文章编号: 1004-0609(2005)03-0471-07

钛合金表面离子束增强沉积的

Cr和CrMo合金膜层及其性能

唐长斌1, 刘道新1, 朱晓东2, 田林海2, 文胜平2, 宗瑞磊2

(1. 西北工业大学 腐蚀与防护研究室, 西安 710072;

2. 西安交通大学 金属材料强度国家重点实验室, 西安 710049)

摘 要: 利用多功能离子束增强沉积(IBED)设备, 在Ti6Al4V钛合金表面制备Cr和CrMo合金膜层, 以提高钛合金表面的耐磨性能。 利用X射线衍射仪、 扫描电子显微镜、 辉光放电光谱仪和显微硬度计分析和测试了IBED膜层的结构、 形态、 成分分布、 硬度和膜基结合强度的大小。 利用球-盘磨损试验机和电化学综合测试仪研究了IBED膜层的摩擦学性能和电化学腐蚀特性。 结果表明, 利用IBED方法可以在难镀材料钛合金表面制备膜基结合强度高、 结晶致密和晶粒尺寸达纳米级的高硬度Cr膜和CrMo合金膜层, 显著提高了钛合金表面的抗磨性能, 且膜层本身有很好的耐Cl-介质环境电化学腐蚀性能, 与钛合金基体之间有很好的接触腐蚀相容性。

关键词: 钛合金; 离子束增强沉积; Cr膜; CrMo合金膜; 磨损; 腐蚀

中图分类号: TG115 文献标识码: A

Cr and Cr-Mo coatings on titanium alloy surface prepared by ion-beam enhanced deposition

TANG Chang-bin1, LIU Dao-xin1, ZHU Xiao-dong2,

TIAN Lin-hai2, WEN Sheng-ping2, ZONG Rui-lei2

(1. Corrosion and Protection Research Laboratory,

Northwestern Polytechnical University, Xian 710072, China;

2. State Key Laboratory for Mechanical Behavior of Materials,

Xian Jiaotong University, Xian 710049, China)

Abstract: Cr and Cr-Mo coatings were prepared on the substrate of Ti6Al4V alloy with multi-function ion-beam enhanced deposition (IBED) equipment in order to improve the wear resistance of the alloy. The microstructures, morphologies, component distributions, hardness and bonding strength of coatings were studied by X-ray diffractometer, scanning electron microscope, glow-discharge photo-electron spectroscope and micro-hardness tester, respectively. The wear resistance and electrochemical corrosion properties of IBED coatings were investigated with ball-on-disk wear tester and electrochemical equipment, respectively. The results show that the denser, harder and nanometer crystalline Cr and Cr-Mo coatings with higher bonding strength can be prepared on titanium alloy surface by IBED method. The IBED Cr and Cr-Mo coatings significantly improve the wear resistance of Ti alloy surface, and the coatings have good corrosion resistance, low galvanic corrosion sensitivity and contact compatibility with titanium alloy in solution containing Cl-.

Key words: titanium alloy; ion-beam-enhanced deposition; Cr coating; CrMo coating; wear; corrosion

