文章编号:1004-0609(2016)-09-2015-08

TiO2-FeO-(SiO2,CaO,MgO)三元渣系的流变特性

李生平1,吕学伟1,宋 兵2,缪辉俊2,韩可喜2

(1. 重庆大学 材料科学与工程学院,重庆 400044;

2. 攀钢集团研究院有限公司,攀枝花 617000)

摘 要:利用内圆柱体旋转法测试TiO2-FeO-SiO2、TiO2-FeO-CaO和TiO2-FeO-MgO三元高钛渣体系的黏度和熔化性温度的变化规律,并结合XRD及激光拉曼光谱对高钛渣结构进行初步的表征。结果表明:SiO2含量增加会提高三元钛渣黏度及熔化性温度,恶化熔渣流动性。CaO和MgO含量增加会降低钛渣黏度及熔化性温度,改善熔渣流动性;钛渣完全熔化后,黏度约为70~100 mPa·s,继续升高温度对钛渣黏度无显著影响。经XRD和Raman光谱分析可知:钛渣凝固后TiO2以金红石形式存在。SiO2、MgO和CaO的添加对TiO2-FeO二元钛渣拉曼特征峰影响不大,但均能使特征峰发生红移;Ca2+和Mg2+以网格修饰子形式进入钛氧八面体,形成CaTiO3和MgTi2O5。

关键词:高钛渣;黏度;拉曼光谱;结构表征

中图分类号:TF803.3 文献标志码:A

随着天然金红石资源的减少,采用钛铁矿生产高钛渣已成为钛工业的主要发展趋势。电炉冶炼钛铁矿是目前制备高钛渣的主流工艺[1-2]。电炉冶炼工艺的核心是后期的渣铁分离,决定着钛渣的冶炼成本、品位,而决定渣铁分离的关键因素是渣相在高温下的流变特性。

国内外对于高钛渣黏度的研究较少, 所能见到公开发表的文献主要包括前苏联科学院工作者[1]测量不同TiO2、Ti2O3、FeO、MgO含量下的高钛渣黏度。研究发现,一旦高钛渣完全熔化后,其表观黏度均为100~300 mPa·s,同时Ti2O3、Al2O3和MgO的添加会增加渣相的体相黏度,FeO、Cr2O3、MnO和CaO的添加可降低钛渣的黏度,但其测试准确度受到后来很多学者质疑,一方面可能是受黏度计的精确度限制,很难测量黏度值低于100 mPa·s的渣;另一方面,炉渣高温下保温时间只有15~20 min,因此,其测试结果的准确性受到质疑。TUSET等[3]报道了其对TiO2-Ti2O3-MgTiO3三元体系下的54种渣样的黏度实验,得出结论:无论化学成分如何变化,炉渣完全融化后,黏度均为50~100 mPa·s,即使温度继续升高,黏度也不受影响。遗憾的是TUSET等[3]并未给出详细的黏度数据及炉渣的粘温曲线。HANDFIELD等[4]研究工业高钛渣的黏度,研究发现钛渣完全熔化后,黏度约为30 mPa·s,继续升温,其黏度无明显变化,但仅报道了FeO(15%)和FeO(3.3%)(质量分数)两种钛渣,更详细的数据没有公开。高国强等[5]研究化学组分及温度对钛渣的黏度和熔点的影响。研究发现当钛渣中TiO2的还原度为0.2~0.3时,黏度最低,一定量的Ti2O3有利于钛渣的冶炼;还原度高(>0.45)则会增加钛渣的黏度和熔点。赵志军等[6-7]研究Al2O3和FeO对钛渣生产的影响,研究发现保持一定的FeO浓度以及控制Al2O3浓度对于正常冶炼非常重要。无论是合成渣还是工业高钛渣,均具有明显短渣的特点,在熔化性温度以上,黏度很低,在接近熔化性温度附近时,黏度突然变大,有少量结晶固体析出悬浮在熔体中,使熔体变得粘稠。

TURKDOGAN[8]指出钛渣中的TiO2主要是八面体结构形式排列。钛渣中的四价钛离子的酸性并未表现出比氧化铝强比二氧化硅的弱,高炉渣中添加适量的TiO2可以降低炉渣的黏度。液态熔渣中的TiO2和SiO2因固态时的结构差异性所表现出的性质有很大差异。TOROMANOFF等[9]和TOGURI[10]研究了索雷尔渣中主要物相——镁钛矿(FeO·MgO·4TiO2)对其钛渣性质的影响规律。渣中二氧化钛主要以6配位八面体结构,二氧化钛的熔点也较低价钛氧化物的熔点低,低价钛含量增加可改变钛渣的物理性质。

