文章编号:1004-0609(2010)07-1353-07

冷喷涂65%Zn-Al复合涂层的沉积特性

李海祥,孙明先,李相波,王洪仁,黄国胜

(中船重工七二五所青岛分部 海洋腐蚀与防护国防科技重点实验室,青岛266071)

摘 要: 以 Zn 和 Al粉末为原料(Zn质量分数为85%),采用冷气动力喷涂方法制备65%Zn-Al 涂层。采用 SEM 和光学显微镜(OM)对涂层的显微组织进行研究,结合 XRD 和 X 射线能谱(EDS)对涂层的沉积特性进行分析。结果表明:在本实验条件下可获得厚度为0.7 mm、孔隙率为1.7%的65%Zn-Al复合涂层;Al 粒子的沉积效率要远高于Zn 粒子的;Zn 和 Al 粒子主要通过塑性变形机械咬合在一起,粒子间结合紧密;交界面处粒子由于连续冲击作用产生破碎细化;涂层显微硬度高于 Zn 和 Al 块材的,涂层的本身强度大于其与基体的结合强度,部分结合面涂层与基体存在元素扩散的现象,组织中未检测到固溶体与化合物相。

关键词: 65%Zn-Al 涂层; 沉积特性; 结合机理; 冷喷涂

中图分类号: TG174.44 文献标志码:A

Depositing characteristic of 65%Zn-Al coatings produced by cold gas dynamic spray

LI Hai-xiang, SUN Ming-xian, LI Xiang-bo, WANG Hong-ren, HUANG Guo-sheng

(State Key Laboratory for Marine Corrosion and Protection,

China Shipbuilding Industry 725 Research Institute, Qingdao 266071, China)

Abstract: With Zn and Al mixed powders as raw materials, 65%Zn-Al coatings were prepared by cold gas dynamic spray. The microstructures of the cold-sprayed 65%Zn-Al coatings were characterized by SEM and OM. XRD and EDS were used to analyze the co-deposited characteristics of 65%Zn-Al coatings. The results reveal that a densely co-deposited 65%Zn-Al coating with thickness of about 0.7 mm and porosity of 1.7% is obtained. The deposition efficiency of Al particles on the co-deposited coating is obviously higher than that of Zn particles. The bonding among Zn and Al particles mainly attributes to the plastic deformed mechanical embedding effect, and the combination among particles is tight. Those particles at the interface are broken and fined by continuous collision, so they have relative higher micro hardness than Zn or Al bulk metal. The bonding among the particles in the coating is more strength than the bonding of coating to substrate. There is element diffusion phenomenon in the interface between the coating and the substrate, and no solid solution and compound is observed.

Key words: 65%Zn-Al coating; deposition characteristic; bonding mechanism; cold spray

在海洋环境中,船舶的内舱和舷外结构、平台和港工设施的潮差、飞溅及大气段均存在着严重的腐蚀问题。这些部位采用常规的涂层和阴极保护技术无法满足其长效防护的要求,喷涂金属防护涂层技术是目前国际上解决海洋环境中钢结构长效防护的重要手 段[1]。传统的热喷涂涂层存在材料易氧化相变、孔隙率高、残余应力高导致涂层的结合力差等问题[2]。对于Zn和Al金属涂层,孔隙率高意味着涂层自身的腐蚀损耗加快,腐蚀产物会使涂层鼓泡导致失效。 采用冷气动力喷涂方法,原料粒子经加速后,与基体碰撞发生强烈塑性变形而沉积形成涂层[3]。冷喷涂制备的涂层组织结构几乎不发生变化,没有出现明显的氧化现象,制备的涂层致密、孔隙率低。冷喷涂对海洋环境中钢结构长效防护有重要的应用价值。目前,对于以机械复合粉末为原料,采用冷气动力喷涂形成涂层的研究鲜见报道[4-7]。本文作者以Zn和Al的机械复合粉末为原料,采用冷喷涂方法制备65%Zn-Al复合涂层,通过光学显微镜、 扫描电镜、X射线衍射研究涂层的显微结构和沉积特征, 并测试涂层的孔隙率、结合强度和显微硬度,进一步解释冷喷涂涂层的结合机理。