钛合金具有比强度高、 耐腐蚀性好、 高温稳定性优异等特点, 已成为重要的航空与航天用结构材料。 但钛合金的导热性能差和不耐磨的特性影响了钛合金零、 构件的安全性和可靠性, 开发先进的表面技术以改善钛合金的耐磨损性能成为发展新一代高可靠性、 长寿命航空发动机的重要研究课题[1, 2]。 为了获得具有一定耐久性的膜层以提高钛合金的耐磨性能, 人们进行了大量的实验研究, 并发现, 由于钛合金表面极易生成氧化膜层, 因此传统的电镀、 化学镀等方法不仅会导致钛合金的氢脆隐患, 而且难以获得结合强度高的防护镀层[3]。 表面等离子喷涂CuNi[4] 或CuNiIn[5]和化学气相沉积TiN[6]处理虽然提高了钛合金表面的耐磨性, 但却使基材常规疲劳强度降低。 离子束增强沉积(ion beam-enhanced deposition, IBED)技术是综合了物理气相沉积和离子注入两项技术的优点而发展起来的一项较新技术, 在以溅射镀和蒸发镀等方式制备膜层的同时, 通过辅助离子束源轰击清洗工件, 实现膜基界面共混, 以促进膜层结晶致密与晶粒细化, 从而可在钛合金等难镀材料表面获得膜基结合强度高, 耐磨性能好的防护层[7, 8]。 目前, 已有研究利用IBED技术制备了TiN[9]、 TiCN[10]、 CrN[11]硬质膜和CuNiIn[11]、 MoS2[7, 12]软质膜等, 但由于这类硬质膜与基体钛硬度差异大, 膜基力学性能的协调性差, 而软质膜减摩耐久性较低, 因此, 需要考虑硬度居中的合金膜层以获得综合性能好的钛合金表面耐磨改性层。 电镀硬铬层目前已被广泛用作耐磨、 耐蚀防护层, 研究表明含1%Mo(质量分数)的CrMo合金电镀层, 其耐磨性比纯铬镀层还好, 同时铬钼镀层具有较好的抗电化学腐蚀性和优异的抗高温氧化性能[13]。 由此推知, IBED Cr或CrMo膜层在不降低钛合金基材耐蚀性能的情况下可实现显著提高钛合金耐磨性能的目的。 本文作者采用改进的IBED设备研究了制备IBED Cr和CrMo膜的工艺, 分析了膜层的结构与成分分布特点, 评价了膜层的摩擦学性能和电化学腐蚀特性, 为钛合金实际工程结构的耐磨性能改进提供了参考。

1 实验

1.1 IBED法制备Cr和CrMo膜层

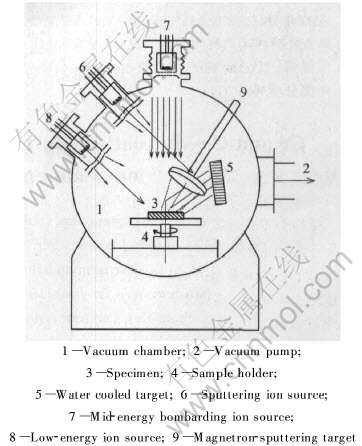

所用镀膜设备是利用早期离子束溅射和增强沉积设备[4]改进的, 其结构原理图如图1所示。 图中的6为直径10cm聚集型Kaufman溅射离子源, 用于产生Ar+离子束流, 溅射Cr或Mo靶沉积薄膜; 7为直径8cm宽束中能Kaufman离子源, 用于膜基界面共混, 增强膜基结合强度; 8为发散型低能Kaufman离子源, 用于清洗基材和辅助膜层沉积; 9为磁控溅射靶, 用于以较高速率制备Cr或Cr-Mo膜层。

工作气体为高纯度Ar气, 磁控溅射气压为1×10-1~2.0×10-1Pa, 离子束溅射气压为1.0×10-2~2.5×10-2Pa, 低能辅助离子源的能量范围0~4kV, 束流范围为0~1A。 实验中所用的离子束溅射和磁控溅射Cr靶与文献[11]所用的相同, 尺寸分别为110mm×100mm×12mm和d120mm×20mm。 Mo靶由热轧的纯度为99.95%的Mo板加工而成, 尺寸分别为110mm×100mm×8mm和60mm×10mm×0.4mm。

图1 IBED装置示意图

Fig.1 Sketch of IBED equipment

实验用基材为Ti6Al4V(TC4)合金, 经过退火处理, 硬度为36HRC。 试样经水砂纸打磨,机械抛光, 表面粗糙度Ra≤0.1μm, 在镀膜前用丙酮超声波清洗。 膜层沉积之前,通过低能辅助源, 采用轰击能量1kV和束流200mA的Ar+束轰击清洗试样表面约25min, 同时溅射清洗靶材。 膜层界面的制备采用动反冲工艺进行,即在溅射沉积膜层的同时,用中能宽束辅助离子源轰击沉积膜, 膜层溅射沉积能量为2.4kV, 束流为150mA, 而中能辅助轰击离子源的能量由25kV逐渐降低到4kV。 动反冲法制备界面后, 膜层进一步增厚的方法主要有: (1) 低能离子束增强磁控溅射纯Cr靶, 获得Cr膜; (2) 以低能束源辅助, 磁控溅射Cr靶和离子束溅射Mo靶联合, 制备低Mo含量的Cr-Mo合金膜; (3) 低能离子束增强磁控溅射Cr-Mo组合靶1制备中等含Mo量的Cr-Mo合金膜; (4) 低能离子束增强磁控溅射Cr-Mo组合靶2制备含Mo量高的Cr-Mo合金膜。 用于膜层制备的低能辅助离子源能量为400V, 束流为40mA。 膜层沉积过程中以流动水冷却试样台, 使试样整体温度控制在150℃以下。