现有的大型电炉冶炼工艺渣铁分离效率低、冶炼过程能耗偏高,使得钛渣的生产成本较高。攀枝花地区钛精矿生产得到的钛渣,氧化钙和氧化镁含量 高[11-12]。关于这类钛渣的高温流变特性及熔体结构数据的报道缺乏。本文作者旨在研究高钙镁硅型钛渣的黏度,并结合高温下熔体的结构揭示其流变行为,以丰富高钛渣的黏度基础数据,为提高渣铁分离效率提供依据。

1 实验

1.1 实验原料及制备

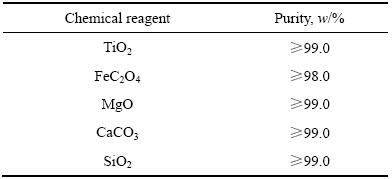

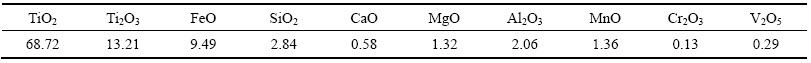

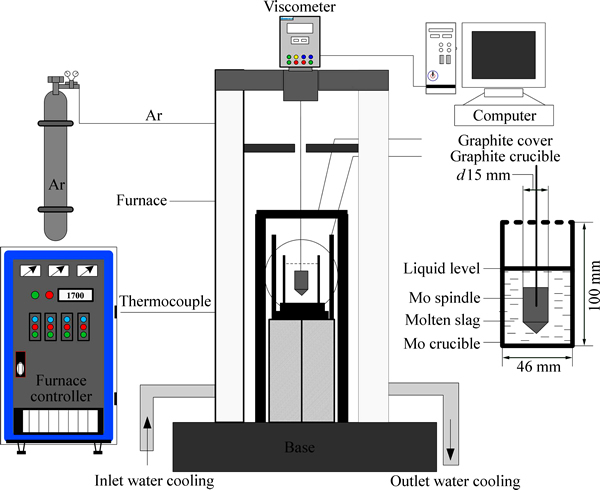

基于攀钢85钛渣化学成分用合成法制备三元高钛渣试样,试剂均为分析纯,如表1所列。其中FeO与CaO分别由草酸亚铁及碳酸钙在隔绝空气条件下分解得到。渣中的Ti2O3全部换算为TiO2。实验前后钛渣的化学成分及变化如表2所列,是由XRF分析所得。

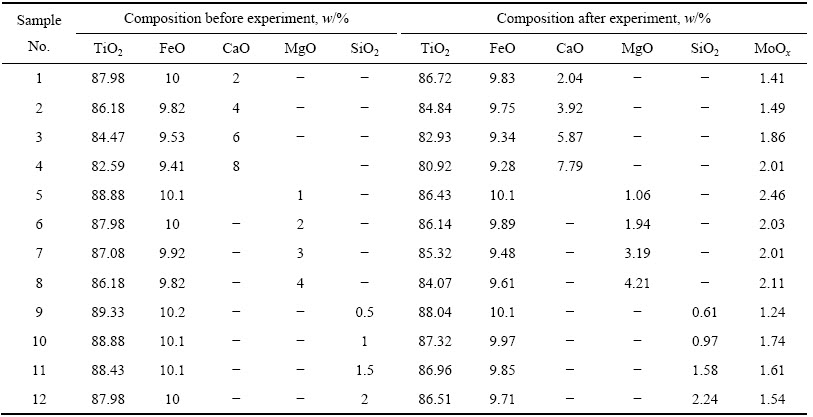

1.2 实验设备及方法

本实验使用内圆柱体旋转测试法[13-15]。所用的主要设备为高温黏度测试仪,其装置如图1所示。实验所用测头和坩埚均为钼制。黏度测试前,先在室温下用标准硅油校准(Brookfield DV-Ⅱ+)仪器,将经真空电弧炉充分预熔后的渣样放入钼坩埚并置于黏度炉中,通过抽高真空结合通高纯氩气如此反复洗炉3次以严格控制气氛保护FeO,后经一定升温速率升至1700 ℃以上。当炉温达到实验温度后保温60 min,精确控制温度在±1 ℃。实验设定转速为24 r/min,采用降温法定点测试黏度。对黏度测试后的高钛渣进行XRF及XRD分析处理,并运用拉曼光谱对通过高温熔化并经Ga-In-Sn合金快速凝固后的高钛渣进行结构表征。

