NiCrAlY涂层/TC4基体界面反应机理

夏长清, 李 佳, 古 一, 彭小敏, 武文花

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要: 采用电弧离子镀技术在TC4 (Ti6Al4V)合金基体表面沉积制备NiCrAlY涂层。通过扫描电镜与能谱分析、X射线衍射分析及显微硬度测试,研究真空热处理对NiCrAlY涂层组织性能的影响;分析界面反应产物的形成过程;讨论Cr元素在界面反应中的作用机制。研究结果表明:真空热处理后NiCrAlY涂层中有γ′-Ni3Al相析出,提高了涂层的表面硬度;在870 ℃以下热处理, NiCrAlY涂层/TC4基体界面反应产物的出现顺序依次为:相变影响区→Ni3(Al,Ti)和Ti2Ni化合物层→TiNi化合层;Cr元素在870 ℃以上开始扩散并参与界面反应,形成TiCr2化合物。

关键词: NiCrAlY涂层; TC4合金; 真空热处理; 界面反应; 显微组织

中图分类号:TB43 文献标识码:A 文章编号: 1672-7207(2005)04-0550-05

Interaction behavior between NiCrAlY coating and TC4 alloy substrate

XIA Chang-qing, LI Jia, GU Yi, PENG Xiao-min, WU Wen-hua

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: NiCrAlY coating was deposited on the TC4 (Ti6Al4V) substrate by arc ion plating. Scanning electron microscope and energy dispersive spectrometer, X-ray diffractometry, microhardness test were used to characterize microstructure and mechanical property of NiCrAlY coating after vacuum heat treatments. The formation of interfacial products and effect of Cr element on interaction between NiCrAlY coating and TC4 substrate were studied. The results show that γ′-Ni3Al phase is precipitated in the NiCrAlY coating after vacuum heat treatments, which can increase the microhardness of the coating. Below 870 ℃, affected zone→Ni3(Al,Ti) and Ti2Ni layers→TiNi layer appeared in turn at the interface between NiCrAlY coating and TC4 substrate. The diffusion of Cr occurs, and then Cr reacts with Ti to form TiCr2 when the vaccum heat treatment temperature is above 870 ℃.

Key words: NiCrAlY coating; TC4 alloy; vacuum heat treatment; interaction; microstructure

钛合金材料密度小,比强度高,耐蚀性强,中低温性能稳定,在航空航天领域得到广泛应用。但是,钛合金不耐烧蚀以及在高温环境下容易与氧结合形成脆性富氧层,严重影响了合金的使用性能[1]。为此,人们在提高钛合金的组织性能的同时,加强对钛合金耐冲刷、抗氧化涂层的研究[2-3]。

NiCrAlY涂层具有较高的强度与韧性,以及良好的抗高温氧化与抗热腐蚀性能,广泛应用于镍基高温合金表面防护[4,5],但是,在钛合金表面的应用还处于研究阶段[6-8]。存在的主要问题是:一方面,在高温氧化环境下涂层与基体的元素互扩散引起[CM(22] 界面附近的组织疏松;另一方面,涂层与基体发生强烈的界面反应,形成的脆性化合物界面层会降低涂层的结合强度。因此,有必要研究涂层/基体的界面反应行为以及元素的在界面反应中的作用机制。

1 试验方法

1.1 材料及涂层制备

选择TC4 (Ti6Al4V)合金轧制板材作为试验基材,试样被加工成尺寸为15 mm×10 mm×2.5 mm(长×宽×高)的小片。基体试样先在500号砂纸上磨光,去除表面氧化物,然后依次在碱液、蒸馏水中清洗,最后在丙酮溶液中超声波清洗,干燥后装于沉积设备中。

采用多弧离子镀技术在TC4合金基体表面沉积制备NiCrAlY涂层。沉积工艺为:先抽真空至压力为5×10-3 Pa;然后在沉积涂层前进行预溅射,轰击偏压为600~800 V,轰击电流为120~140 A,时间为5~10 min;在沉积涂层时加工作偏压为160~180 V,工作电流为120~140 A,沉积时间为120 min。

1.2 真空热处理

将已沉积NiCrAlY涂层的试样封于石英管中,抽真空至压力为1.33×10-2 Pa,并用Ar气保护。随后在箱式电阻炉中进行热处理,加热温度为600~950 ℃,保温时间为3~9 h。

1.3 检测分析

用扫描电镜观察NiCrAlY涂层/TC4合金基体的界面显微结构的演变过程。采用X射线衍射分析,元素线扫描和面扫描技术对涂层的相组成及界面元素的扩散规律进行研究。为了检验热处理对涂层的强化效果,测试显微硬度。

