文章编号: 1004-0609(2005)01-0038-06

Ti811合金的高温微动疲劳行为

高广睿, 刘道新, 张晓化

(西北工业大学 腐蚀与防护研究室, 西安 710072)

摘 要: 利用高频疲劳实验机和自制高温微动疲劳装置, 研究了温度、 位移幅度、 接触压力等因素在对Ti811钛合金高温微动疲劳(FF)行为的影响, 并通过形态特征分析, 研究了微动疲劳的失效机理。 结果表明: 350℃和500℃的高温下, Ti811合金微动疲劳敏感性较高, 且随着温度的升高, 微动疲劳的敏感性增强, 蠕变是高温下Ti811合金FF失效的重要影响因素; FF的寿命随着接触压力和位移幅度的变化均呈现出非单调的变化规律, 原因是名义接触压力的变化改变了接触区应力分布、 应力集中状况和微动位移幅度大小, 进而影响FF裂纹萌生几率和扩展驱动力; 位移幅度变化影响了疲劳应力因素和磨损在FF过程中所起作用和机制。

关键词: 微动疲劳; 高温; 钛合金; 磨损; 蠕变 中图分类号: TG174

文献标识码: A

Fretting fatigue behaviors of Ti811 alloy at elevated temperature

GAO Guang-rui, LIU Dao-xin, ZHANG Xiao-hua

(Corrosion and Protection Research Laboratory,

Northwestern Polytechnical University, Xi'an 710072, China)

Abstract: The fretting fatigue (FF) behaviors of Ti811 alloy influenced by temperature, slip amplitude and contact pressure were investigated using high frequency fatigue machine and self-made high temperature apparatus. The FF mechanisms were discussed by observing fretting surface morphology features. The results show that FF sensitivity is high at both 350℃ and 500℃. The higher the temperature is, the more sensitive the FF failure of the alloy. Creep is the important factor which influences FF failure process of Ti811 alloy at elevated temperature. The FF life of the alloy doesnt change in a monotone way with the increasing slip amplitude and contact pressure. This is due to the fact that slip amplitude affects the action of fatigue and wear in fretting process, the nominal contact pressure affects the distribution and concentration of stress and fretting slip amplitude value at contact surface, further influences crack initiation probability and propagation driving force.

Key words: fretting fatigue; elevated temperature; titanium alloy; wear; creep

微动疲劳(Fretting fatigue, FF)是承受疲劳载荷的构件由于在接触部位同时存在微小位移幅度的摩擦磨损而加速的失效破坏过程, 该类失效广泛存在于航空、 航天、 交通、 核能等诸多工业部门中[1-3], 常常造成关键部件的提前断裂, 导致严重的事故, 尤其是在航空工业中更为突出和普遍[1, 2]。

Ti811(Ti8Al1Mo1V)合金具有密度低、 弹性模量高、 振动阻尼性能优良、 热稳定性好、 焊接性能和成型性能好等诸多优点, 尤其是其比刚度是工业钛合金中最高的, 因而成为先进航空发动机压气机高温端转动部件的重要选材之一。 我国近年来研究和开发了该合金材料[4]。 然而, 钛合金导热性能差、 摩擦系数高, 因而普遍存在抗微动疲劳损伤性能低的缺点[5], 由此影响了钛合金航空发动机压气机转子叶片和盘的可靠性和使用寿命[6, 7]。 目前对Ti811合金的热稳定性、 抗氧化性能、 抗热盐应力腐蚀性能和高温蠕变性能等均进行了较深入的研究[4, 8, 9], 然而, 对其抗高温微动疲劳性能尚未进行过研究。