表1 实验所用化学试剂

Table 1 Chemical reagent in present experiment

表2 攀钢现场85渣的化学成分

Table 2 Main chemical composition of Panzhihua 85 slag (mass fraction, %)

表3 实验前后钛渣的化学成分

Table 3 Chemical composition of titanium slag before and after experiment

图1 高温黏度测试设备

Fig. 1 Experimental apparatus for viscosity measurement

2 结果与讨论

2.1 TiO2-FeO-SiO2渣系黏度

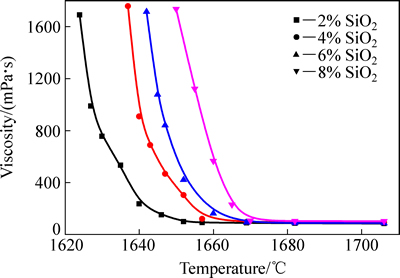

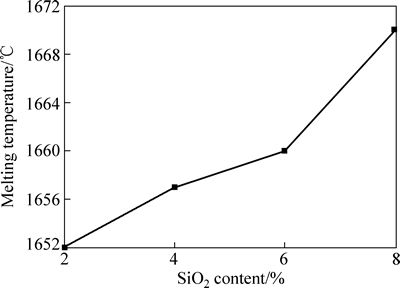

SiO2对TiO2-FeO-SiO2三元钛渣黏度影响规律如图2所示。由图2可知,随着SiO2含量从2%增至8%,其黏度随温度变化趋势基本相似,每条曲线上均有一个明显转折点,其转折点对应温度如图3所示,每增加2% SiO2,钛渣转折温度增加近10 ℃。当温度在转折点温度附近时,随温度降低,黏度从200 mP·s增至1800 mPa·s,急剧增加,结晶区间变窄,而温度仅降低15~20 ℃。当高于转折点温度,黏度随温度升高无显著变化。因此,用此转折点处温度表示钛渣的熔化性温度。

图2 TiO2-FeO-SiO2三元渣系黏温曲线

Fig. 2 Viscosity-temperature curves of ternary slag TiO2-FeO-SiO2

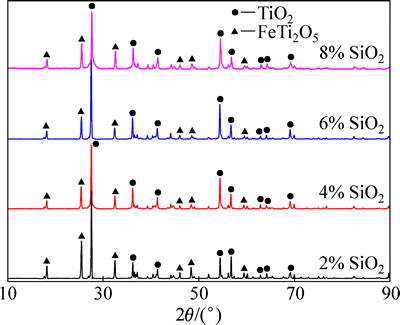

三元钛渣TiO2-FeO-SiO2经黏度测试后的XRD衍射图谱如图4所示。比较图4中不同SiO2添加量所得XRD衍射峰可知,主要物相是金红石(TiO2)和假板钛矿(FeTi2O5)。图中并未发现含硅物相,但在理论物象计算中发现有含硅物象存在,这是由于SiO2在1000 ℃时发生晶型转变,由白色六方晶系磷石英转变为白色四方晶系方石英。由于方石英具有完全化学惰性和中性酸碱值,在有触媒或多成分化学系统中,都不会发生化学变化或诱导化学反应发生,即使在高温或恶劣环境中也不会发生裂解变质,导致钛渣中SiO2物相含量从1000 ℃到1400 ℃未发生变化;温度高于 1400 ℃,SiO2开始进入渣相。

