文章编号:1004-0609(2008)03-0388-06

Zn对铸态Mg-Mn合金力学性能和腐蚀性能的影响

尹冬松1,张二林2,曾松岩 1

(1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 中国科学院金属研究所,沈阳 110016)

摘 要:研究Zn对Mg-Mn合金微观组织、力学性能和在Hank’s溶液中腐蚀性能的影响。结果表明:Zn可以明显细化Mg-Mn合金的铸态组织,当合金中Zn含量(质量分数)为3%时,合金的晶粒尺寸由700~900 μm减小到50~80 μm。合金的力学性能也随Zn含量的增加而显著提高;Zn含量为3%时,拉伸强度提高128.8 MPa,屈服强度提高42.6 MPa,伸长率提高1倍多。在Mg-Mn合金中加入 1%~2%的Zn,能够增强Mg-Mn合金钝化膜的稳定性,使Mg-Mn合金腐蚀速度显著降低。但是,当Zn含量增至3%时,钝化膜变得不稳定,腐蚀速度增加,耐蚀性能降低。

关键词:镁合金;锌;微观组织;力学性能;腐蚀

中图分类号:TG 146.2 文献标识码:A

Effect of Zn on mechanical properties and corrosion properties of

as-cast Mg-Mn alloy

YIN Dong-song 1, ZHANG Er-lin 2, ZENG Song-yan 1

(1. School of Materials Science and Technology, Harbin Institute of Technology, Harbin 150001, China;

2. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The effect of Zn on the microstructure, mechanical properties and corrosion properties in Hank’s solute on of as-cast Mg-Mn alloy was studied. The results indicate that the addition of Zn element can significantly refine the grain size of cast Mg-Mn alloy. When Zn content is increased up to 3% (mass fraction), the grain size of the cast alloy decreases from 700-900 μm to 50-80 ?m. Meanwhile, the mechanical properties of the alloy also increase with increasing Zn content. When Zn content is 3%, the ultimate tensile strength and the yield strength are increased by 128.8 and 42.6 MPa, respectively, while the elongation is increased twice. Addition of Zn element to Mg-Mn alloy can stabilize the passivation film, which mainly contributes to the low corrosion rate of Mn-Mn-Zn alloy. However, when the Zn content is over 3%, the passivation film becomes unstable, which results in a relatively high corrosion rate.

Key words: magnesium alloy; zinc; microstructure; mechanical property; corrosion

镁合金具有密度低、比强度和比刚度高的优点, 可满足航空、航天、汽车及电子产品轻量化和环保的要求,在许多领域的应用将会更加广泛[1]。镁合金在生物医用领域的应用因具有以下优势[2-5]也将有广阔的前景:1) Mg的弹性模量和屈服强度与人骨的弹性模量和屈服强度更接近,能够有效地避免应力遮挡效应;2) Mg是人体新陈代谢和骨组织中的基本元素,具有更好的生物相容性;3) 具有非常低的平衡电极电位,特别是在含有Cl-的溶液中易被腐蚀而降解,如果作为植入材料,可以避免二次手术。

然而,Mg作为生物材料,最大的问题就是耐蚀性能差,这将造成Mg2+浓度过高,氢气释放过多,形成皮下气肿[4]。另外,镁的力学性能也较低,所以,有必要采取相应的措施来控制其腐蚀速度,并提高其力学性能。与其他系列的镁合金相比,Mg-Mn系合金具有优异的耐蚀性,无应力腐蚀倾向。但作为硬组织植入材料,Mg-Mn系合金的耐蚀性能和力学性能仍然较低,有待于提高。利用合金化的方法提高Mg-Mn系合金的力学性能和腐蚀性能的研究已有报道,王登峰等[6]指出:当Ca含量(质量分数)为0.6%时,Mg-Mn合金的显微组织得到细化,腐蚀速度降低56 mm/a。关学丰[7]认为:Nd可以大大提高Mg-Mn系合金的室温和高温瞬时拉伸强度,而耐蚀性能不变。范靖亚[8]发现:Mg-Mn-Y合金力学性能比MB8合金的高,但是耐蚀性略比MB8合金的低。翁康荣等[9]研究发现:在Mg-Mn-0.3Ca合金中增加Si含量,拉伸强度略有提高,耐蚀性能有所改善。Zn元素能够提高镁合金的力学性能,并且能减弱Fe、Ni等杂质对腐蚀性能的不利影 响[10-12],有助于在合金表面形成钝化膜,可以在一定程度上改善镁合金的耐蚀性能。另外,Zn是人体中许多蛋白质、核酸合成酶的成分,能促进细胞的更新[13]。

