文章编号:1004-0609(2011)11-2863-06

高钛渣制备TiN/β′-Sialon 复相导电陶瓷及其性能

姜 涛, 薛向欣, 李 江, 段培宁

(东北大学 材料与冶金学院,沈阳 110819)

摘 要:以高钛渣合成出的TiN/β′-Sialon 粉体作为原料,常压烧结制备了TiN/β′-Sialon 复相导电陶瓷。利用X 射线衍射仪和扫描电镜对材料相组成和显微结构进行了表征分析,研究了材料的致密化行为、力学性能及常温导电性能。结果表明:烧结产物主晶相为β′-Sialon和TiN。其中β′-Sialon多呈板条状,TiN 为细小粒状,粒度多小于0.5 μm。烧结温度为1 530 ℃、初始原料中TiO2 加入量为35%(质量分数)时,材料的体积密度为3.01 g/cm3,硬度为9.62 GPa,抗弯强度为120.07 MPa。30%TiO2 加入量是决定材料能否形成TiN导电网络的最低TiO2加入量,此时材料的电阻率为1.3×10-2Ω·cm。

关键词:高钛渣;TiN/β′-Sialon;复相导电陶瓷;性能

中图分类号:TQ174.75 文献标志码:A

Fabrication and properties of TiN/β′-Sialon electroconductive composites from high titania slag-based mixture

JIANG Tao, XUE Xiang-xin, LI Jiang, DUAN Pei-ning

(School of Materials and Metallurgy, Northeastern University, Shenyang 110819, China)

Abstract: The TiN/β′-Sialon electroconductive composites were fabricated by pressureless sintering from TiN/β′-Sialon powder that was synthesized by the carbothermal reduction nitridation method using high titania slag as the starting material. The phase assembly and microstructure were analyzed by XRD and SEM. The densification, mechanical properties and electrical conductivity of TiN/β′-Sialon were studied. The results show that β′-Sialon and TiN exist in the sintered samples. β′-Sialon grains exhibit lath-shaped morphology and TiN particles show fine granular morphology, most of the grains have lower size than 0.5 μm. For the samples sintered at 1 530 ℃ using raw materials containing 35%TiO2 (mass fraction), the bulk density, hardness and flexure strength are 3.01 g/cm3, 9.62 GPa and 120.07 MPa, respectively. The minimum amount of TiO2 in the initial raw materials is 30% for the formation of electroconductive network in the composites. The electric resistivity of such a composite is 1.3×10-2 Ω·cm.

Key words: high titania slag; TiN/β′-Sialon; multiphase electroconductive ceramics; properties

高温结构陶瓷具有高强度、高硬度、高熔点、耐腐蚀等许多优越性能,但难加工性是限制其实用化的主要障碍之一。 传统的金刚石锯片加工法加工效率低,制品形状受限,材料损耗大,加工成本高。近年来,放电加工已经越来越受到陶瓷研究者的关注。与传统的加工方法相比,放电加工具有效率高、精度高、可加工形状复杂部件、材料损耗小、加工成本低等优点,但要求被加工材料必须具有良好的导电性。因此,如何降低陶瓷材料的电阻率而又不降低其工艺性能就成为提高其加工水平并进而拓宽其应用途径的重要课题。

目前,导电复合材料的研究主要集中在导电高分子复合材料上,而对导电陶瓷基复合材料的研究较少。通过向绝缘β′-Sialon(Si6-zAlzOzN8-z)陶瓷基体中添加导电相TiN来改善材料的功能性是材料改性的主要手段之一。改性后的TiN/β′-Sialon复相陶瓷在保持基相β′-Sialon原有结构性质的同时,又可具有良好的功能性质—导电性,成为集各自优势于一身的结构/功能一体化复相陶瓷,扩大材料的应用领域。除TiN/β′-Sialon外,通过向Si3N4[1-7]、Si2N2O[8-9]、β′-Sialon[10]等陶瓷基体中添加一定量的导电相TiN,得到了具有较高电导率的陶瓷基复合材料,满足放电加工的要求。采用纯氮化物(Si3N4、AlN)和氧化物(Al2O3、TiO2)通过原位反应烧结法虽可制备出性能良好的TiN/β′-Sialon复相导电陶瓷[11],但制备成本高,限制了其规模化的生产和应用。为此,本文作者利用高钛渣经碳热还原氮化合成出的廉价TiN/β′-Sialon粉为原料,采用常压烧结制备TiN/β′-Sialon复相导电陶瓷。确定适宜的制备工艺条件,并对所制材料进行正确的表征和分析。研究材料的致密化行为、力学性能和常温导电性能,为其今后作为电极材料和发热材料使用奠定理论和实验基础。