2.2 TiO2-FeO-CaO三元渣系黏度

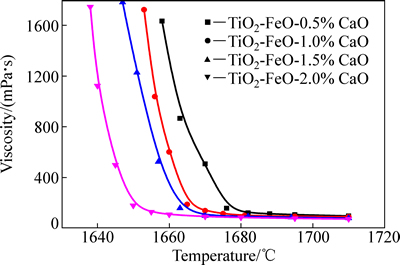

三元钛渣TiO2-FeO-CaO黏温曲线如图5所示。由图5可知,当完全熔化后黏度值均小于100 mPa·s。

图3 熔化性温度随SiO2含量的变化曲线

Fig. 3 Change curve of melt-property temperature with SiO2 content

图4 TiO2-FeO-SiO2黏度测试后物相分析

Fig. 4 XRD patterns of TiO2-FeO-SiO2 ternary titania slag

图5 TiO2-FeO-CaO三元渣系黏温曲线

Fig. 5 Viscosity-temperature curves of ternary TiO2-FeO- CaO slag

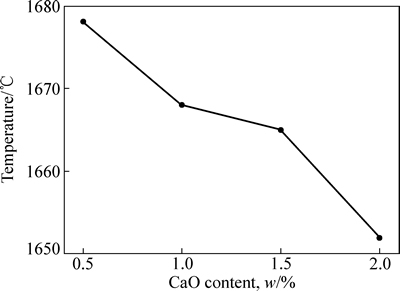

其黏度-温度曲线上均有明显的转折点,高于转折点时,随温度升高,黏度基本不变,低于转折点时,随温度降低,黏度急剧增加,具有明显短渣的特点[16]。这是由于TiO2-FeO-CaO钛渣在熔化性温度处有少量结晶性强的固体析出悬浮在熔体中,使熔体变得黏稠,引起黏度急剧变化。进一步分析还可看出,随CaO含量的增加,黏度-温度曲线变陡,结晶区间变窄,这表明随CaO增加,炉渣碱性增加,所表现出的短渣特性也越明显。在相同温度下,钛渣黏度随CaO含量的增加而降低,表明CaO可降低本渣系黏度。

三元钛渣TiO2-FeO-CaO熔化性温度随CaO含量变化的关系如图6所示。由图6可知,TiO2-FeO-CaO三元钛渣的熔化性温度分别为1678、1668、1665和1652 ℃,其降低的相对温度分别为10、13和26 ℃,这表明CaO能显著降低高钛渣体系熔化性温度。

图6 熔化性温度随CaO含量变化曲线

Fig. 6 Change curve of melt-property temperature with CaO content

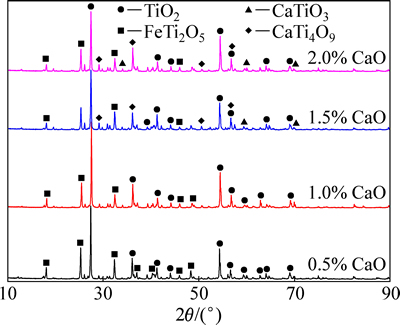

图7 三元钛渣黏度测试后的物相分析

Fig. 7 XRD patterns of ternary titania slag system of TiO2-FeO-CaO

三元钛渣TiO2-FeO-CaO经黏度测试后的XRD衍射图谱如图7所示。由图7可知,不同CaO添加量的XRD衍射峰类似,主要物相是金红石(TiO2)和假板钛矿(FeTi2O5)。0.5%和1.0%CaO的衍射谱中仅发现了FeTi2O5和TiO2两相,但随着CaO含量增至1.5%时,在29°处出现CaTi4O9相,当CaO含量为2%时,在34°处出现CaTiO3新相,与Factsage理论计算结果一致。这是由于随渣中CaO含量增加,与渣中的TiO2结合力增加,渣中的CaTiO3随之增加,CaTiO3在1450 ℃就基本全部转化为渣相了。渣中的TiO2相也随温度升高而逐渐减少进入渣相,且随CaO的含量增加,在相同温度下含量减少,渣相含量增加。

2.3 TiO2-FeO-MgO三元渣系黏度

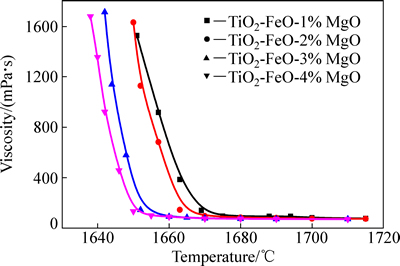

TiO2-FeO-MgO三元渣系黏温曲线如图8所示。由图8可知,三元钛渣一旦完全熔化后均有较低黏度,其黏度值小于80 mPa·s。黏温曲线上均有明显转折点,温度高于转折点时,黏度基本不变,温度低于转折点时,黏度急剧增加,也具有明显短渣的特点。这是由于在降温过程中有高熔点物质偏钛酸镁(MgTiO3)结晶析出,增加体系的黏度。随MgO含量的增加,黏度降低,所测得的黏温曲线变陡,结晶区间变窄,表明MgO增加炉渣碱性。当渣完全熔化后,继续升高温度对渣系的黏度无显著影响。

