复合表面改性协同增强Ti合金高温微动疲劳抗力

张晓化, 刘道新, 唐长斌, 高广睿

(西北工业大学 航空学院, 西安 710072)

摘 要: 研究了Ti 811(Ti8Al1Mo1V)钛合金表面离子束增强沉积(IBED)0Cr18Ni9膜层的膜基界面成分分布、 膜基结合强度、 膜层硬度和摩擦学行为。 利用喷丸形变强化对IBED膜层进行后处理, 拟达到联合提高钛合金高温微动疲劳抗力的目的。 结果表明: 离子束增强沉积技术可以获得致密度高, 晶粒细化, 孔隙率低, 膜基结合强度高的0Cr18Ni9膜层, 从而显著提高了钛合金表面硬度和耐磨性能; 离子束增强沉积0Cr18Ni9膜层的耐磨性能与喷丸形变强化引入的表层残余压应力协同作用, 使Ti 811合金在350℃高温下的微动疲劳抗力显著提高, 并且高于喷丸强化或IBED膜层的单独作用。

关键词: 钛合金; 微动疲劳; 复合表面改性; 高温; 喷丸强化; 离子束增强沉积 中图分类号: TG115

文献标识码: A

Synergistic improving fretting fatigue resistance of Ti alloy at elevated temperature by duplex surface modification

ZHANG Xiao-hua, LIU Dao-xin, TANG Chang-bin, GAO Guang-rui

(School of Aeronautics, Northwestern Polytechnical University, Xian 710072, China)

Abstract: The 0Cr18Ni9 film was deposited on Ti 811 titanium alloy surface by ion-beam-enhanced deposition (IBED). The composition distribution, bonding strength, hardness and the wear resistance of the film were investigated. Shot peening was introduced to post treat the modified surface in order to synergistically improve the fretting fatigue resistance of Ti alloy. The results indicate that IBED can prepare 0Cr18Ni9 film with high density, small grain size, low void radio and high bonding strength. Thus the hardness, wear resistance and fretting fatigue resistance of Ti 811 alloy are increased remarkably. Compared with shot peening treatment or ion-beam-enhanced deposition coating alone, the titanium alloy after IBED 0Cr18Ni9 combined shot peening shows high fretting fatigue resistance at elevated temperature of 350℃. This is due to the synergistic effect of the high wear resistance of the film surface and the residual compressive stress induced by shot peening.

Key words: titanium alloy; fretting fatigue; duplex surface modification; elevated temperature; shot peening; ion beam enhanced deposition

钛合金由于具有高的比强度、 优良的耐蚀性和好的热稳定性等特点, 可用于制造航空发动机风扇、 压气机轮盘、 叶片等零部件。 然而, 由于钛合金的耐磨性差, 摩擦系数高, 对微动疲劳损伤十分敏感, 由此构成了航空发动机钛合金压气机盘榫槽和叶片榫头的微动疲劳失效隐患[1-4]。 因此, 研究可靠的钛合金微动疲劳防护技术, 成为发展高可靠性、 长寿命航空发动机的重要课题之一。

微动疲劳损伤与材料表面的耐磨性能和抗疲劳性能密切相关, 故通过表面涂层和改性技术改善钛合金表面的耐磨和抗疲劳性能, 可达到增强其微动疲劳抗力的目的[5-8]。 喷丸形变强化已被公认为是提高钛合金常温条件下微动疲劳抗力最为有效的方法[8, 9]。 但在高温环境下, 喷丸强化层的残余压应力会发生松弛, 喷丸强化的效果将会降低[10, 11], 因此可考虑将SP和其它表面处理技术进行复合来达到协同提高钛合金FF抗力的目的。 离子束增强沉积技术将离子注入与传统的物理气相沉积技术有机地结合, 在增大材料表面改性层厚度的同时, 显著提高膜基结合强度, 可在不损害基材整体性能的前提下, 达到增强材料表面耐磨性能的目的[12, 13]。 同时, 由于IBED膜层膜基结合强度高, 能够经受住喷丸强化的后处理, 因此十分适合与SP复合。 Chakravaty等[3]和Xue等[9]曾分别试图将喷丸强化与离子注入、 等离子喷涂等技术复合, 拟达到联合提高常温下钛合金FF抗力的目的, 但因彼此效果相削, 结果复合处理尚不及单独喷丸强化的效果。 本文作者曾将IBED膜层与SP复合, 达到了联合提高常温下Ti6Al4V合金FF抗力的目的[14], 然而, 在模拟压气机高温工况环境下, IBED膜层能否与SP有机复合以实现协同提高钛合金FF抗力的目的还不明确, 故需加以探讨。