1 实验

本研究所用原料是以高钛渣、硅灰、高铝矾土为原料采用碳热还原氮化法合成的TiN/β?-Sialon粉体。合成粉体所用初始原料配比中TiN前驱体TiO2的加入量分别为10%、20%、25%、30%、35%和40%(质量分数)。该粉体的主要物相组成为β′-Sialon、TiN以及少量15R和Al2O3。粉体平均粒径约为4.37 mm,比表面积约为425.23 m2/kg,其具体制备过程详见文献[12]。称取一定量TiN/β?-Sialon粉放入钢模中,于200 MPa下单轴向干压成5.7 mm×5.7 mm×40 mm的条状试样,其中未添加烧结助剂的试样分别以ST20、ST25、ST30、ST35和ST40表示(数字表示初始原料中TiO2加入的质量分数,下同);添加3%Sm2O3或3%Y2O3(质量 )烧结助剂的试样分别以SST20、SST25、SST30、SST35、SST40和YST10、YST20、YST25、YST30、YST35、YST40表示。先将条形试样放入石墨坩埚中,并在坩埚内埋Si3N4+SiO2(n(Si3N4): n(SiO2)=1:1)粉,然后置于立式MoSi2电阻炉中,在1 470~1 550 ℃下常压烧结 1 h后随炉冷却至室温。烧结过程中始终由炉底连续通入高纯氮气(w(N2)>99.999%)以防止试样发生氧化和热分解。

采用日本理学D/MAX-RB型X射线衍射仪进行物相分析,测试条件为Cu Kα辐射。将抛光后的试样表面经熔融NaOH腐蚀60s后,采用日本岛津公司SSX-550型扫描电子显微镜观察试样抛光表面、腐蚀表面和断口的显微形貌,并对特征晶粒进行微区成分分析。

采用Archimedes法测定材料的显气孔率和体积密度。采用401MVDTM数显显微维氏硬度计测定抛光试样的维氏硬度,载荷4.9 N,加载时间10 s。在CMT5105型电子万能试验机上采用三点弯曲法测定材料的抗折强度,试样尺寸4 mm×5 mm×35 mm,跨距25 mm,加压速度5 dm/min。

采用四点法测定材料的常温电阻率。对低阻值材料采用QJ5T型直流双臂电桥测量其电阻值,对高阻值材料采用ZC36型高阻计测量电阻值,并根据欧姆定律获得电阻率值。

2 结果与分析

2.1 TiN/β?-Sialon复相导电陶瓷的致密化行为

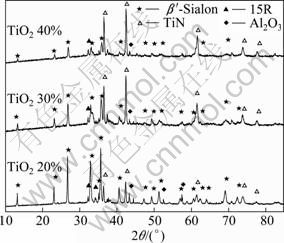

图1所示为试样SST20、SST30、SST40在1530℃烧结1 h后的XRD谱。由图1可见,不同初始TiO2加入量的试样,烧结后产物主要为β′-Sialon和TiN,并含有极少量15R和Al2O3,烧结产物相组成与原料TiN/β?-Sialon粉体基本相同。随初始原料中TiO2加入量的增加,材料中导电相TiN相对含量迅速增加。在TiO2加入量为30%时,材料中TiN已与基体β′-Sialon相的含量相当。

图1 1 530 ℃恒温1 h下制备的TiN/β′-Sialon复相导电陶瓷的XRD谱

Fig.1 XRD patterns of TiN/β′-Sialon electroconductive composites prepared at 1 530 ℃ for 1 h