1.2 膜层结构分析与性能评价方法

IBED膜层形貌采用HITACHI S-570扫描电镜观察。 膜层中钼的含量利用EDAX9900能谱仪分析。 膜层的物相用D/max-3C型X射线衍射仪分析。 硬度用HV-1000型显微硬度计测量, 选用Knoop压头, 载荷为0.25N, 保载时间为20s。 膜层元素沿层深的分布利用GDA750型辉光放电光谱仪进行分析。 膜基结合强度采用WS-2000型自动划痕仪测量, 以临界载荷Pc 值表征。 用自制TCY-A型镀层连续压入仪评价[14]膜层的韧性。

摩擦磨损性能的测试使用自制的球-盘磨损试验机。 实验时盘固定不动, 而让球(固定于夹具上)在盘面上沿圆形轨迹滑动。 摩擦副选用Si3N4球, 直径为4.75mm, 粗糙度平均值Ra≤0.05μm, 硬度为80HRC。 磨痕轨迹直径为20mm, 球与盘的相对转速为110r/min。 实验温度为室温(25±2)℃, 相对湿度为65%。

电化学腐蚀特性用微机辅助PS-168型电化学测量系统测定。 试样暴露面积为0.25cm2, 腐蚀介质为3.5%NaCl, 温度为(30±1)℃。 辅助电极为铂电极, 参比电极为饱和甘汞电极。 使用ZRA-1型电偶腐蚀计测量膜层与基材所组成电偶对的腐蚀电流, 钛合金试样与沉积膜层试样的面积比为6.5, 用以模拟实际工件局部防护处理的情况, 连续测试时间为24h。

2 结果与讨论

2.1 膜层形态与结构

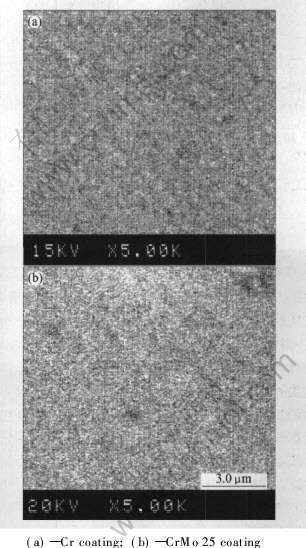

能谱分析表明, 上述方法(2)所制备的膜层为CrMo1.2膜(Mo含量为1.2%(质量分数)); 方法(3)制备的膜层为CrMo8.5膜(Mo含量为8.5%); 方法(4)获得的膜层为CrMo25膜(Mo含量为25%), 各膜层表面成分分布均匀。 图2所示为IBED纯Cr膜和CrMo25合金膜层的SEM微观形貌。 由图可看出, 在IBED过程中, 由于离子束的轰击作用, 所制备的膜层结晶均匀致密, 晶粒细小。