Ti 811(Ti8Al1Mo1V)钛合金具有密度低、 弹性模量高、 振动阻尼性能优良、 热稳定性高、 焊接性能和成型性能好等诸多优点, 尤其是比刚度是现有工业钛合金中最高的[15], 因而十分适宜于制造先进航空发动机压气机高温端转动部件, 为此我国目前正开发和推广应用该合金材料。 作者已对Ti 811合金的高温FF行为进行了探讨[16], 然而, 该合金微动疲劳防护技术的研究工作尚未见报道, 故本研究选择该合金为研究对象。

1 实验

1.1 材料

微动疲劳试样和微动桥均由d16mm的Ti 811合金棒材制备, Ti 811为近α型钛合金, 其化学成分为(质量分数): 7.90%Al, 1.00%Mo, 0.99%V, 0.05%Fe, 0.10%C, 0.01%N, 0.001%H, 0.06%O, 余量为Ti。 Ti811合金采用双重退火处理, 即910℃保温1h, 空冷+580℃保温8h, 空冷。 合金组织为等轴α相+晶间β相, 常温下的力学性能为: σb=931MPa, σ0.2=890MPa, δ=23%, ψ=46%。

1.2 离子束增强沉积膜层的制备

离子束增强沉积技术是在气相沉积的同时, 采用一定能量的离子束进行辅助轰击, 膜基界面形成共混层(或伪扩散层), 从而获得结晶细致、 孔隙率低、 结合强度高的金属或化合物膜层。 IBED膜层克服了离子注入层浅和成本高的缺点, 且可在近室温下制备任意化学配比的膜层。

实验用IBED设备为MIB-850型多功用溅射镀膜和离子增强沉积系统。 溅射靶材为0Cr18Ni9合金, 该合金有较好的高温抗氧化性能和强韧综合性能。 试样镀膜前均经水砂纸打磨, 机械抛光, 丙酮超声清洗。 膜层沉积之前, 首先通入氩气, 采用轰击能量1keV、 束流200mA的Ar+离子束轰击清洗试样表面约25min, 同时溅射清洗靶材。 膜层界面的制备采用动态反冲工艺, 即在磁控溅射沉积膜层的同时, 以宽束辅助离子源轰击沉积膜。 溅射沉积离子源能量为3keV、 束流为150mA。 采用逐步降低辅助轰击离子源能量的方法制备膜基界面, 参数分别为: 轰击离子源能量20keV、 束流为8mA, 时间20min; 轰击能量10keV、 束流6mA、 轰击10min; 轰击能量6keV、 束流5mA、 轰击10min。 膜层生长加厚阶段: 轰击能量4keV、 束流4mA, 时间根据预期膜厚确定。

1.3 膜层性能评价

利用HITACHI S-570型扫描电子显微镜(SEM)观察分析膜层形貌。 利用GDA750型辉光放电光谱仪分析膜层及膜基界面元素分布情况。 采用MSF-2M型微机辅助X射线应力分析仪测定喷丸强化层残余应力分布。 用HV-1000型显微硬度计测量膜层的Knoop硬度, 载荷0.25N, 保载时间20s。 膜层韧性和膜基结合强度采用多冲疲劳实验评价, 实验条件为冲击次数3×104次, 冲击载荷800N, 冲程0.5mm。 采用球-盘磨损实验机测试膜层的摩擦学性能, 实验时球转动, 盘固定。 球摩擦副为Si3N4材料制备, 直径4.75mm, 表面粗糙度平均值Ra 0.05μm, 硬度HRC 80。 盘用退火态的Ti6Al4V合金制备, 直径40mm, 厚度10mm, 表面机械抛光, 粗糙度Ra 0.05μm。

1.4 喷丸强化处理

选用S110铸钢丸, 弹丸平均直径0.3mm; 喷丸强度为0.17A; 覆盖率150%。

1.5 微动疲劳实验

高温微动疲劳实验采用自行研制的专用装置, 在PLG-100C高频疲劳实验机上进行, 选择拉-拉疲劳加载方式, 实验装置和试样尺寸参见文献[16]。 微动桥足和微动疲劳试样表面之间采用平面-平面接触方式, 接触区面积为2mm×6mm。 微动区位移依靠拉-拉疲劳过程中试样相对于微动桥足弹性变形来实现, 调整微动桥的跨距, 即可改变位移幅度。 接触区正压力采用应力环法施加。 疲劳循环载荷波形为正弦波, 频率110Hz, 应力比R 0.1。 实验温度为350℃, 最大循环应力为530MPa, FF寿命取3个平行试样的平均值。 实验的高温环境利用桶式电阻炉获得, 以智能温控仪监控炉内温度。

