文章编号: 1004-0609(2004)10-1694-06

Sn-Zn-Cu无铅钎料的组织、 润湿性和力学性能

谢海平, 于大全, 马海涛, 王 来

(大连理工大学 材料工程系, 大连 116024)

摘 要: 研究了(Sn-9Zn)-xCu无铅钎料的微观组织、 润湿性能和力学性能。 Cu的加入使得Sn-9Zn钎料中针状富Zn相逐渐转变为Cu-Zn化合物, 当Cu含量为8%时, Cu6Sn5相生成。 Sn-Zn-Cu合金熔点随着Cu含量增加而升高, 同时润湿性随Cu的加入得到显著改善。 使用中性活性松香钎剂, 钎料与Cu箔钎焊时的润湿角显著减小。 Sn-9Zn的润湿角为120°, 而(Sn-9Zn)-10Cu的润湿角为54°。 这是由于Cu的加入降低了Zn的活性, 减少了Zn在钎料表面氧化, 降低了液态钎料表面张力, 使得钎料能获得较好的润湿性。 合金在2%Cu时获得较高的强度, 随着Cu含量的增加, Cu-Zn化合物相对增多, 抗拉强度有所下降; 而合金的塑性随着Cu的加入迅速下降。

关键词: 无铅钎料; Sn-Zn-Cu; 微观组织; 润湿性; 抗拉强度 中图分类号: TG425.1

文献标识码: A

Microstructure, wettability and mechanical properties of Sn-Zn-Cu lead free solder

XIE Hai-ping, YU Da-quan, MA hai-tao, WANG Lai

(Department of Materials Engineering, Dalian University of Technology, Dalian 116024, China)

Abstract: The microstructures, wettability and mechanical properties of (Sn-9Zn)-xCu lead free solders were investigated. The addition of Cu element leads the needle Zn rich phase to transform into Cu-Zn compounds and when Cu is 8%, Cu6Sn5 phase emerges. The melting point increases with increasing Cu content; while the wetting properties is improved dramatically. When the solder reflows on Cu substrate, the wetting angle decreases greatly using mildly active rosin (RMA) flux. The wetting angle of Sn-9Zn is 120°; while that of (Sn-9Zn)-10Cu is 54°. The improvement on wettability is due to the addition of Cu which decreases the activity of Zn and refrains the oxidation of Zn atoms at the surface of liquid solder. Better wetting behavior is gotten because of the lower surface tension of liquid solder. And the solders get the higher tensile strength when Cu content is 2%. With more Cu addition, more Cu-Zn compounds formation deteriorates the solder strength and the ductility decreases greatly with Cu addition.

Key words: lead free solder; Sn-Zn-Cu; microstructure; wettability; tensile strength

传统锡铅(SnPb)焊料的应用已有千年的历史, 是目前电子封装互连的主要材料。 但是铅及其化合物属于有毒物质, 给人类生活环境和安全带来较大的危害。 自美国的反铅议案HR-5374(美国国会)、 S-2637和S-391(美国参议院)提出以来, 全世界各种组织、 科研机构和公司纷纷推出系列禁用提案、 试验评估和环保产品。 2003年2月13日, 欧盟公布了《报废电子电气指令》和《关于在电子电气设备中禁止使用某些有害物质指令》, 规定2006年7月1日后投放市场的电气和电子设备不得含有包括铅等在内的6种有害物质。 在环保要求、 市场需求等因素的约束和推动下, 电子封装的无铅化成为学术界和工业界的重大科学技术前沿课题与系统工程问题[1-3]。

目前人们研究开发的无铅钎料大多以Sn为基, 另加一些无毒、 无挥发性元素如Ag、 Zn、 Cu、 Bi、 In等作为合金化元素。 目前广泛研究的无铅钎料主要为Sn-Ag、 Sn-Bi、 Sn-Cu、 Sn-Zn以及Sn-Ag-Cu合金[3-6]。 其中Sn-Zn钎料因其低成本、 优异的力学性能而成为无铅钎料中极有前景的竞争者之一。 但Zn易氧化、 润湿性差等缺点是需要解决的主要问题[7, 8]。 Mccormack 等[9]报道在Sn-Zn系合金中加入5%~10%的In可以有效降低熔点和提高钎料的润湿性能。 Lin等[10, 11]发现加入Al之后能够提高钎料的抗氧化性, 且在界面处获得的一层化合物能够有效阻止Sn、 Cu过量反应。 同时, 对添加少量Bi、 Ag以及稀土元素的组织润湿性和界面反应进行了研究和分析[12-18]; 对添加合金化元素对Sn-Zn合金的抗腐蚀性也进行了相关研究[19]。 为开发焊膏, Vaynman 等[20]还对含Zn钎料的钎剂进行了专门研究。