本文作者研究Zn添加量对Mg-Mn合金力学性能和在模拟体液中腐蚀性能的影响规律,以期通过添加Zn元素来提高合金的力学性能和腐蚀性能。

1 实验

采用高纯镁锭(99.99%)、高纯锌锭(99.99%)、高纯铝锭(99.99%)和MnCl2分析纯试剂,在井式坩埚电阻炉中进行Mg-Mn和Mg-Mn-Zn合金的熔配。熔炼在混合气体(CO2+0.5%SF6)保护下进行,浇注温度为 750 ℃,浇入预热至200 ℃的金属模具中。合金的化学成分采用全谱直读等离子体发射光谱仪(ICP)测定,如表1所列。

表1 Mg-Mn和Mg-Mn-Zn合金的化学成分

Table 1 Chemical compositions of Mg-Mn and Mg-Mn-Zn alloys (mass fraction, %)

在金相显微镜(OM)和场发射扫描电镜(SEM)上观察合金的微观组织。拉伸试样是从上述铸锭上切取的标距长20 mm、宽6 mm和厚2 mm的片状拉伸试样。在INSTRON Series IX自动材料实验机上进行拉伸实验,拉伸速度为1 mm/min,温度为20 ℃。采用标距为10 mm的引伸计测量试样的伸长率,结果取3个试样的平均值。

镁合金的腐蚀性能通过电化学实验和浸渍实验测定。腐蚀介质为采用分析纯化学试剂和蒸馏水配制的Hank’s混合溶液,具体成分为(g/L):8.0 NaCl,0.4 KCl,0.06 Na2HPO4,0.06 KH2PO4,0.35 NaHCO3,0.2 MgSO4?7H2O和0.14 CaCl2。电化学极化实验使用的是标准三电极体系:参比电极为饱和甘汞电极,辅助电极为铂电极,试样作为工作电极,扫描速度为3 ×10-4 V/s。极化实验在盛有300 mL Hank’s溶液的烧杯中进行,溶液温度控制在(37±1) ℃。电化学试样从上述铸锭上切取,经环氧树脂密封镶嵌,裸露表面积为1 cm2,表面抛光至1 ?m。

浸渍试样的尺寸为10 mm×10 mm×3 mm。试样经2000#金相砂纸打磨后,再用丙酮、酒精清洗,用电子天平称量,记为原始质量(m0,单位mg)。将试样分别浸入(37±1) ℃的Hank’s溶液中浸渍96和216 h,每24 h换1次新鲜Hank’s溶液,试样表面积与溶液体积比为1 cm2/150 mL。浸渍后的试样在沸腾的20%铬酸+1%硝酸银混合溶液中清除腐蚀产物,然后清洗,冷风吹干,称量,记为浸渍后质量(m1,单位mg)。计算质量损失率(R):

2 结果与讨论

2.1 微观组织

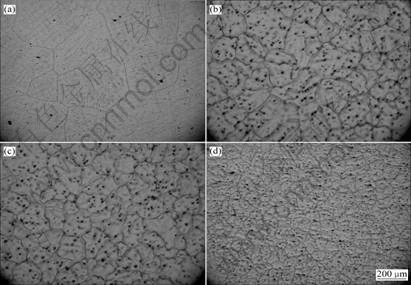

图1(a)所示为Mg-Mn合金的铸态组织金相照片。图1(b)~(d)所示分别为不同Zn含量的Mg-Mn-Zn合金的铸态组织。当加入1% Zn时,合金的晶粒尺寸由原来的700~900 μm减小到200~400 μm。继续增加Zn含量到2%时,合金晶粒尺寸进一步减小到100~200 μm,而当Zn含量为3%时,合金晶粒尺寸仅为50~80 μm。可见,Zn能够细化Mg-Mn合金的晶粒。分析其原因认为:在凝固过程中,Zn元素会在固/液界面前沿富集,产生成分过冷,并且出现成分过冷区,当过冷度足够大时,平界面遭到破坏,形成树枝晶。而随着Zn含量的增加,枝晶前沿和晶界处Zn元素的富集程度进一步增加,二次枝晶增多,并且使枝晶间距减小,晶粒细化[14]。

图1 Mg-Mn和Mg-Mn-Zn合金铸态微观组织

Fig.1 Optical microstructures of as-cast Mg-Mn and Mg-Mn-Zn alloys: (a) Mg-Mn alloy; (b) Mg-Mn-1Zn alloy; (c) Mg-Mn-2Zn

