文章编号:1004-0609(2008)08-1395-07

TC4钛合金高温变形行为及其流动应力模型

罗 皎,李淼泉,李 宏,于卫新

(西北工业大学 材料学院,西安 710072)

摘 要:研究变形工艺参数对TC4钛合金高温变形行为的影响。热模拟压缩实验时选取的变形温度为1 093~1 303 K;应变速率为0.001~10.0 /s;变形程度为60%。结果表明:TC4钛合金在变形开始阶段,流动应力随应变的增加迅速增加,当应变超过一定值后,流动应力开始下降并逐渐趋于稳定,出现稳态流动特征;变形温度升高和应变速率减小使TC4钛合金高温变形时的稳态应力和峰值应力显著降低;应变速率和变形温度会影响TC4钛合金进入稳态变形时变形程度的大小。利用多元回归分析建立TC4钛合金在高温变形时的流动应力模型,模型的计算值与实验数据的平均相对误差为6.25%,该模型较好地描述TC4钛合金在高温变形过程中的流动行为。

关键词:TC4钛合金;高温变形行为;流动应力模型;工艺参数

中图分类号:TG 319 文献标识码:A

High temperature deformation behavior of TC4 titanium alloy and its flows stress model

LUO Jiao, LI Miao-quan, LI Hong, YU Wei-xin

(School of Materials Science and Engineering, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: The effect of processing parameters on deformation behavior of TC4 titanium alloy were investigated by using compression tests. The experiments were carried out in a Thermermaster-Z simulator at deformation temperatures of 1 093? 1 303 K, strain rates of 0.001?10.0 s?1, and height direction reduction of 60%. The results show that the flow stress of TC4 titanium alloy increases quickly with the strain and reaches a peak, then decreases to a steady value. The steady and peak stress significantly decreases with the increase of deformation temperature and decrease of strain rate, and the strain rate and the deformation temperature would also affect the critical value of strain to reach the steady flow of TC4 titanium alloy during high temperature deformation. The flow stress model of TC4 titanium alloy during high temperature deformation was established by using the regression method. The average relative difference between the calculated and experimental flow stress is 6.25%. The flow stress model can efficiently predict the deformation behavior of TC4 titanium alloy during high temperature deformation.

Key words: TC4 titanium alloy; high temperature deformation behavior; flow stress model; processing parameters

TC4(Ti-6Al-4V)合金是一种(α+β)两相钛合金,具有良好的工艺塑性、超塑性、焊接性和抗腐蚀性能等优点,因此被广泛应用于航空和航天工业。钛合金的高温变形行为对变形工艺参数非常敏感,其锻后组织和性能较难控制,为保证塑性成形构件质量的稳定性,各国学者对钛合金的高温变形行为以及成形性能进行了大量的研究[1?9]。材料的流动应力模型是联系材料的流动应力与锻造热力参数之间的最基本函数关系,是进行金属塑性变形工艺设计和控制的基础。在塑性加工领域,研究材料流动应力模型的根本目的在于准确描述流动应力随温度、等效应变和应变速率等变形参数的变化情况,以提高工艺设计计算和仿真的精度,从而为塑性成形工艺方案的制定和设备的选择提供参考依据[10?15]。

本文作者通过TC4钛合金的热模拟压缩实验,研究了变形工艺参数对TC4钛合金高温变形时流动应力的影响规律,并针对TC4钛合金的成形特点,利用多元回归分析的方法建立了TC4钛合金高温变形时的流动应力模型,同时对模型的可靠性进行了验证。

1 实验

原始TC4钛合金是直径为90 mm的棒材,其化学成分如表1所列。为了消除棒材内应力和使微观组织均匀分布,在热模拟实验前对棒材进行退火热处理,热处理规范如下:加热到1 023 K保温90 min后出炉空冷至室温。利用金相法测定TC4钛合金的相转变温度大约为1 263 K。

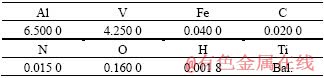

表1 TC4钛合金的主要化学成分

Table 1 Chemical compositions of TC4 titanium alloy (mass fraction, %)

