文章编号:1004-0609(2016)-01-0212-11

湿法炼锌沉铁渣和浸锌渣的焙烧预处理

刘 洋1,谭 军1,尹周澜1,刘常青1,陈启元1,张平民1,廖 舟2,王心皞1

(1. 中南大学 化学化工学院 有色金属资源化学教育部重点实验室,长沙 410083;

2. 株洲冶炼集团股份有限公司,株洲 412000)

摘 要:采用电阻炉对湿法炼锌沉铁渣和浸锌渣进行焙烧预处理。考察氧气浓度、焙烧温度、焙烧时间和气体流量对沉铁渣脱硫率以及焙烧矿硫含量的影响;利用XRD和SEM-EDS技术对沉铁渣焙烧矿和浸锌渣焙烧矿的物相及微观形貌进行表征。结果表明:焙烧脱硫处理湿法炼锌沉铁渣和浸锌渣是可行的;沉铁渣焙烧预处理的合适工艺条件为氧气浓度70%,气体流量0.2 L/min,经1300 ℃焙烧反应20 min,沉铁渣脱硫率为98.2%,焙烧矿硫含量从8.15%降低到0.253%(质量分数),达到炼铁入炉原料硫含量的要求;沉铁渣焙烧矿的物相组成主要是ZnFe2O4,浸锌渣焙烧矿的物相组成主要是ZnFe2O4和Pb2SO5,Pb2SO5的生成表明浸锌渣中PbSO4分解脱硫不彻底,这是浸锌渣焙烧矿硫含量偏高的主要原因。

关键词:沉铁渣;浸锌渣;焙烧预处理;脱硫

中图分类号:TF813 文献标志码:A

湿法锌占世界锌总产量的85%以上(质量分数,下同),至2007年,我国湿法(电解)锌的产量占全国锌总产量的65.9%[1]。传统的湿法炼锌工艺包括焙烧、浸出、净化、电积等主要过程,直接浸出工艺和浸出液净化工艺分别产生浸锌渣和沉铁渣。浸锌渣含铁、锌、铅、铟和银等有价金属,其中w(Fe)>8%,w(Zn)>4%,w(Pb)>20%,w(In)>370 g/t,w(Ag)>260 g/t。沉铁渣也含铁、锌、铅、铟和银等有价金属,其中w(Fe)>20%,w(Zn)>16%,w(Pb)≈2%,w(In)>270 g/t,w(Ag)>130 g/t。浸锌渣与沉铁渣中硫的含量均大于8%,其赋存形式多为硫酸盐,伴有少量单质硫和金属硫化物,不能直接用作炼铁原料;而采用湿法或常规选矿方法回收其中的铁难度又很大,现还没有一种方法能够综合回收利用其中的铁及其他有价金属;仅能够以少量搭配于精矿进入冶炼系统,大部分做堆存处理。

对于锌冶炼产生的浸锌渣、沉铁渣和锌窑渣的回收利用,冶金学者做了大量的研究工作。LI等[2]采用碳还原-磁选分离工艺处理浸锌渣,该法通过在弱还原性气氛下将铁酸锌还原为氧化锌和磁性铁,再用磁选方法分离,达到分离回收铁锌的目的。虽然工艺所需要的还原温度低,节省成本,但由于焙烧和磁选过程中颗粒间的相互团聚包裹严重,致使铁精矿的品位低,仅58.6%,Fe、Zn的回收率也仅分别达到68.4%、86.4%,并且铁精矿中硫含量偏高,达到1.23%。杨慧芬等[3]进行了煤泥对浸锌渣的直接还原研究,结果表明锌和铅挥发率分别达到96.69%和97.65%,铁总回收率为81.19%,但是实验没有考虑生铁危害杂质硫的脱除,由1250 ℃焙烧90 min的焙砂EDS谱也能明显看到硫的衍射峰。薛佩毅等[4]采用焙烧-浸出工艺回收黄钾铁矾渣中多种有价金属,锌、铅和镉的浸出率均在95%以上,铁精矿品位提高到54%,铁总得率在90%以上,且杂质元素含量在铁精矿标准范围之内,但是其所用铁矾渣物相单一,仅主要含黄钾铁矾一种物相,这种方法难以处理以难分解铁酸锌为主要物相组成的浸锌渣和沉铁渣。李密[5]已报道韩国温山锌冶炼厂应用Ausmelt熔池熔炼法成功处理锌浸出渣的工业化范例,该技术搭配处理锌浸出渣、炼铅QSL炉渣和针铁矿渣,但只考虑有价金属锌、铅、银和铟的回收,未把铁作为有价金属看待,未考虑铁的资源化问题。

熔池熔炼是炉料在液态熔池(熔渣、熔锍)中迅速完成气-液-固相间主要反应的熔炼方法,广泛用于炼铜、炼镍、炼铅和炼铁等[6-7]。熔池熔炼法可以实现有价金属的综合回收,相比于回转窑法具有更高的金属挥发率。用熔池熔炼法处理浸锌渣、沉铁渣等含铁冶