Mg-Mn和Mg-Mn-Zn合金微观组织的SEM形貌和EDS分析结果如图2所示。可以看出:Mg-Mn合金基体上均匀分布着块状物,尺寸为1~2 μm,见图2(a)和(b)。由EDS分析为Mg-Mn-Al相(见图2(c)),与之相近的Mg-Al-Mn三元相未见报道,根据Al和Mn的摩尔分数比结合Al-Mn相图,推测该相为AlMn相,由于其尺寸较小(1~2 μm),能谱分析时带入了基体成分的信息。

图2 Mg-Mn、Mg-Mn-Zn合金的SEM像和EDS分析

Fig.2 SEM images and EDS analysis of alloys: For Mg-Mn alloy, (a) SEM micrograph; (b) Morphology of Al-Mn phase; (c) EDS spectrum of Al-Mn phase. For Mg-Mn-Zn alloys, (d) Morphology of Al-Mn phase; (e) Morphology of Mg-Zn phase; (f) EDS spectrum of Mg-Zn phase; (g) SEM micrograph of Mg-Mn-1Zn alloy; (h) SEM micrograph of Mg-Mn-2Zn alloy; (i) SEM micrograph of Mg-Mn-3Zn alloy alloy; (d) Mg-Mn-3Zn alloy

Mg-Mn-Zn合金中的第二相形貌如图2(d)和(e)所示。可见:Mg-Mn-Zn合金基体上分布着两种形貌的第二相:一种为块状,尺寸为1~2 μm,其成分与Mg-Mn合金中第二相近,推测为AlMn相;另一种为椭圆状,尺寸大约为5 μm,EDS分析结果为Mg-Zn相(见图2(f)),其中Mg与Zn的摩尔比接近7?3。根据Mg-Zn相图可知,Mg7Zn3在325 ℃发生共析反应,分解为α-Mg和MgZn相,因此,该相应由α-Mg和MgZn相组成。当Zn含量为1%~2%时,Mg-Zn相较少(见图2(g)和(h));Zn含量增至3%时,合金基体上Mg-Zn相显著增加(见图2(i))。

2.2 力学性能

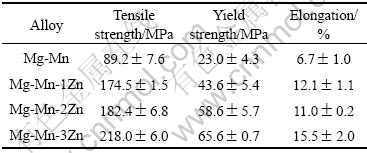

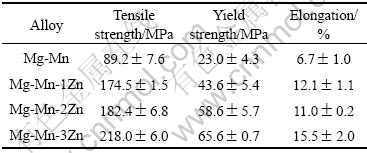

表2所列为Mg-Mn、Mg-Mn-Zn合金的拉伸强度和伸长率。由表2可知:Mg-Mn合金的拉伸强度和伸长率随着Zn含量增加而增加,当Zn含量为3%时,与Mg-Mn合金相比,屈服强度和拉伸强度分别提高42.6和128.8 MPa,伸长率提高到15.5%。原因主要有两方面:一方面,Zn元素细化了晶粒,因此,合金的强度和伸长率得到显著的提高;另一方面,镁基体中固溶了一定量的Zn,固溶强化也使合金的强度得到提高。此外,据报道:AlMn相在凝固析出后会产生一定的强化作用,但强化作用并不显著[15];而与基体共格MgZn相的强化是Mg-Zn合金的硬化效果的来源之一[16]。这种强化效果随MgZn相体积分数的增加而增强。

表2 Mg-Mn和Mg-Mn-Zn合金的力学性能

Table 2 Mechanical properties of Mg-Mn and Mg-Mn-Zn alloys

2.3 腐蚀性能

表3所列为几种镁合金的电化学特征值。可以看出:当Zn含量为1%~2%时,合金的Rp和Eb都有所提高,Icorr降低,当Zn含量为3%时,合金的Rp和Ecorr明显降低,Icorr有所升高。在Mg-Mn合金中加入1%~2%的Zn后,合金的钝化带得到延长,特别是Zn含量为1%时,DE=Eb-Ecorr达到了最大值0.229 V。Zn含量为3%时,合金的钝化带消失。由电化学结果可以看出:在Mg-Mn合金中加入1%~2%的Zn可以提高钝化膜的稳定性,改善合金耐蚀性能。当Zn含量为3%时,钝化膜的保护作用消失,耐蚀性能降低。

