钎料熔滴与焊盘界面反应及再重熔时的界面组织演变

李福泉, 王春青, 田艳红, 孔令超

(哈尔滨工业大学 材料科学与工程学院, 哈尔滨 150001)

摘 要: 采用熔滴直接凸点制作方法, 对共晶SnPb及SnAgCu钎料熔滴与Au/Ni/Cu焊盘所形成的凸点/焊盘界面组织进行了研究, 并与激光重熔条件下获得的凸点/焊盘界面组织进行了比较, 考察了凸点/焊盘界面组织在随后的再重熔过程中的演变。 结果表明: 钎料熔滴与焊盘在接触过程中形成了Au-Sn化合物, Au层并未完全反应。 在随后的再重熔过程中, Au层被完全消耗, 全部溶入钎料基体中, Ni层与钎料发生反应。 无铅钎料(SnAgCu)和SnPb钎料所形成的界面组织明显不同; 再重熔后SnPb钎料/焊盘的界面组织为Ni3Sn4, SnAgCu钎料/焊盘界面组织为(CuxNi1-x)6Sn5。

关键词: 钎料熔滴; 凸点; 无铅钎料; 重熔; 金属间化合物 中图分类号: TG111

文献标识码: A

Interface reaction of solder droplet/pad and intermetallic compounds evolution during reflow soldering

LI Fu-quan, WANG Chun-qing, TIAN Yan-hong, KONG Ling-chao

(School of Materials Science and Engineering,Harbin Institute of Technology, Harbin 150001, China)

Abstract: The interface structures of solder droplet for SnPb and SnAgCu Al/Ni/Cu pad were investigated by droplet direct laser fabrication method, which is compared with the interface structures for bump and pad under laser reflow bumping. The intermetallics evolution at solder bump/pad interface during subsequent reflow soldering is conducted. The results show that, during the contact reaction between molten solder droplet and pad, Au is dissolved into molten solder droplet and Au-Sn intermetallic compounds are precipitated, while Au doesnt react with solder droplet fully. During the subsequent reflow soldering, Au layer disappears from the interface, Au-Sn compounds are distributed into solder matrix, and Ni layer is exposed to solder and reacts with solder directly. Distinctive difference exists between the intermetallics formed at Pb-free solder/pad interface and SnPb solder/pad interface during reflow soldering process. For the SnPb solder/pad system, the Ni3Sn4 layer is formed at the solder/pad interface during reflow. For the SnAgCu solder/pad system, the (CuxNi1-x)6Sn5 layer is formed at the solder/pad interface during reflow.

Key words: solder droplet; bump; lead-free solder; reflow; intermetallic compound

球栅阵列、 倒扣芯片等面阵列封装技术的关键为凸点制作[1-3], 凸点的特性直接影响封装的可靠性。 文献[4]报道了对共晶SnPb钎料熔滴滴落并与焊盘接触反应形成凸点的热过程和界面组织的研究。 熔滴直接凸点制作过程[4-7]的反应条件完全不同于以往的凸点形成方法, 传统研究中的钎料经红外或者热风重熔过程形成凸点, 存在温度上升和在大于钎料熔点温度的保持过程, 保温时间为数分钟。 当凸点的温度达到了平衡时, 长时间的反应使反应充分。 而对于钎料溶滴凸点的制作过程, 显然只有激光重熔制作凸点[8-12]可以相类似。 但激光重熔为典型的加热过程, 熔滴直接凸点制作则是利用熔滴所携带的热量加热焊盘并形成凸点, 此时凸点形成过程为一个温度下降的过程, 温度下降的速度很快, 熔滴凝固时形成凸点时间仅为6~7ms。 在如此短的时间内, 形成的凸点与焊盘界面反应的过程条件完全不同以往, 需要对其特殊性进行研究。