金废渣,对易挥发金属如锌、铅、铟等以氧化物烟尘形式回收,难挥发有价金属铁可经还原熔炼直接得到生铁。虽然经直接还原熔炼可以实现金属锌、铅和铟的回收,但由于入炉原料中硫含量过高,并且硫元素主要以硫酸盐形式存在,致使产出的生铁含硫量高达3%以上,远超出炼钢生铁标准(w(S)<0.07%)。刘洋等[8]对锌浸出渣碳还原炼铁的热力学分析表明,低铁硫酸盐渣可以作为熔池熔炼制铁造氧化物熔体的原料,对于含铁较低的浸锌渣、沉铁渣等低品位含铁渣熔池熔炼制铁是可行的。所以,在进行沉铁渣的还原熔炼之前,应先进行焙烧预处理,脱除其中的硫元素。刘群[9]对沉铁渣脱硫做了部分相关研究,但是其研究方法以配料方式进行,未能反映出沉铁渣的硫元素各主要物相组成,且本实验考察的影响因素与其有别。本文作者拟采用高温焙烧法研究硫的脱除行为,考察氧气浓度、焙烧温度、焙烧时间和气体流量对沉铁渣脱硫率以及焙烧矿硫含量的影响,优化脱硫工艺条件,为沉铁渣、浸锌渣等含铁冶金废渣熔炼还原制铁提供条件和依据。

1 实验

1.1 实验原料与装置

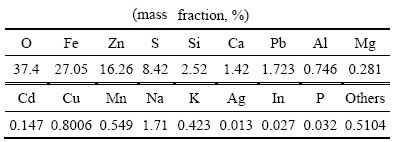

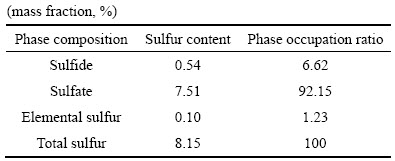

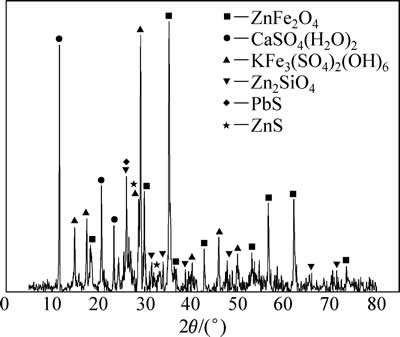

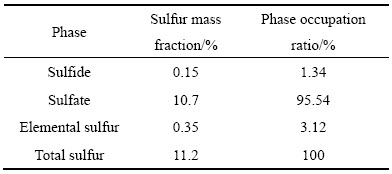

实验原料为湖南省某锌冶炼厂生产的沉铁渣和浸锌渣,沉铁渣物理形貌为褐色固体块状,浸锌渣物理形貌为土黄色固体块状,有刺鼻性气味。将它们破碎干燥,常温下用研钵磨细至74 μm以下进行分析,沉铁渣的X射线荧光分析和X射线衍射分析结果分别如表1和图1所示,沉铁渣中硫元素的物相分析结果如表2所列;浸锌渣的X射线荧光分析和X射线衍射分析结果分别如表3和图2所示,浸锌渣中硫元素的物相分析结果如表4所列。

表1 沉铁渣的化学成分

Table 1 Chemical composition of iron-sinking slag (mass fraction, %)

X射线荧光分析结果显示,沉铁渣中铁、锌、铅、铟和硫含量分别达27.05%、16.26%、1.723%、0.027%和8.42%,具有较高回收价值。硫的物相分析结果显示,沉铁渣中硫元素(其含量以物相分析为准8.15%,荧光分析为半定量)的主要物相组成为硫酸盐,其次为硫化物,微量单质硫。XRD分析结果表明,沉铁渣的主要物相组成是铁酸锌(ZnFe2O4)、二水合硫酸钙(CaSO4(H2O)2)、硅酸锌(Zn2SiO4)、黄钾铁矾(KFe3(SO4)2(OH)6)、硫化铅(PbS)和硫化锌(ZnS)。其中,含硫物相是CaSO4(H2O)2、KFe3(SO4)2(OH)6、PbS和ZnS。

表2 沉铁渣中硫的物相组成

Table 2 Phase composition of sulfur in iron-sinking slag (mass fraction, %)

图1 沉铁渣的XRD谱

Fig. 1 XRD pattern of iron-sinking slag

表3 浸锌渣的化学成分

Table 3 Chemical composition of zinc leaching residue (mass fraction, %)

表4 浸锌渣中硫的物相组成

Table 4 Phase composition of sulfur in zinc leaching residue

图2 浸锌渣的XRD谱

Fig. 2 XRD pattern of zinc leaching residue

浸锌渣中铁、锌、铅、铟和硫含量分别达8.697%、4.783%、24.23%、0.037%和10.36%,也具有较高回收价值。硫的物相分析结果显示,浸锌渣中硫元素(以11.2%计)的主要物相组成为硫酸盐,少量单质硫和硫化物。XRD分析结果表明,浸锌渣的主要物相组成是硫酸铅(PbSO4)、铁酸锌(ZnFe2O4)、二水合硫酸钙(CaSO4(H2O)2)和黄钾铁矾(KFe3(SO4)2(OH)6)。

实验所用电阻炉为可升降式程序控温高温坩埚电阻炉,额定工作温度为1100~1600 ℃,控温精度±5 ℃,加热元件为6根硅钼棒,悬挂于炉膛四周。反应器为刚玉方舟,规格60 mm×30 mm×15 mm。

