文章编号:1004-0609(2009)05-0833-08

高压压铸Mg-4Al-0.4Mn-xPr镁合金的

显微组织和力学性能

于 彭1,张景怀2, 3,唐定骧2,刘 轲2, 3,孟 健2,周德凤1

(1. 长春工业大学 化学与生命科学学院,长春 130012;

2. 中国科学院 长春应用化学研究所 稀土资源利用国家重点实验室,长春 130022;

3. 中国科学院 研究生院,北京 100039)

摘 要:采用高压压铸方法制备了Mg-4Al-0.4Mn-xPr(x = 0, 1, 2, 4, 6, 质量分数,%)系列镁合金,利用X射线衍射仪、场发射环境扫描电子显微镜、显微硬度测试、拉伸和压缩性能测试以及断口分析等手段研究了Pr对高压压铸Mg-4Al基合金微观组织和力学性能的影响。结果表明:高硬度合金铸造表面层与表面层中的高Pr含量和细密的组织有关;随着Pr添加量的增加,Al2Pr和Al11Pr3相在晶界附近形成,且其相对比例随之变化,同时合金组织被明显细化;添加约4%Pr(质量分数)的合金具有最佳的力学性能,良好的力学性能从室温一直保持到200 ℃;合金力学性能的提高主要由于合金致密的铸造表面层、大量第二相聚集晶界带来的晶界强化和细晶强化以及固溶强化所致。

关键词:镁合金;Pr;微观组织;力学性能

中图分类号:TG 146.2 文献标识码:A

Microstructures and mechanical properties of

high-pressure die-cast Mg-4Al-0.4Mn-xPr alloys

YU Peng1, ZHANG Jing-huai2, 3, TANG Ding-xiang2, LIU Ke2, 3, MENG Jian2, ZHOU De-feng1

(1. School of Chemistry and Life Science, Changchun University of Technology, Changchun 130012, China;

2. State Key Laboratory of Rare Earth Resources Application, Changchun Institute of Applied Chemistry,

Chinese Academy of Sciences, Changchun 130022, China;

3. Graduate School of Chinese Academy of Sciences, Beijing 100049, China)

Abstract: Mg-4Al-0.4Mn-xPr (x=0, 1, 2, 4 and 6, mass fraction, %) magnesium alloys were prepared by high-pressure die-casting technique. The effect of Pr on the microstructures and mechanical properties of die-cast Mg-4Al based alloy were investigated by XRD, FESEM, microhardness test, tensile and compressive properties tests and analysis of fracture surface. The results show that the fine rigid skin region is related to the aggregation of Pr and fine microstructure. Al2Pr and Al11Pr3 phases are mainly concentrated along the grain boundaries, and the relative ratio of the above two phases is in correlation with the Pr content in the alloy. Meanwhile, the grain sizes are greatly reduced with increasing Pr content. The mass fraction of Pr around 4% is considered to be suitable to obtain the optimal mechanical properties those can keep well until 200 ℃. The outstanding mechanical properties are mainly resulted from the rigid casting surface layer, grain boundary strengthening obtained by an amount of precipitates, grain refinement strengthening, as well as solid solution strengthening.

Key words: magnesium alloy; Pr; microstructure; mechanical properties

随着全球对汽车轻量化要求的不断提高,镁合金在汽车领域已得到广泛应用[1-2]。Mg-Al-Zn(AZ)和Mg-Al-Mn(AM)两个Mg-Al系列镁合金以其优良的铸造工艺性能和较高的室温力学性能而应用广泛。然而,由于AZ和AM系列铸造镁合金较差的高温(≥120 ℃)性能限制其在汽车自动变速箱和发动机缸体等关键部位应用的瓶颈[3-6],因此,开发高强耐热镁合金成为目前研究工作的重点。

Mg-Al-RE(AE和RE代表富铈混合稀土)系压铸合金是耐热镁合金研发应用的重点之一。早期研发的AE42(Mg-4Al-2RE)合金,由于生成Al11RE3相并抑制热稳定性差的Mg17Al12相形成,从而提高了Mg-Al基压铸合金的耐热性能和其使用温度[7-8]。但随后的相关研究表明,当温度高于150 ℃时,Al11RE3相会部分分解,致使合金抗高温蠕变性能急剧下降[9]。海德鲁镁业通过提高合金中富铈稀土的含量,开发了新型高压压铸合金AE44,通过提高合金中富铈稀土的含量,进一步提高了合金的耐热性能[10],但由于合金中添加的稀土仍为富铈稀土,因此,合金在高于150 ℃时蠕变性能下降的根本原因并没有得到完全解决。由此可见,Mg-Al-RE基合金中Al-RE的相对含量对合金的力学性能起到至关重要的作用。因此,为了完善此类耐热镁合金的性能,有必要对其进行深入研究。目前,单一稀土元素Pr对Mg-Al基压铸合金影响的研究还未见报道。因此,本实验在Mg-4Al-0.4Mn中掺杂稀土元素Pr,研究Pr的掺杂对合金微观组织和力学性能的影响,为进一步开发新型AE系耐热压铸镁合金提供必要的基础数据。

