化学成分

Table 1 Chemical composition of AZ31 alloy (mass fraction, %)

图1 片状拉伸试样的形状和尺寸

Fig.1 Shape and size of rectangle tensile samples (mm)

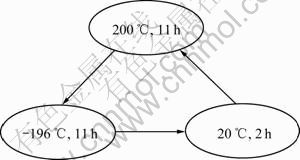

为了模拟月球恶劣的温度环境,对切取的拉伸试样分别进行长时间低温浸泡和多循环高低温交变处理。首先将镁合金试样用细丝吊入装有液氮的容器内,并使试样充分浸泡在液氮中,长时间低温浸泡连续置于液氮罐内10 d;高低温交变处理试样则在-196 ℃下保温11 h后取出放置于室温中,2 h后移入200 ℃的油浴炉内保温11 h,如此过程为一个高低温循环,周期为24 h。同时,取未经低温和高低温处理的室温态试样作为对照,按处理条件不同具体分类如表2所列。为保证结果的可靠性,每种条件下试样取5片。

表2 试样的不同处理条件

Table 2 Different treatment conditions of samples

图2 单循环过程

Fig.2 One-cycle process

1.2 力学性能测试

将处理后的试样室温下在Zwick/Roell-20kN材料测试机上进行拉伸试验,拉伸速度为1 mm/min (1.67×10-5 s-1),每种条件下测试5根试样,取平均值。

硬度测试在HV-30型维氏硬度仪上进行,所加载荷为49 N,保压时间为30 s,每个试样测试5个点,取平均值为试样硬度。

1.3 显微组织观察及相分析

金相样品从拉伸断口附近切取经金刚石研磨膏粗抛光后用MgO粉精抛,制得的金相试样采用5 g苦味酸、100 mL酒精、5 mL醋酸和10 mL水配成的侵蚀剂腐蚀8~10 s,在XJL-03光学显微镜(OM)上进行低倍组织观察,高倍观察在备有能谱分析仪的JSM7600F场发射扫描电镜(SEM)上进行,并进行相成分分析。断口形貌采用JSM-6460型扫描电镜进行观测。

相组成通过X射线衍射测试,衍射仪为D/max2550V,试验电压为40 kV,试验电流为40 mA,采用Cu靶,扫描速度为5 (°)/min。

2 结果与分析

2.1 AZ31镁合金的室温力学性能

不同处理状态下AZ31镁合金的力学性能测试结果如表3所列。室温态AZ31镁合金的屈服强度(σ0.2)为 217 MPa,抗拉强度(σb)为288 MPa,伸长率为18.3%;经过10 d液氮浸泡后合金的屈服强度为221 MPa,抗拉强度为292 MPa,伸长率为18.7%;经过10次高低温交变循环后合金的屈服强度和抗拉强度分别为225 MPa和294 MPa,伸长率为16.9%;而经过20次高低温交变循环后合金屈服强度为218 MPa,抗拉强度为285 MPa,伸长率为16.0%。总的来说,处理后AZ31镁合金的室温屈服强度、抗拉强度、伸长率以及硬度没有发生明显变化,相比室温态合金试样强度略有提高,而硬度稍有下降。

表3 不同处理状态下AZ31镁合金的力学性能测试结果

Table 3 Mechanical properties results of AZ31 magnesium alloy under different treatment conditions

为了便于分析和讨论实验结果,将经过液氮浸泡10 d的试样1和室温态试样4的力学性能进行对比,结果如图3所示。由图3可以看出,经液氮浸泡后,强度和伸长率较浸泡前稍有提高,而硬度则略微降低,但波动幅度均较小,说明长时间的液氮浸泡(-196 ℃)对AZ31镁合金的室温力学性能并未产生明显的影响。