评价凸点制作方法的优劣关键在于能否高效率地获得钎料凸点及凸点的可靠性, 而钎料凸点可靠性与钎料/焊盘界面处的微观组织结构密切相关。 在钎料凸点制作过程中, 钎料与焊盘发生反应, 金属间化合物(intermetallic compounds, IMC)将会在界面处产生并生长。 界面处生成的IMC表明界面实现了较好的润湿和连接, 但较厚的IMC层将会弱化焊点性能[13-15]。 大多数金属间化合物较脆, 裂纹容易在IMC处萌生和扩展, 是导致金属体系失效的潜在因素。 IMC的分布和尺寸对钎料凸点的强度及其可靠性有重要影响, 了解IMC的形成机制将有利于控制其数量、 尺寸和分布。

本文作者对采用熔滴直接凸点制作及激光重熔凸点制作方法所获得的凸点/焊盘界面组织进行了比较研究。 由于环保问题, 无铅钎料替代SnPb钎料已成为必然趋势, 因此本文作者同时考察了作为无铅钎料代表的SnAgCu共晶钎料合金熔滴与焊盘的相互作用。 由于凸点制作是器件的封装工艺之一, 而在器件组装到PCB上时, 需要经历再重熔过程。 因此, 本文作者对采用熔滴直接制作形成的凸点和凸点/焊盘界面的IMC组织在随后的再重熔过程中的演变也进行了研究。

1 实验

实验材料选用SnPb共晶(Sn-37%Pb)和SnAgCu共晶(Sn-3.0%Ag-0.5%Cu)作为Sn基钎料。 BT树脂基板上的焊盘UBM金属化层的结构自上至下依次为Au/Ni/Cu。 焊盘直径为0.6mm, Au层厚度为2μm、 Ni层厚度为7μm。 焊盘外缘有阻焊膜。 分别采用熔滴直接凸点制作方法及激光重熔方法制作凸点。

熔滴直接凸点制作基本过程: 加热使钎料球熔化, 并达到给定的温度, 从一定的高度滴落到焊盘上的UBM金属化层上, 焊盘被钎料熔滴所携带的热量加热到钎料的熔点温度以上, 钎料熔滴在焊盘上润湿铺展并与焊盘UBM发生反应, 凝固后形成凸点。 凸点成形的两个工艺参数为钎料熔滴的初始温度和下落高度。 根据凸点制作要求设定钎料熔滴初始温度为400℃, 下落高度为1mm[4]。

激光重熔方法制作凸点的过程: 超声波清洗基板及焊盘表面, 然后在焊盘上涂水溶性钎剂并固定钎料球。 采用聚焦直径为0.6mm的连续Nd∶YAG激光进行重熔制作凸点, 通过计算机控制激光功率和加热时间。

对采用钎料熔滴所形成的钎料凸点进行红外再重熔。 再重熔工艺参数为SnPb钎料凸点和再重熔温度为225℃, 再重熔时间分别为30、 60、 120和180s; SnAgCu钎料凸点的再重熔温度为245℃, 再重熔时间分别为30、 60、 120和180s。