1.2 实验原理

根据表征结果,硫元素在沉铁渣和浸锌渣中的赋存形式有3种,主要为硫酸盐,少量硫化物和单质硫。这就决定了硫的以下几种脱除方式。

1) 硫酸盐热分解反应方程式及其起止反应温度[9-14]:

KFe3(SO4)2(OH)6(s)=KFe(SO4)2(s)+Fe2O3(s)+3H2O(g) (200~450 ℃) (1)

KFe(SO4)2(s)=1/2Fe2O3(s)+1/2K2SO4(s)+3/2SO3(g) (500~800 ℃) (2)

ZnFe2O4(s)+Fe2(SO4)3(s)=ZnSO4(s)+2Fe2O3+2SO3(g) (>530 ℃) (3)

ZnSO4(s)=ZnO(s)+SO3(g) (700~862 ℃) (4)

Fe2(SO4)3(s)=Fe2O3(s)+3SO3(g) (500~600 ℃) (5)

PbSO4(s)=PbO(s)+SO3(g) (>873.35 ℃) (6)

CaSO4(s)=CaO(s)+SO2(g)+1/2O2(g) (1200~1550 ℃) (7)

2) 硫化物氧化反应方程式:

PbS(s)+3/2O2=PbO(s)+SO2 (8)

ZnS(s)+3/2O2=ZnO(s)+SO2 (9)

3) 单质硫挥发及氧化反应方程式:

S+O2=SO2 (10)

S(s)=S(l) (11)

S(l)=S(g) (12)

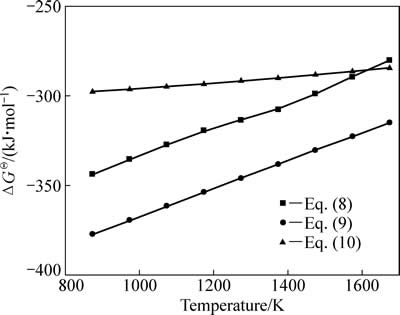

图3所示为根据反应式(8)~(10)计算的ΔGΘ与温度的关系。可见,反应(8)~(10)的ΔGΘ均小于0,说明在温度大于1000 ℃的高温体系中,硫化物和单质硫均可按各自的反应式氧化生成二氧化硫。据文献[9-14]可知,硫酸盐热分解反应(1)~(5)的终止反应温度都不超过900 ℃,在焙烧温度(>1000 ℃)下,可充分保证铁、锌硫酸盐的分解脱硫。

图3 反应(8)~(10)的ΔGΘ与温度的关系

Fig. 3 Relationship between standard free energy (ΔGΘ) and temperature of Eq. (8)-(10)

据文献[14],CaSO4的热分解反应温度高于1200 ℃,在1550 ℃以上才能彻底分解,相比与锌、铁、铅硫酸盐,CaSO4较难分解脱硫。从式(2)可知,黄钾铁矾分解会产生K2SO4,但其化学性质不活泼,即使高温也不易发生分解反应,高温条件下,K2SO4中的硫元素可以通过两种方式进入气相,一是K2SO4固体的升华或是K2SO4液体的挥发,二是K2SO4的热分解。反应方程式如式(13)~(16)所示[15]:

K2SO4(s)=K2SO4(g) (13)

K2SO4(l)=K2SO4(g) (14)

K2SO4(s,l,g)=2K(g)+SO2(g)+O2(g) (15)

K2SO4=K2O(g)+SO2(g)+1/2O2(g) (16)

K2SO4的蒸气压数据如表5所列[15-16],从K2SO4的蒸气压数据表可见,1600 K时其蒸气压值比1200 K时的提高了近1000倍,温度对K2SO4中的硫元素的脱除影响明显。由此可以判断,在充分保证硫化物和单质硫氧化脱硫及锌、铁硫酸盐分解脱硫的前提下,适当提高焙烧炉温,促进CaSO4和K2SO4中硫元素的脱除,可使沉铁渣脱硫能够充分进行。

表5 硫酸钾的蒸气压数据[15-16]

Table 5 Vapor pressure data of potassium sulphate[15-16]

1.3 实验方法

把粉末样沉铁渣或浸锌渣平铺在刚玉方舟中,RSY型智能温控柜程序控温使电阻炉升温至指定温度,升温速率10 ℃/min,然后快速打开炉膛把刚玉方舟放置于圆柱平台上,关闭炉膛,保温一定时间,打开炉膛,冷却取样分析。全过程在指定氧气浓度下进行,气氛条件由氮气与氧气混合配制,混气装置为合肥科晶GSL-2Z型混气系统。

用S4 Pioneer型X射线荧光光谱仪分析沉铁渣和浸锌渣的化学组成;用化学分析法分析沉铁渣和浸锌渣中硫元素的物相组成;用硫分析仪分析焙烧矿中硫元素的含量;用硫酸钡重量法分析焙烧矿中硫酸根含量;用D/max 2500型 X-射线衍射仪(日本Rigaku公司生产)分析沉铁渣、浸锌渣以及各自焙烧矿的物相组成,步宽0.02°,扫描范围5°~80°,扫描速度8 (°)/min; 用NETZSCH STA 449C型热分析仪对沉铁渣进行热重-差示扫描量热(TG-DSC)热分析;用JSM-6360LV型高低真空扫描电镜(SEM)及EDX-GENESIS型X射线能谱仪(EDS)对沉铁渣、浸锌渣以及焙烧矿进行微观形貌观察和化学成分定量分析。