同样,将经过高低温交变循环的试样2、3与室温态试样4的实验结果进行对比,结果如图4所示。随着高低温交变循环次数的增多,AZ31镁合金的屈服强度和抗拉强度总体呈现出先增大后减小的趋势,伸长率和硬度值则不断降低,但是变化并不显著。说明较长时间的高低温交变循环(-196~200 ℃)未引起合金力学性能的大幅度变化,不过随着循环次数的增多可能会引起AZ31合金各种力学性能的降低。

WIGLEY[15]认为温度对金属结构材料的拉伸性能影响显著,当温度由室温降至液氮、液氢温度时,材料的弹性变形抗力增加,但影响较小(一般为百分之几),然而,合金的强度及断裂韧性通常会有较大幅度的提高。张津等[16]在研究AZ91D的低温力学性能时将合金分别置于20 ℃、-20 ℃以及-40 ℃下进行加载测试,发现随着温度的降低,AZ91D的屈服强度由室温下的107 MPa依次提高至123 MPa和140 MPa,而抗拉强度则由室温下的190 MPa依次提高至241 MPa和258 MPa。教晓冬[17]在对AZ31B镁合金进行热处理后分别在300、77和4.2 K下测试力学性能,试验结果表明,随着温度的降低,镁合金的强度显著增加,其中4.2 K的抗拉强度比室温下至少高60%。而刘瑛等[18]在研究2519铝合金的低温拉伸力学性能时分别沿板材的纵向与横向截取拉伸试样,并分别在77 K和293 K下进行测试,研究表明温度由293 K下降至77 K时,纵向试样的抗拉强度由493.64 MPa上升至607.35 MPa,提高了23.1%,屈服强度由454.83 MPa上升至516.53 MPa,提高了13.7%;横向试样的低温抗拉强度与屈服强度分别提高了23.6%和20.0%。

图3 AZ31合金经低温浸泡后的性能变化

Fig.3 Performance changes of AZ31 alloy after cryogenic treatment

图4 AZ31合金经高低温交变循环后性能变化

Fig.4 Performance changes of AZ31 alloy after high-low temperature alternation processing

低温下材料性能的提高可能是由于在低温下晶格的热振动能降低,位错移动跨越势垒所需的外力增大,位错形成割阶的阻力以及割阶运动中所受阻力均增大,因此,强度提高。但与以往研究结果不同的是,AZ31镁合金的各项力学性能并未产生明显的变化,这主要是因为采用了不同于以往的实验方法。而结果中合金强度的小幅提高可能是由于激冷激热使试样中产生一定的内应力及变形能,增加了晶界处第二相的析出,使基体产生了少量可以与位错相互作用的亚晶,增强了结构的稳定性以及对位错运动的阻碍作用。

2.2 微观组织

图5所示为AZ31镁合金经不同处理后拉伸断口的光学金相观察结果。可见,断口主要由α-Mg基体和离异共晶析出的化合物相β-Mg17Al12构成。根据Mg-Al二元合金平衡相图[19-20],Mg-Al合金在437 ℃将发生由液相转变为α-Mg和β-Mg17Al12的共晶反应。α-Mg是密排六方结构,使得合金元素在α-Mg基体中固溶率低,容易发生非平衡凝固而形成离异共晶体组织。离异共晶化合物相呈不规则状,大部分分布在晶界附近,少数位于晶粒内部。

由图5(d)中室温态金相照片可以看出,AZ31镁合金微观组织中晶粒大小不均匀,主要由再结晶产生的细小等轴晶和原始粗大晶粒组成。这是由于热挤压过程中动态再结晶过程并不完全,一部分晶粒发生了再结晶,细化成细小等轴晶粒,而未发生再结晶的晶粒则在变形过程中沿着挤压方向被拉长,这在一定程度上降低了材料的力学性能。刘晓菲等[21]和WATANABE等[22]在研究AZ31镁合金动态再结晶过程时认为热挤压过程中,镁合金易发生动态再结晶过程。理论上,动态再结晶性能依赖于材料的堆垛层错能和晶格扩散率。增加堆垛层错能或减少晶格扩散率都可以阻碍动态再结晶发生。金属铝的堆垛层错能很高(200 mJ/m2),所以,铝合金需要很复杂的过程才能发生动态再结晶。相对地,镁的堆垛层错能仅为 78 mJ/m2,通过动态再结晶而细化晶粒的过程要容易得多。因而,伴随着热塑性加工(热挤压),AZ31镁合金中经过大变形形成的平行纤维变形组织在挤压应力和挤压热的作用下,首先沿晶界形成亚晶结构[23],进而通过亚晶合并机制形成较大尺寸的大角度亚晶;随后通过晶界迁移,亚晶进一步合并和转动,发生动态再结晶,最终形成细小的大角度晶粒。