热模拟压缩实验在Thermermaster?Z型热模拟实验机上进行,压缩过程中抽真空。压缩试样为d 8 mm×12 mm的圆柱体,上下两端面加工有直径为7.6 mm,深为0.2 mm的浅槽,用于贮存高温保护润滑剂,以便尽可能减小摩擦获得单向应力状态下的实验条件。试样采用电频感应加热,压缩过程中由焊接在试样侧面中部的热电偶实时测量温度,通过闭环温控系统实现控温,控温精度为±1.0 ℃。实验过程中,配有微机处理系统的试验机自动采集有关数据,并进行修正和计算,最后以表格形式输出载荷—行程和流动应力—应变等数据。热模拟压缩实验方案如下。变形温度为(K):1 093,1 123,1 143,1 163,1 183,1 203,1 223,1 233,1 243,1 253,1 263,1 273,1 283,1 293, 1 303;应变速率为(/s):0.001,0.01,0.1,1.0,10.0;变形程度为60%。完成高温压缩变形后冷却方式为空冷。

2 变形行为分析

图1所示为TC4钛合金在不同温度和应变速率下变形时的流动应力曲线。由图1可以看出,在不同应变速率和变形温度条件下,TC4钛合金的流动应力曲线表现为相似的特征。在变形开始阶段,流动应力随应变的增加迅速增加,当应变超过一定值后,流动应力开始下降并逐渐趋于稳定,出现稳态流动特征。TC4钛合金对应变速率非常敏感。在给定温度下,随着应变速率的增加,流动应力明显增加。TC4钛合金对变形温度也具有较大的敏感性。在给定应变速率下,变形温度的上升会导致流动应力的下降。TC4钛合金进入稳态流动阶段所需的变形程度对应变速率较为敏感。当应变速率小于或等于10?2 /s时,在本文实验的整个变形温度范围内,TC4钛合金在变形程度较小的情况下就进入稳态流动阶段。当应变速率高于10?2 /s时,TC4钛合金进入稳态流动阶段所需的变形量与变形温度有关,即当变形温度高于1 243 K时,TC4钛合金能较早的进入稳态流动阶段,但当变形温度低于1 243 K时,TC4钛合金进入稳态流动阶段所需的变形量较大。TC4钛合金高温变形过程中稳态应力与变形工艺参数之间的关系如图2(a)所示。由图2(a)可以看出,变形温度高于1 243 K以后,TC4钛合金的稳态应力基本上不受变形温度的影响,但对应变速率较敏感。在实验的变形温度和应变速率范围内,TC4钛合金都有应力峰值出现。峰值应力的大小对估算最大变形载荷具有重要作用。TC4钛合金高温变形过程中峰值应力与变形工艺参数之间的关系如图2(b)所示。由图2(b)可以看出,TC4钛合金的峰值应力对应变速率较敏感。当应变速率较小时,变形温度对峰值应力的影响较小;当应变速率较大时,变形温度对峰值应力的影响较大。TC4钛合金在1 223 K以上变形时,在较高的应变速率下,应力达到峰值后出现一个明显的应力振荡,这可能是动态再结晶所致。

图1 TC4钛合金高温变形时的流动应力曲线

Fig.1 Typical flow stress curves of TC4 titanium alloy during high temperature deformation: (a) 1 163 K; (b) 1 203 K; (c) 1 273 K; (d) 1 303 K

图2 TC4钛合金高温变形过程中的稳态应力和峰值应力

Fig.2 Steady stress and peak stress curves of TC4 titanium alloy during high temperature deformation: (a) Steady stress (ε = 0.6); (b) Peak stress

综上所述,应变速率对TC4钛合金高温变形过程中的流动应力的影响比较大,而变形温度的影响则由于温度范围不同而有所差别。变形温度在1 243 K以下时,TC4钛合金的流动应力随着变形温度的降低而显著地升高;而变形温度在1 243 K以上时,TC4钛合金的流动应力随变形温度变化不明显。