将所获得的钎料凸点/焊盘进行垂直切片, 用HITACH-S4700场发射扫描电镜分析界面组织形貌, 用EDX确定生成相的化学组成。

2 结果与讨论

2.1 熔滴直接制作凸点所得凸点/焊盘界面组织

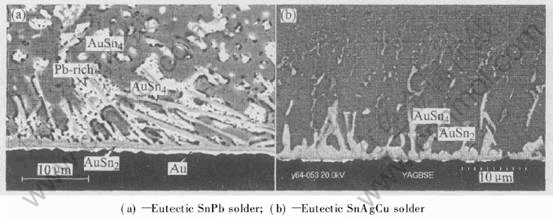

图1所示为SnPb钎料熔滴在初始温度为400℃时所形成的凸点/焊盘界面微观组织。 由图1可看出, 凸点/焊盘界面出现连续层状的金属间化合物, 并有棒状化合物从界面处长出, 棒状化合物之间出现白色富Pb相。 由EDX分析可知, 下部靠近Ni层的连续层状物的成分为AuSn2和未反应的Au, 上部靠近钎料处的棒状化合物成分为AuSn4。 出现金属间化合物层说明钎料熔滴与Au焊盘接触后, Au向液态钎料中溶解并在界面一薄层达到饱和溶解度, 从而生成金属间化合物。 由于温度较高, Au向熔融钎料中溶解速度较高, 金属间化合物长大明显。 但焊盘在大于SnPb钎料熔点(183℃)的温度停留时间不够长, 仍然有一部分Au未参加反应。 由于在生成AuSn4的过程中消耗了大量的Sn, 使局部Sn的浓度降低, 从而导致在棒状化合物间的富Pb相形成。

在离界面不远的钎料里发现细小AuSn4, 即界面金属间化合物脱离界面进入钎料中。 这可能由于在钎料熔滴下落与焊盘撞击和凝固过程中都会产生液态金属的流动, 而Au-Sn化合物较脆, 在金属流动的作用下折断所致。 同时, 在冷却过程中, 较大的冷却速率导致界面处存在较高应力, 也可能致使Au-Sn化合物折断。 另一方面, 由于Au在高温下迅速地向熔融钎料中溶解, 部分Au会溶解扩散进入钎料基体中, 凝固时从钎料基体中析出形成AuSn4所致。

SnAgCu钎料熔滴在初始温度为400℃条件下所形成的凸点/焊盘界面微观组织的SEM像见图1(b)。 在界面处形成的化合物主要为Au-Sn化合物。 与SnPb钎料相比, Au层反应更为充分, 仅有极少量Au层未完全参与界面反应形成Au-Sn化合物。 所用SnAgCu钎料的熔点(217℃)高于SnPb钎料的熔点, 钎料熔滴在熔点以上温度的停留时间要短于SnPb钎料的。 但由于SnAgCu钎料的Sn含量(96.5%)远高于SnPb钎料中的Sn含量(37%), 而在熔滴/焊盘界面反应中参与反应的主要为Au与Sn元素, 因此SnAgCu钎料熔滴与焊盘中的Au层反应更为充分。 由凸点/焊盘界面处化合物层成分的EDX能谱分析结果可知, 下部层状的化合物主要为AuSn2, 上部靠近钎料处的为棒状AuSn4, 同时有部分AuSn4分布于靠近界面的钎料基体内部。

2.2 激光重熔所获得的凸点/焊盘界面组织

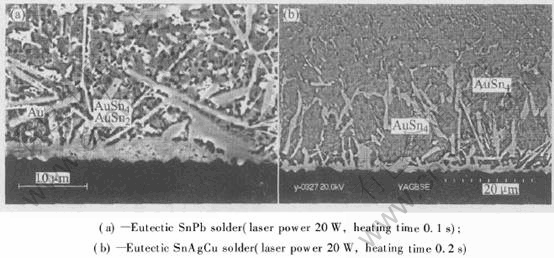

激光重熔法所形成凸点/焊盘界面的微观组织如图2所示。 所选用的激光工艺参数是经过优化获得的, 对SnPb钎料所采用的激光功率为20W, 加热时间为0.1s; 对SnAgCu钎料所采用的激光功率为20W, 加热时间为0.2s。 比较图1与2可知, 两者所形成的凸点/焊盘界面化合物主要为Au-Sn化合物。 由图2(a)可知, 经激光重熔后, SnPb钎料/焊盘界面处存在残余Au元素, 连续的金属间化合物层包括AuSn2和AuSn4, 且棒状AuSn4从连续化合物层中生长出来。 棒状AuSn4的形成表明, 采用激光重熔形成凸点及熔滴直接制作凸点的热过程都是非平衡的。 而激光重熔过程中的钎料处于液态时间比熔滴直接凸点制作过程中的钎料处于