对比图5(a)~(d)可以看出,AZ31镁合金微观组织均由细小等轴晶和原始粗晶组成。但是试样经过液氮浸泡和高低温交变循环后,由于温度变化使试样产生内应力,在基体中产生了细小的亚晶组织,从而使基体上局部晶粒得到细化。

图6所示为不同处理状态下AZ31镁合金的XRD谱。由图6可以看出,AZ31经过液氮浸泡和高低温交变循环前后相组成并未发生明显变化,且处理前后衍射最高峰晶面取向也未发生改变,但最高峰峰值却发生了一定的变化。仔细观察衍射图谱发现,经过处理后最高峰峰值得到加强,并以经10次高低温循环试样增强最多,这说明有晶粒取向朝着峰值取向偏转,进而使衍射峰增强,一定程度上提高了材料的性能。为了进一步分析AZ31镁合金组织相组成和特点,对试样进行了扫描电镜观察和成分分析,合金室温组织的SEM像和EDS谱如图7所示。由图7可以看出,β-Mg17Al12主要分布在基体相α-Mg晶界处,还有很少一部分位于晶粒内部。除此之外,通过图7还看到组织中存在少量具有较规则形状的白色富锰相颗粒。Mn常被添加到Mg-Al系合金中来降低Fe的含量,从而提高合金的耐蚀性,Mg-Al系合金中富锰相主要以β-Mn和Al8Mn5的形式存在[24-27]。实验中富锰相含量较低,并未在XRD分析中检测出来,难以定性和定量分析。

图5 经不同处理后AZ31镁合金断口附近的金相组织

Fig.5 Metallographs of AZ31 magnesium alloy near fracture by different treatments: (a) -196 ℃, 10 d; (b) 10 cycles; (c) 20 cycles; (d) Untreated

图6 不同处理状态下AZ31镁合金的XRD谱

Fig.6 X-ray diffraction patterns of AZ31 magnesium alloy by different treatments: (a) -196 ℃, 10 d; (b) 10 cycles; (c) 20 cycles; (d) Untreated

2.3 断口形貌

图8所示分别为试样1、2、3和4拉伸试验后的断口形貌扫描电镜像。由图8可见,它们的断裂机理均为准解理断裂,这表明液氮浸泡以及高低温交变处理均不改变AZ31镁合金的断裂特征。

观察图8(d)可以看出,试样4拉伸后的显微断口存在河流花样,断口上有解理面和解理台阶,还有因较大塑性变形产生的撕裂棱,具有准解理断裂断口的典型特征。这也是密排六方晶体结构的镁的典型断裂方式。将图8(a)与图8(d)对比可以看出,试样1的断裂方式仍为准解理断裂,但是解理面较少,撕裂棱增多,而且出现了少量大小不等的韧窝,呈现出脆性和韧性断裂的混合机制。而将图8(b)与图8(c)和(d)进行对比可以看出,随着高低温交变循环次数的增加,显微断口中解理平面明显增多,河流花样特征更加明显,而撕裂棱数量则逐渐减少,趋向于解理断裂。

图7 β相和富锰相的SEM像和EDS能谱

Fig.7 SEM images ((a), (c)) and EDS spectra ((b), (d)) of Mn-rich phase((a), (b)) and β-Mg17Al12((c), (d))

