文章编号:1004-0609(2008)04-0601-07

TC4钛合金沉积NiCrAlY涂层的氧化行为

彭小敏1, 2,夏长清1, 2,王金惠1, 2,刘莹颖1, 2,刘 娟1, 2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:采用电弧离子镀(AIP)技术在TC4 (Ti-6Al-4V) 钛合金基体表面沉积制备NiCrAlY涂层,测定TC4钛合金和NiCrAlY涂层在700~900 ℃的氧化动力学曲线。通过扫描电镜(SEM)、能谱(EDS)分析与X射线衍射分析 (XRD)研究TC4钛合金和NiCrAlY涂层氧化前后物相组成和组织形貌,讨论氧化过程中元素的扩散行为。结果表明:在700~900 ℃静态空气中氧化100 h,NiCrAlY涂层能明显提高TC4钛合金的抗氧化性能,TC4钛合金氧化后形成Al2O3层和TiO2层交替出现的氧化膜层;经700和800 ℃氧化后,NiCrAlY涂层保持其原始的相组成,但在表面形成Al2O3和Cr2O3混合氧化膜;经900 ℃氧化后,氧化膜由Al2O3和TiO2组成;经700 ℃氧化时,主要发生Ti和Ni两种元素的扩散;经800和900 ℃氧化时,由于Ti及Ni元素的剧烈扩散,界面附近出现Kirkendall疏孔带和约100 μm的β相稳定区;经900 ℃氧化时,Ti扩散到涂层表面形成氧化物导致氧化速率提高,Cr元素开始向基体扩散并在近界面处富集。

关键词:NiCrAlY涂层;TC4钛合金;氧化;扩散

中图分类号:TB 43 文献标识码:A

Oxidation behavior of TC4 titanium alloy with NiCrAlY coating

PENG Xiao-min1, 2, XIA Chang-qing1, 2, WANG Jin-hui1, 2, LIU Ying-ying1, 2, LIU Juan1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metals Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: The NiCrAlY coating was deposited on TC4 titanium alloy by arc ion plating (AIP). The oxidation kinetic curves of TC4 titanium alloy and NiCrAlY coating were obtained. The microstructures and morphologies of TC4 alloy and NiCrAlY coating before and after oxidation were analyzed by SEM, EDS and XRD, and the elements diffusion behavior was also studied. The results show that the oxidation resistance of TC4 alloy is evidently improved by NiCrAlY coating at 700-900 ℃. The oxidation layer of TC4 consists of TiO2 and Al2O3 layers alternately. After oxidation at 700 and 800 ℃, NiCrAlY coating still contains the original phases and the oxidation produces are made up of Al2O3 and Cr2O3. At 900 ℃, the oxidation coat consists of Al2O3 and TiO2. At 700 ℃, Ti and Ni are the major diffusion elements. Because of the violent diffusion of Ti and Ni, Kirkendal porosity belts and β-stabilizes zones appear near the interface at 800 and 900 ℃. At 900 ℃, Ti diffuses to the coating surface and form TiO2, which increases the oxidation speed. Cr begins to diffuse to the substrate and accumulates at the interface at 900 ℃.

Key words: NiCrAlY coating; TC4 titanium alloy; oxidation; diffusion

钛合金材料密度小,比强度高,耐蚀性强,中低温性能稳定,在航空航天领域得到广泛应用。但是,钛合金的不耐烧蚀,高温下容易氧化,且在合金表面形成不具保护作用的氧化物,同时在氧化过程中氧化物层下面的基体易固溶大量的氧原子从而形成脆性富氧层,这些都严重损害了合金的高温使用性能,影响了合金的使用[1-3]。随着大推重比涡轮发动机的发展,对钛合金的研究趋向于提高它们的使用温度极限,但钛合金在高温环境中的严重氧化以及氧化脆性仍未得到有效解决[4]。为此,采取了一系列的措施来提高钛合金的抗氧化性能,包括在合金中加入其它元素,如Nb、W和Mo[5],对合金表面进行表面改性如低压氧处理[6],如渗Al[7],在合金表面涂覆抗氧化涂层,如TiAl3、TiAlCr和MCrAlY(M为Ni, Co, NiCo)[8]等。