2 结果与讨论

2.1 沉铁渣的热分析

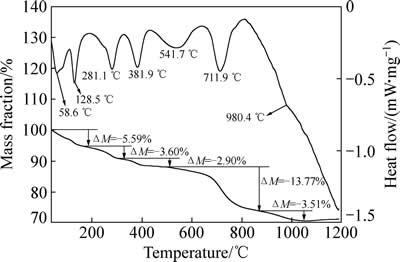

沉铁渣在35~1200 ℃范围内进行热重-差示扫描量热(TG-DSC)热分析,如图4所示。反应容器为Al2O3坩埚,载气为氩气,升温速率10 K/min。在DSC曲线上,58.6 ℃处出现一个吸热峰,这可能是沉铁渣未充分干燥或其易吸湿性导致的。DSC曲线在128.5 ℃上出现第二个吸热峰,这是沉铁渣中硫酸钙结晶水的脱除。TG曲线上第一阶段质量损失5.59%,主要是沉铁渣的非结合水和硫酸钙的结晶水。

DSC曲线在281.1℃和381.9 ℃处的吸热峰是黄钾铁矾脱水生成斜钾铁矾和三氧化二铁。结果与文献[10]中黄钾铁矾发生脱水反应的温度区间(200~450 ℃)一致。DSC曲线在541.7 ℃和711.9 ℃处的吸热峰是斜钾铁矾热分解脱硫,对应TG曲线上第四阶段质量损失13.77%。根据式(2),此部分质量损失(ΔM)主要是SO3的脱除,折算成S元素为5.508%。

此外,DSC曲线在980.4 ℃处出现吸热峰,据文献[9],CaSO4在1200 ℃内不发生热分解。这可能是ZnSO4分解的吸热峰。文献[9]中ZnSO4分解在921.05 ℃出现吸热峰,与本实验相差59.35 ℃。根据式(4),SO3质量损失3.51%,折算成S元素为1.404%。

热分析结果说明,沉铁渣在惰性气氛中受热温度达到1200 ℃时,硫酸盐的热分解脱硫率达到约92%。

图4 沉铁渣的TG-DSC曲线

Fig. 4 TG-DSC testing results of iron-sinking slag

2.2 焙烧参数对沉铁渣脱硫的影响

2.2.1 氧气浓度的影响

氧分压对金属硫酸盐分解和金属硫化物氧化的影响机理用二氧化硫平衡分压表示:

Me1SO4(s)=Me1O(s)+SO2(g)+ O2(g) ΔG1Θ (17)

O2(g) ΔG1Θ (17)

Me2S(s)+ O2(g)=Me2O(s)+SO2(g) ΔG2Θ (18)

O2(g)=Me2O(s)+SO2(g) ΔG2Θ (18)

式中:Me1为Ca、Fe(II)或Zn;Me2为Zn或Pb。

反应达到平衡时,ΔG=0,

(19)

(19)

(20)

(20)

取 ,

,

(21)

(21)

取 ,则,对于硫酸盐分解有

,则,对于硫酸盐分解有

(22)

(22)

对于硫化物氧化有

(23)

(23)

显然,氧分压增加减小金属硫酸盐分解的二氧化硫平衡分压,增大金属硫化物氧化的二氧化硫平衡分压,即氧气浓度增加抑制金属硫酸盐的分解,促进金属硫化物的氧化。

沉铁渣中硫元素的物相组成是硫酸盐、硫化物和单质硫。硫酸盐和硫化物的同时存在,决定了气氛中氧分压高低对沉铁渣脱硫有着显著的影响。表6所列为氧气浓度对脱硫率、焙烧矿总硫含量w(ST)及负二价硫离子含量w(S2-)的影响。固定条件:焙烧温度1300 ℃、焙烧时间40 min、气体流量0.6 L/min。

表6 氧气浓度对脱硫率、ST含量及S2-含量的影响

Table 6 Effects of oxygen concentration on desulfurization rate, sulfur content and S2- content

由表6可见,脱硫率随氧气浓度增大总体呈先增大后减小趋势,在氧气浓度为70%时,脱硫率达到最大值95.61%,对应ST含量先减小后增大。根据热重分析结果及文献中给出的硫酸盐起止分解温度可知,在1300℃的实验条件下,大部分硫酸盐均分解彻底,此部分硫均进入气相。这也与不同氧气浓度的脱硫率均达到93.5%以上这一结果相符。

S2-含量随氧气浓度变化(10%~70%)从0.59%减小到0.383%。沉铁渣中硫元素的主要脱除方式为硫酸盐(占总含硫量92.15%)的热分解脱硫和硫化物(占总含硫量6.62%)的氧化脱硫。在脱硫率的上升段,影响脱硫率的主要因素可能是沉铁渣中硫化物的氧化,随着氧分压的增加,硫化物氧化脱硫速率加快。当氧浓度达到70%后,可能因气固反应传质的影响,S2-氧化脱除速率不再明显增大,再增加氧分压反而不利于残余硫酸盐(硫酸钙)的分解脱硫,致使脱硫率减小。

1300 ℃时,K2SO4的蒸气压较小,未达到86.657 Pa,K2SO4中的硫只有很少一部分进入气相。根据以上分析,选定氧气浓度为70%,此时脱硫率为95.63%,焙烧矿总硫含量为0.573%。