图8 不同处理状态下AZ31镁合金的断口形貌

Fig.8 Fracture surfaces of AZ31 magnesium alloy by different treatments: (a) -196 ℃, 10 d; (b) 10 cycles; (c) 20 cycles; (d) Untreated

3 结论

1) 经过10 d液氮浸泡后AZ31镁合金σb和δ分别为292 MPa和18.7%,经过10次高低温循环后合金的σb和δ分别为294 MPa和16.9%,而经过20次循环后合金的σb和δ分别为285 MPa和16.0%,与室温态AZ31镁合金相比并无显著变化,而强度的小幅提高可能是由于激冷激热作用使试样产生内应力及变形能,使基体产生了少量可以与位错相互作用的亚晶,增强了对位错运动的阻碍作用。

2) 经过液氮浸泡和高低温交变循环后AZ31镁合金微观组织特点较室温态没有明显变化,金相组织由热挤压过程中再结晶形成的细小等轴晶和原始粗大晶粒组成,但处理后基体中产生的细小亚晶组织使局部晶粒得到细化。相组成主要是α-Mg基体和β相(主要分布在晶界处),此外,还有少量白色富锰相。

3) 与室温态AZ31镁合金拉伸断口形貌相比,液氮浸泡后合金断口中解理平面减少,撕裂棱增多,出现少量大小不等的韧窝,呈现出脆性和韧性断裂的混合机制;而经高低温交变循环后,AZ31合金显微断口中解理平面明显增多,河流花样特征更加明显,撕裂棱数量则逐渐减少,趋向于解理断裂。断裂方式均为准解理断裂。

REFERENCES

[1] 刘 英, 李元元, 张卫文, 罗宗强, 张大童. 镁合金的研究进展和应用前景[J]. 轻金属, 2002(8): 56-61.

LIU Ying, LI Yuan-yuan, ZHANG Wei-wen, LUO Zong-qiang, ZHANG Da-tong. A review on the development and application prospects of magnesium alloys[J]. Light Metals, 2002(8): 56-61.

[2] 刘 正, 张 奎, 曾小勤. 镁基轻质合金理论基础及其应用[M]. 北京: 机械工业出版社, 2002.

LIU Zheng, ZHANG Kui, ZENG Xiao-qin. Theoretical basisand application of Mg-based light alloys[M]. Beijing: China Machine Press, 2002.

[3] 王小强, 李全安, 张兴渊. Nd对AZ91镁合金组织和高温力学性能的影响[J]. 材料导报, 2007, 21(z2): 389-394.

WANG Xiao-qiang, LI Quan-an, ZHANG Xing-yuan. Effects of neodymium on microstructure and high-temperature mechanical properties of AZ91 magnesium alloy[J]. Materials Review, 2007, 21(z2): 389-394.

[4] 徐宏兴, 刘长海, 戴 宁. 镁合金材料的发展与研究[J]. 热处理, 2006, 21(4): 17-20.

XU Hong-xing, LIU Chang-hai, DAI Ning. Research and development of magnesium alloy[J]. Heat Treatment, 2006, 21(4): 17-20.

[5] 陈广森, 吴国华, 黄玉光, 王 玮, 卢 晨. 高强高韧耐热镁合金的研究现状与展望[J]. 铸造工程, 2007, 31(4): 30-33.

CHEN Guang-sen, WU Guo-hua, HUANG Yu-guang, WANG Wei, LU Chen. Review on research of high strength, high toughness and heat-resistant magnesium alloy[J]. Foundry Engineering, 2007, 31(4): 30-33.

[6] 杨明波, 唐丽文, 杨 慧, 赵玮霖, 陈 健. 高强镁合金的研究现状及进展[J]. 材料导报, 2007, 21(z2): 307-309.

YANG Ming-bo, TANG Li-wen, YANG Hui, ZHAO Wei-lin, CHEN Jian. Current research and development on high strength magnesium alloys[J]. Materials Review, 2007, 21(z2): 307-309.