2 结果与讨论

2.1 真空热处理对NiCrAlY涂层组织性能的影响

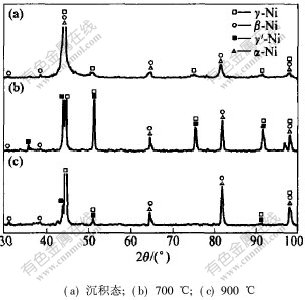

真空热处理后NiCrAlY涂层中的相组成将发生明显变化[9]。涂层的XRD衍射分析结果如图1所示。可以看出,沉积态NiCrAlY涂层主要由γ-Ni相、β-NiAl相 以及过饱和的α-Cr固溶体组成(见图1(a));试样在700 ℃真空保温3 h后,NiCrAlY涂层中有γ′-Ni3Al金属间化合物析出(见图1(b));随着热处理温度从700 ℃升高至900 ℃,涂层中γ′-Ni3Al相的衍射峰强度明显减弱,含量显著降低(见图1(c))。从NiCrAlY三元相图的等温截面可以发现:当温度由750 ℃升至850 ℃时,γ′相区呈减少趋势,并且当温度进一步升高时,γ相区显著增大。根据杠杆定律,可以得出γ′相含量呈减少趋势。这一点与实验结果完全吻合。

图 1 在不同温度下真空热处理后NiCrAlY涂层的XRD图谱

Fig. 1 XRD patterns of NiCrAlY coatings by vacuum heat treatment at different temperatures

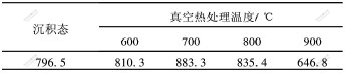

从Ni-Cr-Al合金中析出的γ′-Ni3Al相细小、弥散,并且与基体保持共格,能够强化合金基体[10]。经不同温度热处理后NiCrAlY涂层表面的显微硬度变化如表1所示。沉积态NiCrAlY涂层的显微硬度HV0.10为796.5,当热处理温度为600 ℃时,涂层的硬度的提高不是很明显;当温度提高到700 ℃时,硬度HV0.10达到最大值883.3;当热处理温度进一步升高时,硬度开始下降,当温度上升至900 ℃后,硬度显著下降到不足650[11],在700~750 ℃的温度范围内,即γ′-Ni3Al相脱离母相的温度区间,可以得到最好的沉淀硬化效果。当时效温度接近γ′-Ni3Al溶解界限时,沉淀过程会发生中断,沉淀相在原来的地方进行积聚;当温度超过固溶度时,还会引起沉淀相的重新溶解。

表 1 不同温度真空热处理对NiCrAlY涂层显微硬度HV0.10的影响

Table 1 Effect of temperatures on micro-hardness of NiCrAlY coating

2.2 涂层/基体界面产物的形成过程

真空热处理过后,由于NiCrAlY涂层/TC4基体界面元素的相互作用,将发生界面反应,形成一系列界面反应产物。在含Ni-Cr-Al-Ti的合金相图中包含多种金属间化合物相,但是实际的界面反应产物却不多。汪晓红等[11]研究了NiCrAlY/Ti60界面反应产物,结果表明:经870 ℃真空热处理后,涂层最外层主要包含NiAl,Ni3Al和Cr等原始涂层组织。首先出现的界面反应产物是Ni3(Al,Ti);随着向基体接近,依次出现TiNi,Ti2Ni,α-Ti以及微量的Ti3Al,整个界面区没有出现Ti-Cr中间化合物。

在870 ℃以下进行真空热处理,界面反应产物的形成过程如下:

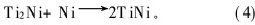

a. 在600 ℃进行真空热处理时,基体中近界面区受界面元素扩散的影响,组织发生明显变化,如图2所示。扩散到基体表层的Ni元素与基体元素作用形成少量的Ti2Ni和Ti3Al相,它是界面反应的孕育阶段。

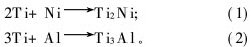

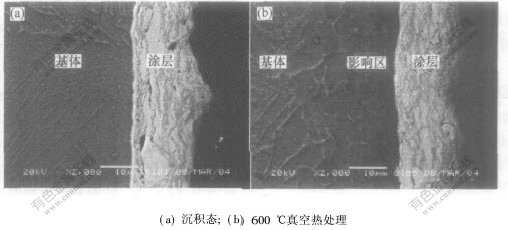

b. 在基体中近界面区Ti2Ni和Ti3Al相的形成,不断消耗扩散到界面的Ti元素,引起界面区Ti元素贫乏。随着扩散的继续进行,涂层中Ti元素含量逐渐增加,Ti元素向外扩散到达涂层后与涂层中的Ni和Ni3Al发生反应(1)和(2),形成Ti2Ni与Ni3(Al,Ti)相,如图3所示。Ni元素的线扫描结果(图3(a))显示涂层与基体界面区出现的2个平台分别与Ti2Ni与Ni3(Al,Ti)中间化合物层相对应。此外,在Ti2Ni化合物层内侧还出现向基体中生长的针状Ti2Ni。