关于Ti6Al4V等常用钛合金的微动疲劳损伤已进行了较为广泛的研究, 如Hutson等[10-12]通过扫描电镜(SEM)观察FF损伤形态特征提出了Ti6Al4V合金的FF损伤机理模型; Jin等[13, 14]研究了位移幅度和接触几何对Ti6Al4V钛合金FF寿命的影响规律; Mall等[15]对Ti6Al4V合金FF裂纹萌生机理进行了分析; 刘道新等[5, 16]和Chakravarty等[1, 6, 17]则较全面地研究了表面处理对Ti6Al4V合金FF抗力的作用规律。 但由于微动疲劳损伤过程十分复杂, 涉及到摩擦磨损、 疲劳、 腐蚀(包括氧化)多种失效形式, 影响因素颇多[18], 因而致使目前人们对微动疲劳损伤机制, 尤其是对高温环境下的微动疲劳失效机理的认识仍不够深入, 由此导致在FF有效控制方法的研究中存在一定的盲目性 [1, 6, 19]。 基于以上研究背景, 本文作者以Ti811合金为对象, 选择温度、 微动位移幅度和接触压力等主要参数, 研究其高温FF行为, 既可为Ti811合金的工程应用提供依据, 同时也有助于对材料高温微动疲劳失效机理的深入认识。

1 实验

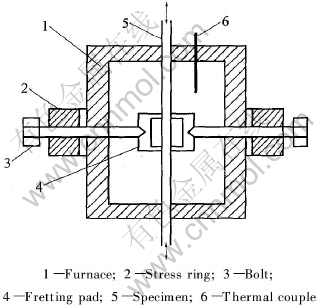

高温微动疲劳实验通过自行研制的专用装置, 在PLG-100C高频疲劳实验机上进行, 选择拉—拉疲劳加载方式, 试样几何尺寸和实验装置如图1和图2所示。 微动桥足和微动疲劳试样表面之间采用平面—平面接触方式, 接触区面积为2mm×6mm。 微动区位移依靠拉—拉疲劳过程中, 试样表面弹性变形相对于微动桥足改变来实现, 调整微动桥的跨距, 即可改变位移幅度。 接触区正压力采用应力环法施加, 通过最大循环应力与微动疲劳寿命之间的关系曲线(即S—N曲线)来评价实验温度对微动疲劳敏感性的影响, 循环载荷波形为正弦波, 频率110Hz, 应力比R=0.1。 位移幅度和接触压力的影响在固定循环应力幅和环境温度下进行研究, 温度350℃, 最大循环应力530MPa, FF寿命取3个平行试样的平均值。 实验过程中的高温环境采用桶式电阻炉进行加热获得, 利用热电偶和智能温控仪实现炉内温度的监控。

图1 试样几何尺寸

Fig.1 Size of fretting fatigue specimen (mm)

图2 实验装置示意图

Fig.2 Sketch of FF test apparatus

微动疲劳实验所用试样和微动桥均由直径为16mm的Ti811合金棒材制备, Ti811合金为近α型钛合金, 其化学成分为: 7.9%Al, 1.0%Mo, 0.99%V, 0.05%Fe, 0.1%C, 0.01%N, 0.001%H, 0.06%O, 余量为Ti(质量分数)。 Ti811合金采用双重退火处理, 即: 910℃保温1h, 空冷+580℃保温8h, 空冷。 合金组织为等轴α+晶间β, 常温下的力学性能为σb=931MPa, σ0.2=890MPa, δ=23%, Ψ=46%。

利用HITACHI S-570型扫描电子显微镜观察和分析微动疲劳试样的微动区损伤的形态特征。

2 结果与讨论

2.1 温度对Ti811合金FF行为的影响

图3所示为350℃下Ti811合金常规疲劳(PF)和微动疲劳的S—N曲线, 实验表明微动疲劳试样断裂全部发生在微动接触区。 实验中微动桥足跨距为15mm, 桥足与试样表面间的名义接触压应力为85MPa。 由图可以看出, 退火态Ti811合金对微动疲劳损伤较为敏感, 接触区微动作用使疲劳极限下降了约40%。 微动作用促进疲劳裂纹的萌生与早期扩展, 因而对疲劳极限的影响显著。 在高的外加循环应力水平下, 轴向载荷起主导作用, 无论常规疲劳还是微动疲劳, 裂纹均较容易萌生, 疲劳寿命相对较短, 而由于表面微动作用主要促使裂纹萌生和早期扩展, 因而与低应力水平相比, 高循环应力下微动的作用不是十分明显。