MCrAlY涂层自20世纪70年代以来,越来越广泛地被用作抗氧化涂层或热障涂层(TBC)基体与陶瓷涂层间的粘结层,其优点是硬度高、抗氧化性能好,热膨胀系数与高温合金及陶瓷接近[9]。MCrAlY涂层表面在高温氧化气氛中形成富Al2O3氧化层,能有效地阻止氧元素向基体扩散,从而保护基体合金,氧化膜的微观结构取决于涂层的成分、制备方法和制备工艺[10]。制备MCrAlY涂层的方法很多,如真空等离子喷涂(VPS)、电子束物理气相沉淀(EBPVD)及磁控溅射等。电弧离子镀(AIP)是在蒸镀和溅射镀膜的基础上逐步改进和发展起来的新型镀膜技术[10]。电弧离子镀在沉积过程中对基体的离子轰击作用能够改善涂层结构及其粘附性,因而在制备MCrAlY涂层中体现了众多优点[11]。

TC4钛合金为α和β两相钛合金,广泛应用于航空航天发动机最冷端压气机叶片,其工作温度一般低于450 ℃。但随着对发动机功率的提高,压气机的工作温度也会随着提高。然而随着温度的提高,在高温氧化条件下,TC4钛合金表面形成的氧化膜会很快失去其保护功能[12],其原因主要由于氧化层的脆性使得氧化膜容易沿基体表面方向形成裂纹并最终脱离基 体[13]。本文作者利用电弧离子镀在TC4钛合金表面沉积NiCrAlY涂层,研究了NiCrAlY涂层对TC4钛合金氧化行为的影响。

1 实验

1.1 材料及涂层制备

选择TC4(Ti-6Al-4V)钛合金轧制板材作为实验基材,试样被加工成尺寸为15 mm×10 mm×2.5 mm的小片。基体试样先在500#砂纸上磨光,去除表面氧化物,然后依次在碱液、蒸馏水中清洗,最后在丙酮溶液中超声清洗,干燥后置于沉积设备中。

采用电弧离子镀(AIP)技术在TC4基体表面沉积制备NiCrAlY涂层。实验用NiCrAlY靶材成分为57%Ni、30%Cr、12%Al和1%Y(质量分数,%)。沉积工艺参数为:先抽真空为5 mPa,在沉积涂层前进行预溅射,轰击偏压为600~800 V,轰击电流为120~140 A,时间为5~10 min,沉积涂层时,工作偏压为160~ 180 V,工作电流为120~140 A,沉积时间为120 min。

1.2 真空热处理

将沉积好NiCrAlY涂层的试样封于石英管中,抽真空为13.3 mPa,并用Ar气保护。随后在箱式电阻炉进行热处理,加热至700 ℃,保温3 h后冷却至室温,使涂层内部致密,提高与基体的结合力,获得较高的表面硬度和抗高温氧化性能,同时避免在长时间高温状态下界面层的脆化以及基体的热变形与组织恶化[14]。

1.3 氧化实验

将试样放入已烧至质量恒定的氧化铝坩埚中,在700、800及900 ℃静态空气中氧化100 h。氧化初期20 h,每隔5 h将坩埚取出冷却至室温,连同坩埚称质 量;氧化20 h后,每隔20 h将坩埚取出冷却至室温并称质量,记录试样氧化的质量增加,称质量的精确度为0.1 mg。

1.4 检测分析

采用Rigaku D/Max 2500型X-ray衍射仪对氧化前后试样相组成进行分析,实验使用Cu 靶Kα1射线,波长为0.154 056 nm,加速电压为36 kV,电流为30 mA,扫描速率为4 (?)/min,步宽为0.02?。采用Sirion200场发射扫描电镜(SEM)观察氧化前后试样表面及截面微观形貌,并使用其自带的GENESIS60E能谱仪(EDS)分析氧化前后试样元素的分布情况。