1 实验

1.1 合金的制备

实验用原材料为工业纯Mg、纯Al、Al-10%Mn和Mg-20%Pr(质量分数),配料时考虑到合金元素的实际收得率,所以配制的合金实际成分和设计成分基本相符。根据Pr掺入量的不同,合金的组成标记为Mg-4Al-0.4Mn(简写为AM40)、Mg-4Al-1Pr-0.4Mn(简写为AlPr41)、Mg-4Al-2Pr-0.4Mn(简写为AlPr42)、Mg-4Al-4Pr-0.4Mn(简写为AlPr44)和Mg-4Al-6Pr- 0.4Mn(简写为AlPr46)。在容量为30 kg的钢制坩埚电阻炉中熔炼合金, 采用手动方式将合金液浇入压铸机压射室中。合金样品采用280 t冷室压铸机进行压铸。

1.2 实验方法

采用Ultima2型电感耦合等离子体光谱仪(ICP-AES)分析合金成分,结果如表1所列。用Philips X′ Pert Pro Super X射线衍射仪(XRD)分析合金的相组成。从拉伸试棒中间段截取金相试样,以4%硝酸-酒精进行腐蚀,采用带有能谱仪(EDS)的XL30ESEM- FEG场发射环境扫描电子显微镜(FESEM)分析相形貌、断口形貌和组成,采用截线法测定合金的晶粒尺寸。用FM-700维氏硬度仪测定合金的维氏硬度(HV),载荷为0.25 N,保压时间为10 s,每组实验结果至少取5个测试点的平均值。采用的拉伸试棒标距为75 mm,直径为6.1 mm,压缩试样直径为6.1 mm,高度为10 mm。常温和高温拉伸、压缩实验均在Instron5869型材料实验机上进行,应变速率均为4.4×10-4 s-1,每组实验结果均取4个以上实验数据的平均值。