2 结果与讨论

2.1 离子束增强沉积0Cr18Ni9膜层及其性能

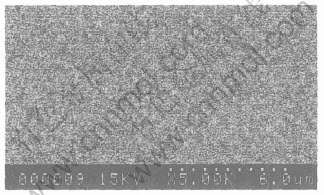

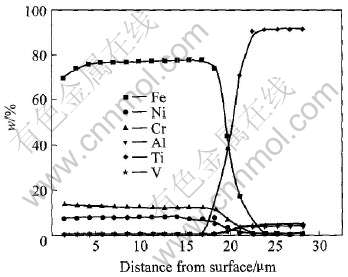

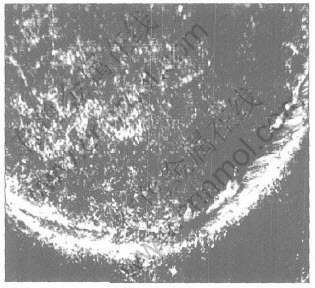

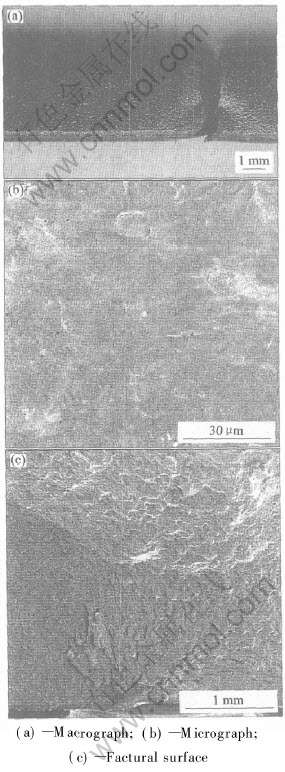

离子束增强沉积0Cr18Ni9膜层的表面SEM形貌如图1所示。 可见, 所获膜层致密, 孔隙率低, 晶粒细小, 分析表明晶粒尺寸在60~100nm范围。 晶粒细化的主要原因在于IBED成膜过程中, 辅助离子束的轰击提高了膜层结晶成核率。 图2所示为膜层元素沿深度分布, 膜层中Fe含量约为77%, Ni含量约为7%, Cr含量约为13%, 膜层厚度约为18μm。 由于膜基界面制备过程中, 辅助离子源的轰击和混合作用, 导致在膜基界面处膜层元素Fe、 Cr、 Ni与基体元素Ti、 Al、 V产生约4μm的共混层, 这有助于提高膜基结合强度。 硬度测试结果表明, 离子束增强沉积制备的0Cr18Ni9膜层的硬度约为HK25800, 为Ti 811合金基体硬度值的2.1倍, 为0Cr18Ni9靶材的1.4倍。 0Cr18Ni9膜层较高的硬度与IBED工艺所制膜层的致密度高及膜层中存在一定的压应力有直接关系。 多冲疲劳实验表明, IBED 0Cr18Ni9膜层有很好的韧性和膜基结合强度, 即使将基体材料冲出塌陷坑, 膜层仍然未发生脱落, 同时膜层表面无裂纹出现(如图3所示)。

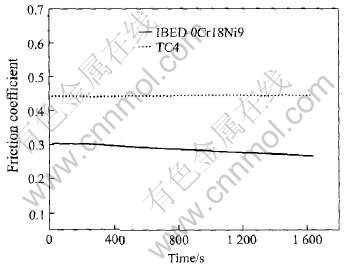

图4对比了钛合金表面IBED 0Cr18Ni9膜层

图1 IBED膜层的微观形貌

Fig.1 Micrograph of IBED coating

图2 膜层元素沿深度的分布

Fig.2 Element distribution on cross section of films

图3 膜层多冲实验失效形态

Fig.3 Repeat impact failure micrograph of 0Cr18Ni9 film

图4 0Cr18Ni9膜层与TC4基材摩擦因数的比较

Fig.4 Comparison of friction coefficient of 0Cr18Ni9 film and TC4 base

和钛合金基材的摩擦因数随摩擦行程的变化特征。 可以看出, IBED 0Cr18Ni9膜层使钛合金表面摩擦因数从0.45降低到0.3左右。 同时, 膜层使Ti6Al4V合金表面耐磨性能显著提高。 其主要原因是由于IBED 0Cr18Ni9膜层致密度高、 硬度较高、 韧性较好, 并处于一定的压应力状态。