由以上分析可知,TC4钛合金高温变形时分过渡变形(非稳态)和稳态变形两个阶段。热压缩过程是受热激活过程控制的,其流动应力行为与变形体内的位错组态密切相关。从金属高温塑性变形的物理本质来看,在变形初期,位错的交滑移为主要软化机制,但它引起的动态软化不足以补偿位错密度增加而带来的硬化,因此流动应力以较快的速度增大。流动应力达到峰值后,随应变增加,王斌等[16]认为在快速变形条件下,由于畸变能的剧烈增加,引起动态回复和再结晶,因而出现明显的软化现象,引起流动应力曲线显著下降。相反,在慢速变形条件下,由于动态回复过程的相对加强,畸变能较难增加,再结晶很难发生,因而流动应力曲线形状比较平缓。可见,应变速率对动态回复、动态再结晶及流动应力曲线形状有显著的影响。随着变形程度的增大,TC4钛合金中的空位浓度增加,位错的攀移在过渡变形的中后期也参与软化过程,位错克服障碍力的能力增强,TC4钛合金变形时硬化和软化的平衡向低硬化指数方向变化,流动应力曲线趋于平衡。当软化和硬化之间达到动态平衡时,变形进入稳态流动阶段。稳态变形的实质是位错增殖引起的应变硬化和异号位错之间的相互销毁与位错重排引起的回复软化之间达到动态平衡,后者主要包括螺型位错的交滑移和与扩散有关的刃型位错的攀移等动态回复过程,它们都是与时间和变形温度有关的现象。随着应变速率的增加,单位应变所需的时间缩短,位错产生、运动的数目增大,位错运动速度增加,位错间相互交割的几率也增大,平衡位错浓度增高,从而提高TC4钛合金变形时的临界切应力。同时,实现由动态回复等提供的软化时间及实现完全塑性变形的时间也缩短。这时,只有在更高变形温度下才可能提供足够大的软化速度及平衡因应变速率增加而引起的硬化速率增大。因此,随着应变速率的增加,相应以相同过渡变形量进入稳态变形阶段所需的变形温度也就升高。

综上所述,从降低变形抗力和提高合金可成形性能的角度来看,TC4钛合金比较适合于使用等温锻造工艺进行锻造。这是因为采用等温锻造工艺时,由于工件和模具处于相同温度,因而可以采用适当低的成形速度,此时变形过程中应变和应变速率硬化的作用较小,材料的塑性较好,从而能够较好地发挥TC4钛合金的成形性能。从流动应力的大小及其变化规律来考虑,当TC4钛合金在高应变速率锻造时,适宜的锻造温度范围较窄,而低应变速率锻造时,适宜的锻造温度范围可增宽。

3 流动应力模型

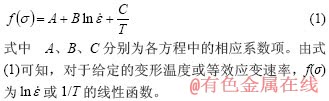

对Arrhenius型方程式两边取自然对数后,可表示为

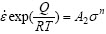

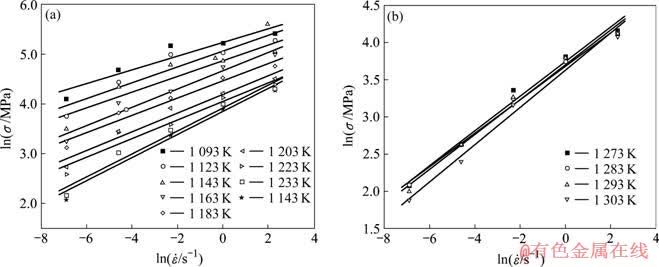

当ε = 0.6时,通过对实验数据作图,结果表明ln σ不仅与 和1/T呈线性关系,还与ln ε呈线性关系,它们的对应关系分别见图3~5。在其它应变条件下对实验数据作图,可获得类似的结果。由图3~5表明TC4钛合金适用于Arrhenius型方程中的幂函数方程(

和1/T呈线性关系,还与ln ε呈线性关系,它们的对应关系分别见图3~5。在其它应变条件下对实验数据作图,可获得类似的结果。由图3~5表明TC4钛合金适用于Arrhenius型方程中的幂函数方程( )构造其流动应力模型。

)构造其流动应力模型。

图3 对数应力与对数应变速率的关系

Fig.3 Variations of flow stress with strain rate (ε = 0.6): (a) Two phase fields; (b) Single phase field

图4 对数应力与温度倒数的关系

Fig.4 Variations of flow stress with deformation temperature (ε = 0.6): (a) Two phase fields; (b) Single phase field

图5 对数应力与对数应变的关系

Fig.5 Variations of flow stress with strain: (a) =1.0 /s; (b)

=1.0 /s; (b)  =0.01 /s

=0.01 /s

在高温条件下等效应变ε在塑性变形过程中也是一个不可忽略的路径变量。经过许多研究实验证实,累积塑性应变是决定材料显微组织演变的主要参数,在流动应力模型中显示塑性应变项极为有用。考虑变形程度对流动应力的影响,通常用以下公式来表示:

为了准确地描述TC4钛合金高温塑性变形时的变形行为,改进后的流动应力模型为[17]:

对式(6)进行多元回归分析,各系数的拟合结果见表2。

表2 式(6)中TC4钛合金的材料常数

Table 2 Constants of TC4 titanium alloy in Eqn. (6)

4 模型验证

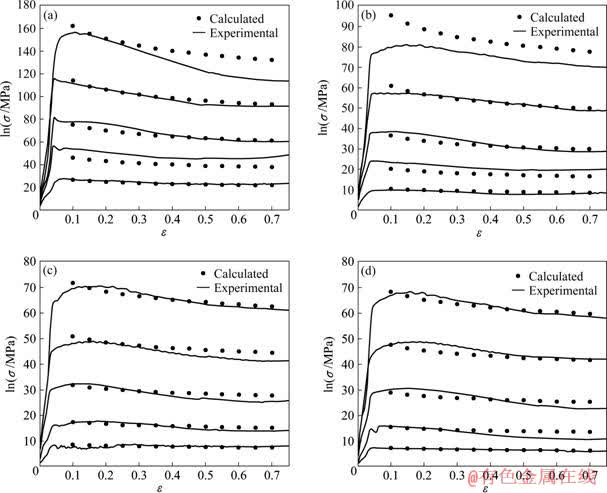

利用TC4钛合金在不同变形工艺参数条件下的流动应力数据对流动应力模型进行验证。

图6所示为所建立的流动应力模型的计算结果与实验数据的对比情况。由图6可以看出,上述方法确定的流动应力曲线能够达到满意的拟合精度。误差分析结果表明,流动应力模型的计算值与实验数据的平均相对误差为6.25%。因此本文所建立的TC4钛合金流动应力模型能够较好地描述TC4钛合金在高温变形过程中的流动行为。

图6 TC4钛合金流动应力模型的计算结果与实验数据的对照

Fig.6 Comparision of calculated with experimental flow stress of TC4 titanium alloy: (a) 1 183 K; (a) 1 243 K; (a) 1 283 K; (a) 1 303 K

5 结论

1) 以TC4钛合金的热模拟压缩实验结果为基础,获得了变形工艺参数(变形温度、变形程度、应变速率)对流动应力的影响规律。流动应力随应变的增加迅速增加,当应变超过一定值后,流动应力开始下降并逐渐趋于稳定,出现稳态流动特征;变形温度升高和应变速率减小使TC4钛合金高温变形时的稳态应力和峰值应力显著降低;应变速率和变形温度会影响TC4钛合金进入稳态变形时变形程度的大小。

2) 基于Arrhenius方程和Z-H参数,利用热模拟压缩实验数据,运用多元回归分析方法建立了TC4钛合金在高温变形过程中的流动应力模型。模型的预测精度较高,计算值与实验数据的平均相对误差为6.25%,该模型能够较好地描述TC4钛合金在高温变形过程中的流动行为。

REFERENCES

[1] SEMIATIN S L, SEETHARAMAN V, WEISS I. Flow behavior and globularization kinetics during hot working of Ti-6Al-4V with a colony alpha microstructure[J]. Mater Sci Eng A, 1999, 263(2): 257?271.

[2] MANERO J M, GIL F J, PLANELL J A. Deformation mechanisms of Ti-6Al-4V alloy with a martensitic microstructure subjected to oligocyclic fatigue[J]. Acta Mater, 2000, 48(13): 3353?3359.

[3] SESHACHARYULU T, MEDEIROS S C, FRAZIER W G, PRASAD Y V R K. Hot working of commercial Ti-6Al-4V with an equiaxed α-β microstructure: materials modeling considerations[J]. Mater Sci Eng A, 2000, 284(1/2): 184?194.

[4] BALASUBRAHMANYAM V V, PRASAD Y V R K. Deformation behaviour of beta titanium alloy Ti-10V-4.5Fe- 1.5Al in hot upset forging[J]. Mater Sci Eng A, 2002, 336(1/2): 150?158.