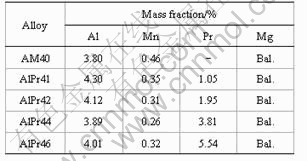

表1 合金的化学成分

Table 1 Chemical compositions of studied alloys

2 结果与讨论

2.1 合金的微观组织

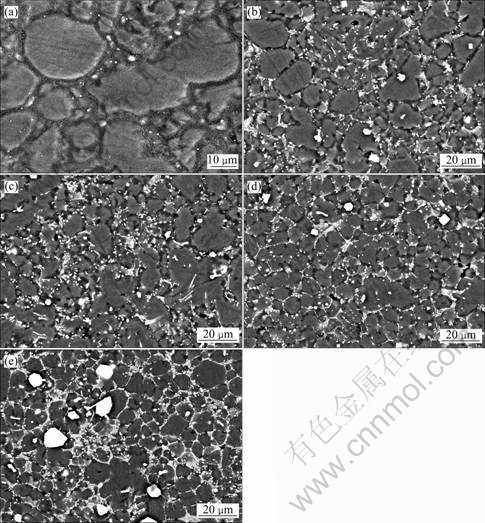

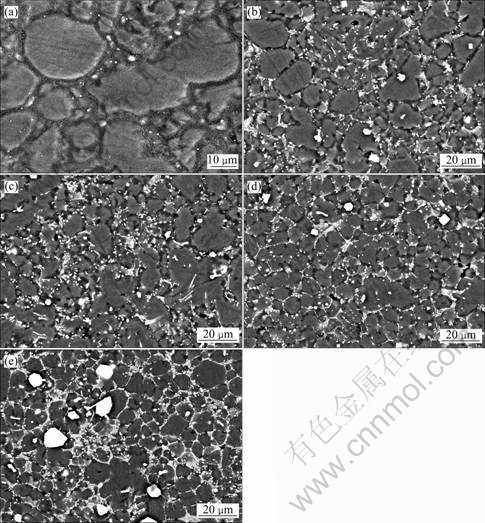

图1所示为5种压铸合金拉伸试棒中心区域的FESEM像。由图1可知,5种合金的微观结构主要由初生α-Mg固溶体和共晶组织组成。由图1(a)可知, AM40合金的初生α-Mg晶粒尺寸大小很不均匀,尺寸较大的可达30 μm。由图1(b)~(e)可以看出,随着Pr加入量的增多,初生α-Mg晶粒变得更细小、更均匀,当Pr含量为6%时,合金AlPr46的平均晶粒尺寸为11.1 μm。晶粒尺寸随Pr掺入量的变化关系如图2所示。此外,在晶界附近有白色的第二相存在,且随着Pr含量的增加,第二相的体积分数也明显增大,大尺寸的块状相也随之增多。

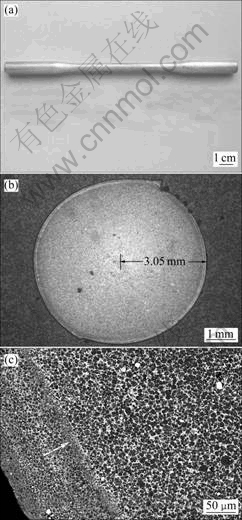

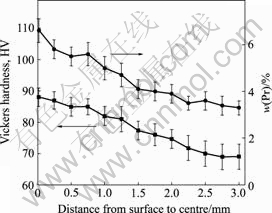

高压压铸AlPr44合金的显微硬度和选区位置的关系如图3所示。图3(a)所示为合金拉伸试棒的宏观形貌。由图3(a)可以看出,合金的冲模成形性良好,样品完整,表面光滑,没有裂纹和缺陷。图3(b)所示为拉伸试棒的截面光学组织。由图3(b)可以看出,合金组织均匀,没有明显的缩孔和微裂纹,说明该合金具有良好的压铸性能。从合金的微观组织可以看出(见图3(c)),截面上一条平行于铸造表面的“窄带”将合金分为较窄的表层区和宽的中心区。整个合金截面主要由细小的等轴晶构成,且晶粒尺寸从表层到中心,由小变大;表层的平均晶粒尺寸为8.4 μm,中心区的平均晶粒尺寸为11.5 μm。表层形成的主要原因是合金在压铸过程中表层液体接触到相对较冷的模具壁时,由于温度梯度大,在高压作用下迅速凝固,因而合金组织更加细密。

图1 压铸合金显微组织的FESEM像

Fig.1 FESEM images of die-cast alloys: (a) AM40; (b) AlPr41; (c) AlPr42; (d) AlPr44; (e) AlPr46

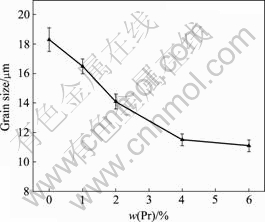

图2 Pr含量对合金中心区域晶粒大小的影响

Fig.2 Effect of Pr content on grain size in core regions

图4所示为合金截面(见图3(c))沿半径由表面向中心方向的硬度和Pr含量分布图。由图4可看出,合金的硬度由外至内逐渐降低,表层最大维氏硬度达到88 HV,约是中心硬度的1.3倍。从Pr的截面分布趋势来看,合金表层Pr的含量明显比中心区域高;在表层基体中,局部富集的稀土可达6.5%,中心仅为3.3%。由此可得:表层中高的硬度与合金化元素(例如Pr)的富集有很大关系。

图3 AlPr44合金拉伸试棒和拉伸试棒横截面照片以及铸造表层区的显微结构

Fig.3 Photos of die-cast bar(a), cross-section of hardness test(b) and SEM image of skin and partial interior regions(c)

图4 从AlPr44合金拉伸试棒表面到中部显微硬度和Pr含量的变化曲线

Fig.4 Change curves of vickers hardness and Pr content of tensile test bar from surface to center

高压压铸AlPr44合金拉伸试棒的横截面被一条与铸造表面平行的“窄带”分成窄的表层区和中心区(见图3(c))。类似的铸造特征在其它的高压压铸镁合 金[11]和铝合金[12-13]中也有报道。一般来说,在合金微观组织特征与合金的化学组成和铸造状态有关[11]。在合金制备过程中,高速流动的合金液在遇到较冷的模具壁时,由于高压下的剧烈传热,合金形成致密的表面层。“窄带”被认为是在压射室形成的半固态的软块进入模具型腔时,由于剪切变形而形成[9]。而内部区域由于相对传热较慢,少量在压射室凝固形成的晶体被压射入模具型腔后容易聚集在固液混合物的中心区域,因此,合金中心区域组织相对粗大。以上这些过程共同促成了高压压铸AlPr44合金的微观组织特征。