1 实验

1.1 实验材料

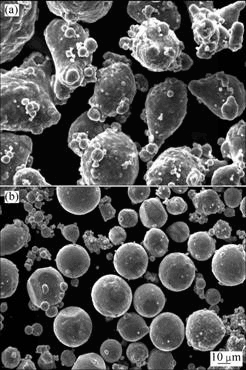

Zn和Al粉末均为粒子雾化方法制备,Zn和Al原料粉末的显微结构见图1所示。粒子雾化制备的Al粉体呈不规则的球形,粒度主要为30~80 μm;Zn粉体呈规则的球形,粒度主要为5~30 μm,其形貌与粒度分布满足冷喷涂制备工艺要求,有利于制备质量较好的涂层[8-9]。将2种粉末按照质量比85?15机械混匀在一起。

图1 喷涂用Zn和Al粉末的SEM像

Fig.1 SEM images of Al (a) and Zn (b) powders for feedstock of spray

1.2 实验方法

以压缩空气为工作气体,在载气压力2.7 MPa,载气温度400 ℃、喷涂距离20 mm的条件下制备65% Zn-Al复合涂层。对涂层喷涂态表面进行SEM观察及EDS分析。为了便于观察,将试样加工成10 mm× 10 mm的试样,用环氧树脂固化在PVC管中,用200、500、800、1000和1500号水磨砂纸逐级打磨,并用W5金刚石研磨膏和绒布抛光。对Zn和Al喷涂粉体以及抛光后的65%Zn-Al涂层进行XRD分析,实验设备为D8A衍射仪,扫描角度为30?~90?,速度为2(?)/min。对Zn和Al喷涂粉体、涂层喷涂表面以及抛光态的涂层及其截面进行SEM观察及EDS分析,实验仪器为Philips XL30型环境扫描电镜。

采用静态压痕法对涂层的抛光态横截面(以线切割法沿垂直于涂层表面方向切断)进行显微硬度测试。从接近涂层表面位置开始直到基体为止,每隔一段距离测试一个点。实验参照GB 4340.1—1999《金属显微维氏硬度试验方法》[10],使用HXD-1000TM型数字式显微硬度仪,载荷0.98 N,加载20 s。将涂层的抛光态横截面用0.5%(体积分数)HF+4%HNO3酒精溶液侵蚀5 s,在OLYMPUS PME3光学显微镜(OM)下观察涂层显微组织。使用WDW-20电子拉伸实验机进行涂层的抗拉结合强度实验,参照GB/T 8642—2002《热喷涂抗拉结合强度的测定》[11]将涂层与基体拉开,然后用SEM观察断面形貌并分析成分。

2 结果与讨论

2.1 涂层沉积特性

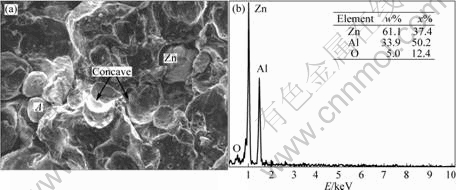

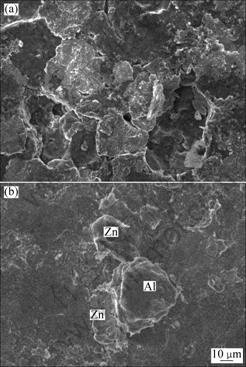

由于无后续粒子的冲击变形,涂层表面的粒子结合比较松散(见图2(a)),经过EDS(见图2(b))分析,可以观察到涂层表面有变形不明显的Zn颗粒嵌入到变形的Al颗粒内部,Zn颗粒边缘有少量孔隙,部分变形粒子表面存在粒子冲击后留下的凹坑 (箭头所指)。涂层表面抛光后(见图3(a)),经EDS分析黑色区域为Al(见图3(b)),灰色区域为Zn(见图3(c))。