[7] 孟若愚, 张代东, 原洪加. 镁合金成型技术研究进展[J]. 热加工工艺, 2008, 37(7): 89-92.

MENG Ruo-yu, ZHANG Dai-dong, YUAN Hong-jia. Progress of forming technologies for magnesium alloy[J]. Hot Working Technology, 2008, 37(7): 89-92.

[8] 陈 鼎, 陈振华. 铝合金在低温下的力学性能[J]. 宇航材料工艺, 2000(4): 1-7.

CHEN Ding, CHEN Zhen-hua. Mechanical properties of pure aluminum alloys at cryogenic temperature[J]. Aerospace Materials & Technology, 2000(4): 1-7.

[9] 徐永波, 张 匀, 王中光, 胡壮麟. 铝锂合金在室温和低温下的疲劳与断裂行为[J]. 材料工程, 1990(2): 16-18.

XU Yong-bo, ZHANG Yun, WANG Zhong-guang, HU Zhuang-lin. Fatigue and fracture behavior of an aluminum-lithium alloy at ambient and cryogenic temperature[J]. Journal of Materials Engineering, 1990(2): 16-18.

[10] XIONG Chuang-xian, ZHANG Xin-ming, DENG Yun-lai, XIAO Yang, DENG Zhen-zhen, CHEN Bu-xiang. Effects of cryogenic treatment on mechanical properties of extruded Mg-Gd-Y-Zr(Mn) alloys[J]. Journal of Central South University of Technology, 2007, 14(3): 305-309.

[11] 刘 瑛, 张新明, 李慧中, 刘 波, 高 慧, 李惠杰. 3种高强铝合金的低温拉伸力学性能研究[J]. 金属热处理, 2007, 32(1): 53-56.

LIU Ying, ZHANG Xin-ming, LI Hui-zhong, LIU Bo, GAO Hui, LI Hui-jie. Tensile properties of three kinds of aluminum alloy at low temperature[J]. Heat Treatment of Metals, 2007, 32(1): 53-56.

[12] 陈 鼎, 夏树人, 姜 勇, 刘 芳, 滕 杰. 镁合金深冷处理研究[J]. 湖南大学学报: 自然科学版, 2008, 35(1): 62-65.

CHEN Ding, XIA Shu-ren, JIANG Yong, LIU Fang, TENG Jie. Study on improving performance of magnesium alloy by deep cryogenic treatment[J]. Journal of Hunan University: Natural Sciences, 2008, 35(1): 62-65.

[13] MESHINCHI K A, TARI A, KHOMAMIZADEH F. Effect of deep cryogenic treatment on microstructure, creep and wear behaviors of AZ91 magnesium alloy[J]. Materials Science and Engineering A, 2009, 523: 27-31.

[14] 叶培建, 肖福根. 月球探测工程中的月球环境问题[J]. 航天器环境工程, 2006, 23(1): 1-11.

YE Pei-jian, XIAO Fu-gen. Issues about lunar environment in lunar exploration project[J]. Spacecraft Environment Engineering, 2006, 23(1): 1-11.

[15] WIGLEY D A. Mechanical properties of materials at low temperatures[M]. New York-London: Plenum Press, 1971.

[16] 张 津, 王东亚, 孙智富. AZ91D镁合金的低温力学性能[J]. 中国有色金属学报, 2004, 14(S3): 37-40.

ZHANG Jin, WANG Dong-ya, SUN Zhi-fu. Mechanical properties of AZ91D at low temperature[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(S3): 37-40.

[17] 教晓冬. 轻质合金的低温物性研究[D]. 北京: 中国科学院理化技术研究所, 2006: 39-44.

JIAO Xiao-dong. Properties of low density alloys at cryogenic temperatures[D]. Beijing: Technical Institute of Physics and Chemistry, Chinese Academy of Sciences, 2006: 39-44.