2.2 合金增强相分析

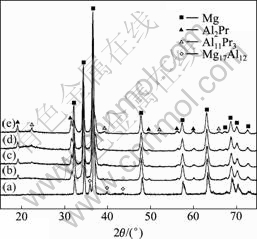

图5所示为AM40-xPr合金的XRD谱。由图5可看出,AM40合金的铸态组织主要由α-Mg相及少量β-Mg17Al12相组成。随着Pr的加入,Mg17Al12相的特征峰消失,在含Pr的4种合金中,Al2Pr相是其中主要的第二相之一,此外,随着Pr含量的增加,Al11Pr3相的特征峰出现,且越来越明显。

图5 压铸合金的XRD谱

Fig.5 XRD patterns of die-cast alloys: (a) AM40; (b) AlPr41; (c) AlPr42; (d) AlPr44; (e) AlPr46

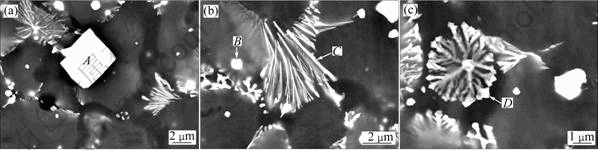

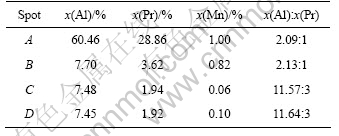

图6所示为高压压铸合金AlPr44中心区域不同形貌的第二相FESEM放大照片。由图6可知,合金中的第二相主要有4种形貌,分别标记为A、B、C、D点。对这4个点的EDS分析结果列于表2。根据XRD分析结果和Al与Pr的质量比可知,尺寸约为几个微米的四边形颗粒(A点)和尺寸为几百个纳米的多边形颗粒(B点)均为Al2Pr相。针状沉淀相(C点)的长度约为2~5 μm,直径为100~200 nm,丛聚在一起并以一定的角度分布在晶界上。另外还存在少量花瓣状的沉淀相(D点)。通过XRD和EDS的分析结果可知两者的化学式均为Al11Pr3。图7所示为合金AlPr44的SEM像及相应Mg、Al、Pr和Mn元素面扫描分布。从图7中可以看出,Mn除部分分布在基体外,大部分富集在Al2Pr相中。该分析结果和第二相的点能谱分析结果相一致(见表2)。

图6 AlPr44合金中第二相的FESEM像

Fig.6 FESEM images of secondary phases near grain boundaries in die-cast AlPr44 alloy

图7 AlPr44合金的SEM像及相应合金元素的面扫描分布

Fig.7 SEM images of die-cast AlPr44 alloy(a) and corresponding EDS area scanning of elements Mg(b), Al(c), Pb(d) and Mn(e)

表2 图6中各点的EDS分析结果

Table 2 Results of EDS analysis of spots in Fig.6

高压压铸Mg-4Al基合金中添加Pr完全抑制了Mg17Al12相的形成,Pr结合Al形成的Al-Pr相成为合金的主要第二相。且两种Al-Pr相的比例与合金中Pr的含量有关。当Pr的含量小于4%(质量分数)时,合金中主要的Al-Pr相为Al2Pr相;进一步增加Pr含量时,Al11Pr3相随之明显增多。相似的规律在高压压铸Mg-Al-Nd基合金中也有报道[13]。多边形的Al2Pr相被认为是作为共晶相形成,而Al11Pr3相被认为是包晶反应的产物[14]:

3Al2Pr+L→Al11Pr3 (1)

Al11Pr3相的形成伴随高Pr含量可能是因为高Pr含量能够加速包晶反应[15]。因此,Al11Pr3相总是存在于Pr和Al含量相对较高的晶界附近。

2.3合金的力学性能

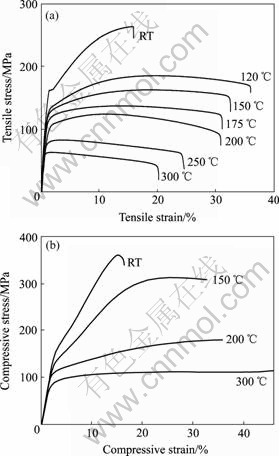

图8所示为高压压铸AlPr44合金在不同温度下的典型拉伸和压缩应力—应变曲线。由图8可知,室温下合金具有较高的屈服强度、明显的形变硬化行为及良好的塑性。随着温度的增加,屈服强度和形变硬化效果逐渐降低,表明合金在室温到200 ℃范围内保持了良好的力学性能。