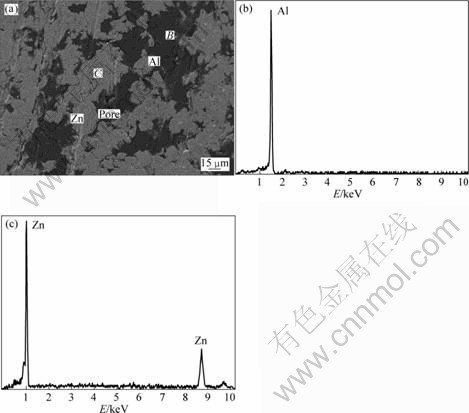

图4(a)所示为65%Zn-Al复合涂层的抛光横截面的SEM像,涂层均匀、平整,厚度达0.7 mm。这是因为冷喷涂过程中前期沉积的涂层受到后续粒子的持续撞击,涂层内部主要是压应力,有利于沉积较厚的涂层。对涂层截面进行EDS面分析(见图 4(b))。涂层截面元素含量反映了整个涂层内部Zn和Al含量分布情况和氧化程度。参考图2(b),涂层原始表面Al含量较高,Al颗粒表面存在撞击凹坑,同时涂层截面Zn的质量分数少于原始粉末中Zn的质量分数,说明在实验所用喷涂工艺条件下,Al颗粒的沉积效率要大于Zn颗粒的。由于Zn的密度比Al的大,相同体积的Zn的质量比Al的大,在同样的冷喷涂工艺条件下,大颗粒的Zn加速困难,更多的Al颗粒优先到达喷涂面形成沉积,同时Zn的粒度分布较窄,集中在20 μm左右(见图1),小颗粒不利于在气固双相流场中加速,造成Zn粉体的沉积效率比Al粉体的低。

图2 冷喷涂65%Zn-Al涂层表面的SEM像以及图2(a)中A点的EDS分析结果

Fig.2 SEM image of cold-sprayed 65% Zn-Al coating (a) and EDS pattern (b) of point A shown in Fg. 2(a)

图3 抛光后65%Zn-Al 涂层的SEM像以及图3(a)中B和C区的EDS分析 结果

Fig.3 SEM image (a) of 65% Zn-Al coating after being polished and EDS spetra of Area B (b) and Area C (c)

图4 65%Zn-Al 涂层抛光后的横截面的SEM像及EDS结果

Fig.4 SEM image (a) and EDS spectrum (b) of polished cross-section of 65%Zn-Al costing

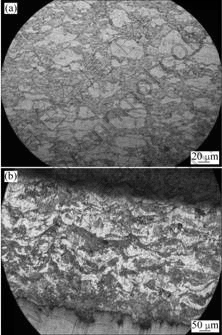

图5(a)所示为65%Zn-Al涂层横截面抛光侵蚀后的光学显微(OM)照片,亮场为Al,暗场为Zn。喷涂过程中Zn被打碎形成细小颗粒,这与Zn在一定温度下的脆性有关。使用金相检查法,采用Photoshop软件的珊格来计算涂层的孔隙率,分析10幅图片并取平均值,65%Zn-Al涂层的孔隙率为1.7%,而电弧喷涂的75%Zn-Al涂层孔隙率则高达6.3%(见图5(b))。

图5 Zn-Al 涂层抛光侵蚀后横截面的光学显微照片

Fig.5 Optical micrographs on cross-sections of cold-sprayed 65%Zn-Al (a) and arc-sprayed 75%Zn-Al deposits (b) after being etched in 0.5%HF+8%HNO3

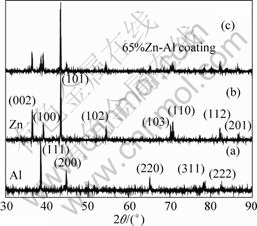

图6所示为Zn和Al喷涂粉体以及冷喷涂65%Zn-Al 复合涂层抛光表面的XRD谱。采用MDI Jade 5软件进行寻峰发现,65%Zn-Al复合涂层中对应的Zn和Al的衍射峰位和粉末单质保持一致,查PDF卡片数据库,与Zn和Al单质的完全吻合,利用RIR方法计算物相含量,Al的质量分数为36%,与EDS分析结果(见图4(b))吻合。在65%Zn-Al涂层衍射峰中

未检索出明显的氧化物和其它金属化和物相存在,结合EDS分析可知,在喷涂过程中,Zn和Al粒子并没有发生明显氧化,涂层中其它相低于检测水平。由于晶块细化和微观应变都会导致衍射峰变宽,使用Hall方法[12]:测量两个以上的衍射峰的半高宽FW(S),选

择同一方向衍射面,以sinθ/λ为横坐标,作 图,用最小二乘法作直线拟

图,用最小二乘法作直线拟

合,直线的斜率为微观应变的两倍,直线在纵坐标上的截距即为晶块尺寸的倒数。原Zn和Al 粉末的晶粒尺寸均大于100 nm,计算得出65%Zn-Al 复合涂层中Al的平均晶粒尺寸为90 nm左右,微观应变为0.37。说明在冷喷涂过程中,Al颗粒经过连续冲击作用后变形明显,导致晶块破碎细化 (见图7),可有效地提高涂层的强度和韧性。有研究[13]表明,晶粒细化会增加样品表面微观缺陷,从而促进保护性氧化膜的形成,提高金属均匀的耐腐蚀性能。