2 结果与讨论

2.1 氧化动力学

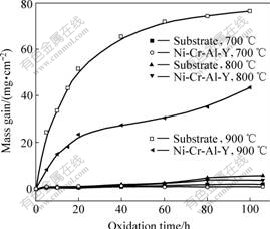

经700和800 ℃氧化100 h后,TC4钛合金表面分别呈深蓝色和褐色(氧化前呈金属光泽),在氧化过程中氧化膜出现轻微的剥落现象,而NiCrAlY涂层表面宏观上并无明显变化;当氧化温度升高到900 ℃时,合金氧化膜疏松,呈黑色,有明显的剥落,NiCrAlY涂层表面呈灰黑色(氧化前呈灰白色),涂层基本完好,只是在试样边缘菱角处有少许剥落。图1所示为TC4钛合金及NiCrAlY涂层在700~900 ℃的氧化动力学曲线。由图1可知,在700~900 ℃温度范围,同温度比较时,带涂层试样的氧化质量增加始终低于合金试样的氧化质量增加。在氧化初期,由于TC4钛合金和涂层表面氧化物迅速形成,使得二者的氧化质量增加均较明显;氧化20 h后,合金的氧化质量增加幅度仍然较大;大约氧化40 h后才进入稳定期,但涂层20h后便进入稳定期,氧化质量增加不大。其原因是由于NiCrAlY涂层表面形成的氧化物保护膜能够有效地阻挡氧进一步向内扩散,减缓氧化速率[2],而对于TC4钛合金来说,其形成的氧化膜较疏松,只有当氧化膜到一定厚度时才能对氧的内扩散起到一定的阻挡作用。另外,经900 ℃氧化80 h后,NiCrAlY涂层的氧化速率有所提高。其原因可能为以下两点:一方面是由于长时间氧化,基体中的Ti元素通过涂层缺陷向外扩散到涂层表面与氧结合形成TiO2[15];另一方面是由于试样边缘涂层的局部剥落使基体直接氧化质量增加。经700、800和900 ℃氧化100 h后,合金的氧化速率分别18.25、52.83和762 μg/(cm2·h),而带涂层试样的氧化速率分别为8.92、34.63、434.8 μg/(cm2·h)。因此,在本研究的温度区间,带涂层试样的氧化速率均约为合金的1/2。由此可见,经700、800和900 ℃静态空气氧化100 h后,NiCrAlY涂层能有效地保护TC4钛合金基体。