2.2.2 焙烧温度的影响

表7所列为焙烧温度对脱硫率及焙烧矿总硫含量和钾含量的影响。固定条件:氧气浓度70%、焙烧时间40 min、气体流量0.6 L/min。

表7 焙烧温度对脱硫率、ST含量和钾含量的影响

Table 7 Effects of roasting temperature on desulfurization rate, sulfur content and potassium content

由表7可见,焙烧温度对沉铁渣焙烧脱硫有较大影响。随着焙烧温度的升高,脱硫率逐渐增大再趋于平缓。随着温度从1200 ℃升高到1300 ℃,脱硫率从95.86%增大到97.73%,继续增大焙烧温度,脱硫率不再明显变化。因此,选择焙烧温度为1300 ℃,此时脱硫率为97.73%,焙烧矿总硫含量为0.321%。

1200 ℃后影响脱硫率的主要因素是金属硫酸盐硫酸钙和硫酸钾的脱硫效果。根据上述氧分压对金属硫酸盐分解机理影响的计算式,结合CaSO4、CaO、SO2和O2的热力学数据,计算CaSO4热分解的SO2平衡分压,计算结果如表8所列。

表8 不同温度下CaSO4分解气氛中SO2平衡分压

Table 8 Equilibrium partial pressures of SO2 in decomposition atmosphere of CaSO4 at different temperatures

由表8可见,温度由1200 ℃升至1400 ℃,CaSO4热分解的SO2平衡分压从17.174 Pa显著增大到1653.01 Pa,温度升高促进CaSO4分解脱硫,这与实验结果相符。1200 ℃时SO2的平衡分压显然很小,仅达到101数量级,此温度下CaSO4刚发生分解反应,理论计算结果与POPESCU等[14]的研究结论一致。

随着温度的升高,脱硫产物中钾元素的含量逐渐降低,这与1.2节中K2SO4的蒸气压随温度升高而增大的结果一致。所以,钾元素进入气相的量增加使K2SO4中硫脱除量也增加,这也与实验结果相符。

2.2.3 焙烧时间的影响

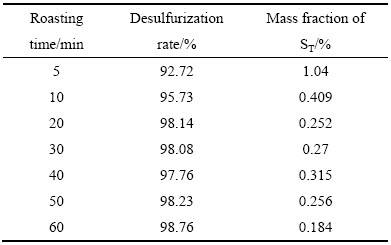

表9所列为焙烧时间对脱硫率及焙烧矿总硫含量的影响。固定条件:氧气浓度70%、焙烧温度1300 ℃、气体流量0.6 L/min。

由表9可见,随着焙烧时间的延长,脱硫率增幅较大,从5 min到20 min时,脱硫率增大了5.42%,反应20 min后,脱硫率增幅显著减小,基本保持恒定。因此,选择焙烧时间为20 min,此时脱硫率为98.14%,焙烧矿总硫含量为0.252%。

表9 焙烧时间对脱硫率和ST含量的影响

Table 9 Effects of roasting time on desulfurization rate and sulfur content

2.2.4 气体流量的影响

表10所列为气体流量对脱硫率及焙烧矿总硫含量的影响。固定条件:氧气浓度70%,焙烧温度1300 ℃、焙烧时间20 min。

由表10可见,随着气体流量的增大,脱硫率整体呈增大趋势,但增加幅度很小。因此,选择气体流量为0.2 L/min,此时脱硫率为98.2%,脱硫产物总硫含量为0.253%。

表10 气体流量对脱硫率和ST含量的影响

Table 10 Effects of gas flow on desulfurization rate and sulfur content

综上所述,沉铁渣焙烧脱硫的优化工艺参数为氧气浓度70%、焙烧温度1300 ℃、焙烧时间20 min、气体流量0.2 L/min,在此条件下,沉铁渣脱硫率为98.2%,焙烧矿总硫含量为0.253%。

2.3 焙烧矿的物相以及微观结构表征

由于沉铁渣和浸锌渣中硫元素均是以硫酸盐为主要存在形式,主要的含硫物相中浸锌渣只比沉铁渣多出PbSO4,且PbSO4的起始分解温度低于900 ℃,所以不再对浸锌渣焙烧参数进行优化,以2.2节得出的优化工艺参数对沉铁渣和浸锌渣进行焙烧脱硫。

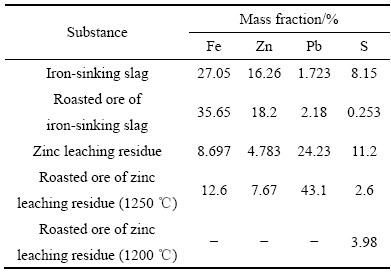

表11所列为原始沉铁渣、浸锌渣和优化工艺参数下焙烧矿的Fe、Zn、Pb和S含量。其中,浸锌渣熔点比沉铁渣低,1200 ℃时已完全熔融,1300 ℃时浸锌渣蒸发严重,所以焙烧温度取1200和1250 ℃。由表11可见,沉铁渣焙烧矿主要有价金属Fe、Zn和Pb的品位分别提高到35.65%、18.2%和2.18%,总和达到56.03%。硫元素含量降低到0.253%,达到炼铁入炉原料硫含量的要求。浸锌渣1250 ℃焙烧矿主要有价金属Fe、Zn和Pb的品位分别提高到12.6%、7.67%和43.1%,总和达到63.37%。但是,浸锌渣的脱硫效果不佳,1250 ℃时浸锌渣焙烧矿硫含量仍高达2.6%。