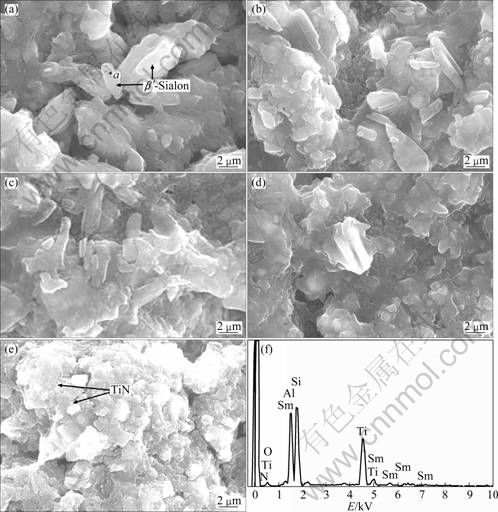

图2所示为1 530 ℃烧结1 h后试样SST20~SST40抛光表面腐蚀后的SEM像。由图2可见,绝缘相β′-Sialon晶粒多呈板条状,且晶粒表面光滑;导电相TiN晶粒为细小粒状,粒度多小于0.5 μm,属亚微米级。从试样SST20(见图2(a))到SST40(见图2(e)),板条状β′-Sialon晶粒数量逐渐减少,粒度也逐渐减小,而粒状TiN晶粒逐渐增多。TiN晶粒数目的增加限制了烧结过程中β′-Sialon晶粒的长大,从而导致其晶粒尺寸变小。图2(f)所示为试样SST20中板条状晶粒a点处的EDS谱。能谱分析表明,板条状晶粒主要由Si、Al、O、N元素构成,且其比例与β′-Sialon的组成基本相符。经计算,该条件下β′-Sialon材料的z值为2.89,较合成粉体中β′-Sialon的z值(2.87)略有上升,其原因可能是由于烧结过程中原料粉体中少量残余Al2O3继续向β′-Sialon晶格中固溶所致。EDS谱中还有少量Ti和Sm元素,这主要来自于β′-Sialon晶粒周围的TiN和由烧结助剂Sm2O3与其它氧化物形成的杂质相。

图2 经1 530 ℃烧结1 h后试样SST20~SST40表面腐蚀后的SEM像及柱状β′-Sialon晶粒a点的EDS谱

Fig.2 SEM images and EDS spectrum of etching surface of samples sintered at 1 530 ℃ for 1 h: (a) SST20; (b) SST25; (c)SST30; (d) SST35; (e) SST40 ; (f) EDS spectrum of β′-Sialon grain

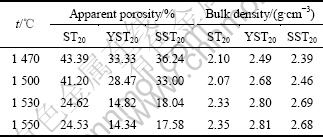

表1所列为采用不同烧结助剂的试样在1 470~ 1 550 ℃烧结1 h后制备的TiN/β′-Sialon陶瓷的显气孔率与体积密度。由表1可知,随烧结温度的升高,材料显气孔率降低,体积密度增大。当温度低于1 530 ℃时,材料显气孔率迅速降低,体积密度升高,而后二者变化很小。由此确定TiN/β′-Sialon陶瓷较适宜的烧结温度为1 530 ℃,此时材料的致密度最高。另外,与相同温度下不添加任何烧结助剂所得到的烧结体相比,使用烧结助剂的材料致密度有很大提高,且添加剂Y2O3的促烧结作用优于Sm2O3的。

表1 TiN/β′-Sialon陶瓷的显气孔率与体积密度

Table 1 Apparent porosity and bulk density of TiN/β′-Sialon

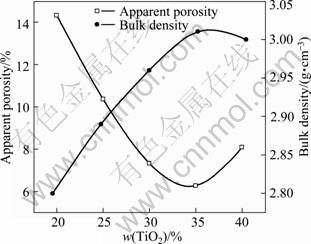

图3 材料显气孔率、体积密度与初始原料中TiO2加入量的关系

Fig.3 Relationships among apparent porosity, bulk density and TiO2 content in initial raw materials