图1 TC4钛合金及NiCrAlY涂层氧化动力学曲线

Fig.1 Oxidation kinetic curves of TC4 and NiCrAlY coating

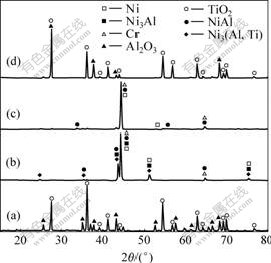

2.2 X射线衍射分析

沉积态NiCrAlY涂层经700 ℃真空热处理3 h后,主要由γ-Ni、β-NiAl、过饱和α-Cr固溶体及γ′-Ni3Al相组成[14]。图2所示为NiCrAlY涂层和TC4钛合金经不同温度氧化后的X射线衍射谱。由图2可知,TC4钛合金经900 ℃氧化100 h后,其表面氧化膜主要由TiO2组成,并含有少量的Al2O3。红金石型TiO2组成的氧化膜往往呈片状结构,片层与片层之间的过渡区域结合弱,甚至为裂隙,对基体并不能起到理想的抗氧化效果[16]。NiCrAlY涂层经700 ℃氧化100 h后,其相组成基本没有变化,主要由γ-Ni、β-NiAl和α-Cr固溶体和γ′-Ni3Al相组成,同时由于X射线有一定的穿透力,出现了少量的扩散层中的Ni3(Al, Ti)相。经 800 ℃氧化100 h后,NiCrAlY涂层主要由γ-Ni、β- NiAl、α-Cr固溶体组成,并没有发现γ′-Ni3Al和Ni3- (Al, Ti)相。李佳等[14]的研究表明,经700 ℃以上真空热处理,NiCrAlY涂层开始析出γ′-Ni3Al相,当温度升高到750 ℃以上时,γ′相呈减少趋势。Ni3(Al, Ti)相的消失可能是由于内氧化层(氧化层靠近基体的部分)中Al2O3的形成,消耗了基体中的Al原子,致使基体表层以下的一定厚度区域贫Al,导致Ni3(Al, Ti)相消失[17]。涂层经700和800 ℃氧化100 h后,已经在涂层表面形成了很薄的Cr2O3和Al2O3混合氧化膜,由于其厚度太薄,未能在XRD谱上反映出来。以上实验结果说明,经700和800 ℃氧化100 h后,NiCrAlY涂层基本保持完整,能显著提高TC4钛合金基体的抗氧化性能。经900 ℃氧化100 h后,NiCrAlY涂层氧化膜主要由Al2O3和TiO2组成,说明随着温度的提 高,涂层的氧化变得更加剧烈,元素的扩散开始起作用。NiCrAlY涂层的高温氧化过程比较复杂,氧化初期涂层表面形成多个氧化物相,如NiO、Al2O3、Cr2O3和Ni(Cr, Al)2O4等。随着氧化的继续进行,扩散开始起作用,生长速度较快的Cr2O3和NiO优先外延生长,涂层中的Al与向内扩散的O结合,使Al2O3在内部生长。同时,由于Al与O的亲和力较强,与Cr2O3和NiO等相中的金属发生置换反应,Al2O3继续生长。当Cr和Al含量较低时,最外层形成以NiO为主的氧化膜;当Cr和Al的含量较高时,则易形成以Cr2O3和Al2O3为主的复杂氧化膜,而在高温下,Cr2O3会逐渐以CrO3的形式蒸发[10, 16]。王冰等[10]研究了NiCrAlY涂层对K17合金抗氧化性能的影响,发现随着温度的升高,Ti元素从基体扩散到涂层形成TiO2是导致涂层抗氧化性能降低的原因之一。

图2 NiCrAlY涂层和TC4钛合金经不同温度氧化后X射线衍射谱

Fig.2 XRD patterns of NiCrAlY coating and TC4 after oxidation at different temperatures: (a) Ti-6Al-4V substrates, 900 ℃, 100 h; (b) NiCrAlY coating, 700 ℃, 100 h; (c) NiCrAlY coating, 800 ℃, 100 h; (d) NiCrAlY coating, 900 ℃, 100 h

2.3 微观形貌及元素分布

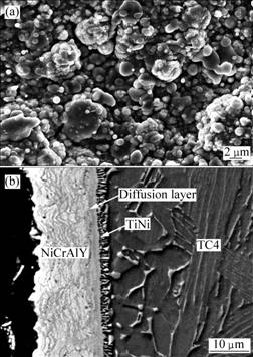

图3所示为沉积态NiCrAlY涂层经700 ℃真空热处理3 h后表面与截面形貌。由图3(a)可知,涂层由细小颗粒(直径约1~3 μm)堆积而成,部分颗粒团聚成粗大粒子在涂层表面形成瘤状突起。涂层厚度约为 20 μm。热处理后,涂层连续、均匀、致密,与基体结合紧密,沉积过程中的缺陷如空洞等较少,这些都有助于提高涂层的抗氧化性能。同时,涂层和基体间存在较薄的扩散层,并出现向基体方向生长的齿状相。根据文献[1]和[4],该扩散层为Ni3(Al, Ti)三元化合物,

图3 NiCrAlY涂层经700 ℃真空热处理3 h后的微观形貌

Fig.3 Morphologies of NiCrAlY coating after vacuum heat treatment at 700 ℃ for 3 h: (a) Surface; (b) Cross-section

齿状相为TiNi化合物。

图4所示为TC4基体经900 ℃氧化100 h后表面和截面形貌。由图4(a)可知,TC4基体经900 ℃氧化100 h后,氧化膜较疏松,结合XRD分析结果(见图2),其氧化膜主要由粗大金红石型TiO2组成,并分布了少量的粒状Al2O3。TC4钛合金经900 ℃氧化100 h后生成了一层约200 μm的氧化膜,该氧化膜中两种不同的氧化物层交替出现(见图4(b))。经元素能谱分析表明,浅色氧化膜为TiO2(Ti和O的摩尔分数之比约为0.5),深色氧化膜为Al2O3(Al和O的摩尔分数之比约为0.66)。DU等[18]认为:TC4钛合金氧化时首先形成TiO2氧化膜,随着TiO2氧化膜的增厚,O元素内扩散受阻,此时Al元素向外扩散与氧结合形成Al2O3层。同样,当Al2O3层到一定厚度时,Ti元素向外扩散与O反应形成TiO2层,从而TiO2层和Al2O3层交替出现。