图2 IBED膜层的SEM微观形貌

Fig.2 SEM micrographs of IBED coatings

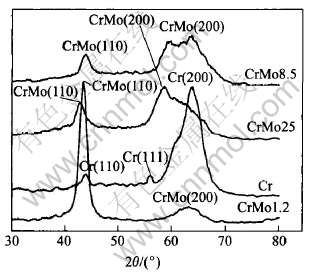

图3所示为各IBED膜层的X射线衍射谱。 除CrMo1.2膜以(110)晶面择优取向外, 其它各膜层均以(200)晶面择优取向, 膜层的衍射峰呈宽化现象。 膜层衍射峰宽化的原因主要是膜层的晶粒细化和存在的残余压应力。 若不考虑膜层中残余应力的影响, 则可根据Scherrer公式估算出Cr膜、 CrMo1.2 膜、 CrMo8.5膜和CrMo25膜的平均晶粒尺寸分别为8.5、 34.2、 26.5和27.9nm, 由此可见, IBED膜层晶粒尺寸为纳米级。 IBED膜层的择优取向是由于辅助离子源轰击所致, 而CrMo1.2膜层与其他膜层的择优取向不同, 则是由于所采用的IBED工艺方法不同所致。 此外, (200)晶面与其他晶面衍射峰的合成导致了峰形复杂化, 且随Mo含量的不同而有所改变。

图3 IBED膜层的X射线衍射谱

Fig.3 XRD patterns of IBED coatings

2.2 膜层元素沿深度分布及膜基结合强度

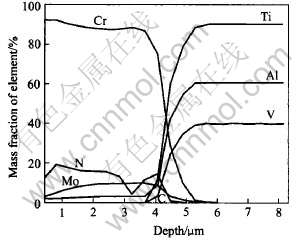

辉光放电光谱仪对膜层成分沿膜层层深的分析表明, IBED膜层的膜基界面存在一定的共混层。 图4所示为CrMo8.5膜层元素沿深度的分布情况。 由图可看出, 膜层中Cr含量约占88%左右, Mo含量约为8%~9%, 膜层厚度约为4μm, 这与能谱分析及金相剖面测量结果一致。 在界面处存在微量的污染元素C和N的富集, 膜基界面处膜层元素Cr、 Mo与基体元素Ti、 Al、 V呈现出一定厚度的共混层(图中的Al放大了10倍), 该混合层的存在是IBED膜基结合强度的提高所致。

图4 CrMo8.5膜层元素沿深度的分布

Fig.4 Element distribution curves of CrMo8.5 coating along depth direction

自动划痕仪对膜层临界破坏载荷Lc 值的测试表明, 纯Cr膜为 26N, CrMo1.2 膜为18N, CrMo8.5膜为18N, CrMo25膜为39N。 由于Lc值受膜基硬度、 膜层厚度和膜层失效形式等多因素的影响, 同时与实验参数有关, 因此它仅反映了膜、 基体系的综合承载能力。

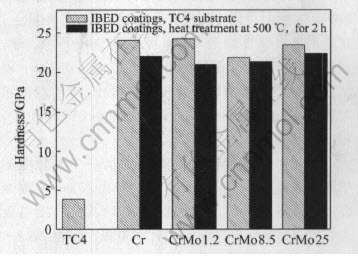

2.3 膜层的硬度和韧性

硬度是抗磨性膜层的重要力学参量。 图5所示为各膜层的Knoop显微硬度对比(包括退火前后的数值)。 由图可见, 以IBED方法制备的CrMo系膜层的硬度较高, 均在HK0.25N20GPa以上, 这比用直流溅射法在GCr15上沉积的钼膜[15]和电镀Cr膜或电镀Cr膜后离子注入后处理[16]的硬度高。 膜层的硬度除与膜层成分和组织结构有关外, 还受残余应力的影响, 为消除残余应力的影响, 对膜层进行了退火处理。 退火前后Cr膜的硬度均为最大, 这主要可能是由于IBED Cr膜的晶粒度明显小于其它膜层。 退火前后CrMo1.2膜的硬度值变化最大, 这表明CrMo1.2膜采用离子溅射和磁控溅射相结合的工艺, 造成膜层晶格较大的畸变, 因而存在较大的残余应力值。 CrMo合金膜层的晶粒尺寸较为接近, 退火后CrMo合金膜层的硬度随Mo含量的增加略呈增大的趋势, 可能与Cr、 Mo合金膜层的固溶强化作用(或晶格畸变程度)增加有关。