c. 随着扩散温度的升高与时间的延长,涂层组分与Ti2Ni相继续反应,最后形成TiNi中间层,如图4(b)所示。在Ni3(Al,Ti)与Ti2Ni层之间出现齿状的TiNi化合物:

在870 ℃以下进行真空热处理,NiCrAlY涂层/TC4基体界面固相反应及界面结构演变过程见图4。

2.3 Cr元素在界面反应中的作用机制

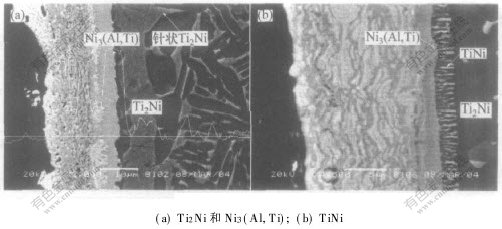

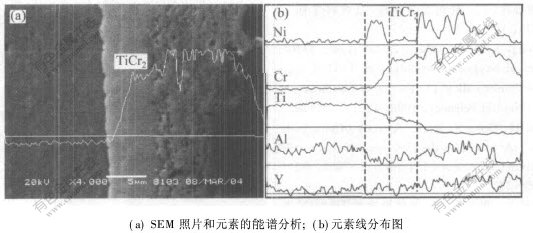

在870 ℃以下真空热处理界面区主要发生了Ti和Ni的扩散,Cr主要分布在原始界面外的涂层中并在涂层界面外侧聚集,如图5所示。界面区没有含Cr相,表明Cr没有参与界面反应。当温度上升[CM(22] 到870 ℃时,界面固相反应发生转变,Cr的扩散变

图 2 基体中界面附近相变影响区的形成

Fig. 2 Formation of affected zone in substrate near interface

图 3 NiCrAlY涂层/TC4基体界面反应产物的形成

Fig. 3 Formation of interaction products between NiCrAlY coating and TC4 substrate

图 4 温度低于870 ℃时NiCrAlY涂层/TC4基体界面固相反应示意图

Fig. 4 Sketch map of interfacial solid reaction between NiCrAlY coating and TC4 substrate below 870 ℃

图 5 700 ℃真空热处理后涂层形貌及元素面扫描分析

Fig. 5 SEM images and element planar distributions around interface after vacuum heat treatment at 700 ℃

图 6 在870 ℃真空热处理后的NiCrAlY涂层/TC4 基体界面TiCr2的形成

Fig. 6 Formation of TiCr2 at interface between NiCrAlY coating and TC4 substrate

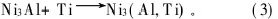

得明显,并开始参与界面反应,如图6所示。在靠近涂层一侧的界面反应层中出现了Cr与Ti含量的平台,而Ni含量相对较低。根据前面的能谱分析结果,由于Ni-Cr固溶体分解,大量Ni向界面扩散,而Cr在涂层底部聚集,为Cr的扩散提供了驱动力。当温度上升到870 ℃时,向外扩散的Ti与向内扩散的Cr在此处结合,反应形成新的中间化合物。根据Ti-Cr二元相图,Cr在Ti中的固溶度以及Ti在Cr中的固溶度都很低,并且Ti与Cr只能形成TiCr2型金属间化合物,由此可以推断在界面层靠近涂层一侧形成了以TiCr2为主要相的化合物层:

当温度继续升高至950 ℃时,界面反应变得更加剧烈和复杂。在高温条件下,界面反应显著加剧以及Ni元素的大量内迁,使得界面处Ni含量高的化合物被破坏,生成新的NiAlTi和Ni2AlTi型三元化合物,其Ni含量低于Ni3(Al,Ti)中的Ni含量[12]。

3 结 论

a. 在700 ℃以上真空热处理NiCrAlY涂层中会析出γ′-Ni3Al相,能提高涂层的表面硬度。

b. 在870 ℃以下界面产物的形成过程为:首先是基体中界面附近形成相变影响区,然后出现Ni3(Al,Ti)和Ti2Ni化合物层,最后在Ni3(Al,Ti)和Ti2Ni化合物层之间形成齿状TiNi化合物。

c. 当温度升高到870 ℃时,界面反应发生转变,Cr开始发生扩散并参与界面反应。向内扩散的Cr与向外扩散的Ti在界面处反应,生成新的TiCr2化合物。

参考文献:

[1]崔文芳, 罗国珍, 周廉. 氧在Ti-1100高温钛合金氧化中的扩散规律[J]. 东北大学学报(自然科学版), 1998, 19 (1): 19-22.