本研究中, 通过在Sn-9Zn合金中加入Cu元素, 研究成分转变对合金的组织、 熔化行为、 润湿性和力学性能的影响, 为获得综合性能良好、 成本低廉的无铅钎料奠定基础。

1 实验

合金成分(Sn-9Zn)-xCu, x=0, 0.5, 1, 2, 4, 6, 8, 10(为方便起见, 文中Sn-9Zn 简写为SZ且Cu的含量皆为质量分数, %)按质量比配好后在真空熔炼炉中熔炼, 熔炼温度为600℃, 保温4h。 其中原料Sn, Zn, Cu的纯度分别为99.95%, 99.99%, 99%。 合金在(500±3)℃的电阻炉中重熔后, 浇铸成d8mm的圆棒。

用差示扫描量热计(DSC)测定无铅钎料合金熔化温度。 钎料质量约为10mg, 样品室通入高纯N2作为保护气氛。 分析温度范围为50~550℃, 加热速度为10℃/min。

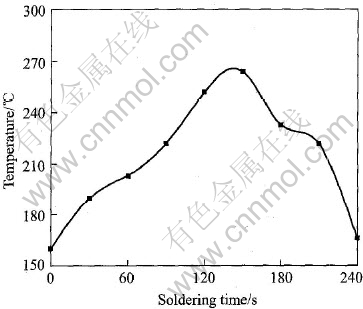

利用钎料与Cu箔钎焊来研究其润湿性。 Cu箔纯度为99.9%, 用1000#砂纸细磨后, 在NaOH溶液、 HCl溶液、 水溶液分别浸泡15s后吹干。 试验钎料块尺寸为d5mm×1.5mm, 质量约为200mg。 焊剂为中性松香焊剂(RMA), 将钎料放置在Cu箔上, 放入再流焊炉进行钎焊, 再流焊过程曲线如图1所示。 为方便界面润湿角的测量, 钎焊接头用环氧树脂进行镶嵌。

钎料基体、 焊接接头经打磨、 抛光, 最后用92%甲醇-5%硝酸-3%盐酸(体积比)腐蚀液进行腐蚀。 采用SEM, EMPA观察分析组织及成分分布, 利用EDS、 XRD确定相成分。

图1 再流焊过程曲线示意图

Fig.1 Reflow curve for soldering process

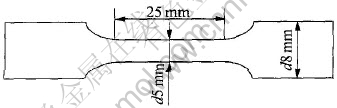

钎料拉伸试验在自动控制电子万能拉伸试验机上进行, 拉伸速率为 10mm/min。 拉伸试样按GB397—86标准制备, 直径为5mm, 标距长为25mm, 如图2所示。

图2 拉伸试样示意图

Fig.2 Schematic diagram of tensile specimen

2 结果与讨论

2.1 合金微观组织形貌

图3所示为SZ、 SZ-2Cu、 SZ-6Cu、 SZ-10Cu在钢冷条件下获得的微观组织形貌。 在SZ合金中, 棒状富Zn相均匀分布在Sn基体上而表现出典型的共晶结构。 随着Cu含量增加, 在SZ-2Cu钎料中富Zn相逐渐消失, 取而代之的是一种颗粒状化合物。 根据Cu-Sn、 Cu-Zn二元相图, Cu与Sn、 Zn都有生成化合物的可能, 但Cu5Zn8相的吉布斯生成能比Cu6Sn5相的低, 因此观察到的这种化合物只能为Cu-Zn化合物。 由于SZ-2Cu合金中Cu与Zn的质量比为2∶8.82, 而且Sn中可以固溶最多为[CM(22]2%的Zn原子[3], 因此在图3(b)中应当存在少量的富Zn相。 随着Cu含量增加时, 富Zn相消失, 而Cu-Zn化合物颗粒增多并逐渐长大。 当Cu含量增加到8%后, 微量的Cu6Sn5相开始出现。 并且在钢冷条件下, 即使当Cu含量增加到10%, 合金的组织仍然比较细密。