图8 TiO2-FeO-MgO三元渣系黏温曲线

Fig. 8 Viscosity-temperature curves of ternary slag TiO2-FeO-MgO

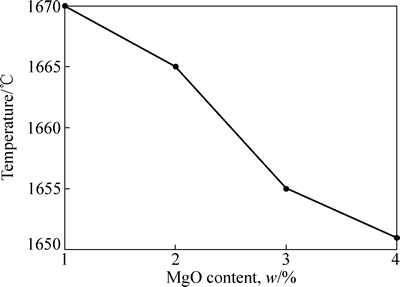

图9所示为熔化性温度随MgO含量的变化。由图9进一步分析可知,随MgO含量从1%增至4%,三元钛渣TiO2-FeO-MgO的转折点温度从1678 ℃降低至1652 ℃,因此,MgO可降低该渣系转折点温度,且降低的相对温度分别为5、15和19 ℃。然而文献[17]中指出钛渣的黏度随MgO的增加而增大,这可能是由于在文献的研究过程中,当温度达到实验温度时仅保温15~20 min,这就使得黏度测试是在部分结晶并非完全熔融态下进行,因此其黏度结果饱受争议。本研究的钛渣体系中,MgO对钛渣黏度的影响规律与高国强等[5]和赵志军等[6]的研究结果基本符合。

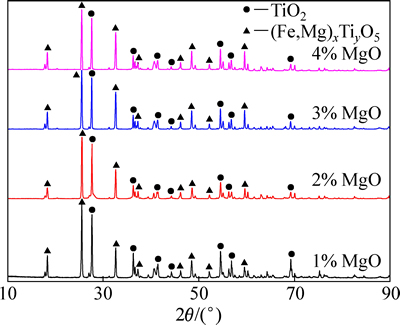

黏度测试后TiO2-FeO-MgO三元钛渣的XRD衍射图谱如图10所示。由图10可知,不同MgO添加量的XRD衍射峰类似,主要物相是金红石(TiO2)和铁镁板钛矿((Fe Mg)xTiyO5)。通过理论计算,随着MgO含量增加,与渣中TiO2可生成偏钛酸镁(MgTiO3),其熔点为1630 ℃,相对钛渣其熔点有所降低。

图9 熔化性温度随MgO含量变化

Fig. 9 Change of melt-property temperature with MgO content

图10 TiO2-FeO-MgO黏度测试后物相分析

Fig. 10 XRD patterns of TiO2-FeO-MgO ternary titania slag

通过比较CaO和MgO对三元钛渣黏度的影响,由此可以看出,MgO降低三元钛渣熔化性温度没有CaO明显。相对TiO2-FeO-MgO和TiO2-FeO-CaO三元钛渣,TiO2-FeO-SiO2三元钛渣黏温曲线在转折点附近斜率变化稍缓,这可能是随SiO2量增加,渣中硅酸盐结构增加,硅酸盐结构中Si4+之间没有键直接相连,而是通过O2-连接起来形成以硅氧四面体结构为基础。

3 结构表征

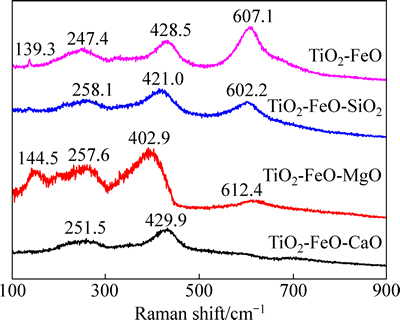

高钛渣结晶迅速,随着温度的降低,很快在液体渣中析出一系列高结晶性能的高温矿物,如钙钛矿、尖晶石、钛酸镁,并且这些矿物结晶温度都很高。本文作者采用法国HORIBA Scientific拉曼仪器—HR Evolution, 对二元及三元高钛渣进行全波长范围微观测试分析,其拉曼光谱如图11所示。