图4 TC4钛合金经900 ℃氧化100 h后的微观形貌

Fig.4 Morphologies of TC4 alloy after oxidation at 900 ℃ for 100 h: (a) Surface; (b) Cross-section

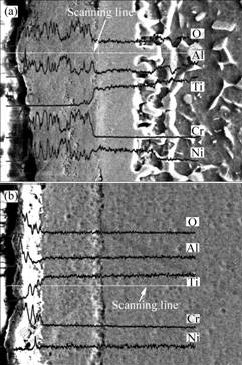

图5所示为NiCrAlY涂层700 ℃氧化100 h后表面和截面的形貌。图6所示为氧化后NiCrAlY涂层/ TC4基体界面元素线扫描分析。由图5可看出,沉积了NiCrAlY涂层的试样经700 ℃氧化100 h后,其表面形成了一薄层颗粒细小、覆盖均匀、致密的氧化膜,且涂层与基体结合紧密(见图5(a)和(b))。由图6(a)可知,该氧化膜中的Cr、Al、O和Ni元素的含量较高,但NiO只有在NiCrAlY涂层的氧化初期生成[10],因此该氧化膜应为Al2O3和Cr2O3混合膜,且O元素仅分布在氧化膜及涂层中,说明在氧化过程中氧化膜及涂层有效地阻挡了氧元素的内扩散,明显提高了基体的抗氧化性能。由图5(b)可知,NiCrAlY涂层经700 ℃氧化100 h后,扩散层及齿状TiNi层明显变厚,说明NiCrAlY涂层和TC4基体发生了元素的互扩散。由图6(a)可知,经700 ℃氧化100 h后,主要发生了Ni和Ti两种元素的扩散,Ni元素分布在涂层和界面扩散层中,而Ti元素分布在基体及界面扩散层中。Ni元素向基体方向扩散,而基体中的Ti元素向涂层方向扩散,这就使Ni和Ti两种元素在涂层和基体界面处继续反应,从而使扩散层及TiNi层变厚。Cr元素并没有明显的扩散,仍然分布在涂层中。涂层与基体之间的互扩散会恶化涂层的抗长期氧化性能及基体的力学性能,特别是硬而脆的扩散化合物层会显著降低基材的疲劳寿命[15]。

图5 NiCrAlY涂层700 ℃氧化100 h后的微观形貌

Fig.5 Morphologies of NiCrAlY coating after oxidation at 700 ℃ for 100 h: (a) Surface; (b) Cross-section

图6 氧化后NiCrAlY涂层/TC4基体界面元素线扫描分析

Fig.6 Elements line distribution of NiCrAlY coating/TC4 substrate interface after oxidation at 700 ℃(a) and 800 ℃(b)