图3 钢冷条件下钎料显微组织

Fig.3 SEM images of steel-cooled solders

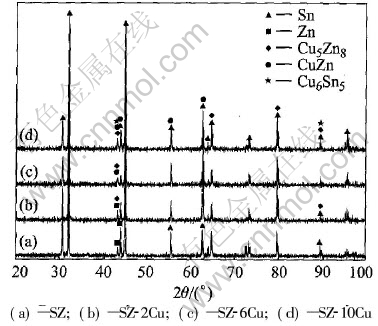

图4所示为不同成分钎料的X射线衍射图。 当Cu 含量小于4%时, 钎料合金主要由富Sn相、 富Zn相和Cu5Zn8相组成; 当Cu含量为4%~8%时, 主要由Sn、 Cu5Zn8、 CuZn相组成; Cu含量大于8%时, Cu6Sn5相开始出现, 即合金组织由Sn、 CuZn 和Cu6Sn5相构成。

2.2 钎料合金的熔化特性

表1所示为钎料液固相线和熔点, 图5所示为DSC分析曲线。 从表1可以看出SZ在199.5℃发生共晶反应, 少量Cu(0.5%)的加入可以使熔点略微下降, 但当Cu含量达到4%时由于CuZn相的形成, 出现了两个峰值。 它们可能分别对应的是Sn、 Cu5Zn8近共晶反应和Sn、 CuZn近共晶反应。 随着Cu含量逐渐增加, 钎料熔点在228℃左右, 由组织分析结果可知, 对于SZ、 SZ-2Cu, 对应着L→Sn+Zn+Cu5Zn8反应, Cu含量6%时对应着近共晶反[CM(22]应, 而Cu含量为8%时对应着L→Sn+CuSn+Cu6Sn5近共晶反应。 除了SZ-4Cu外, 所有的合金融化区间都比较小, 这对形成好的接头组织是有利的。

图4 SZ-xCu钎料X射线衍射谱

Fig.4 XRD patterns of SZ-xCu solder alloys

2.3 钎料润湿行为

钎焊过程中, 液态钎料在母材表面润湿、 流动、 铺展并借助毛细作用填满整个钎缝的过程是钎焊过程中至关重要的一步, 直接关系到钎焊的成功与否。

表1 SZ-xCu钎料的固、 液相线及熔点

Table 1 DSC results of SZ-xCu solders

图5 Sn-Zn-Cu钎料的DSC分析曲线

Fig.5 DSC profile of Sn-Zn-Cu solder alloys

图6所示为钎料与Cu箔钎焊润湿角随Cu含量的变化曲线。 从图6中可以看出: Cu元素的添加能够有效提高合金的润湿性。 当Cu含量小于2%时, 钎料润湿角呈直线下降, 随着Cu含量的不断增加, 钎料的润湿角逐渐减小, 最终由120°下降为54°左右。

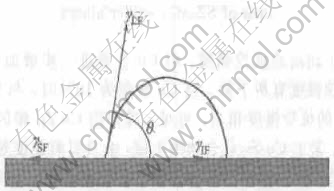

由图7可知, 平衡状态时的润湿角是由界面表面张力决定的:

式中 γSF、 γIF、 γLF分别指基体/钎剂(substrate/flux)、 钎料/钎剂(liquid solder/flux)以及IMC/钎料 (IMC/liquid solder)之间的表面张力。 从式(1)可以得出, 当 γLF较小时或者(γSF-γIF)较大时, 才能得到较小的润湿角。

在SZ钎料中, Zn在表面的氧化造成合金具有较大的表面张力, 影响了润湿性。 而Cu的加入使[CM(22]得钎料富Zn相中游离态的Zn原子与Cu生成了Cu-[CM)]