图8 不同温度下AlPr44合金典型的拉伸(a)和压缩应力—应变曲线(b)

Fig.8 Typical tensile curves(a) and compressive stress—strain curves(b) of die-cast AlPr44 alloy at different temperatures

表3所列为从室温到300 ℃范围内5种合金的抗拉强度(σb)、拉伸屈服强度(σs)和伸长率(η)。由表3可知,AM40合金抗拉强度最差,随着Pr的添加,无论是室温还是高温下的抗拉强度都得到明显提高。如室温下AM40合金的抗拉强度为210 MPa,200 ℃时为77 MPa;室温下AlPr44合金的抗拉强度为263 MPa,200 ℃时为128 MPa,分别提高25%和66%。随着Pr含量的增大,合金屈服强度的变化趋势和抗拉强度的变化趋势基本一致。室温下,AlPr44合金具有最高的屈服强度,在高温下(200 ℃)AlPr46合金的屈服强度比AlPr44合金的稍高,如AM40合金室温下屈服强 度为105 MPa,200℃时为60 MPa;室温下,AlPr44和AlPr46合金的屈服强度分别为163和160 MPa, 200 ℃时,AlPr44和AlPr46合金的屈服强度分别为109和111 MPa。同样,随着Pr含量的增大,合金的延展性也得到提高。室温下,AlPr44合金的延展性较大,这5种合金的延展性随着温度的升高而增加,并在一定温度下达到最大值。

表3 不同温度下合金的拉伸性能

Table 3 Tensile properties of studied alloys at different temperatures

高压压铸Mg-Al-Pr基合金显示了较高的力学性能和在中高温区可接受的耐热性能。可以认为这主要与以下几个方面有关:1) 合金表面层的Pr含量比内部区域的Pr含量高(见图4),且表面层的微观结构更加致密(见图3(c)),致密的铸造表面层对合金力学性能的提高具有积极的作用;2) Pr元素与Al具有更高的亲和力,抑制了热稳定性差的Mg17Al12相的形成,同时大量热稳定性高的Al2Pr相和Al11Pr3相在合金晶界附近形成,这样能够有效地抑制晶界滑移和晶界附近的位错运动,从而提高合金的室温和高温力学性能;3) Mg、Al和Pr的原子半径分别为0.160,0.143和 0.183 nm[16],可以看出,与Mg和Al的半径差相比,Mg与Pr的原子半径相差更大,因此,Pr原子固溶到Mg基体中能更有效地使基体产生晶格畸变,产生内应力场,增大位错运动的阻力,从而强化合金基体。Pr的添加使得合金晶粒细化也是非常重要的一种强化机制。晶界是位错滑移的障碍,即位错要穿越不同晶格取向的晶粒时必须改变方向,因此,一般细晶意味着合金强度的提高,同时,晶粒细化也是提高合金塑性的有效途径。然而,在本实验中,具有最小晶粒尺寸的AlPr46合金并没有具备最好的塑性。本文作者认为这是由于随着Pr含量的增大,合金中尺寸较大的脆性块状Al2Pr相的数量增多,它们对基体的割裂作用促使合金在应力作用下微裂纹容易在此处萌生和扩展。图9所示的合金的拉伸断面形貌有效支持了这种观点。因此,在高压压铸Mg-4Al-0.4Mn基合金中添加约4%的Pr能够使合金具有最佳的力学性能。

图9 AlPr46合金拉伸断口的FESEM像

Fig.9 FESEM images of big bulk Al2Pr phase with second cracks on fractural surface of HPDC AlPr46 alloy: (a) Secondary FESEM observation; (b) Corresponding backscatter FESEM observation

3 结论

1) 高压压铸Mg-4Al-4Pr-0.4Mn合金的硬度由铸造表面层到中心区域的硬度逐渐降低,主要是由于表面层具有含量较高的合金化元素(例如Pr),使其冷却速率也较大,导致形成更致密的合金组织。

2) 添加Pr后,合金中的Mg17Al12相被完全抑制,随着Pr含量的增加,两种新的第二相Al2Pr和Al11Pr3的数量明显增多,且其相对比例也发生变化。

3) Mg-4Al-0.4Mn基合金中添加4%Pr时具有最佳的力学性能,随温度升高到200 ℃均能很好地保持较佳的力学性能。合金良好的力学性能主要由于合金致密的铸造表面层、大量第二相聚集晶界带来的晶界强化和细晶强化以及固溶强化所致。

REFERENCES

[1] LUO A A. Processing maps for hot deformation of rolled AZ31 magnesium alloy plate: Anisotropy of hot workability[J]. Int Mater Rev, 2004, 49: 13-30.