[5] MAJORELL A, SRIVATSA S, PICU R C. Mechanical behavior of Ti-6Al-4V at high and moderate temperatures- Part I: Experimental results [J]. Mater Sci Eng A, 2002, 326(2): 297?305.

[6] BRUSCHI S, POGGIO S, QUADRINI F, TATA M E. Workability of Ti-6Al-4V alloy at high temperatures and strain rates[J]. Mater Lett, 2004, 58(27/28): 3622?3629.

[7] BAO R Q, HUANG X, CAO C X. Deformation behavior and mechanisms of Ti-1023 alloy[J]. Trans Nonferrous Met Soc China, 2006, 16: 274?280.

[8] 潘雅琴, 杨昭苏. TC4钛合金热压变形行为的研究[J]. 稀有金属材料与工程, 1993, 22(5): 45?51.

PAN Ya-qin, YANG Zhao-su. Hot compressive deformation behavior of TC4 titanium alloy [J]. Rare Metal Materials and Engineering, 1993, 22(5): 45?51.

[9] 沙爱学, 李兴无, 王庆如, 鲍如强. 热变形温度对TC18钛合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2005, 15(8): 1167?1172.

SHA Ai-xue, LI Xing-wu, WANG Qing-ru, BAO Ru-qiang. Influence of hot deformation temperature on microstructure and mechanical properties of TC18 alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(8): 1167?1172.

[10] 李淼泉, 姚晓燕, 罗 皎, 林莺莺, 苏少博, 王海荣. 镍基高温合金GH4169高温变形流动应力模型研究[J]. 金属学报, 2007, 43(9): 937?942.

LI Miao-quan, YAO Xiao-yan, LUO Jiao, LIN Ying-ying, SU Shao-bo, WANG Hai-rong. Study of flow stress model of the nickel-based superalloy GH4169 at high temperature deformation[J]. Acta Metallurgica Sinica, 2007, 43(9): 937?942.

[11] SEO S, MIN O, YANG H. Constitutive equation for Ti-6Al-4V at high temperatures measured using the SHPB technique [J]. Int J Impact Eng, 2005, 31(6): 735?754.

[12] KIM J H, SEMIATIN S L, LEE C S. Constitutive analysis of the high-temperature deformation of Ti-6Al-4V with a transformed microstructure[J]. Acta Mater, 2003, 51(18): 5613?5626.

[13] KIM J H, SEMIATIN S L, LEE C S. Constitutive analysis of the high-temperature deformation mechanisms of Ti-6Al-4V and Ti-6.85Al-1.6V alloys [J]. Mater Sci Eng A, 2005, 394(1/2): 366?375.

[14] PICU R C, MAJORELL A. Mechanical behavior of Ti-6Al-4V at high and moderate temperatures-Part Ⅱ: constitutive modeling[J]. Mater Sci Eng A, 2002, 326(2): 306?316.

[15] 胡建平, 庄景云, 杜金辉, 邓 群, 冯 涤, 仲增墉. In718合金锤击锻造过程中的本构方程[J]. 金属学报, 2000, 36(9): 952?955.

HU Jian-ping, ZHUANG Jing-yun, DU Jin-hui, DENG Qun, FENG Di, ZHONG Zeng-yong. Constitutive equation of hammer forging for supperalloy In718 process[J]. Acta Metallurgica Sinica, 2000, 36(9): 952?955.

[16] 王 斌, 郭鸿镇, 姚泽坤, 陈金科, 李蓬川. 热压参数对TA15合金流动应力及显微组织的影响[J]. 锻压技术, 2006(6): 106?109.

WANG Bin, GUO Hong-zhen, YAO Ze-kun, CHEN Jin-ke, LI Peng-chuan. Influence of hot compression parameters on flow stress and microstructure of TA15 alloy[J]. Forging Stamping Technology, 2006(6): 106?109.

[17] LI M Q, PAN H S, LIN Y Y, LUO J. High temperature deformation behavior of near alpha Ti-5.6Al-4.8Sn-2.0Zr alloy[J]. J Mater Process Tech, 2007, 183(1): 71?76.

基金项目:国家自然科学基金资助项目(50475144);西北工业大学基础研究基金资助项目(NPU-FFR-006)

收稿日期:2007-11-21;修订日期:2008-03-31

通讯作者:李淼泉,教授,博士;E-mail: honeymli@nwpu.edu.cn

(编辑 陈爱华)