2.2 材料的力学性能

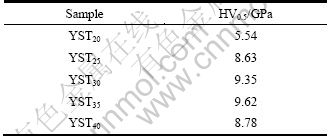

表2所列为加入3%Y2O3烧结助剂的试样在 1 530 ℃、1 h条件下制备的TiN/β′-Sialon材料的维氏硬度。由表2可知,随初始原料中TiO2加入量的增加,材料硬度先增加后降低。原料中TiO2加入量为35%的试样YST35的硬度最高,达9.62 GPa。这是由于原位还原氮化生成的TiN颗粒细小,且为高硬度相(显微硬度为21 GPa)。将其引入到β′-Sialon材料中,可使材料的硬度明显提高。但材料中TiN含量过高,将破坏β′-Sialon基体的连续性,影响材料的致密度,从而使材料的硬度减小。以上结论进一步支持了关于TiN含量对材料烧结致密化程度影响的分析。

表2 1 530 ℃、1 h条件下制备材料的硬度(HV0.5)

Table 2 Hardness(HV0.5) of various samples sintered at 1 530 ℃ for 1 h

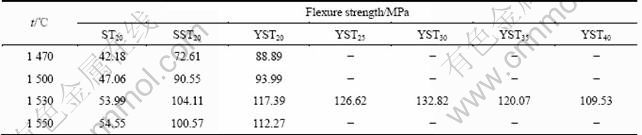

表3所列为不同条件下制备材料的室温抗折强度。由表3可知,随着烧结温度增加,不同组成材料的抗折强度均先增加后降低,且在1 530 ℃时的抗折强度最大。这是由于随着烧结温度增加,材料的致密化程度明显增加,晶粒之间结合更牢固,从而使断裂能增大。但过高的烧结温度可使晶粒发生长大,从而降低了TiN颗粒的增韧补强效果,导致抗折强度降低。添加剂的加入大大提高了材料的抗折强度,这主要是由于添加剂的加入降低了体系液相生成的温度,使得液相量增加,促进了TiN/β′-Sialon材料的致密化,从而使其抗折强度进一步提高。加入3% Y2O3的试样YST30的抗折强度最高,达132.82 MPa。

由表3还可知,随原料中TiO2加入量的增加,TiN/β′-Sialon材料的抗折强度先增加后降低,且变化趋势较明显。通常晶体材料在断裂应力的作用下,裂纹主要是通过晶界传播,即发生晶间断裂。由于TiN/β′-Sialon材料中的TiN是经TiO2原位碳热还原氮化后形成的,晶粒非常细小,主要分布在β′-Sialon晶粒的晶界处,且界面结合牢固。这些细小的TiN晶粒在晶界的存在,使得裂纹沿晶界传播过程中的阻力增大或在扩展过程中发生偏转,耗散裂尖部分能量,起到强化晶界的作用[13]。而且,由于TiN与Sialon之间存在一定的热膨胀系数和弹性系数的差异,两者形成的复合材料在其界面处能形成一定的残余压应力,该应力场诱发的增强、增韧机制进一步强化了这种晶界效应,从而使材料的抗折强度明显增加。但TiN的这种增强作用受其在材料中含量的限制。当TiN含量较低时,对晶界的强化作用贡献较小;当其含量过高时,β′-Sialon基体的连续性受到破坏,TiN晶粒之间形成了大量的晶界,并使得部分裂纹沿该晶界扩展,从而使材料抗折强度降低。

表3 不同制备条件下材料的室温抗折强度

Table 3 Flexure strength of samples prepared at various conditions

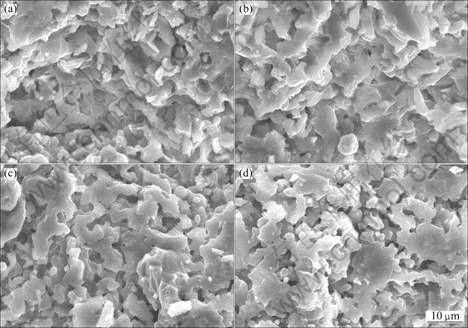

图4所示为不同温度下试样YST30烧结1 h后断口的SEM像。由图4可见,经1 470 ℃烧结试样的断口(见图4(a))主要表现为沿晶断裂,大部分晶粒的轮廓清晰可见,晶粒间结合较为疏松。随烧结温度的升高,试样断口(见图4(b))逐渐从沿晶断裂向穿晶断裂和沿晶断裂的混合形式转变,晶粒间结合更为紧密,尺寸有所增大,烧结程度增加,且局部发生了晶粒的异常长大。在部分穿晶断裂面上可以看到镶嵌其中的TiN晶粒以及TiN晶粒被拔出后留下的界面和凹坑。