图11 二元及三元钛渣拉曼光谱

Fig. 11 Raman spectra of binary and ternary titania slag system

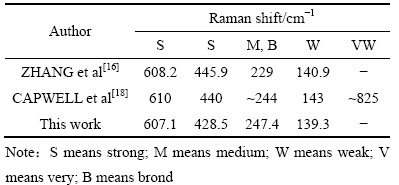

由图11可知,TiO2-FeO二元钛渣样品的Raman光谱包括了607.1 cm-1处最强峰,位于428.5 cm-1处次强度峰以及位于247.4 cm-1和139.3 cm-1处中等强度峰。其拉曼光谱与CAPWELL等[18]研究金红石型TiO2拉曼光谱基本一致,如表4所列。而TiO2-FeO二元钛渣中TiO2含量达到85%,可见TiO2-FeO二元钛渣结构主要以金红石型结构为主,但因受到FeO影响,其峰有发生红移现象。

表4 不同研究者对于金红石型TiO2的拉曼光谱的研究结果对比

Table 4 Comparison with other results on Raman spectrum of rutile

图11中TiO2-FeO-SiO2三元钛渣显示出3个Raman活性模式,分别为258.1 cm-1、421.0 cm-1和602.2 cm-1,硅酸盐玻璃体拉曼波段主要在800~1100 cm-1内,对应着Si—O拉伸振动,本研究中TiO2-FeO-SiO2三元钛渣拉曼光谱在800~1100 cm-1区间并未发现有特征峰,其原因是高炉渣中硅含量达到40%,而钛渣中硅含量才6%左右,硅氧四面体聚合程度不明显,不是熔渣中主要的黏滞留动单元。MCMILLAN[19]研究表明,在硅酸盐拉曼图谱中,图谱中430 cm-1处Si与Si连接方式只有通过桥氧。而比较TiO2-FeO二元钛渣拉曼光谱,特征峰出现在421 cm-1处,表明硅氧化物的添加会使TiO2峰发生红移,并且特征峰在139.3 cm-1处消失。

图11中TiO2-FeO-MgO三元钛渣显示4个Raman活性模式,分别为144.5 cm-1、257.6 cm-1和402.9 cm-1和612.4 cm-1。257.6 cm-1处峰是由于Ti原子沿Z轴振动所导致,402.9 cm-1处是由于Ti—O—Mg弯曲振动所得,而607.1 cm-1处峰明显消失,这可能是渣中MgO与TiO2固熔生成MgTi2O5相,Mg2+以网格修饰子(网格破坏者)形式进入钛氧八面体,部分[TiO6]进入MgTi2O5晶格[20]。而MgTi2O5熔点比TiO2和Ti2O3低,这也是MgO降低钛渣转折点温度原因。612.4 cm-1峰处是由于Ti-O-Ti对称伸缩振动所导致[21]。

图11中TiO2-FeO-CaO三元钛渣拉曼光谱仅能观测到251.5 cm-1和429.9 cm-1两个特征峰,且这两个峰与TiO2-FeO二元钛渣在此处特征峰相匹配,251.5 cm-1处对应于O—Ti—O扭曲振动。在429.9 cm-1附近高频模主要是钛氧八面体顶端氧原子在相对振动[22]。CaO的加入,使其在139.3 cm-1和607.1 cm-1处的特征峰消失。TiO2-FeO-CaO三元渣中虽然只加入2%CaO,却表明CaO对于其渣系结构有较大影响,XRD结果也表明渣中产生高结晶性能CaTiO3新物相,使渣结构发生改变。

4 结论

1) 三元钛渣一旦完全熔化后,均具有较低的黏度,约为70~100 mPa·s,继续升温,黏度基本保持不变。在转折点附近,结晶区间窄,随温度降低,黏度急剧增加,具有明显短渣特性,属于碱性渣。

2) CaO和MgO均能降低所研究体系中三元钛渣的黏度和转折点温度,且CaO比MgO更明显,而SiO2增加体系黏度和转折点温度。

3) 钛渣主要成分是TiO2,经XRD和Raman分析可知,高钛渣中TiO2为金红石型,钛渣结构与金红石型TiO2结构相似,由相互连接TiO2八面体构成,晶格中心为Ti原子,八面体棱角上为6个氧原子。

4) SiO2对于钛渣拉曼特征峰影响不大,但能使特征峰发生红移;Ca2+和Mg2+以网格修饰子(网格破坏者)形式进入钛氧八面体,形成高结晶性能矿物CaTiO3和MgTi2O5。

REFERENCES

[1] 胡克俊, 锡 淦, 姚 娟, 席 歆. 国内钛渣科研及生产现状[J]. 稀有金属快报, 2007, 26(3): 7-15.