2.2 微动疲劳抗力

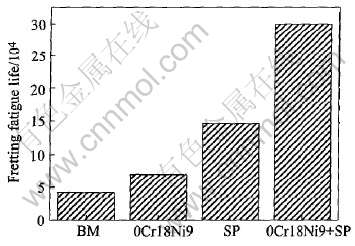

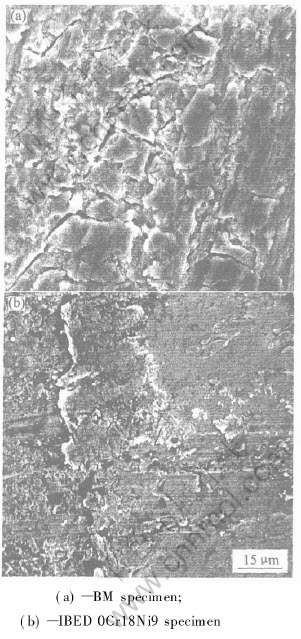

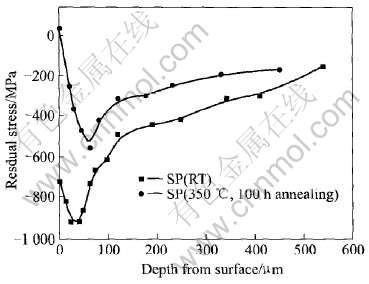

图5对比了Ti 811合金裸件(用BM表示)、 IBED 0Cr18Ni9膜层、 喷丸强化(SP)以及IBED 0Cr18Ni9膜层+喷丸强化后处理(表示为0Cr18Ni9+SP)4种表面状态试样在350℃高温下的微动疲劳寿命。 4种试样FF寿命Nf比值为Nf(0Cr18Ni9+SP)∶Nf(SP)∶Nf(IBED 0Cr18Ni9)∶Nf(BM)=6.9∶3.4∶1.8∶1, 即先进行离子束增强沉积 0Cr18Ni9, 此后再进行喷丸的复合处理对Ti 811合金FF抗力的提高最为显著。 同时, IBED 0Cr18Ni9膜层和SP也分别使高温下Ti 811合金的微动疲劳寿命提高了0.8倍和2.4倍。 IBED 0Cr18Ni9膜层显著提高了Ti 811合金的耐磨性能, 同时膜层硬度适中, 且具有良好的韧性和较低的缺口敏感性, 故表现出较高的FF抗力。 图6对比了Ti 811合金及其IBED 0Cr18Ni9试样的微动疲劳表面损伤的SEM照片。 Ti 811合金FF损伤表面呈疲劳脱层特征, 而IBED 0Cr18Ni9试样表面仅有较轻的擦痕。 喷丸强化使高温下Ti 811合金的微动疲劳寿命显著提高的主要原因是由于SP引入的残余压应力抑制了FF裂纹的早期扩展[17]。 残余应力测试结果表明, 即使在350℃高温条件下, SP试样表面100μm层深内仍然保留约450MPa的残余压应力, 如图7所示。

图5 不同表面处理试样的微动疲劳寿命

Fig.5 Fretting fatigue lives of Ti 811 alloy with different surface treatments

图6 Ti 811合金BM和IBED 0Cr18Ni9状态试样微动疲劳损伤表面的SEM照片

Fig.6 SEM morphologies of fretting fatigue damaged surface of Ti 811 and IBED 0Cr18Ni9 alloy

图中SP(RT)表示室温条件, SP(350℃, 100h退火)则表示350℃下保温100h的模拟发动机压气机工况条件。 未经喷丸处理的试样, 裂纹一经萌生就会迅速扩展。 喷丸引入的残余压应力一方面通过增大裂纹闭合力而抑制裂纹早期扩展, 另一方面降低了试样承受的疲劳循环载荷的拉应力水平。 另外, 由于SP引入的表层残余压应力使疲劳主应力方向向垂直于试样表面方向偏移, 残余压应力会对FF裂纹早期阶段的扩展路径方向产生影响(图8)。 SP断口源区有明显的台阶状特征, 这表明喷丸强化使裂纹扩展路径转折, 扩展阻力增大。 另外, SP引入的表层残余压应力既消弱了有效FF驱动应力, 同时也减缓了微动磨损作用[18], 因此, 对FF裂纹的萌生也有一定的延缓作用。