图3 Ti811合金在350℃时的常规疲劳与微动疲劳的S—N曲线

Fig.3 S—N curves of PF and FF of Ti811 alloy at 350℃

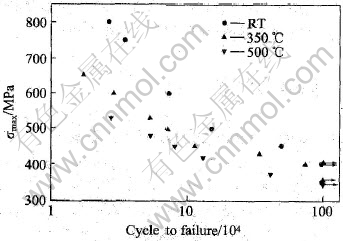

压气机零部件的工况温度随压气机的级数增加而升高, 最高温度通常在500℃左右。 图4所示为室温(RT)、 350℃和500℃ 3个典型温度下Ti811合金的微动疲劳S—N曲线。 由图可以看到, 随着温度的升高, 微动疲劳极限降低, 同一循环应力水平下的微动疲劳寿命减小。 特别是在高应力水平下, 温度造成疲劳寿命降低更加显著, 或者说相同的FF失效寿命, 高温所需要的最大循环应力水平更低。

图4 不同温度下Ti811合金微动疲劳的S-N曲线

Fig.4 S—N curves of FF of Ti811 alloy at different temperatures

温度升高会带来两方面的影响: 一是蠕变作用增大, 促进材料整体疲劳性能下降; 二是加速了材料表面的氧化。 应力水平、 温度和时间是影响蠕变行为的重要因素, 本文实验结果表明, 高应力水平下温度的影响更为显著, 其主要原因是蠕变的作用。 研究表明[8], 低于425℃时, Ti811合金的蠕变机制以扩散机制为主, 蠕变敏感性较低; 高于425℃时, 由于滑移系增多和交滑移的开动及晶界滑动的出现, Ti811合金的蠕变敏感性增大, 因而其疲劳抗力降低。 本文的研究表明, 在500℃和530MPa最大循环应力的实验条件下, 尽管微动疲劳试样的断裂仍然发生在微动接触区, 但在试样的微动区外的部位已经存在许多常规疲劳引发的裂纹, 这进一步说明了应力和温度的协同作用造成的蠕变在较高温度和较高应力水平下对微动疲劳破坏的重要影响。

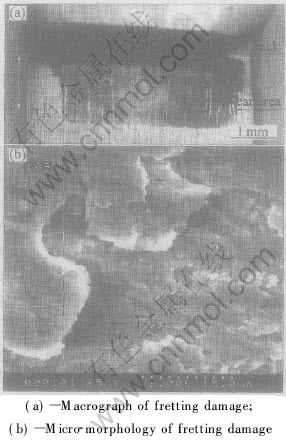

高温环境会促进钛合金表面的氧化, 在微动接触区表面由于摩擦磨损作用导致的高应变和大变形, 形成了黑色微动斑, 微动区与未经微动作用的自由表面之间形成了明显的界限(图5(a))。 SEM表面分析表明, Ti811合金微动区表面损伤以表面脱层为主要失效形式(图5(b)), 表面脱层导致微动接触区表面产生磨屑, 磨屑在高温氧化环境作用下有可能进一步氧化成TiO2硬质磨粒, 加速磨粒磨损, 进而影响微动疲劳损伤过程。 另外, 一旦微动区出现裂纹, TiO2硬质磨粒会进入裂纹, 产生楔入效应, 将加速裂纹的扩展。

图5 350℃时FF试样的表面损伤形态(接触压力为85MPa)