表3 Mg-Mn和Mg-Mn-Zn合金的电化学参数

Table 3 Electrochemical parameters of Mg-Mn and Mg-Mn-Zn alloys

图3所示为Mg-Mn和Mg-Mn-Zn 4种合金在Hank’s溶液中经过96和216 h浸渍后的平均腐蚀速度柱状图。可以看出:4种合金浸渍216 h的平均腐蚀速度都低于浸渍96 h的平均腐蚀速度。浸渍216 h的平均腐蚀速度由小到大排列如下:Mg-Mn-1Zn、Mg-Mn- 2Zn、Mg-Mn-3Zn和Mg-Mn 合金。图4所示为上述4种合金在Hank’s溶液中浸渍216 h后的腐蚀宏观形貌。可以看出,经216 h浸渍后,几种合金发生了不同程度的腐蚀,Mg-Mn和Mg-Mn-3Zn合金的腐蚀较为严重,Mg-Mn-1Zn和Mg-Mn-2Zn合金的腐蚀较轻。

图3 Mg-Mn和Mg-Mn-Zn合金的腐蚀速度

Fig.3 Corrosion rate of Mg-Mn and Mg-Mn-Zn alloys

图4 Mg-Mn 和Mg-Mn-Zn合金的腐蚀形貌

Fig.4 Corrosion morphologies of Mg-Mn and Mg-Mn-Zn alloys: (a) Mg-Mn alloy; (b) Mg-Mn-1Zn alloy; (c) Mg-Mn-2Zn alloy; (d) Mg-Mn-3Zn alloy

Mg及其合金产生腐蚀的原因是相似的,一般是因为杂质和合金元素的引入,使得活性很高的镁基体与杂质形成电偶腐蚀,在含有C1-的腐蚀液中,腐蚀产物膜破坏一般是基于孔蚀机制[17]。而重金属尤其是铁,在镁合金中的溶解度小,当过多的铁以夹杂物形式存在于合金中时,将大大缩短蚀坑孕育期并加大合金的孔蚀速率。虽然Mg的表面钝化膜易被Cl-破坏,但是镁基体合金化能改善这层膜的性能。从实验结果可以看出:人们对于Zn含量为1%~2%时,合金的耐蚀性能显著提高。Zn提高耐蚀性的观点有两种:一种观点认为,加入Zn元素后形成了Mg-Zn固溶体,有助于合金表面形成致密的钝化膜[12];另一种观点认为,Zn元素可与杂质Fe生成FeZn相,减弱了Fe的有害作用[11]。本研究中添加1%~2%的Zn后,点蚀电位和钝化带发生变化,即表明添加Zn元素有助于在合金表面形成致密的钝化膜。当Zn元素含量增加到3%时,合金的钝化带消失,耐蚀性能也降低,这是由于此时合金析出了较多的阴极第二相,形成大量的微电偶腐蚀,析氢反应剧烈,加大合金的孔蚀速率,使合金的耐蚀性能降低。

3 结论

1) Zn元素可以显著地细化Mg-Mn合金的铸态组织。当Zn含量为3%时,合金铸态晶粒尺寸可以由原来的700~900 μm细化到50~80 μm。

2) 铸态Mg-Mn合金的力学性能随Zn含量的增加而增加,当Zn含量为3%时,拉伸强度达到218 MPa,较Mg-Mn合金提高128.8 MPa,屈服强度达到65.6 MPa,较Mg-Mn合金提高42.6 MPa,伸长率达到15.5%。

3) 1%~2%的Zn可以有效地改善铸态Mg-Mn合金的耐腐蚀性能,当Zn含量达到3%时,耐蚀性能反而下降。

REFERENCES

[1] CAHN R W, HAASEN P, KRAMER E J. Materials science and technology[M]. New York: VCH Publishers Inc, 1996: 18-20.

[2] WITTE F, FISCHER J, NELLESEN J, CROSTACK H A, KAESE V, PISCH A. In vitro and in vivo corrosion measurements of magnesium alloys[J]. Biomaterials, 2006, 27(7): 1013-1018.

[3] WITTE F, KAESE V, HAFERKAMP H, SWITZER E, MEYER-LINDENBERG A, WIRTH C J, WINDHAGEN H. In vivo corrosion of four magnesium alloys and the associated bone response[J]. Biomaterials, 2005, 26(17): 3557-3563.

[4] STAIGERA M P, PIETAKA A M. Magnesium and its alloys as orthopedic biomaterials: A review [J]. Biomaterials, 2006, 27(9): 1728-1734.

[5] ZHANG Er-lin, XU Li-ping, YANG Ke. Formation by ion plating of Ti-coating on pure Mg for biomedical applications[J]. Scripta Materialia, 2005, 53(5): 523-527.