图1 采用熔滴直接凸点制作形成凸点/焊盘界面的微观组织

Fig.1 Microstructures of interface between solder bump/pad fabricated by molten droplet

图2 激光再流焊所形成凸点/焊盘界面的微观组织

Fig.2 Microstructures of interface between solder bump/pad reflowed by laser

液态时间高2个数量级, 因此激光重熔过程中对流效应更为显著, Au层反应更为充分。 由图2(a)与图1(a)可知, 残余的Au更少, 所形成棒状AuSn4组织更为粗大, 更多的棒状AuSn4断开进入钎料中。 且在图2(a)中, 棒状AuSn4生长方向性不明显, 由界面随机向钎料内部不同方向生长。 而在图1(a)中, 凸点与焊盘界面处的棒状AuSn4生长具有明显的方向选择, 棒状AuSn4基本平行地向钎料中生长。 这取决于熔滴直接凸点制作过程与激光重熔形成凸点过程中的钎料与焊盘界面附近的不同温度梯度分布。 在图2(b)中, 界面Au-Sn化合物主要以AuSn4为主, 更多的AuSn4从界面处断开进入钎料基体中, 这主要是由于SnAgCu钎料的Sn含量远高于SnPb钎料中的Sn含量, Au-Sn反应更为强烈, 更易于形成高Sn含量的AuSn4。 而相对较长的激光加热时间, 由于Maragoni效应的驱动, 形成更强大的熔融金属流[16], 从而促使AuSn4从界面脱离进入钎料中。

2.2 再重熔条件下的界面组织

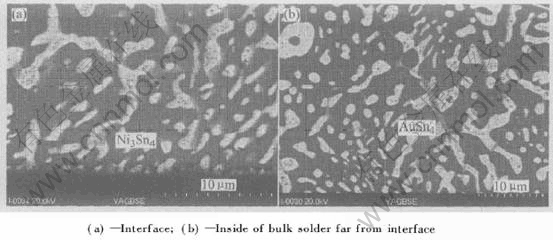

对采用熔滴直接制作形成的SnPb钎料凸点/焊盘进行再重熔过程, 发现再重熔30s后Au层完全反应进入钎料中, 界面处的化合物层为部分Ni层与Sn反应的产物, 经EDX分析化合物层为Ni3Sn4层。 随着再重熔时间的增加, Ni3Sn4层逐渐增厚。 图3所示为SnPb钎料凸点/焊盘的微观组织。 由图3可看出, 在Ni3Sn4层下还存在很厚的Ni层未反应, Au层在再重熔条件下已完全以Au-Sn化合物的形态进入了钎料基体内部。 再重熔后在钎料凸点顶部距界面较远处的钎料基体仍可以发现AuSn4组织的存在, AuSn4在基体中以棒状和细小针状形态存在于钎料基体中。 比较再重熔过程与上述的钎料熔滴/焊盘接触反应过程, 再重熔条件下钎料凸点处于液态的时间为秒级, 而接触反应过程中钎料熔滴与焊盘反应时间为毫秒级。 Au向熔融钎料的溶解速率很高, 因此在接触反应后, 残存的Au经再重熔后会全部溶入钎料中, 凝固时饱和的Au析出形成Au-Sn化合物。

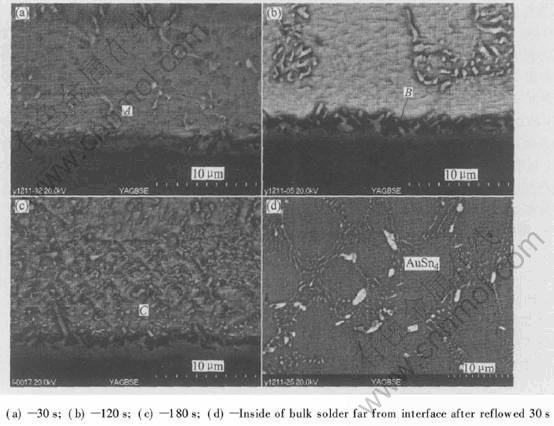

图4所示为再重熔后SnAgCu钎料凸点/焊盘的界面微观组织。 由图4可看出, 再重熔30s后, Au层从界面消失, Ni层与钎料直接接触, 这表明Au层被完全消耗掉。 由此可推断再重熔30s, Au会全部溶入钎料中。 在随后的冷凝过程中, Au析出并生成金属间化合物, 再重熔后仍可发现有棒状和细小针状的AuSn4存在于远离界面的钎料基体中。