[2] BAKKE P, WESTENGEN H. Eutectic phase investigation in a Ca-added AM50 magnesium alloy produced by die casting[J]. Adv Eng Mater, 2003, 5: 879-885.

[3] LUO A, PEKGULERYUZ M O. Review of cast magnesium alloy for elevated temperature applications[J]. Mater Sci, 1994, 29: 5259-5271.

[4] MIN Xue-gang, SUN Yang-shan, XUE Feng, DU Wen-wen, WU Deng-yun. Thermodynamic calculation of intermetallic compounds in AZ91 alloy containing calcium[J]. Materials Chemistry and Physics, 2002, 78(1): 88-93.

[5] WANG Y, LIU G, FAN Z. Microstructural evolution of rheo-diecast AZ91D magnesium alloy during heat treatment[J]. Acta Materialia, 2006, 54(3): 689-699.

[6] 张新明, 彭卓凯, 陈健美, 邓运来. 耐热镁合金及其研究进展[J]. 中国有色金属学报, 2004, 14(9): 1444-1450.

ZHANG Xin-ming, PENG Zhuo-kai, CHEN Jian-mei, DENG Yun-lai. Heat-resistant magnesium alloys and their development [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(9): 1444-1450.

[7] PETTERSEN G, WESTENGEN H, HOIER R, LOHNE O. Microstructure of a pressure die cast magnesium-4wt.% alumimium alloy modified with rare earth additions[J]. Mater Sci Eng A, 1996, 207(1): 115-120.

[8] MORENO I P, NANY T K, JONES J W, ALLISON J E, POLLOCK T M. Thermodynamic evaluation and optimization of the Li, Na, K, Mg, Ca//F, Cl reciprocal system using the modified quasi-chemical model[J]. Scripta Mater, 2001, 45: 1423-1429.

[9] POWELL B R, REZHETS V, BALOGH M P, WALDO R A. Forming and bonding techniques for high-strength aluminum alloys[J]. JOM, 2002, 54: 34-38.

[10] BAKKE P, WESTENGEN H. Effect of rare earth elements on the microstructure of Mg-Al alloys[J]. Magnesium Technology, 2005, 12: 291-296.

[11] GOURLAY C M, LAUKLI H I, DAHLE A K. Defect band characteristics in Mg-Al and Al-Si high pressure die castings[J]. Metall Mater Trans A, 2007, 38: 1833-1844.

[12] DAHLE A K, SANNES S, St JOHN D H, WESTENGEN H. Effect of microstructure on mechanical properties of as-cast Mg-Al alloys[J]. Light Metals, 2001(1): 99-103.

[13] LAUKLI H I, GOURLAY C M, DAHLE A K, LOHNE O. Effects of Si content on defect band formation in hypoeutectic Al-Si die castings[J]. Mater Sci Eng A, 2005, 413: 92-97.

[14] ZHANG Jing-huai, WANG Jun, QIU Xin, ZHANG De-ping, TIAN Zheng, NIU Xiao-dong, TANG Ding-xiang, MENG Jian. Effect of Nd on the microstructure, mechanical properties and corrosion behavior of die-cast Mg-4Al-based alloy[J]. Journal of Alloys and Compounds, 2008, 464(1/2): 556-564.

[15] ZOU Hong-hui, ZENG Xiao-qin, ZHAI Chun-quan, DING Wen-jiang. The effects of yttrium element on microstructure and mechanical properties of Mg-5wt.%Zn-2wt.%Al alloy[J]. Mater Sci Eng A, 2005, 402(1/2): 142-148.

[16] 余永宁, 强文江. 工程材料科学与技术[M]. 北京: 机械工业出版社, 2003: 637-638.

YU Yong-ning, QIANG Wen-jiang. The science and design of engineering materials[M]. Beijing: China Machine Press, 2003: 637-638.

基金项目:国家高技术研究发展计划资助项目(2006AA03Z520);中国科学院重大基金资助项目(2006BAE04804B01-1)

收稿日期:2008-07-28;修订日期:2008-12-01

通讯作者:周德凤,教授,博士;电话:0431-85716473;E-mail: defengzhou65@126.com

(编辑 龙怀中)