图6 钎料与Cu箔钎焊润湿角

Fig.6 Wetting angle between SZ-xCu solder and Cu foil

图7 润湿平衡状态下的表面张力示意图

Fig.7 Schematic diagram of surface tension under equilibrium state

Zn化合物。 即使在熔化时, 由于熔化温度较低, 合金中会大量存在Cu-Zn的短程有序结构, 甚至中程有序结构, 这必然会降低Zn原子的活性, 减少Zn原子在钎料表面的氧化, 从而有效降低液态钎料的表面张力。 因此当Cu含量大于2%时, Zn与 Cu生成化合物, 使得液态钎料能较好地在Cu母材上铺展开来而获得更小的润湿角。 在以前的研究当中, 虽然In、 Bi、 RE的加入都能一定程度地提高SZ合金的润湿性, 但是, 这种提高作用十分有限, 只有用活性钎剂(RA)才能获得润湿。 这是因为, 这些元素在加入时, 富Zn相依然存在, Zn原子的氧化使得其表面张力依然很大, 因此合金的润湿性依旧很差[6, 16-18]。

2.4 力学性能

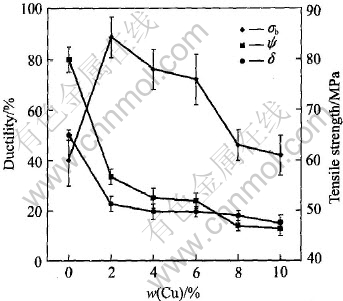

钎料抗拉强度(σb)、 延伸率(δ)、 收缩率(ψ)与Cu含量的关系如图8所示。 由图8可见, Cu含量为2%时, 其抗拉强度由60MPa上升到84MPa, 获得了较高的抗拉强度。 但Cu含量进一步增加后, 抗拉强度有所下降, 当Cu含量为10%时, 与Sn-Zn的抗拉强度相当。 可见, 过多的Cu-Zn相的出现, 甚至Cu-Sn化合物的生成, 会对钎料强度起负面作用。 这种脆性相的大量存在极大损害了钎料的塑性, 使钎料的延伸率和断面收缩率迅速降低。

图8 SZ-xCu钎料抗拉强度、 延伸率、 收缩率与铜含量的关系

Fig.8 Relationship between Cu content and tensile strength, elongation and reduction of area of SZ-xCu solder alloys

3 结论

1) 在Cu含量不大于8%时, SZ-xCu钎料随着Cu含量的增加针状富Zn相逐渐转变为Cu-Zn化合物。 当Cu含量超过8%后, Cu6Sn5相开始出现。

2)SZ-xCu(0〈x≤10)钎料熔点随着Cu的加入逐渐升高, Cu含量小于4%时对应着L→Sn+Zn+Cu5Sn8反应, Cu含量大于4%小于8%时对应着L→Sn+CuZn近共晶反应, 而Cu含量大于8%时对应着L→Sn+CuZn+Cu6Sn5近共晶反应。

3) Cu的加入减少了Zn原子在钎料表面的氧化, 有效降低了液态钎料的表面张力, 使钎料与Cu之间的润湿性得到显著提高, 获得了较小的润湿角。 但随着Cu含量的增加, 合金熔点逐渐升高。

4) SZ-xCu(0〈x≤10)钎料的抗拉强度随着Cu含量的增加先增大后减小。 Cu含量为2%时获得了较高的抗拉强度。 但Cu含量进一步增加后, 过多的Cu-Zn相的出现, 甚至Cu-Sn化合物生成, 使得合金抗拉强度有所下降, 同时Cu的添加会使钎料的延伸率和断面收缩率降低。

REFERENCES

[1] Tu K N, Zeng K. Tin-lead (SnPb) solder reaction in flip chip technology [J]. Mater Sci Eng Rep, 2001, 34: 1-58.

[2] Zeng K, Tu K N. Six cases of reliability study of Pb-free solder joints in electronic packaging technology [J]. Mater Sci Eng Rep, 2002, 38: 55-105.

[3] Abtew M, Selvaduray G. Lead-free solders in microelectronics [J]. Mater Sci Eng Rep, 2000, 27(1): 85-141.

[4] Suganuma K. Advances in lead-free electronics soldering [J]. Current Opinion in Solid State and Materials Science, 2001, 5 (1): 55-64.