图6 喷涂Al和Zn粉末与65%Zn-Al涂层的XRD谱

Fig.6 XRD patterns of Al (a), Zn (b) powders and cold- sprayed 65%Zn-Al coating (c)

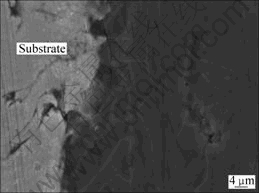

图7 65%Zn-Al涂层抛光后横截面的SEM像

Fig.7 SEM image of cold-sprayed 65%Zn-Al coating after being polished

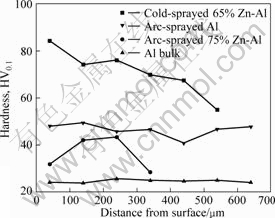

综合图2~7可知,冷喷涂65%Zn-Al 复合涂层,其结构为Zn和Al颗粒的机械结合物。经过强烈的塑性变形,颗粒间相互挤压呈扁平长条状嵌合在一起形成致密涂层,涂层内结合方式主要为颗粒之间的机械咬合,涂层与基体和涂层内部之间结合非常致密,整个横截面只有少量的孔隙,并且孔隙的面积很小,只有涂层表面较为疏松。冷喷涂粒子的喷涂速度高,粒子沉积时撞击力大,变形充分并产生破碎细化,大大减少了粒子间的不完全重叠,从而降低了孔隙率。同

时,涂层的显微硬度沿沉积方向逐渐减小(见图8),验证了后续粒子对涂层的持续冲击作用,使涂层产生加工硬化。对比电弧喷涂75%Zn-Al涂层(34 HV0.1),电弧喷涂Al涂层(51HV0.1)和Al块材(24 HV0.1)的显微硬度,说明65%Zn-Al复合涂层存在加工硬化现象。

图8 Zn-Al复合涂层的显微硬度沿沉积方向的变化曲线

Fig.8 Variations of Vickers microhardness measured in Zn-Al coatings along depositing direction

2.2 结合机理

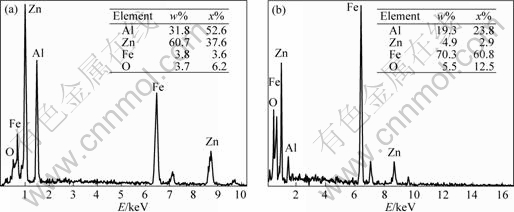

Zn和Al是相对较软的金属,当基体为钢时,相当于在硬基体上喷涂较软的材料,可能出现的情况是基体基本不发生变形而喷涂材料发生较大的塑性变形,以适应基体表面的粗糙不平,这样就产生了镶嵌式的机械咬合和冷焊作用。图9所示为涂层与基体拉断面的SEM像,涂层一侧(见图9(a))粒子撞击基体后发生明显变形,由原来的球形变成扁平状,另一侧可见部分Zn和Al粒子呈扁平状粘在基体上(见图9(b))。FUKANUMA等[14]的研究结果表明:涂层与基体是否存在冶金结合可采用断口形貌分析来表征,若断面上有对方元素存在,则涂层与基体的结合有冶金结合的可能。本实验断裂面位于涂层与基体结合面,说明涂层本身结合强度大于涂层与基体的结合强度,从EDS数据(见图10)可以看出,拉断面上有对方元素存在。

图9 冷喷涂 65%Zn-Al 复合涂层拉断面的SEM像

Fig.9 SEM images of rupture surface of 65%Zn-Al coatings after tension test: (a) Coatings; (b) Substrate surface

喷涂层与基体的结合强度反映的是喷涂材料与基体材料在碰撞时的状况,而涂层的内聚结合强度反映的是喷涂材料本身在碰撞结合时的状况。有模拟计算[15-17]得出,颗粒变形过程中在变形边缘微区温度分布最高,随着载气温度的升高,熔点较低的金属颗粒在碰撞沉积时,可能出现微区熔化,形成冶金结合,导致拉断面涂层一侧出现微量Fe元素。涂层与基体能否形成冶金结合与喷涂颗粒和基体的性质有关,两类原子在严重变形与热作用下能否相互扩散形成固溶体或化合物是冶金结合的先决条件。本试验喷涂温度为400 ℃,接近Al的熔点,随载气温度的升高,喷涂粉体的能量增大,有利于颗粒的塑性变形并发生剪切失稳。