图5 膜层硬度对比

Fig.5 Hardness contrast of different coatings

韧性是硬质膜层的重要性能指标。 结果表明, CrMo8.5合金膜层在压入载荷为60N时, 膜层压痕中心出现网格状裂纹; Cr膜在压入载荷为50N时出现网格状裂纹; CrMo1.2膜在压入载荷为50N时出现网格状裂纹和掉块; 而CrMo25膜则在压入载荷为30N时就出现了网格状裂纹, 这说明无论IBED纯Cr膜还是CrMo合金膜, 由于其硬度较高, 因而韧性相对较低, 并且在其它条件相同的情况下, 通常硬度愈高, 其韧性往往愈低。

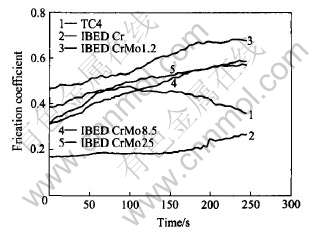

2.4 膜层摩擦学性能

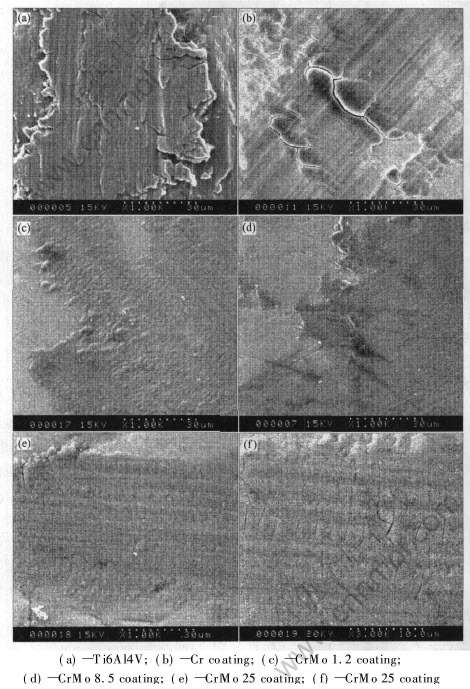

图6所示为TC4钛合金及其IBED 膜层处理后的摩擦系数随磨损进程的变化情况。 TC4钛合金的摩擦系数呈现出先增后降的变化趋势。 IBED Cr膜的摩擦系数较为稳定, 且对TC4钛合金基材有明显的减摩作用。 IBED CrMo合金膜层经过早期磨合阶段后, 摩擦系数均高于TC4钛合金基材, 即CrMo合金膜层无减摩作用。 Cr膜层与CrMo膜层摩擦系数的差异与膜层成分、 组织结构的不同有关, 而CrMo1.2较CrMo8.5和CrMo25摩擦系数稍高的原因主要是由于膜层晶体学结构和残余应力状态的差异所致。 图7所示为各试样摩擦学行为的不同在磨损形态上的反映。 TC4钛合金以犁削和疲劳脱层为主要磨损失效形式, 而IBED Cr和CrMo膜层由于硬度高, 抗犁削磨损能力强, 因而表面犁沟特征轻微, 但由于IBED膜层的韧性较低, 因此疲劳开裂和脱层为主要失效形式。

图6 CrMo系膜层和TC4钛合金摩擦系数的变化

Fig.6 Variations of frication coefficients for CrMo coatings and TC4 alloy

图7 基体TC4钛合金和膜层磨痕形貌

Fig.7 Wear morphologies of TC4 alloy and coatings

由于IBED Cr膜和CrMo合金膜层硬度较高, 改善了TC4钛合金基材的表面抗粘着、 抗磨粒磨损能力, 显著地提高了钛合金的耐磨性能。 实验表明, 磨损30min后, TC4钛合金试样表面沿磨痕轨迹出现较深的沟槽, 而IBED膜层试样表面用轮廓仪仍然难以测出磨损量的大小, 此时与之接触的Si3N4球摩擦副表面磨出明显的平台。 IBED膜层磨损后期的摩擦系数呈增加趋势变化的主要原因是由于表面膜层的磨损疲劳开裂及脱层造成的表面粗糙化, 其中IBED CrMo1.2膜层表面的粗糙度较高, 相应的摩擦系数也高。