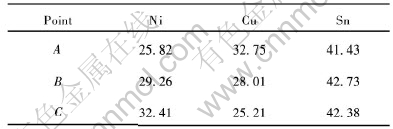

表1 图4中点A, B和C的能谱分析结果

Table 1 EDX analysis results of points A, B and C in Fig.4 (molar fraction, %)

图4中A, B和C点的能谱成分分析结果列于表1。 由表1可看出, 界面化合物为Cu-Ni-Sn三元化合物。 Cu元素与Ni元素的摩尔分数之和与Sn元素摩尔分数的比值接近6∶5, 因此界面化合物可表示为(CuxNi1-x)6Sn5。 可以认为再重熔后SnAgCu钎料凸点/焊盘界面化合物为(CuxNi1-x)6Sn5, 化合物(CuxNi1-x)6Sn5是基于Cu6Sn5晶体结构形成的。 Ni原子替代了Cu6Sn5相中的部分Cu原子。 由于Cu和Ni都具有面心立方

图3 再重熔60s后SnPb钎料凸点/焊盘的微观组织

Fig.3 Microstructures of SnPb solder bump/pad after reflowed 60s

图4 SnAgCu钎料凸点/焊盘经不同时间再重熔后界面的微观组织

Fig.4 Microstructures of interface between eutectic Sn-Ag-Cu solder bump/pad after reflowed different time

结构, 其大小尺寸仅差2%。 因此, 可以部分替代Ni溶入Cu6Sn5中不会引起点阵畸变, 且新相形成较为顺利[17]。

3 结论

1) 采用钎料熔滴直接凸点制作, Au/Ni/Cu焊盘与SnPb钎料及SnAgCu钎料熔滴所形成的界面组织都是Au-Sn化合物, 即靠近焊盘的层状AuSn2及靠近钎料的棒状AuSn4。 在靠近界面处, 钎料基体中也有细小针状的AuSn4分布。 与SnPb钎料相比, 在SnAgCu钎料/焊盘体系中, Au层与钎料熔滴反应更为迅速。

2) 采用激光重熔制作凸点, 并与熔滴直接制作凸点进行比较, 所获得的凸点/焊盘界面金属间化合物都以Au-Sn化合物为主。 由于不同过程的特点, 前者界面处的棒状AuSn4生长方向性不明显, 后者AuSn4基本平行地向钎料中生长。

3) 对熔滴直接制作的凸点, 在随后的再重熔过程中Au层全部溶入钎料基体中, Ni层与钎料发生反应。 无铅的SnAgCu钎料及SnPb钎料所形成界面组织明显不同, 再重熔后SnAgCu钎料/焊盘界面组织为(CuxNi1-x)6Sn5, 再重熔后的SnPb钎料/焊盘的界面组织为Ni3Sn4。

致谢:

本文研究经费及实验材料由香港先进自动器材有限公司(ASM)提供, 在此表示感谢。

REFERENCES

[1]Kloeser J, Coskina P, Aschenbrenner R, et al. Bump formation for flip chip and CSP by solder paste printing[J]. Microelectronics Reliability, 2002, 42: 391-398.

[2]Koshoubu N, Ishizawa S, Tsunetsugu H, et al. Advanced flip chip bonding techniques using transferred micro-solder bumps[J]. IEEE Transactions on Components and Packaging Technologies, 2000, 23(2): 399-404.