焙烧参数对沉铁渣和浸锌渣脱硫具有显著影响。

表11 沉铁渣、浸锌渣以及焙烧矿的Fe、Zn、Pb和S含量

Table 11 Iron, zinc, lead and sulfur contents of iron-sinking slag, zinc leaching residue and roasted ores

图5所示为沉铁渣及其焙烧矿的XRD谱,图6所示为浸锌渣及其1200和1250 ℃焙烧矿的XRD谱。由图5可见,沉铁渣经焙烧预处理,CaSO4(H2O)2、KFe3(SO4)2(OH)6和Zn2SiO4衍射峰均消失,ZnFe2O4衍射峰相对强度增大,焙烧矿中主要含ZnFe2O4一种物相。从图6可以看出,浸锌渣焙烧预处理后,PbSO4、CaSO4(H2O)2和KFe3(SO4)2(OH)6衍射峰均消失,ZnFe2O4衍射峰强度增大。同时,有新的物相SiO2和Pb2SO5衍射峰出现。1200 ℃时出现CaSO4衍射峰,这是因为CaSO4(H2O)2脱水后生成CaSO4,1250 ℃时CaSO4衍射峰消失,表明CaSO4发生了热分解反应。PbO与PbSO4复合物Pb2SO5的生成,表明PbSO4热分解没有彻底进行,这是浸锌渣焙烧矿含硫量偏高的主要原因。

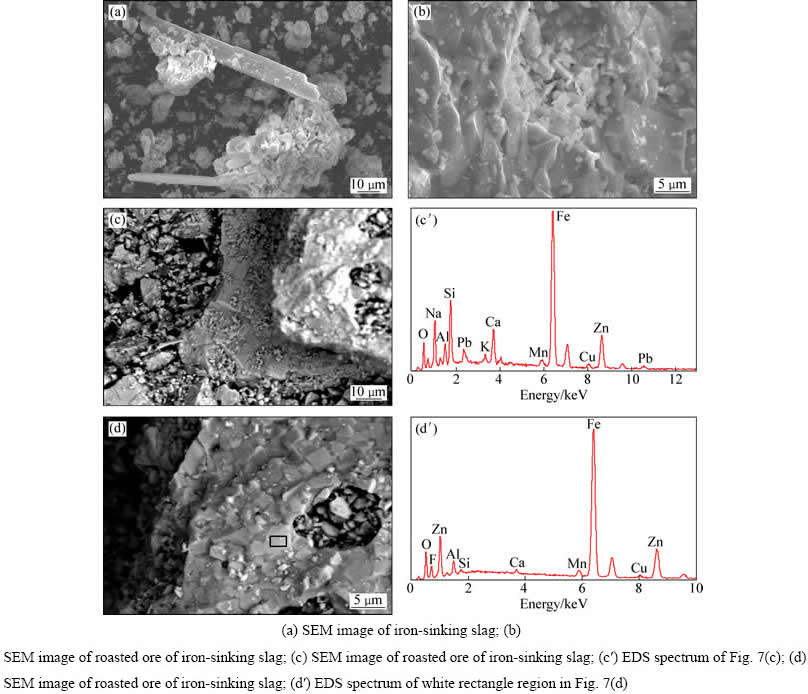

图7所示为沉铁渣的SEM像及其焙烧矿的SEM像和EDS谱。由图7可见,沉铁渣中的矿物颗粒,不仅粒度细小,而且组成成分复杂。但经过高温焙烧处理,部分物相消失,形成单一致密的颗粒状物相,其成分主要为ZnFe2O4。根据EDS谱,浅颜色区域的Fe、Zn含量较高,杂质元素Ca、Si含量低,SiO2、CaO等夹杂在ZnFe2O4相中。

图5 沉铁渣及其焙烧矿的XRD谱

Fig. 5 XRD patterns of iron-sinking slag and its roasted ore

图6 浸锌渣及其焙烧矿的XRD谱

Fig. 6 XRD patterns of zinc leaching residue and its roasted ores

图8所示为浸锌渣的SEM像及其1250 ℃焙烧矿的SEM像和EDS谱。由图8可见,浸锌渣中的矿物颗粒,粒度也非常细小。但经过高温焙烧处理,出现了颜色不同的分相。根据EDS谱,深颜色区域的Fe、Zn含量高,主要为ZnFe2O4相,浅颜色区域的Pb含量高,主要为Pb2SO5相。杂质元素Si、Ca的氧化物SiO2、CaO等主要夹杂在Pb2SO5相中。