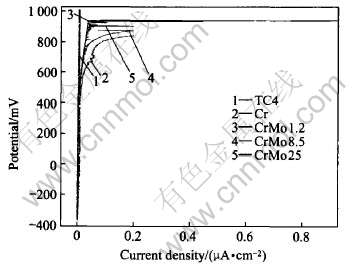

2.5 膜层电化学腐蚀特性

图8所示为基材TC4钛合金与IBED Cr膜和CrMo合金膜层在3.5% NaCl溶液中的阳极极化曲线。 由图可看出, CrMo膜及Cr膜在自腐蚀电位小于500mV时均处于钝化状态; 当电位超过500mV后, 随电极电位升高, Cr膜最先呈现活性特征; 当电位高于700mV后, CrMo膜层的电化学活性逐步增大, 而TC4钛合金在所测试的电位范围内一直呈现出很好的钝化特征, 即钛合金有很好的耐Cl-介质环境的腐蚀性能。

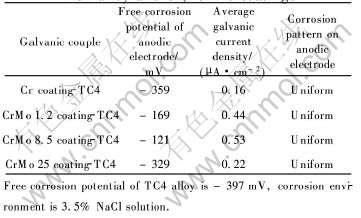

从自腐蚀电位看, TC4钛合金较Cr膜和CrMo膜的自腐蚀电位低, 即膜层与基材构成电偶对时均为阴极, 而TC4态基材为阳极。 表1所示为TC4态与CrMo膜及Cr膜电偶对的腐蚀实验结果。 电偶腐蚀电流的测试表明, CrMo膜及Cr膜与基材TC4态合金间的电偶腐蚀敏感性均较低, 即CrMo膜及Cr膜与钛合金在Cl-介质环境中是电化学接触相容的, 同时膜层材料本身也具有较好的腐蚀抗力。

图8 TC4钛合金与CrMo系膜层在3.5%NaCl溶液中的阳极极化曲线

Fig.8 Potentiodanamic polarization curves of TC4 alloy, Cr and CrMo coatings in 35%NaCl solution

表1 TC4态合金与CrMo膜及Cr膜电偶对的腐蚀实验结果

Table 1 Corrosion results of galvanic couple for TC4 alloy and Cr, CrMo coatings

3 结论

1) 离子束增强沉积(IBED)方法可以在易钝化材料钛合金表面制备膜基结合强度高、 结晶致密、 晶粒尺寸达纳米级的Cr膜和CrMo合金膜层, 这类膜层硬度约为HK0.25N20~30GPa, 显著提高了TC4钛合金表面的耐磨性能。 Cr膜层既具有抗磨作用, 同时也具有减摩作用, 而CrMo合金膜层仅具有抗磨作用。

2) IBED Cr膜和CrMo合金膜层本身具有很好的耐Cl-介质环境电化学腐蚀性能, 同时与TC4态钛合金基体之间有较好的接触腐蚀相容性。 CrMo合金膜层与IBED Cr膜层相比具有更好的钝化能力。

3) IBED膜层具有一定的择优取向特征, 择优取向晶面依赖于IBED工艺过程。 在Cr中加入一定量的Mo形成CrMo合金膜层, 并未明显影响其硬度, 但对其摩擦学行为和电化学腐蚀行为具有一定的影响作用。

REFERENCES

[1]WU L L, Holloway B C, Beesabathina D P, et al. Analysis of diamond-like carbon and Ti/MoS2 coating on Ti6Al4V substrates for applicability to turbine engine application[J]. Surface and Coatings Technology, 2000, 130(2):207-213.

[2]Rai A K, Ahmed J. Development of advanced coatings as palliatives for avoidance of fretting and galling in titanium alloy[R]. AD-A387446, San Diego: Unitedstates Air Force Research Laboratory, 2001.

[3]张轲, 刘道新. 钛合金湿法镀前活化预处理工艺的研究[J]. 材料保护, 2001, 34(10):42-43.

ZHANG Ke, LIU Dao-xin. Investigation of surface pretreatment for titanium alloys[J]. Materials Protection, 2001, 34(10): 42-43.

[4]Huston A L, Niinomi M, Nicholas T. Effect of various surface conditions on fretting fatigue behavior of Ti-6Al-4V[J]. International Journal of Fatigue, 2002, 24: 1223-1234.