[3]Li L, Thompson P. Stencil printing process development for flip chip interconnect[J]. IEEE Transactions on Electronics Packaging Manufacturing, 2000, 23(3): 165-170.

[4]李福泉, 王春青, 田德文, 等. SnPb钎料熔滴与Au/Ni/Cu焊盘的反应过程[J]. 中国有色金属学报, 2004, 14(7): 1139-1143.

LI Fu-quan, WANG Chun-qing, TIAN De-wen, et al. Interfacial reaction between molten 63Sn37Pb droplet and Au/Ni/Cu pad[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1139-1143.

[5]Liu Q B, Orme M. High precision solder droplet printing technology and the state-of-the-art[J]. Journal of Materials Processing Technology, 2001, 115: 271-283.

[6]Hayes D J, Cox W R, Grove M E, et al. Micro-jet printing of polymers and solder for electronics manufacturing[J]. Journal of Electronics Manufacturing, 1998, 8(3-4): 209-216.

[7]王春青, 李福泉. 激光直接钎料凸点制作方法[P]. CN03111157, 2003-09-03.

WANG Chun-qing, LI Fu-quan. Laser Direct Solder Bumping Technology[P].CN03111157, 2003-09-03.

[8]Economikos L. Laser system for fine pitch tape automated bonding[J]. Journal of Vacuum Science and Technology B, 1994, 12(4): 2394-2399.

[9]James D, Hayward A. Development of laser bonding as a manufacturing process for inner lead bonding[A]. Proceedings of SPIE1598. Laser in Microelectronic Manufacturing[C]. San Jose, CA: SPIE, 1991. 164-169.

[10]Motullo G, Kasulke P, Heinicht K, et al. A low cast bumping process for flip chip technology using electroless Nickel and solder ball placement[A]. Proceedings of the First IEMT/IMC Symposium[C]. Tokyo: The Organizing Committee, 1997. 174-181.

[11]Lee J H, Lee Y H, Kim Y S. Fluxless laser reflow bumping of Sn-Pb eutectic solder[J]. Scripta Materia-lia, 2000, 42(8): 789-793.

[12]田艳红, 王春青. 激光与红外重熔对63Sn37Pb/焊盘界面微观组织的影响[J]. 中国有色金属学报, 2002, 12(3): 471-475.

TIAN Yan-hong, WANG Chun-qing. Effect of laser and infrared secondary reflow on the microstructure of 63Sn37Pb/pad interface[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 471-475.

[13]Bradley E, Banerji K. Effect of PCB finish on the reliability and wettability of ball grid array packages[J]. IEEE Transactions on Components, Packaging, and Manufacturing technology- Part B, 1996, 19(2): 320-330.

[14]Puttlitz K J. Preparation, structure and fracture modes of Pb-Sn and Pb-In terminated flip-chips attached to gold capped microsockets[J]. IEEE Transactions on Components, Hybrids and Manufacturing Technology, 1990, 13(4): 647-655.

[15]Tu K N, Zeng K. Tin-lead (SnPb) solder reaction in flip chip technology[J]. Mater Sci Eng R, 2001, R34: 1-58.

[16]周尧和, 胡壮麒, 介万奇. 凝固技术[M]. 北京: 机械工业出版社, 1998. 75-83.

ZHOU Yao-he, HU Zhuang-qi, JIE Wan-qi. Solidification Technology[M]. Beijing: China Machine Press, 1998. 75-83.

[17]Park J Y, Yang C W, Ha J S, et al. Investigation of interfacial reaction between Sn-Ag eutectic solder and Au/Ni/Cu/Ti thin film metallization[J]. Journal of Electronic Materials, 2001, 30(9): 1165-1170.

(编辑李艳红)

收稿日期: 2005-05-25; 修订日期: 2005-07-08

作者简介: 李福泉(1972-), 男, 博士研究生

通讯作者: 王春青, 教授, 博士; 电话: 0451-86418725; E-mail: wangcq@hit.edu.cn