HU Ke-jun, XI Gan, YAO Juan, XI Xin. Domestic research and production status of titanium slag[J]. Journal of Rare Metal, 2007, 26(3): 7-15.

[2] SONG Bing, ZHANG Kai, XI Fei, L Xue-wei. Carbothermic reduction of ilmenite concentrate with coke assisted by high energy ball milling[C]//TMS, 2014.

Xue-wei. Carbothermic reduction of ilmenite concentrate with coke assisted by high energy ball milling[C]//TMS, 2014.

[3] TUSET J, TIDSSKR K, BERGV K. High-temperature phase relations and thermodynamics in the iron-titanium-oxygen system[J]. Metallurgical & Materials Transactions B, 1999, 30(4): 695-705.

[4] HANDFIELD G, CHARETTE G G. Viscosity and structure of industrial high TiO2 slags[J]. Canadian Metallurgical Quarterly, 1971, 10(3): 235-243.

[5] 高国强, 杨玉成, 杨大贤. 钛渣黏度和熔点的测定[J]. 钢铁钒钛, 1987, 1(9): 50-56.

GAO Guo-qiang, YANG Yu-cheng, YANG Da-xian. Viscosity and melting point determination of titanium slag[J]. Iron Steel Vanadium Titanium, 1987, 1(9): 50-56.

[6] 赵志军, 马恩泉, 连玉锦. Al2O3在钛渣中的行为[J]. 钢铁钒钛, 2002, 23(3): 36-38.

ZHAO Zhi-jun, MA En-quan, LIAN Yu-jin. Behavior of Al2O3 in titanium slag[J]. Iron Steel Vanadium Titanium, 2002, 23(3): 36-38.

[7] 赵志军. FeO在高钛渣冶炼过程中的行为和影响[J]. 钒钛, 1996(3): 21-23.

ZHAO Zhi-jun. Behavior and effect of FeO during the smelting processing of high titanium slag[J]. Vanadium and Titanium, 1996(3): 21-23.

[8] TURKDOGAN E T. Physicochemical properties of molten slags and glasses[M]. London: Metals Society, 1983.

[9] TOROMANOFF I, FATHI H. The composition of a titanium slag from sorel[J]. Journal of the Less Common Metals, 1984, 97 (3): 317-329.

[10] TOGURI J M. Annual volume featuring hydrogen in metals and titanium[M]. Canadian: Canadian Institute of Mining and Metallurgy, 1978.

[11] 董海刚, 郭宇峰, 姜 涛, 陈家林, 范兴祥. 高钙镁型钛渣物相重构法制取人造金红石[J]. 中国有色金属学报, 2012, 22(9): 2642-2647.

DONG Hai-gang, GUO Yu-feng, JIANG Tao, CHEN Jia-lin, FAN Xing-xiang. Production of synthetic rutile from high CaO and MgO type titanium slag by mineral phase reconstruction process[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2642-2647.

[12] 蒋 伟, 蒋训雄, 汪胜东, 范艳青, 刘 巍. 高钛渣制备人造金红石工艺研究[J]. 有色金属(冶炼部分), 2012, 7(3): 22-25.

JIANG Wei, JIANG Xun-xiong, WANG Sheng-dong, FAN Yan-qing, LIU Wei. Preparation of synthetic rutile by high titanium slag[J]. Nonferrous Metals (Extractive Metallurgy), 2012, 7(3): 22-25.

[13] 吴德志, 徐东亮, 吴耀楚. 黏度测定原理与应用[J]. 中国仪器仪表, 2002, 6: 41-43.

WU De-zhi, XU Dong-liang, WU Yao-chu. Principles and applications of viscosity measurement[J]. Instrument of China, 2002, 6: 41-43.

[14] 陈惠钊. 黏度测量[M]. 北京: 中国计量出版社, 2003.

CHEN Hui-zhao. Viscosity determination[M]. Beijing: China Metrology Press, 2003.

[15] 杜忠选, 胡亚非, 张始斋. 黏度测量原理与方法[J]. 煤矿机械, 2006, 27(6): 1071-1072.