图7 喷丸试样残余应力的分布

Fig.7 Residual stress distributions of shot peened Ti 811 specimen

图8 BM和SP状态FF试样的断口形貌

Fig.8 Facture feature of BM and SP specimens

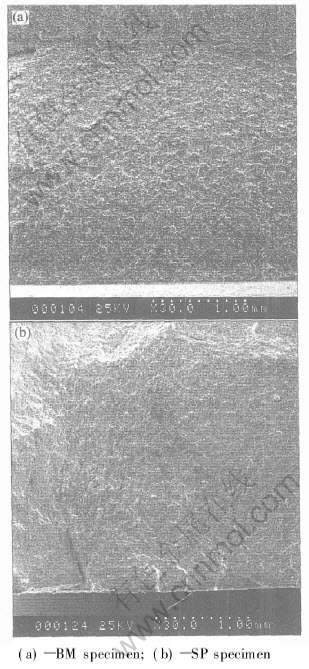

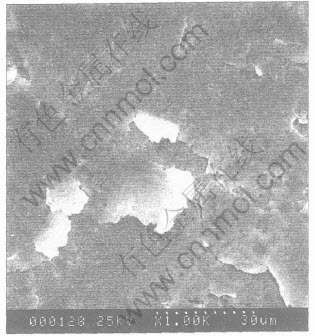

对于IBED 0Cr18Ni9膜层+SP复合处理, 结合强度高、 强韧性好的IBED 0Cr18Ni9膜层能够经受住SP的后处理, 而且硬度较高的IBED 0Cr18Ni9膜层的喷丸强化效果高于钛合金基材, 并能保持较好的表面完整性(如图9(a)、 (b)所示)因而IBED膜层与SP达到了协同增强钛合金基材FF抗力的目的, 复合处理使高温下Ti 811合金的微动疲劳寿命提高了近6倍。 而单独进行喷丸强化的钛合金表面由于硬度相对较低, 表面容易产生塑性变形, 在经受弹丸反复冲击的过程当中, 容易形成疲劳损伤,由此会造成试样表面产生微裂纹(如图10所示)。

图9 复合处理FF试样微动疲劳损伤特征

Fig.9 Morphologies of FF damaged of IBED 0Cr18Ni9+SP duplex surface treatment

图10 喷丸试样表面的SEM形貌

Fig.10 SEM micrograph of shot peened specimen

因此, 在相同的喷丸强度下, 0Cr18Ni9+SP复合处理在FF情况下的裂纹萌生寿命要比单独喷丸强化的裂纹萌生寿命长, 故强化效果好。 图9(c)所示为IBED 0Cr18Ni9+SP复合处理后的钛合金微动疲劳试样断口形貌特征表明, 复合处理后的钛合金与单一喷丸强化处理的试样相比, 断口上呈现出较长的裂纹缓慢扩展区, 这是其表面存在较大的残余压应力, 因而有效地阻止了FF裂纹早期扩展的缘故。

3 结论

1) 离子束增强沉积技术可以在Ti 811钛合金表面获得致密度高, 晶粒细化, 孔隙率低, 膜基结合强度高的膜层, 并可有效提高钛合金表层硬度和耐磨性能。

2) 离子束增强沉积0Cr18Ni9膜层硬度适中, 韧性好, 能够有效地改进Ti 811合金350℃高温下的微动疲劳抗力。

3) 离子束增强沉积0Cr18Ni9膜层与喷丸强化有机地复合, 可使Ti 811合金350℃下的FF抗力提高近6倍, 其效果优于喷丸处理或离子束增强沉积0Cr18Ni9膜层的单独作用。

REFERENCES

[1]Sahan O. Fretting Fatigue Behavior of a Titanium Alloy Ti-6AL-4V at Elevated Temperature[R]. ADA401275, WPAFB: AFIT/EN, 2002.

[2]Bhaumik S K, Rangaraju R, Venkataswamy M A. Fatigue fracture of crankshaft of an aircraft engine[J]. Engineering Failure Analysis, 2002, 9(3): 255-263.