[5]Xue L, Koul A K, Bibby M. A survey of surface treatments to improve the fretting fatigue resistance of Ti6Al4V[A]. Proceeding Conference on Computer Methods and Experimental Measurement for Surface Treatment Effect (Ⅱ)[C]. Milan: Computational Mechanics Public, 1995. 265-272.

[6]Kolkman H J. Effect of TiN/Ti gas turbine compressor coatings on the fatigue strength of Ti6Al4V base metal[J]. Surface and Coating Technology, 1995, 72: 30-36.

[7]刘道新, 唐宾, 陈华. 钛合金表面离子束增强沉积MoS2基膜层及其性能[J]. 中国有色金属学报, 2001, 11(3): 454-460.

LIU Dao-xin, TANG Bin, CHEN Hua. MoS2 composite films on Ti alloy prepared by ion-beam-enhanced deposition[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3): 454-460.

[8]Kligenberg M, Arps J, Wei R. Practical application of ion beam and plasma processing for improving corrosion and wear protection[J]. Surface and Coatings Technology, 2002, 158-159: 164-169.

[9]蔡洵, 顾剑锋, 周平南, 等. 离子束辅助增强沉积TiN薄膜界面结合强度的研究[J]. 金属热处理学报, 1997, 18(2): 30-35.

CAI Xun, GU Jian-feng, ZHOU Ping-nan, et al. The interfacial bonding strength of TiN films prepared by IBED[J]. Transactions of Metal Heat Treatment, 1997, 18(2): 30-35.

[10]王培录, 刘仲阳, 孙官清, 等. TC4钛合金上离子束辅助沉积TiCxNy膜的微结构与机械性质研究[J]. 真空科学与技术, 1998, 18(6): 454-458.

WANG Pei-lu, LIU Zhong-yang, SUN Guan-qing, et al. Studies of the microstructures and mechanical properties of the TiCxNy films on TC4 titanium alloys by ion beam assisted deposition[J].Vacuum Science and Technology, 1998, 18(6): 454-458.

[11]刘道新, 张必强, 唐宾. 钛合金表面离子束辅助沉积CuNiIn固体润滑膜和Cr-N硬质膜[J]. 材料工程, 1998, 6: 38-41.

LIU Dao-xin, ZHANG Bi-qiang, TANG Bin. CuNiIn solid lubricating films and Cr-N hard coating on Ti alloy prepared by ion-beam-enhanced deposition[J]. Materials Engineering, 1998, 6: 38-41.

[12]Reneier N M, Hamphire J, Fox V C, et al. Advantages of using self-lubricating, hard, wear-resistant MoS2-based coatings[J]. Surface and Coatings Technology, 2001, 142-144: 67-77.

[13]Goward G W. Progress in coatings for gas turbine airfoil[J]. Surface & Coatings Technology, 1998, 108-109(1): 73-79.

[14]胡奈赛, 徐可为, 何家文. 涂、 镀层的结合强度评定[J]. 中国表面工程, 1998, 38(1): 31-35.

HU Nai-sai, XU Ke-wei, HE Jia-wen. Evaluation of bonding strength on coating layers[J]. China Surface Engineering, 1998, 38(1): 31-35.

[15]许世红, 王金清, 刘维民, 等. 钼薄膜的制备、 力学性能和磨损性能[J]. 材料保护, 2003, 36(12): 12-14.

XU Shi-hong, WANG Jin-qing, LIU Wei-min, et al. Preparation, mechanical and tribological properties of molybdenum thin films[J]. Materials Protection, 2003, 36(12): 12-14.

[16]Walter K C, Schener J T, Mcintyre P C. Increased wear resistance of electrodeposited chromium through applications of plasma source ion implantation techniques[J]. Surface and Coatings Technology, 1996, 85(1-2): 1-6.

(编辑李艳红)

基金项目: 国家自然科学基金资助项目(50171054); 航空科学基金资助项目(01H53066)

收稿日期: 2004-08-30; 修订日期: 2005-01-06

作者简介: 唐长斌(1973-), 男, 硕士研究生.

通讯作者: 刘道新, 教授, 博士; 电话: 029-88491479; E-mail: liudaox@nwpu.edu.cn