Fig.5 Surface morphologies of FF specimen at 350℃ under 85MPa

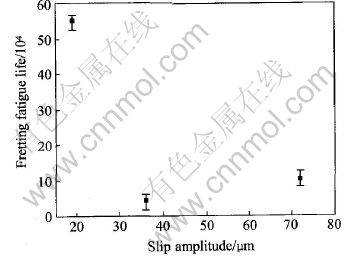

2.2 位移幅度对Ti811合金FF寿命的影响

图6所示为位移幅度对350℃下Ti811合金FF寿命影响规律的实验结果, 实验中最大循环应力为530MPa, 名义接触压应力固定为85MPa。 由图可以看到, 位移幅度对Ti811合金FF寿命的影响并非单调变化, 而是在某一位移幅度时出现寿命最低的现象。 本文作者在Ti6Al4V钛合金常温微动疲劳的研究中也曾发现这种特征[20], 其原因主要是微动接触区接触情况受位移幅度的影响。 当位移幅度较大时, 接触区趋于整体滑移(gross slip), 在整体滑移状态下, 磨损区增大, 表面的磨损程度增强, 不仅导致可扩展裂纹形成的几率减小, 而且会使已萌生的裂纹去除。 另外, 整体滑移状态下, 微动接触区应力集中部位也由局部滑动状态下的接触区边缘处转移到接触区中部(图7(a))。 同时, 被氧化的磨屑对接触体表面能起到一定的调节作用, 因而试样表面的应力集中程度会得到一定的缓解, 局部接触疲劳效应降低。 因此位移幅度足够高时, FF寿命反而呈增大趋势。

当位移幅度较小时, 粘着区(stick region, 即桥足与试样表面保持相对静止的区域)增大, 滑移区减小(图7(c)), 接触表面呈现局部滑动, 表面切向位移引起粘着区表面接触状态的“微凸峰”发生弹性变形, 微动接触区磨损轻微, 此时裂纹萌生的几率降低, 故FF寿命也较高。 当处于上述2种状态间的某位移幅度时, 粘着区外侧被滑移区包围, 处于混合的状态(图7(b)), 切向摩擦力随位移的变化十分剧烈, 同时接触表面在滑动区和粘着区的交界处受到较大的切向力的反复作用, 在滑动区前出现很高的局部压应力, 而在滑动区后缘拉应力达到最大, 表层塑性变形和局部磨损强烈, 由此导致在滑移区和粘着区的交界处易于萌生裂纹, 并能迅速发展, 故FF寿命低。

图6 位移幅度对Ti811合金FF寿命的影响

Fig.6 Slip amplitude on FF life of Ti811 alloy

图7 不同位移幅度下Ti811合金的FF宏观形态

Fig.7 FF surface macrographs of Ti811 alloy under different slip amplitudes

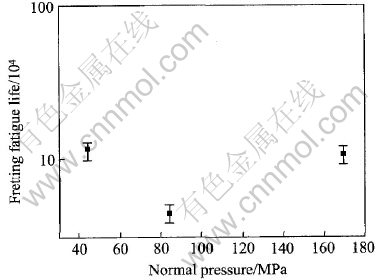

2.3 接触压力对Ti811合金FF寿命的影响

图8所示为350℃下表面名义接触压应力对Ti811合金FF寿命影响的实验结果。 实验中最大循环应力为530MPa, 微动桥跨距均为15mm。 由图可以看到, 接触压应力对FF寿命的影响同样呈非单调变化规律。 其原因是当接触压力高时, 粘着区增大(图9(a)), 表面上保持接触状态的“微凸峰”弹性变形量增加, 真实接触面积增大, 实际接触应力降低, 裂纹萌生的几率也随之降低, 故FF寿命增加。 当接触压力低时, 接触区处于整体滑移状态, 表面磨损较为严重(图9(c)), 会使已有的微裂纹成核点磨去, 由此导致可扩展性裂纹萌生几率下降; 同时聚集在界面上的磨屑还可起微动调节作用, 缓解表面间的直接作用, 使界面切应力降低, 故FF寿命反而较高。 只有当接触压力处于某一范围时, 接触表面的非滑动区很窄, 接触应力在滑移区与非滑移区交界处高度集中, 促使裂纹在此处萌生, 导致较低的FF寿命。 另外, 依靠试样弹性形变改变微动位移幅度的实验中, 接触压力与位移幅度的变化并非独立的, 而是存在耦合关系, 即在同样的微动桥跨度和循环应力幅度下, 名义接触压力愈大, 则接触区的真实位移幅度愈小, 而前面的结果已表明, 位移幅度足够小时, FF寿命较高。