[18] 刘 瑛, 张新明, 李慧中, 高 慧, 刘 波, 李惠杰. 2519铝合金的低温拉伸力学性能[J]. 中南大学学报: 自然科学版, 2006, 37(4): 641-645.

LIU Ying, ZHANG Xin-ming, LI Hui-zhong, GAO Hui, LIU Bo, LI Hui-jie. Tensile properties of 2519 aluminum alloy at low temperature[J]. Journal of Central South University: Science and Technology, 2006, 37(4): 641-645.

[19] 屠怡范, 陈晶益, 张波萍, 李鹏喜, 铃木洋夫. AZ31铸造镁合金的物相和显微组织[J]. 铸造, 2006, 55(5): 509-512.

TU Yi-fan, CHEN Jing-yi, ZHANG Bo-ping, LI Peng-xi, SUZUKI H G. Phases and microstructure of as-cast AZ31 magnesium alloy[J]. Foundry, 2006, 55(5): 509-512.

[20] 郑来苏. 铸造合金及其熔炼[M]. 西安: 西北工业大学出版社, 1994.

ZHENG Lai-su. Alloy casting and smelting[M]. Xi’an: Northwestern Polytechnical University Press, 1994.

[21] 刘晓菲, 严 巍, 陈国学. AZ31B镁合金塑性变形动态再结晶的实验研究[J]. 塑性工程学报, 2005, 12(3): 10-13.

LIU Xiao-fei, YAN Wei, CHEN Guo-xue. The experiment study on recrystallization of magnesium alloy AZ31B during plastic deformation[J]. Journal of Plasticity Engineering, 2005, 12(3): 10-13.

[22] WATANABE H, TSUTSUI H, MUKAI T, ISHIKAWA K, OKANDA Y, KOHZU M, HIGASHI K. Grain size control of commercial wrought Mg-Al-Zn alloys utilizing dynamic recrystallization[J]. Materials Transactions, 2001, 42(7): 1200-1205.

[23] 瞿秋亚, 王智民, 袁 森, 蒋百灵, 李树丰. 挤压变形对AZ31镁合金组织和性能的影响[J]. 西安理工大学学报, 2002, 18(3): 254-258.

QU Qiu-ya, WANG Zhi-min, YUAN Sen, JIANG Bai-ling, LI Shu-feng. Effects of extrusion deformation on AZ31 Mg alloy microstructure and properties[J]. Journal of Xi’an University of Technology, 2002, 18(3): 254-258.

[24] 韩 广. Mg-Al系合金中α-Mg晶粒细化与富锰相转变的研究[D]. 济南: 山东大学, 2010: 15-19.

HAN Guang. Grain refinement of α-Mg and Mn-rich phase transformation in Mg-Al alloys[D]. Ji’nan: Shandong University, 2010: 15-19.

[25] LASER T, NURNBERG M R, JANZ A, HARTIG H, LETZIG D, SCHMID-FETZER R, BORMANN R. The influence of manganese on the microstructure and mechanical properties of AZ31 gravity die cast alloys[J]. Acta Materialia, 2006, 54: 3033-3041.

[26] SIN S L, DUBE D, TREMBLAY R. Characterization of Al-Mn particles in AZ91D investment castings[J]. Materials Characterization, 2007, 58: 989-996.

[27] JI S, ZHEN Z, FAN Z. Effects of rheo-die casting process on the microstructure and mechanical properties of AM50 magnesium alloy[J]. Materials Science and Technology, 2005, 21: 1019-1024.

(编辑 龙怀中)

基金项目:国家重点基础研究发展计划资助项目(2007CB613701);国家高技术研究计划资助项目(2009AA033501);中国航天科技集团公司航天科技创新基金资助项目(0502)

收稿日期:2010-11-24;修订日期:2011-03-10

通信作者:吴国华,教授,博士;电话:021-54742630;传真:021-54742794;E-mail: ghwu@sjtu.edu.cn