2.3 材料的常温导电性能

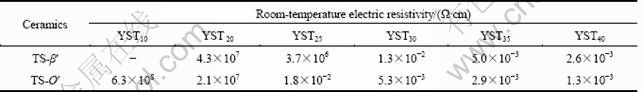

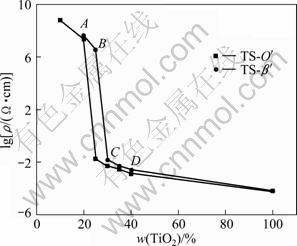

表4所列为1 530 ℃、1 h条件下烧成的试样YST10、YST 20、YST25、YST30、YST35、YST40的常温电阻率。其中TS-O′为本课题组前期采用相同工艺制备的复相导电陶瓷[10]。

图5所示为上述两种材料的电阻率对数值与初始原料中TiO2加入量的关系。其中TiO2加入量为100%时直接取纯TiN电阻率值(0.25×10-4 Ω·cm)。由图5可见,无论是材料TS-O′还是TS-β′,其常温电阻率与初始原料中TiO2加入量的关系均呈现出与前述导电高分子复合材料相似的变化规律,表现为渗流现 象[14],即随TiO2加入量的增加,材料电阻率开始时缓慢降低,在达到某一临界值时急剧降低,随后又缓慢下降,说明TiN的分布发生了由分散状态向网络状态的转变。 在本实验条件下,初始原料中30%左右的TiO2加入量是决定材料中TiN能否形成导电网络的最低加入量,此时材料的电阻率为1.3×10-2 Ω·cm,表明此时TiN已基本形成了相互联结的导电网络。再增加TiN含量,材料电阻率降低,但幅度明显减小。两次研究结果对比分析可知,25%TiO2加入量是材料TS-O′的导电临界值,且其电阻率始终高于相应的TS-β′。对于复相导电陶瓷,导电相粒度较小时有利于形成导电网络。由于两种材料采用的制备工艺基本相同,所生成的导电相TiN粒度(小于0.5?μm)基本相当,因此,导电相颗粒尺寸对材料的导电性影响不大[15]。材料TS-β′的电阻率略低于TS-O′的,主要可能与两种材料的致密度有关。以30% TiO2加入量材料为例,材料TS-O′的体积密度为3.1 g/cm3[10],高于TS-β′的体积密度2.96 g/cm3,这表明材料TS-O′中的导电相颗粒之间的联结更紧密,降低了导电粒子间的界面电阻,从而导致材料TS-O′的电阻率较低。

图4 不同温度下烧结1 h后试样YST30断口的SEM像

Fig.4 SEM images of fracture surfaces of YST30 after sintered at different temperatures for 1 h: (a) 1 470 ℃; (b) 1 500 ℃; (c) 1 530 ℃; (d) 1 550 ℃

表4 1 530 ℃、1 h条件下制备的材料的常温电阻率

Table 4 Room-temperature electric resistivity of samples fabricated at 1 530 ℃ for 1 h

图5 材料的常温电阻率与初始原料中TiO2加入量的关系

Fig.5 Dependence of room-temperature electric resistivity on TiO2 content in initial raw materials

3 结论

1) 利用高钛渣合成的TiN/β′-Sialon粉为原料,常压烧结制备出了TiN/β′-Sialon复相导电陶瓷。材料中β′-Sialon晶粒多呈板条状,TiN晶粒多为细小粒状。

2) 烧结温度为1 530 ℃、初始原料中TiO2加入量为35%、添加3%Y2O3材料的体积密度为3.01 g/cm3,硬度为9.62 GPa,抗折强度为120.07 MPa。

3) 初始原料中30%TiO2加入量是TiN/β′-Sialon材料导电的临界值,此时材料的电阻率为1.3×10-2 Ω·cm。

REFERENCES

[1] GOOR G V D, S?GESSER P, BERROTH K. Electrically conductive ceramic composites[J]. Solid State Ionics, 1997, 101/103: 1163-1170.