图8 表面名义接触压应力对Ti811合金FF寿命的影响

Fig.8 Surface nominal pressure on FF life of Ti811 alloy

图9 Ti811合金在不同接触压力下的FF表面损伤形态

Fig.9 FF surface morphologies of Ti811 alloy under different contact pressures

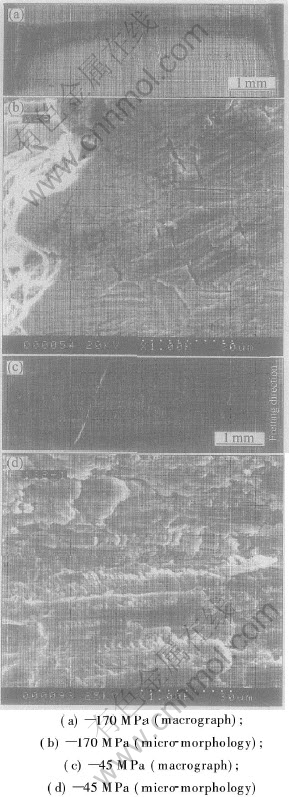

表面接触压力对Ti811合金微动疲劳行为的影响, 在微动接触区宏观和微观损伤形态上均有明确的反映(图5、 9和10)。 压应力足够高时, 整体磨损较轻, 应力因素在FF失效中起主导作用, 断口附近呈现出严重的塑性流变; 压应力较低时, 整体磨损强烈, 磨损机制为脱层和磨粒磨损混合型, 此时可扩展性裂纹较少, 断裂位置则由高压应力时的接触区边缘处转移到接触区中部(图10)。 当处于上述 2种压应力状态中间的某一应力范围时, 力学因素和局部磨损协同作用, 促进FF裂纹的萌生和扩展, 由此导致FF失效倾向增高。

图10 接触压应力为45MPa的微动损伤区断裂形貌

Fig.10 FF fracture morphology under 45MPa

3 结论

1) 在350℃和500℃的高温下, Ti811合金微动疲劳敏感性较高, 且温度愈高, 微动疲劳的敏感性愈强, 蠕变在高温下Ti811合金FF失效中起着重要影响作用。

2) FF寿命随位移幅度的变化呈现出非单调的变化规律, 原因是位移幅度的变化影响了疲劳应力因素和磨损在FF失效过程中所起作用和机制。

3) FF寿命随接触压力的增大呈现出非单调的变化规律, 原因是名义接触压力的变化改变了接触区应力分布、 应力集中、 微动位移幅度大小及磨损的程度大小与磨损的作用机制, 进而影响FF裂纹萌生几率和扩展驱动力。

REFERENCES

[1]Chakravarty S, Koul A K. The effect of surface modification on freting fatigue in Ti alloy turbine components[J]. Journal of Metals, 1995, 47(3): 31-37.

[2]Hoeppner D, Adibnazari S, Moesser M W. Literature Review and Preliminary Studies of Fretting and Fretting Fatigue Including Special Application to Aircraft Joints[R]. AD-A280310, 1994.

[3]Lindley T C. Fretting fatigue in engineering alloy[J]. Int J Fatigue, 1997, 19(1): 39-49.

[4]赵永庆, 刘炳南. 合金成分对Ti811棒材性能的影响[J]. 稀有金属材料与工程, 1994, 23(3): 59-65.

ZHAO Yong-qing, LIU Bin-nan. Effect of alloying composition on the mechanical properties of Ti811 alloy rods[J]. Rare Metal Materials and Engineering, 1994, 23(3): 59-65.

[5]刘道新, 唐宾, 陈华, 等. 钛合金表面离子束增强沉积MoS2基膜层及其性能[J]. 中国有色金属学报, 2001, 11(3): 454-460.

LIU Dao-xin, TANG Bin, CHEN Hua, et al. MoS2 composite films on titanium alloys prepared by ion beam enhanced deposition[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3): 454-460.

[6]Xue L, Bibby M, Wallace W, et al. A survey of surface treatment to improve the fretting fatigue resistance of Ti6Al4V[A]. Proc of Conf on Computer Methods and Experimental Measurement for Surface Treatment Effect Ⅱ[C]. Milan, Italy: Computional Mechanics Publishing House, 1995. 265-272.