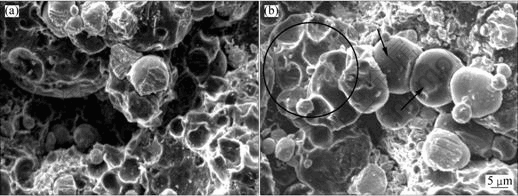

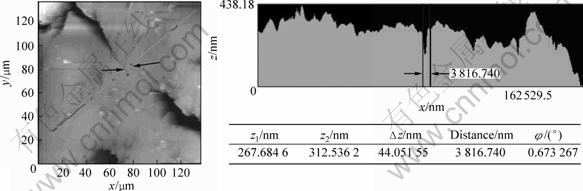

在冷喷涂过程中,粒子经过连续冲击作用形成涂层,涂层热残余应力较小,主要为压应力,有利于结合强度的提高。同时,在高速颗粒沉积瞬间,颗粒的动能转变为变形能和热能,显然,颗粒的动能愈大则撞击力愈大,颗粒与基体塑性变形程度愈高,涂层与基材的结合强度也相应提高。当颗粒速度达到临界速度时,即意味着颗粒动能足以使颗粒间克服变形阻力,产生强烈塑性变形,彼此之间可以相互结合。这种结合类似于金属爆炸成型、爆炸焊接的结合,或者类似于冷焊结合机制。转变的热能使颗粒间温度升高,有利于两者的变形,喷涂过程中球形粒子发生大量的塑性变形,产生了大量的“新鲜表面”,因此冷喷涂过程中粒子可能会在“新鲜的表面”上形成部分冶金结合。在冷喷涂Zn-Al复合涂层表面可以观察到颗粒表面微区熔化现象(见图11箭头和圆圈所示);另外,涂层表面经过机械打磨抛光侵蚀后,利用原子力显微镜(AFM)观察到两个粒子之间紧密的局部结合(图12),对照片左侧箭头所示划线经过结合处进行剖面分析,照片右侧显示剖面分析结果,箭头处两个粒子在结合处成为一个整体,实现了微区冶金熔合。

图10 冷喷涂 65%Zn-Al 复合涂层拉断面的EDS谱

Fig.10 EDS spectra of cold-sprayed 65%Zn-Al coating after tension test: (a) Coatings; (b) Substrate surface

图11 冷喷涂Zn-Al复合涂层表面颗粒微区熔化

Fig11 Local melt of cold-sprayed Zn-Al coatings: (a) 65%Zn-Al; (b) 40% Zn-Al

图12 冷喷涂65%Zn-Al复合涂层的抛光表面的AFM照片

Fig.12 AFM photograph of polished surface for cold-sprayed 65%Zn-Al coatings

3 结论

1) 采用冷喷涂方法制备的65%Zn-Al复合涂层厚度可达0.7 mm。喷涂过程中初期沉积的涂层受到后续粒子的持续撞击作用,粒子经过强烈塑性变形挤压咬合在一起,涂层组织结构致密,孔隙率为1.7%,明显低于电弧喷涂Zn-Al涂层的。

2) 涂层中Zn和Al粒子没有发生明显氧化,未检测到氧化物等新相,内部Zn和Al颗粒经连续冲击作用变形明显,Al颗粒晶块破碎细化。冷喷涂65%Zn-Al复合涂层维氏显微硬度高于电弧喷涂Zn-Al涂层和Al块材的。

3) 冷喷涂方法制备的涂层,其结合机制以机械咬合为主,颗粒存在微区融化现象,涂层间、涂层与基体存在少量冶金结合的现象。

致 谢

作者在此诚挚感谢法国 UTBM 大学(Universitéde Technologie de Belfort- Montbéliard) 材料、工艺与表面研究实验室 (LERMPS,Laboratoire d'Etudes et de Recherches sur les Matériaux, les Procédés et les Surfaces) 廖汉林教授及西北工业大学李文亚副教授在样品制备方面提供的帮助。

REFERENCES

[1] ROSBROOK T, THOMASON W H, BYRD J D. Flame sprayed aluminum coatings used on subsea components[J]. Material Performance, 1989, 28(9): 34-38.