图7所示为NiCrAlY涂层经800 ℃氧化100 h后表面和截面的形貌。由图7(a)可知,当氧化温度升高到800 ℃时,涂层表面仍然形成了一层均匀、致密的保护性混合氧化膜。由图7(b)可知,经800 ℃氧化 100 h后,涂层明显变薄,涂层/基体界面变得更加复杂,在涂层和基体之间出现了厚为100 μm的β相稳定区域,这与MCKEE等[19]的研究结果相符,同时在离界面约20 μm处出现了一条连续的Kirkendall疏孔带,说明涂层和基体元素互扩散更剧烈。图6(b)反映了经800 ℃氧化100 h后NiCrAlY涂层试样截面元素分布情况,O元素分布在氧化膜及涂层中,说明在该氧化条件下,涂层起到了较好的防护作用。Ni分布在涂层中,但已经向基体扩散了相当长的距离。Ni元素为α+β型钛合金β相稳定元素[19],由于Ni元素向基体的扩散,使涂层与基体之间形成了β相稳定区 域。与经700 ℃氧化100 h后的Ti元素分布情况(图6(a))对比,经800 ℃氧化100 h后的Ti元素已经明显向涂层中扩散,但在氧化膜中几乎不含Ti元素。由于Cr元素在同一温度下的扩散系数远小于Ni和Ti等元素的扩散系数,且在Ni-Cr合金体系中引入Al元素时会降低Cr的扩散系数[20],因此经800 ℃氧化100 h 后,Cr元素仍然集中分布在涂层和氧化膜中,没有明显向基体扩散的迹象。由于Ti和Ni两种元素的剧烈互扩散,且Ni向基体的扩散较Ti向涂层中的扩散较慢,因此在涂层和基体之间形成了Kirkendall疏孔带。

图7 NiCrAlY涂层经800 ℃氧化100 h后的微观形貌

Fig.7 Morphologies of NiCrAlY coating after oxidation at 800 ℃ for 100 h: (a) Surface; (b) Cross-section

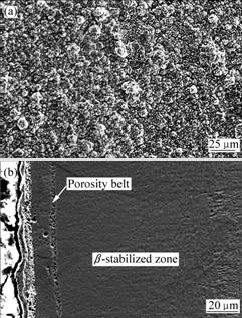

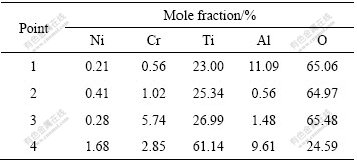

图8所示为NiCrAlY涂层经900 ℃氧化100 h后的表面和截面形貌。由图8(a)可知,经900 ℃氧化 100 h后,其氧化膜由细小颗粒状氧化物和粗大的短棒状氧化物组成。根据XRD分析结果(见图2)及氧化膜元素能谱分析(见表1)可知,氧化膜由颗粒状Al2O3和金红石型TiO2组成。TiO2的形成使得NiCrAlY涂层抗氧化性能有所下降,这可能是由于经900 ℃氧化 80 h后NiCrAlY涂层氧化速率有所上升的原因之一(见图1)。随着氧化温度的升高,涂层和基体元素的互扩散也更加剧烈。由表1可知:基体中的Ti元素已经扩散到涂层表面,出现在表面混合氧化膜中(图8(b) 1点位置);Ni继续向基体方向扩散,Ni向基体扩散为反应扩散控制过程,即使涂层中(图8(b) 2点位置)的Ni含量比基体(图8(b) 4点位置)的低,上坡扩散也会发生[15];Cr元素开始向基体扩散,并在近界面处富集(图8(b) 3点位置的Cr含量为5.74%)。夏长清等[1, 14]的研究表明,在NiCrAlY涂层/TC4基体体系中,Cr元素在870 ℃开始扩散,并参与界面反应。由于元素的扩散,特别是β相区稳定元素Ni和Cr向涂层方向扩散,使带涂层试样经900 ℃氧化100 h后,也出现了厚约100 μm的β相稳定区域和Kirkendall疏孔带(见图8(b))。

图8 NiCrAlY涂层经900 ℃氧化100 h后的微观形貌

Fig.8 Morphologies of NiCrAlY coating after oxidation at 900 ℃ for 100 h: (a) Surface; (b) Cross-section

表1 图8(b)中NiCrAlY涂层/TC4基体界面元素能谱分析结果

Table 1 EDS results of NiCrAlYcoating/TC4 substrate interface in Fig.8(b)

3 结论

1) 采用电弧离子镀技术在TC4钛合金上沉积了厚约20 μm的NiCrAlY涂层。经700 ℃真空热处理 3 h后,涂层连续、均匀、致密,与基体结合紧密。

2) NiCrAlY涂层在700~900 ℃静态空气氧化 100 h后,均能明显提高TC4钛合金的抗氧化性能。经700和800 ℃氧化时,带涂层试样的氧化速率分别仅为8.92和34.63 μg/(cm2·h);经900 ℃氧化时,氧化速度稍高,为434.8 μg/(cm2·h)。