2.4 浸锌渣焙烧矿含硫偏高的因素分析

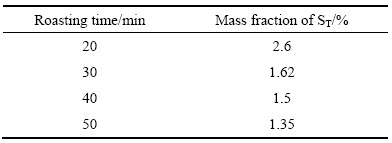

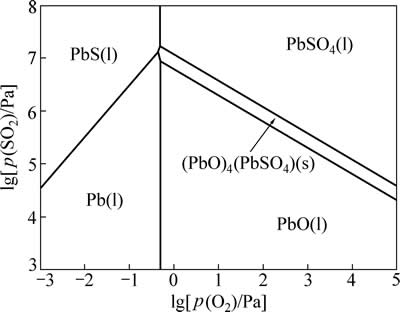

对比浸锌渣和沉铁渣的物相可知,主要的含硫物相中浸锌渣只比沉铁渣多出PbSO4,而浸出渣焙烧矿含硫量高出沉铁渣焙烧矿含硫量一个数量级,结合2.3节的分析,氧气浓度、焙烧温度和气体流量均不是影响浸出渣焙烧矿含硫量偏高的主要原因。其主要原因是复合物Pb2SO5的生成致使PbSO4未能充分分解。根据图9所示Pb-S-O系的优势区图,在焙烧条件下,稳定区为PbO(l)相,所以可能是动力学因素导致PbSO4(l)不能顺利转化为PbO(l)。为此,固定条件如下氧气浓度70%、焙烧温度1250 ℃、气体流量0.2 L/min。考察焙烧时间对浸锌渣焙烧矿总硫含量的影响,结果如表12所列。

由表12可见,随着焙烧时间的延长,浸锌渣焙烧矿的硫含量逐渐减小,当焙烧时间达到50 min时,焙烧矿的硫含量已降低至1.35%。

图7 沉铁渣的SEM像及其焙烧矿的SEM像和EDS谱

Fig. 7 SEM image of iron-sinking slag and SEM images and EDS spectrums of roasted ore

表12 焙烧时间对浸锌渣焙烧矿ST含量的影响

Table 12 Effects of roasting time on sulfur content of roasted ore of zinc leaching residue

3 结论

图8 浸锌渣的SEM像及其焙烧矿的SEM像和EDS谱

Fig. 8 SEM image of zinc leaching residue and SEM images and EDS spectrums of roasted ore

图9 1250 ℃的Pb-S-O系优势区图

Fig. 9 Predominance diagram of Pb-S-O system at 1250 ℃

1) 沉铁渣焙烧预处理的合适工艺条件为氧气浓度70%、焙烧温度1300 ℃、焙烧时间20 min、气体流量0.2 L/min,在此条件下,沉铁渣脱硫率为98.2%,焙烧矿硫含量为0.253%,达到炼铁入炉原料硫含量的要求。

2) 经氧化焙烧,沉铁渣焙烧矿中主要有价金属Fe、Zn和Pb的品位分别提高到35.65%、18.2%和2.18%,总和达到56.03%;浸锌渣1250 ℃焙烧矿中主要有价金属Fe、Zn和Pb的品位分别提高到12.6%、7.67%和43.1%,总和达到63.37%。有价金属品位的提升,增加了焙烧矿的回收价值。

3) SEM像和XRD、EDS谱分析表明,沉铁渣焙烧矿的物相组成主要是ZnFe2O4,浸锌渣焙烧矿的物相组成主要是ZnFe2O4和Pb2SO5,其中Pb2SO5的生成表明浸锌渣中PbSO4分解脱硫不彻底,这是浸锌渣焙烧矿硫含量偏高的主要原因。

4) 浸锌渣焙烧矿硫含量偏高且铁品位仅12.6%,不宜直接作为提铁的原料,可通过搭配沉铁渣焙烧矿,实现综合回收Fe、Zn和Pb。

5) 焙烧预处理对黄钾铁矾沉铁渣、浸锌渣这类硫主要以硫酸盐形式存在的低铁高硫渣脱硫炼铁具有指导作用。

REFERENCES

[1] 王吉坤, 冯桂林. 铅锌冶炼生产技术手册[M]. 北京: 冶金工业出版社, 2012: 293-294.

WANG Ji-kun, FENG Gui-lin. Handbook of lead and zinc smelting production technology[M]. Beijing, Metallurgical Industry Press, 2012: 293-294.

[2] LI Mi, PENG Bing, CHAI Li-yuan, PENG Ning, YAN Huan, HOU Dong-ke. Recovery of iron from zinc leaching residue by selective reduction roasting with carbon[J]. Journal of Hazardous Materials, 2012, 237/238: 323-330.

[3] 杨慧芬, 蒋蓓萍, 王亚运, 苑修星, 张莹莹. 煤泥对浸锌渣的直接还原作用[J]. 中国有色金属学报, 2015, 25(1): 250-257.

YANG Hui-fen, JIANG Bei-ping, WANG Ya-yun, YUAN Xiu-xing, ZHANG Ying-ying. Direct reduction effect of coal slime on zinc-leaching residue[J]. TheChinese Journal of NonferrousMetals, 2015, 25(1): 250-257.

[4] 薛佩毅, 巨少华, 张亦飞, 王新文. 焙烧-浸出黄钾铁矾渣中多种有价金属[J]. 过程工程学报, 2011, 11(1): 56-60.

XUE Pei-yi, JU Shao-hua, ZHANG Yi-fei, WANG Xin-wen. Recovery of valuable metals by leaching of roasted jarosite residue[J]. The Chinese Journal of Process Engineering, 2011, 11(1): 56-60.

[5] 李 密. 锌焙砂选择性还原与铁锌分离的基础研究[D]. 长沙: 中南大学, 2013: 5-13.

LI Mi. Fundamental research on selective reduction of zinc calcine and separation of zinc and iron[D]. Changsha: Central South University, 2013: 5-13.