CUI Wen-fang, LUO Guo-zhen, ZHOU Lian. Diffusion kinetics of oxygen in oxidation of Ti-1100 high temperature titanium alloy[J]. Journal of Northeastern University (Natural Science), 1998, 19(1): 19-22.

[2]Zhou C, Xu H, Gong S, et al. A study of aluminide coatings on TiAl alloys by the pack cementation method [J]. Material Science and Engineering, 2003, A341 (1-2): 169-173.

[3]李秀燕, 范爱兰, 唐宾,等. 基体温度对Ti6Al4V表面渗Mo合金层性能的影响[J]. 中国有色金属学报, 2003, 13(2): 319-322.

LI Xiu-yan, FAN Ai-lan, TANG Bing, et al. Influence of Ti6Al4V base temperature on properties of molybdenum alloying layer[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 319-322.

[4]Zhang Y J, Sun X F, Guan H R, et al. 1050 ℃ isothermal oxidation behavior of detonation gun sprayed NiCrAlY coating[J]. Surface and Coatings Technology, 2002, 161(2-3): 302-305.

[5]Li M H, Zhang Z Y, Sun X F, et al. Oxidation of behavior of sputter-deposited NiCrAlY coating[J]. Surface and Coatings Technology, 2003, 165(3): 241-247.

[6]郝杉杉, 刘海平, 汪晓红, 等. 真空电弧镀沉积NiCrAlY涂层工艺[J]. 材料工程, 1999(2): 40-42.

HAO Shan-shan, LIU Hai-ping, WANG Xiao-hong, et al. Deposition of the NiCrAlY coating by vacuum arc ion plating[J]. Journal of Materials Engineering, 1999(2): 40-42.

[7]曾潮流, 吴维岁, 朱圣龙. 溅射NiCrAlY涂层对Ti3Al金属间化合物氧化性能的影响[J]. 航空材料学报, 1994, 14(4): 21-25.

ZENG Chao-liu, WU Wei-sui, ZHU Sheng-long. Effect of sputtered NiCrAlY coating on oxidation resistance of Ti3Al intermetallic compound[J]. Journal of Aeronautical Materials, 1994, 14(4): 21-25.

[8]Tang Z, Wang F, Wu W. Effect of MCrAlY overlay coatings on oxidation resistance of TiAl intermetallics[J]. Surface and Coatings Technology, 1998, 99(3): 248-252.

[9]王冰, 宫骏, 汪爱英, 等. IC-6高温合金及其防护性涂层的摩擦特性[J]. 金属学报, 2002, 38(7): 750-754.

WANG Bing, GONG Jun, WANG Ai-ying, et al. Tribological behaviors of superalloy IC-6 and its protective coating[J]. Acta Metallurgica Sinica, 2002, 38(7): 750-754.

[10]刘桂兰, 邹宇超. 回火温度对Ni-Cr-Al硬弹性合金组织和性能的影响[J]. 东北大学学报(自然科学版), 1994, 15(4): 399-402.

LIU Gui-lan, ZOU Yu-chao. Effect of tempering temperature on structures and properties of Ni-Cr-Al hard elastic alloys[J]. Journal of Northeastern University (Natural Science), 1994, 15(4): 399-402.

[11]汪晓红, 刘海平, 郝杉杉, 等. Ti3Al基体/NiCrAlY涂层体系界面固态反应行为研究[J]. 航空材料学报, 1997, 17(4): 8-14.

WANG Xiao-hong, LIU Hai-ping, HAO Shan-shan, et al. Study of the interfacial solid reaction between the Ti3Al substrate and the NiCrAlY coatings[J]. Journal of Aeronautical Materials, 1997, 17(4): 8-14.

[12]Liu H, Hao S, Wang X, et al. Interaction of a near α type titanium alloy with NiCrAlY protective coating at high temperatures[J]. Scripta Materialia, 1998, 39(10): 1443-1450.

收稿日期:2004-10-18

基金项目:国防预先研究项目(MKPT0489)

作者简介:夏长清(1945-),男,湖南益阳人,教授,从事材料表面与涂层技术研究

论文联系人: 夏长清,男,教授;电话:0731-8830267(O); E-mail: xia-gro@mail.csu.edu.cn