[5] 黄明亮, 于大全, 王来, 等. Sn-6Bi-2Ag(Cu, Sb)无铅钎料合金微观组织分析 [J]. 中国有色金属学报, 2002, 12(3): 486- 490.

HUANG Ming-liang, YU Da-quan, WANG Lai, et al. Microstructures of Sn-6Bi-2Ag (Cu, Sb) lead free solder alloys [J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 486-490.

[6] Cormack M Mc, JIN S. Improved mechanical properties in new, Pb-free solder alloys [J]. J Electron Mater, 1994, 23: 715-720.

[7] Suganuma K. Heat resistance of Sn-9Zn solder/Cu interface with or without coating [J]. J Mater Res, 2000, 15: 484-491.

[8] Yu S P, Lin H J. Effect of process parameters on the soldering behavior of the eutectic Sn-Zn solders on Cu substrate [J]. J Mater Sci, 2000, 11: 461-471.

[9] Mccormack M, Jin S. New lead-free Sn-Zn-In solder alloys [J]. J Electron Mater, 1994, 23: 687-690.

[10] Knott S. Thermodynamic properties of liquid Al-Sn-Zn Alloys: a possible new lead-free solder material [J]. Mater Trans, 2002, 43: 1868-1872.

[11] Lin K L, Hsu H M. Sn-Zn-Al Pb-free solder— an inherent barrier solder for Cu contact [J]. J Electron Mater, 2001, 30: 1068-1072.

[12]Kim Y S. Effect of composition and cooling rate on microstructure and tensile properties of Sn-Zn-Bi alloys [J]. J Alloy Comp, 2003, 352: 237-245.

[13] 段莉蕾, 于大全, 赵杰, 等. Sn-9Zn-3Bi/Cu 钎焊接头在170℃时效过程中的显微结构研究[J]. 中国有色金属学报, 2004, 14(5): 842-847.

DUAN Li-lei, YU Da-quan, ZHAO Jie, et al. Microstructure of Sn-9Zn-3Bi solder/Cu joint during long-term aging at 170℃ [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(5): 842-847.

[14] Lin K L. Wetting interaction between Sn-Zn-Ag solders and Cu [J]. J Electron Mater, 2003, 32: 95-100.

[15] Chang T C, Hon M H, Wang M C. Intermetallic compounds formation and interfacial adhesion strength of Sn-9Zn-0.5Ag solder alloy hot-dipped on Cu substrate [J]. J Alloy Comp, 2003, 352: 168-174.

[16] 于大全, 赵杰, 王来. 稀土元素对Sn-9Zn合金润湿性的影响. 中国有色金属学报 [J], 2003, 13(4): 1001-1004.

YU Da-qian, ZHAO Jie, WANG Lai. Wetting properties of Sn-9Zn solder alloy with trace rare earth elements [J]. The Chinese Journal of Nonferrous Metals, 2003, 13(4): 1001-1004.

[17] Wu C M L, Yu D Q. The wettability and microstructure of Sn-Zn-RE alloys [J]. J Electron Mater, 2003, 32: 63-69.

[18] Wu C M L, Yu D Q. The properties of Sn-9Zn lead-free solder alloys doped with trace rare earth elements [J].Electronic Mater, 2002, 31: 921-927.

[19] Lin K L, Chung F C, Liu T P. The potentiodynamic polarization behavior of Pb-free Xin-9(5Al-Zn)-Ysn solders [J]. Mater Chem Phys, 1998, 53: 55-59.

[20] Vaynman S, Fine M E. Development of fluxes for lead-free solders containing zinc [J]. Scrip Mater, 1999, 41: 1269-1271.

[21] Yu D Q, Xie H P, Wang L. Investigation of interfacial microstructure and wetting property of newly developed Sn-Zn-Cu solders with Cu substrate [J]. J Alloy Comp, Accepted.

基金项目: 大连市科委计划资助项目(大科计发[2001]145)

收稿日期: 2004-02-19; 修订日期: 2004-05-29

作者简介: 谢海平(1980-), 男, 硕士研究生.

通讯作者: 王 来, 教授; 电话: 0411-4707636; E-mail: wangl@dlut.edu.cn

(编辑 吴家泉)