3) TC4钛合金氧化后生成Al2O3和TiO2疏松混合氧化膜,其结构为Al2O3层和TiO2层交替出现结构。带涂层试样经700和800 ℃氧化100 h后,NiCrAlY涂层基本保持其原始的相组成,并在涂层表面形成了Al2O3和Cr2O3致密氧化膜;经900 ℃氧化时,由于Ti元素扩散到涂层表面,其氧化膜为Al2O3和TiO2混合氧化膜。

4) 随着氧化温度的升高,涂层和基体之间的元素扩散加剧,导致涂层的抗氧化能力下降。经 700 ℃氧化时,主要发生Ti和Ni两种元素的扩散,使得涂层和基体间扩散层及TiNi层变厚;经800和900 ℃氧化时,由于Ti和Ni两种元素的剧烈扩散,界面附近出现Kirkendall疏孔带和厚约100 μm的β相稳定区;经 900 ℃氧化时,Ti扩散到涂层表面形成氧化物导致氧化速率提高,Cr元素开始向基体扩散并在近界面处富集。

REFERENCES

[1] 夏长清, 李 佳, 古 一, 彭小敏, 武文花. NiCrAlY 涂层/ TC4基体界面反应机理[J]. 中南大学学报: 自然科学版, 2005, 36(4): 550-553.

XIA Chang-qing, LI Jia, GU Yi, PENG Xiao-min, WU Wen-hua. Interaction behavior between NiCrAlY coating and TC4 ally substrate[J]. Journal of Central South University: Science and Technology, 2005, 36(4): 550-553.

[2] 崔文芳, 罗国珍, 周 廉. 氧在Ti-1100高温钛合金氧化中的扩散规律[J]. 东北大学学报: 自然科学版, 1998, 19(1): 19-22.

CUI Wen-fang, LUO Guo-zhen, ZHOU Lian. Diffusion kinetics of oxygen in oxidation of Ti-1100 high temperature titanium alloy[J]. Journal of Northeastern University: Natural Science, 1998, 19(1): 19-22.

[3] 崔文芳, 罗国珍, 周 廉, 洪 权. 高温钛合金溅射NiCrAlY 涂层氧化行为的研究[J]. 稀有金属材料与工程, 1998, 27(6): 348-351.

CUI Wen-fang, LUO Guo-zhen, ZHOU Lian, HONG Quan. Oxidation behaviors of a sputtered NiCrAlY coating on the surface of a high temperature titanium alloy[J]. Rare Metal Materials and Engineering, 1998, 27(6): 348-351.

[4] LIU Hai-ping, HAO Shan-shan, WANG Xiao-hong, FENG Zi-xiu. Interaction of a near-α type titanium alloy with NiCrAlY coating at high temperatures[J]. Script Materialia, 1998, 36(10): 1443-1450.

[5] SHIDA Y, ANADA H. The effect of various ternary additives on the oxidation behavior of TiAl in high-temperature air[J]. Oxidation of Metals, 1996, 45(1/2): 197-219.

[6] YOSHIHARA M, TANAKA R, SUZUKI T, SHIMIZU M. Development of surface treatment techniques to improve oxidation resistance of titanium aluminide[C]//High-Temperature Ordered Intermetallic Alloys Ⅳ Symposium. Pittsburgh: Mater Res Soc, 1991: 975-980.

[7] 沈嘉年, 江竹梅. Ti3Al金属间合金渗铝涂层及其高温氧化行为[J]. 腐蚀科学与防护技术, 1992, 4(3): 139-143.

SHEN Jia-nian, JIANG Zhu-mei. High temperature behavior of alumetizing coatings on Ti3Al intermetallic alloy[J]. Corrosion Science and Protection Technology, 1992, 4(3): 139-143.

[8] 郑传林, 徐 重, 谢锡善, 贺志勇, 董建新, 张麦仑. NiCrMoNb合金化层对TiAl金属间化合物抗氧化性能的影响[J]. 稀有金属材料与工程, 2003, 32(1): 32-36.