[7]Joseph N G, Lalita U. Quantitative Characterization of Fretting Damage in Aircraft Turbine Disks[R]. AD-A396375, Chicago: ONRR, 2000.

[8]赵永庆, 朱康英, 李左臣. Ti811合金棒材的热稳定性能和蠕变性能[J]. 材料开发与应用, 1995, 10(4): 16-21.

ZHAO Yong-qing, ZHU Kang-ying, LI Zuo-chen, Thermal stability and creep behavior of Ti811 alloy rods[J]. Development and Application of Materials, 1995, 10(4): 16-21.

[9]张卫方, 刘新灵, 赵爱国. 钛合金在500℃~650℃下的氧化行为研究[J]. 材料热处理学报, 2003, 24(2): 55-61.

ZHANG Wei-fang, LIU Xin-ling, ZHAO Ai-guo. Investigation on oxidation behaviors of titanium alloy at temperature from 500℃ to 650℃[J]. Transactions of Materials and Heat Treatment, 2003, 24(2): 55-61.

[10]Hutson A L, Neslen C, Nicholas T. Characterization of fretting fatigue crack initiation processes in CR Ti-6Al-4V[J]. Tribology International, 2003, 36: 133-143.

[11]Conner B P, Hutson A L, Chambon L. Observations of fretting fatigue micro-damage of Ti-6Al-4V[J]. Wear, 2003, 255: 259-268.

[12]Hutson A L, Nicholas T, Goodman R. Fretting fatigue of Ti-6Al-4V under flat-on-flat contact[J]. International Journal of Fatigue, 1999, 21: 663-669.

[13]Jin O, Mall S. Effects of independent pad displacement on fretting fatigue behavior of Ti-6Al-4V[J]. Wear, 2002, 253: 585-596.

[14]Jin O, Mall S. Influence of contact configuration on fretting fatigue behavior of Ti-6Al-4V under independent pad displacement condition[J]. International Journal of Fatigue, 2002, 24: 1243-1253.

[15]Mall S, Namjoshi S A, Porter W J. Effects of microstructure on fretting fatigue crack initiation behavior of Ti-6Al-4V[J]. Materials Science and Engineering A, 2004, A383: 334-340.

[16]刘道新, 陈华, 何家文. 等离子渗氮与喷丸强化复合改进钛合金抗微动损伤性能[J]. 材料热处理学报, 2001, 22(3): 49-54.

LIU Dao-xin, CHEN Hua, HE Jia-wen. The effect of plasma nitriding and shot peening on the fretting damage resistance of Ti-alloy[J]. Transactions of Materials and Heat Treatment, 2001, 22(3): 49-54.

[17]Chakravarty S. Dyer J P. Influence of surface treatments on fretting fatigue of Ti-6242 at elevated temperature[A]. ASTM-STP1367[C]. West Conshohocken: American Society for Testing and Materials, 2000. 495-508.

[18]Dobromirski J M. Variables of fretting process[A]. Helmi Attia M, Waterhouse R B. ASTM-STP1159[C]. Philadelphia: American Society for Testing and Materials, 1992. 60-66.

[19]WU Ling-ling, Holloway B C, Beesabathina D P. Analysis of diamond-like carbon and Ti/MoS2 coatings on Ti6Al4V substrates for applicability to turbine engine applications[J]. Surface and Coatings Technology, 2000, 130(2): 207-213.

[20]刘道新, 何家文. 微动疲劳影响因素及钛合金微动疲劳行为[J]. 航空学报, 2001, 21(2): 454-457.

LIU Dao-xin, HE Jia-wen. Review of factors that influence fretting fatigue (FF) and investigation on FF behavior of Ti-alloy[J]. Acta Aeronautica et Astronautica Sinica, 2001, 21(2): 454-457.

基金项目: 国家自然科学基金资助项目(50171054); 航空科学基金资助项目(01H53066)

收稿日期: 2004-07-20; 修订日期: 2004-11-15

作者简介: 高广睿(1979-), 男, 硕士研究生.

通讯作者: 刘道新, 教授; 电话: 029-88491479; E-mail: liudaox@nwpu.edu.cn

(编辑李向群)