[2] ZIVKOVIC L, NIKOLIC Z, BOSKOVIC S, MILJKOVIC M. Microstructural characterization and computer simulation of conductivity in Si3N4-TiN composites[J]. J Alloy Comp, 2004, 373: 231-236.

[3] LIU C C. Microstructure and tool electrode erosion in EDMed of TiN/Si3N4 composites[J]. Mater Sci Eng A, 2003, 363: 221-227.

[4] BO?KOVI? S, SIGULINSKI F, ?IVKOVI? L. Liquid-phase sintering and properties of Si3N4-TiN composites[J]. J Mater Syn Proc, 1999, 7(2): 119-126.

[5] LIN W, YANG J M. Thermal stability of electroconductive TiN-reinforced silicon oxynitride composites[J]. J Eur Ceram Soc, 1994, 13(1): 53-60.

[6] SHIH C J, YANG J M, EZIS A. Feasibility study of developing an in-situ TiN-reinforced Si3N4 composites[J]. Scrip Metall Mater, 1990, 24(12): 2419-2424.

[7] LIN W, YANG J M, TING S J, EZIS A, SHIH C J. Processing and microstructural development of in-situ TiN-reinforced silicon nitride/silicon oxynitride composites[J]. J Am Ceram Soc, 1992, 75(11): 2945-2952.

[8] MORIYAMA M, AOKI H, KAMATA K. Mechanical and electrical properties of pressureless sintered TiN-TiB2 system[J]. J Ceram Soc Jpn, 1995, 103(8): 844-849.

[9] MIYAKE M, TAKEUCHI H. Electrical discharge machinable ceramics—Chiefly Si3N4[J]. Bull Ceram Soc Jpn, 1986, 21(8): 718-725.

[10] 姜 涛, 薛向欣. TiN/O′-Sialon导电复合材料的制备及其性能[J]. 金属学报, 2007, 43(2): 131-136.

JIANG Tao, XUE Xiang-xin. Fabrication and properties of TiN/O?-Sialon electroconductive composites[J]. Acta Metallurgica Sinica, 2007, 43(2): 131-136.

[11] EKSTROM T, OLSSON P O. β′-Sialon-TiN particle composite ceramics[J]. Ceram Trans, 1994, 42: 247-255.

[12] 姜 涛, 李 江, 薛向欣, 巫俊斌. 碳热还原氮化高钛渣合成TiN/β′-Sialon导电陶瓷粉体[J]. 东北大学学报, 2008, 29(6): 857-860.

JIANG Tao, LI Jiang, XUE Xiang-xin, WU Jun-bin. Synthesis of electroconductive ceramic powder of TiN/β′-Sialon by carbothermal reduction-nitridation of high titania slag[J]. Journal of Northeastern University, 2008, 29(6): 857-860.

[13] 王 浩, 高 濂, 冯景伟. Ca-α′-Sialon/SiC纳米相复合材料[J]. 无机材料学报, 1995, 10(2): 180-182.

WANG Hao, GAO Lian, FENG Jing-wei. Nano phase Ca-α′-Sialon/SiC composites[J]. Journal of Inorganic Materials, 1995, 10(2): 180-182.

[14] 曾竟成, 罗 青, 唐羽章. 复合材料理化性能[M]. 长沙: 国防科技大学出版社, 1998.

LUO Jing-cheng, LUO Qing, TANG Yu-zhang. Physical and chemical properties of composites[J]. Changsha: National University of Defense Technology press, 1998.

[15] KUSY R P. Influence of particle size ratio on the continuity of aggregates[J]. J Appl Phys, 1977, 48(12): 5301-5305.

(编辑 李艳红)

基金项目:国家重大基础研究发展计划资助项目(2007CB613504);高等学校博士学科点专项科研基金资助项目(20070145041)

收稿日期:2010-10-08;修订日期:2011-01-24

通信作者:姜 涛,副教授,博士;电话/传真:024-83687719;E-mail: jiangt@smm.neu.edu.cn