[2] GILMORE D L, DYKHUIZEN R C, NEISER R A, SMITH M F, ROEMER T J. Particle velocity and deposition efficiency in the cold spray process[J]. Journal of Thermal Spray Technology, 1999, 8(4): 576-582.

[3] ALKIMOV A P, KOSAREV V F, PAPYRIN A N. A method of cold gas dynamic deposition [J]. Soviet Physics Doklady, 1990, 35(12): 1047-1049.

[4] NOVOSELOVA T, FOX P, MORGAN R, O’NEILL W. Experimental study of titanium/aluminum deposits produced by cold gas dynamic spray[J]. Surface and Coating Technology, 2006, 200(8): 2775-2783.

[5] DESHPANDE S, KULKARNI A, SAMPATH S, HERMAN H. Application of image analysis for characterization of porosity in thermal spray coatings and correlation with small angle neutron scattering[J]. Surface and Coatings Technology, 2004, 187(1): 6-16.

[6] DYKHUIZEN R C, NEISER R A. Optimizing the cold spray process[C] // MOREAU C, MARPLE B R. Thermal Spray 2003: Advancing the Science and Applying the Technology. Ohio: ASM International Material Park, 2003: 19-26.

[7] van STEENKISTE T H, SMITH J R, TEETS R E, MOLESKI J J, GORKIEWICZ D W, TISON R P, MARANTZ D R, KOWALSKY K A, RIGGS W L, ZAJCHOWSKI P H. Kinetic spray coatings[J]. Surface and Coatings Technology, 1999, 111(1): 62-71.

[8] MCCUNE R C, DONLON W T, POPOOLA O O,CARTWRIGHT E L. Characterization of copper layers produced by cold gas-dynamic spraying[J]. Journal of Thermal Spray Technology, 2000, 9(1): 73-82.

[9] STOLTENHOFF T, KREYE H, RICHTER H J, ASSADI H. Optimization of the cold spray process[C]//BERNDT C C, KHOR K A. Thermal Spray 2001: New Surfaces For a New Millennium. Ohio: ASM International Material Park, 2001: 409-416.

[10] GB 4340.1—1999. 金属显微维氏硬度试验方法[S].

GB 4340.1—1999. Metallic Vickers hardness test—Part 1: Test method[S].

[11] GB/T 8642—2002. 热喷涂抗拉结合强度的测定[S].

GB/T 8642—2002. Thermal spraying—Determination of tensile adhesive strength[S].

[12] 黄继武. MDI Jade 使用手册[M]. 长沙: 中南大学, 2006.

HUANG Ji-wu. MDI Jade users handbook[M]. Changsha: Central South University, 2006.

[13] 张 强, 李 聪, 邱绍宇. 晶粒细化对Zr-4合金均匀腐蚀性能的影响[J]. 稀有金属, 2009, 33(2): 170-174.

ZHANG Qiang, LI Cong, QUY Shao-yu. Effect of grain refinement on uniform corrosion resistance of zircaloy-4[J]. Chinese Journal of Rare Metals, 2009, 33(2): 170-174.

[14] FUKANUMA H, OHNO N. TODA. A study of adhesive strength of cold spray coatings[C]// Proceedings of the International Thermal Spray Conference. Osaka: Thermal spray society, 2004: 329-334.

[15] PAPYRIN A N, KOSAREV V F, KLINKOV S V, ALKHIMOV A P. On the interaction of high speed particles with a substrate under the cold spray[C]. Proceedings of the International Thermal Spray Conference. Essen, 2002: 380-384.

[16] DYKHUIZEN R C, SMITH M F, GILMORE D L, NEISER R A, JIANG X, SAMPATH S. Impact of high velocity cold spray particles[J]. Journal of Thermal Spray Technology, 1999, 8(4): 559-564.

[17] GARTNER F, BORCHERS C, STOLTENHOFF T, KREYE H, ASSADI A. Numerical and microstructural investigations of the bonding mechanisms in cold spraying[C]// MOREAU C, MARPLE B R. Thermal Spray 2003: Advancing the Science and Applying the Technology. Ohio: ASM International Material Park, 2003: 1-8.

(编辑 杨 华)

基金项目:国防重点实验室基金资助项目(9140C2505010605)

收稿日期:2009-03-18;修订日期:2010-03-09

通信作者:孙明先,研究员;电话:0532-68725988;传真:0532-68725001;E-mail:sunmx@sunrui.net