[3]Chakravarty S, Koul A K. The effect of surface modification on fretting fatigue in Ti alloy turbine components[J]. Journal of Metals, 1995, 47(3): 31-37.

[4]刘道新, 何家文. 微动疲劳影响因素及钛合金微动疲劳行为[J]. 航空学报, 2001, 22(5): 454-457.

LIU Dao-xin, HE Jia-wen. Review of factors that influence fret-ting fatigue and investigation on FF behavior of Ti-alloy[J]. Acta Aeronoutica et Astronautica Sinica, 2001, 22(5): 454-457.

[5]WU Ling-ling, Holloway B C. Analysis of diamond-like carbon and Ti/MoS2 coatings on Ti6Al4V substrates for applicability to turbine engine applications[J]. Surface and Coatings Technology, 2000, 130(2): 207-213.

[6]Ren W J, Shankar M, Jeffrey H. Evaluation of coatings on Ti-6Al-4V substrate under fretting fatigue[J]. Surface and Coatings Technology, 2005, 192(3): 177-188.

[7]Hutson A L, Niinomi M, Nicholas T, et al. Effect of various surface conditions on fretting fatigue behavior of Ti-6Al-4V [J]. International Journal of Fatigue, 2002, 24(12): 1223-1234.

[8]Chakpavarty S, Dyer J P, Conway J C. Influence of surface treatments on fretting fatigue of Ti-6242 at elevated temperature[A]. ASTM STP1367[C]. West Conshohochen: American Society for Testing and Materials, 2000. 491-505.

[9]Xue L, Koul A K, Bibby M. A survey of surface treatments to improve the fretting fatigue resistance of Ti6Al4V[A]. Proc of Con on Computer Methods and Experimental Measurement for Surface Treatment Effect[C]. Milan: Computational Mechanics Pub, 1995. 265-272.

[10]Hyukjae L, Shankar M. Stress relaxation behavior of shot peening Ti-6Al-4V under fretting fatigue at elevated temperature[J]. Mater Sci Eng A, 2004, A366: 412-420.

[11]Hyukjae L, Shankar M, Shamachary S. Investigation into effects of re-shot-peening on fretting fatigue behavior of Ti-6Al-4V[J]. Mater Sci Eng A, 2005, 390(1): 227-232.

[12]Wang X H, Liu X H, Wang X. Mechanical properties of titanium oxide film deposited on LTI-carbon by IBED[J]. Surface and Coatings Technology, 2002, 158-159: 563-567.

[13]Tang B, Zhu X D, Hu N S. Study on the structure and tribological properties of CrN coating by IBED[J]. Surface and Coatings Technology, 2000, 131(3): 391-394.

[14]Liu D X, He J W, Celis J P. Improvement of the fretting fatigue wear of Ti6Al4V by duplex surface modification[J]. Surface and Coating Technology, 1999, 116-119: 234-238.

[15]赵永庆, 刘炳南. 合金成分对Ti 811合金棒材性能的影响[J]. 稀有金属材料与工程, 1994, 23(3): 59-65.

ZHAO Yong-qing, LIU Bing-nan. Effect of alloying composition on the mechanical properties of Ti 811 alloy rods[J]. Rare Metals and Engineering, 1994, 23(3): 59-65.

[16]高广睿, 刘道新, 张晓化. Ti 811钛合金的高温微动疲劳行为研究[J]. 中国有色金属学报, 2005, 15(1): 38-43.

GAO Guang-rui LIU Dao-xin ZHANG Xiao-hua. Investigation on fretting fatigue behaviors of Ti 811 alloy at elevated temperature[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 38-43.

[17]刘道新, 何家文. 喷丸强化因素对Ti合金微动疲劳抗力的作用[J]. 金属学报, 2001, 37(2): 156-160.

LIU Dao-xin, HE Jia-wen. Effect of shot peening factors on fretting fatigue resistance of titanium alloy [J]. Acta Metallurgica Sinica, 2001, 37(2): 156-160.

[18]Fridrici V, Fouvry S, Kapsa P. Effect of shot peening on the fretting wear of Ti6Al4V[J]. Wear, 2001, 250: 642-649.

(编辑陈爱华)

基金项目: 国家自然科学基金资助项目(50171054, 50371060); 航空科学基金资助项目(01H53066)

收稿日期: 2005-10-19; 修订日期: 2005-12-23

通讯作者: 刘道新, 教授; 电话: 029-88491479; E-mail: liudaox@nwpu.edu.cn