[6] MACKEY P J, CAMPOS R. Modern continuous smelting and concerting by bath smelting technology[J]. Canadian Metallurgical Quarterly, 2001, 40(3): 355-376.

[7] 彭容秋. 铅冶金[M]. 长沙: 中南大学出版社, 2004: 71-86.

PENG Rong-qiu. Metallurgy of lead[M]. Changsha: Central South University Press, 2004: 71-86.

[8] 刘 洋, 谭 军, 刘常青, 尹周澜, 陈启元, 张平民, 廖 舟. 碳还原锌浸出渣炼铁过程的热力学分析[J]. 中国有色金属学报, 2015, 25(7): 1978-1986.

LIU Yang, TAN Jun, LIU Chang-qing, YIN Zhou-lan, CHEN Qi-yuan, Zhang Ping-min, LIAO Zhou. Thermodynamic analysis on iron-making process of zinc leaching residue by carbon reduction[J]. TheChinese Journal of NonferrousMetals, 2015, 25(7): 1978-1986.

[9] 刘 群. 熔池熔炼处理铅锌冶炼渣的高温脱硫及碳热还原研究[D]. 长沙: 中南大学, 2014: 25-43.

LIU Qun. Research on high-temperature desulfurization and carbon-thermal reduction of lead-zinc metallurgical slags for metals recovery by bath smelting[D]. Changsha: Central South University, 2014: 25-43.

[10] DROUET C, NAVROTSKY A. Synthesis, characterization, and thermochemistry of K-Na-H3O jarosites[J]. Geochimica et Cosmochimica Acta, 2003, 67(11): 2063-2076.

[11] FROST R L, WEIER M L, MARTENS W. Thermal decomposition of jarosites of potassium, sodium and lead[J]. Journal of Thermal Analysis and Calorimetry, 2005, 82: 115-118.

[12] 宁顺明, 陈志飞. 从黄钾铁矾渣中回收铟[J]. 中国有色金属学报, 1997, 7(3): 56-58.

NING Shun-ming, CHEN Zhi-fei. Recovery of zinc and indium from jarosite residues[J]. The Chinese Journal of Nonferrous Metals, 1997, 7(3): 56-58.

[13] SIRIWARDANE R V, POSTON JR. J A, FISHER E P, SHEN Ming-shing, MILTZ A L. Decomposition of the sulfates of copper, iron(II), iron(III), nickel, and zinc: XPS, SEM, DRIFTS, XRD, and TGA study[J]. Applied Surface Science, 1999, 152(3): 219-236.

[14] POPESCU M, SIMION A, MATEI V. Study of thermal behaviour up to 1550° of materials containing calcium sulphate [J]. Journal of Thermal Analysis, 1985, 30: 297-303.

[15] ELIEZER I, HOWALD R A. Thermodynamics of the vaporization processes foe potassium sulfate[J]. The Journal of Chemical Physics, 1976, 65: 3053-3062.

[16] LAU K H, CUBICCIOTTI D, HILDENBRAND D L. Effusion Studies of the vaporization/decomposition of potassium sulfate[J]. Journal of the Electrochemical Society, 1979, 126(3): 490-495.

Roasting pretreatment of iron-sinking slag and zinc leaching residue in zinc hydrometallurgy

LIU Yang1, TAN Jun1, YIN Zhou-lan1, LIU Chang-qing1, CHEN Qi-yuan1,

ZHANG Ping-min1, LIAO Zhou2, WANG Xin-hao1

(1. Key Laboratory of Resources Chemistry of Nonferrous Metals, Ministry of Education,

College of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China;

2. Zhuzhou Smelter Group Co., Ltd., Zhuzhou 412000, China)

Abstract: The iron-sinking slag and zinc leaching residue were pretreated in resistance furnace. The effects of oxygen concentration, roasting temperature, roasting time and gas flow on the desulfurization rate of iron-sinking slag and sulfur content of roasted ore were studied. The phase composition and changes in microstructure of roasted ores were discussed and analyzed by XRD and SEM-EDS. The results show that the sulfur element in iron-sinking slag and zinc leaching residue is successfully discharged as gas form. The optimum conditions of roasting pretreatment by using resistance furnace are 1300 ℃ for 20min with oxygen concentration 70% at 0.2 L/min gas flow. Under the pretreatment conditions, the desulfurization rate is as high as 98.2%, and sulfur content turns from 8.15% to 0.253%(mass fraction), and this meets the requirements of low sulfur content for iron-making. ZnFe2O4 is the main phase of roasted ore of iron-sinking slag, and ZnFe2O4 and Pb2SO5 are the main phases of roasted ore of zinc leaching residue. Generation of Pb2SO5 demonstrates the incomplete decomposition of PbSO4. This is the main reason for the slightly high sulfur content in roasted ore of zinc leaching residue.

Key words: iron-sinking slag; zinc leaching residue; roasting pretreatment; desulfurization

Foundation item: Project(2011AA061003) supported by the National High-Tech Research and Development Program of China

Received date:2015-05-29;Accepted date:2015-10-16

Corresponding author: TAN Jun; Tel: +86-731-88877364; E-mail: yytanjun@163.com

(编辑 王 超)

基金项目:国家高技术研究发展计划资助项目(2011AA061003)

收稿日期:2015-05-29;修订日期:2015-10-16

通信作者:谭军,副教授,博士;电话:0731-88877364;E-mail:yytanjun@163.com