ZHENG Chuang-lin, XU Zhong, XIE Xi-shan, HE Zhi-yong, DONG Jian-xin, ZHANG Mai-lun. Effect of NiCrMoNb alloying coating on the oxidation resistance of TiAl intermetallics[J]. Rare Metal Materials and Engineering, 2003, 32(1): 32-36.

[9] BOSE S, DEMASHI-MARCIN J. TBC experience in gas turbine engines at Part & Whitney[J]. J Thermal Spray Technol, 1997, 6(1): 99-104.

[10] 王 冰, 卢春燕, 孙 超, 黄荣芳, 闻立时. NiCrAlY涂层对 Ni基高温合金K17抗氧化性能的影响[J]. 腐蚀科学与防护技术, 2002, 14(1): 7-10.

WANG Bing, LU Chun-yan, SUN Chao, HUANG Rong-fang, WEN Li-shi. Effect of NiCrAlY coatings on oxidation resistance of Ni-base superalloy K17[J]. Corrosion Science and Protection Technology, 2002, 14(1): 7-10.

[11] VETTER J, KNOTEK O, BRAND J, BEELE W. MCrAlY coatings deposited by cathodic vacuum arc evaporation[J]. Surface and Coatings Technology, 1994, 68/69: 27-31.

[12] SIAB R, BONNET G, BROSSARD J M, BALMAIN J, DINHUT J F. Effect of an electrodeposited yttrium containing thin film on the high-temperature oxidation behavior of TA6V alloy[J]. Applied Surface Science, 2007, 253(7): 3425-3431.

[13] GARBACZ H, LEWANDOWSKA M. Microstructural changes during oxidation of titanium alloys[J]. Materials Chemistry and Physics, 2003, 81(2/3): 542-547.

[14] 李 佳, 夏长清, 古 一, 吴安如, 武文花. 真空热处理对Ti6Al4V基体/NiCrAlY涂层体系组织结构及元素扩散行为的影响[J]. 中国有色金属学报, 2004, 14(11): 1889-1894.

LI Jia, XIA Chang-qing, GU Yi, WU An-ru, WU Wen-hua. Effect of vacuum heat treatment on microstructure and elements diffusion behavior of NiCrAlY coating on Ti6Al4V[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(11): 1889-1894.

[15] TANG Zhao-lin, WANG Fu-hui, WU Wei-tao. Effect of MCrAlY overlay coatings on oxidation resistance of TiAl intermetallics[J]. Surface and Coatings Technology, 1998, 99(3): 248-252.

[16] 李美栓. 金属的高温氧化[M]. 北京: 冶金工业出版社, 2001.

LI Mei-shuan. High temperature oxidation of metals[M]. Beijing: Metallurgy Industry Press, 2001.

[17] 腾 浩, 尹志民, 朱远志, 黄继武, 张保胜. Ni76Cr19AlTi合金的高温氧化行为[J]. 中国有色金属学报, 2006, 16(5): 894-898.

TENG Hao, YIN Zhi-min, ZHU Yuan-zhi, HUANG Ji-wu, ZHANG Bao-sheng. High temperature oxidation behavior of Ni76Cr19AlTi superalloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(5): 894-898.

[18] DU H L, DATTA P K, LEWIS D B, BURNELL-GRAY J S. Air oxidation behaviour of Ti-6Al-4V alloy[J]. Corrosion Science, 1994, 36(4): 631-642.

[19] MCKEE D W, LUTHRA K L. Plasma-sprayed coatings for titanium alloy oxidation protection[J]. Surface and Coatings Technology, 1993, 56(2): 109-117.

[20] KOLOMATSEV P T. 耐热扩散涂层[M]. 马志春, 译. 北京:国防工业出版社, 1988.

KOLOMATSEV P T. Hot-resistant diffusion coatings[M]. MA Zhi-chun, transl. Beijing: National Defence Industry Press, 1988.

基金项目:国防预先研究资助项目(MKPT0489)

收稿日期:2007-09-14;修订日期:2007-12-19

通讯作者:夏长清,教授;电话:0731-8830267;E-mail: xia-gro@mail.csu.edu.cn

(编辑 李艳红)