DU Zhong-xuan, HU Ya-fei, ZHANG Shi-zhai. Principles and methods of viscosity measurement[J]. Coal and Mine Machinery, 2006, 27(6): 1071-1072.

[16] 张 力, 李光强, 娄太平, 隋智通. 高钛渣中钛组分的选择性富集与长大[J]. 金属学报, 2002, 38(4): 400-402.

ZHANG Li, LI Guang-qiang, LOU Tai-ping, SUI Zhi-tong. Selective enrichment and growth of Ti component in high titanium slag[J]. Acta Metallurgica Sinica, 2002, 38(4): 400-402.

[17] REZNICHENKO V A. The metallurgy of titanium: Investigation of electric melting of titanium slags[R]. U.S. Department Commerce, 1963.

[18] CAPWELL R J, SPAGNOLO F, DESESA M A. A rapid determination of low concentrations of anatase in rutile TiO2 pigments by Raman spectroscopy[J]. Applied Spectroscopy, 1972, 26(5): 537-539.

[19] MCMILLAN P. Structural studies of silicate glasses and melts. applications and limitations of Raman spectroscopy[J]. American Mineralogist, 1984, 69(7): 622-644.

[20] EAV F, SCZANCOSKI J C, CAVALCANTE L S, PARIS E C, ESPINOSA J W M. Photoluminescence behavior in MgTiO3 powders with vacancy distorted clusters and octahedral tilting[J]. Materials Chemistry and Physics, 2009, 117(1): 192-198.

[21] 王丽红, 尤静林, 王媛媛, 郑少波, 西 蒙. 六方晶型MgTiO3 温致微结构变化及其原位拉曼光谱研究[J]. 物理学报, 2011, 60(10): 319-325.

WANG Li-hong, YOU Jing-lin, WANG Yuan-yuan, ZHENG Shao-bo, XI Meng. Temperature dependent Raman spectra and micro-structure study of hexagonal MgTiO3 crystal[J]. Journal of Physics, 2011, 60(10): 319-325.

[22] 陈春燕. 层状钙钛矿多铁改性研究[D]. 扬州: 扬州大学, 2013.

CHEN Chun-yan. Research on the modification of layered perovskite[D]. Yangzhou: Yangzhou University, 2013.

Rheological property of TiO2-FeO-(SiO2,CaO,MgO) ternary slag

LI Sheng-ping1, L Xue-wei1, SONG Bing2, MIAO Hui-jun2, HAN Ke-xi2

Xue-wei1, SONG Bing2, MIAO Hui-jun2, HAN Ke-xi2

(1. School of Materials Science and Engineering, Chongqing University, Chongqing 400044, China.

2. Panzhihua Iron and Steel Research Institute, Panzhihua 617000, China)

Abstract: The viscosity and the melt-property temperature of TiO2-FeO-SiO2, TiO2-FeO-CaO and TiO2-FeO-MgO ternary slag were measured by the cylinder rotation method. The XRD and Raman spectroscope method were used for structural characterization. The results show that SiO2 increases the viscosity and melt-property temperature of slag and worsens the slag fluidity, while CaO and MgO decrease the viscosity and melt-property temperature of slag, and improve the slag fluidity. Once the slag is completely molted, the viscosity is around 70-100 mPa·s, and continuing raising temperature will have no significant effect on viscosity. TiO2 in the solidified slag is in formation of crystal type according to analysis of XRD and Raman spectroscope. The addition of CaO, MgO, SiO2 only has a little influence on TiO2-FeO binary Raman characteristic lines, but all these influence can lead red shift. Ca2+ and Mg2+, as network modifier, enter into the titanium oxide octahedron as a result of forming CaTiO3 and MgTi2O5.

Key words: high titania slag; viscosity; Roman spectra; structural characterization

Foundation item: Project (51374262) supported by the National Natural Science Foundation of China

Received date: 2015-08-25; Accepted date: 2016-01-14

Corresponding author: L Xue-wei; Tel: +86-13658335559; E-mail: lvxuewei@cqu.edu.cn

Xue-wei; Tel: +86-13658335559; E-mail: lvxuewei@cqu.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51374262)

收稿日期:2015-08-25;修订日期:2016-01-14

通信作者:吕学伟,教授,博士;电话:13658335559;E-mail:lvxuewei@cqu.edu.cn