[6] 王登峰, 张金山, 杜宏伟, 许春香, 王红霞, 韩富银, 赵兴国, 梁 伟. 镁锰合金的晶粒细化及其耐蚀性的研究[J]. 铸造设备研究, 2005, 1: 12-14.

WANG Deng-feng, ZHANG Jin-shan, DU Hong-wei, XUN Chun-xiang, WANG Hong-xia, HAN Fu-yin, ZHAO Xing-guo, LIANG Wei. Study on grain refinement and the corrosion resistance of magnesium-manganese alloy[J]. Research Studies on Foundry Equipment, 2005, 1: 12-14.

[7] 关学丰. 改善变形Mg-Mn系合金性能的研究[J]. 湖南冶金, 1993, 1: 7-9.

GUAN Xue-feng. Study of meliorate transmutative Mg-Mn system alloys[J]. Hunan Metallurgy, 1993, 1: 7-9.

[8] 范靖亚, 康广范. Mg-Y-Mn合金高性能板材研究[J]. 轻合金加工技术, 1994, 22(8): 45-47.

FAN Jing-ya, KANG Guang-fan. The study plank of high property of Mg-Y-Mn alloy[J]. Light Alloy Fabrication, 1994, 22(8): 45-47.

[9] 翁康荣, 赵红岩, 周占霞, 赵红亮. Si、Ca 对Mg-2Mn 变形镁合金组织和性能的影响[J]. 热加工工艺: 铸锻版, 2006, 35(1): 1-3.

WENG Kang-rong, ZHAO Hong-yan, ZHOU Zhan-xia, ZHAO Hong-liang. Influence of Si, Ca on microstructure and properties of Mg-2Mn alloy[J]. Hot Working Technology: Casting and Forging, 2006, 35(1): 1-3.

[10] BALLERINI G, BARDI U, BIGNUCOLO R, CERAOLO G. About some corrosion mechanisms of AZ91D magnesium alloy[J]. Corrosion Science, 2005, 47(9): 2173-2184.

[11] 张忠林, 刘兆晶, 李凤珍. 镁合金燃点和耐蚀性及力学性能的研究[J]. 轻合金加工技术, 2003, 31(7): 31-33.

ZHANG Zhong-lin, LIU Zhao-jing, LI Feng-zhen. Study on burning point & the corrosion resistance & the mechanical property of magnesium alloy[J]. Light Alloy Fabrication, 2003, 31(7): 31-33.

[12] 李冠群, 吴国华, 樊 昱, 丁文江. 主要合金元素对镁合金组织及耐蚀性能的影响[J]. 铸造技术, 2006, 27(1): 81-82.

LI Guan-qun, WU Guo-hua, FAN Yu, DING Wen-jiang. Effect of the main alloying elements on microstructure and corrosion resistance of magnesium alloys[J]. Foundry Technology, 2006, 27(1): 81-82.

[13] 谢 苗, 王 斌, 邓海燕, 甘纯玑. 海带膳食纤维的制备条件与营养评价[J]. 河南科技大学学报: 农学版, 2004, 24(4): 56-59.

XIE Miao, WANG Bin, DENG Hai-yan, GAN Chun-ji. Preparation and nutrition assessment on dietary fiber of kelp[J]. Journal of Henan University of Science and Technology: Agricultural Science, 2004, 24(4): 56-59.

[14] 胡汉起. 金属凝固原理[M]. 北京: 机械工业出版社, 2000: 126-130.

HU Han-qi. Principles of metal solidification[M]. Beijing: China Machine Press, 2000: 126-130.

[15] QIU D, ZHANG M X, Taylor J A, FU H M, Kelly P M. A novel approach to the mechanism for the grain refining effect of melt superheating of Mg-Al alloys[J]. Acta Materialia, 2007, 55(6): 1863-1871.

[16] MA Yan-long, PAN Fu-sheng, ZUO Ru-lin, ZHANG Jin, YANG Ming-bo. Effects of heat-treatment on microstructure of wrought magnesium alloy ZK60[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(3): 1889-1990.

[17] BARIL G, PEBERE N. The corrosion of pure magnesium in aerated and deaerated sodium sulphate solutions [J]. Corrosion Science, 2001, 43(3): 471-484.

基金项目:中国科学院“百人计划”资助项目;沈阳市创新平台建设计划资助项目

收稿日期:2007-09-04;修订日期:2007-12-10

通讯作者:张二林,教授;电话:024-23971605;E-mail: erlin.zhang@imr.ac.cn

(编辑 何学锋)