文章编号:1004-0609(2010)S1-s0659-05

2种制度热处理后Ti-600合金的高温蠕变行为

曾立英1, 2,杨冠军1,洪 权2,赵永庆2

(1. 西安建筑科技大学 冶金科学与工程学院,西安 710055;

2. 西北有色金属研究院 钛合金研究所,西安 710016)

摘 要:研究β和α+β 2种制度热处理后Ti-600合金在550~650 ℃和300 MPa时的高温蠕变行为。计算合金在不同应力、不同温度下的稳态蠕变速率及蠕变激活能,并在此基础上研究其蠕变强化机制。结果表明:当蠕变应力为300 MPa时,β处理和α+β处理的Ti-600合金的蠕变激活能Q分别为490.1 kJ/mol和473.5 kJ/mol,表明这2种制度处理的Ti-600合金的蠕变机制均主要表现为位错攀移机制;随着温度的升高,Ti-600合金在蠕变过程中位错的攀移速度加快,原子和空位移动加剧,因而出现稳态蠕变速率随着温度的升高而加快,而稳态蠕变的时间缩短的趋势。

关键词:Ti-600合金;高温钛合金;稳态蠕变速率;蠕变激活能;蠕变机制

中图分类号:TG 146.2; TG 113.25+5 文献标志码:A

High temperature creep behaviors of Ti-600 alloy by two thermal treatments

ZENG Li-ying1, 2, YANG Guan-jun1, HONG Quan2, ZHAO Yong-qing2

(1. School of Metallurgical Science and Engineering, Xi’an University of Architecture and Technology,

Xi’an 710055, China;

2. Titanium Alloy Research Center, Northwest Institute for Nonferrous Metals Research, Xi’an 710016, China)

Abstract: After α and α+β heat treatments respectively, creep tests were made on Ti-600 alloy at the temperature varying from 550 ℃ to 650 ℃ and the stress of 300 MPa. Steady creep rate and activation energy Q were calculated for the alloy at different temperatures. Creep deformation mechanism was also investigated. The creep activation energies are 490.1 kJ/mol and 473.5 kJ/mol, respectively, for the alloy crept at the stress of 300 MPa after β and α+β thermal treatment, suggesting that dislocation climb is the rate-controlling mechanism at the testing region. As temperature increases, the dislocation climb and the movement rate for atoms and vacancies will increase abruptly for the alloy during the creep process, so the steady creep rate will increase with the increase of temperature, and the steady creep time tends to be shortened.

Key words: Ti-600 alloy; high temperature Ti alloys; steady creep rate; creep activation energy; deformation mechanism

近年来,随着航空工业的迅猛发展,新型先进航空发动机对高温钛合金的研究提出了越来越高的要求,为此,世界各国都在竞相发展600 ℃及以上温度长时间使用的高温钛合金[1-3],如目前使用的典型钛合金有IMI834合金和Ti-1100合金[2-5]。Ti-600合金是西北有色金属研究院自主研发的一种可在600 ℃使用的添加稀土元素钇的近α型高温钛合金,可作为 航空航天发动机高温零部件的候选材料[4-5]。合金在 600~650 ℃均具有较好的综合机械性能、高温强度和热稳定性能等[4-5]。高性能发动机的零部件对材料要求苛刻,它要求材料不仅具有良好的室温性能、疲劳性能、高温强度、热稳定性和断裂韧性,还要求材料具有良好的蠕变性能。蠕变通常是指物体在恒定应力作用下,应变随着时间的延长而增大的流变现象。一些重要的内外因素,如温度、时间、应力和组织结构等对钛合金的蠕变性能都有影响。因为合金在服役条件下的蠕变行为决定了合金的使用寿命和发动机的安全可靠性[6],因此,研究其高温蠕变行为是至关重要的。本文作者重点研究2种制度热处理后,Ti-600合金在300 MPa、3种不同温度下的蠕变性能。

1 实验

材料为西北有色金属研究院研制的Ti-600合金轧制棒材。合金相变温度Tb 约为1 010 ℃。实验采用二次重熔的d420 mm铸锭。铸锭经β相区开坯锻造后,在α+β两相区加热轧制出d16 mm圆棒,从其上切取蠕变试样。对蠕变试样采用2种不同的热处理制度进行处理:第一种是在1 020 ℃(β处理)固溶1 h,空冷,随后时效;第二种是在1 000 ℃(α+β处理)固溶1 h,空冷,随后时效。分别测试合金在550,600和650 ℃时的蠕变性能,蠕变应力为300 MPa。蠕变试样工作直径为5 mm,标距长度为27 mm,蠕变实验在RD-30型试验机上完成。蠕变实验后在蠕变试样上沿轧制方向切取小片,在奥林巴斯PMG-3型显微镜上观察其组织。同时,切取小片机械磨制至40~50 μm,电解双喷减薄后获TEM样品,采用JEM200CX透射电镜观察分析蠕变实验后试样的组织形貌。

2 结果与讨论

2.1 Ti-600合金的稳态蠕变速率

当应力为300 MPa时,在3种不同温度下Ti-600合金的蠕变曲线如图1所示。从图1可以看到蠕变曲线的3个典型阶段:第一阶段是减速蠕变阶段,从曲线的斜率可以看出,这一阶段开始的蠕变速率很大,随着时间的延长,蠕变速率逐渐减小;第二阶段是稳态蠕变阶段,其特征是蠕变速率恒定,应变—时间曲线中表现为直线段;第三阶段是加速蠕变阶段,其特征是蠕变速率急剧增大直至断裂。影响材料蠕变过程的2个最主要参数是温度和应力。从图1还可以看出:当温度降低时,蠕变过程减慢,这时可以看到蠕变第二阶段很长,第三阶段甚至可以不出现;反之,当温度升高时,第二阶段较短,很快地由蠕变第一阶段过渡到第三阶段。在600 ℃和650℃,外加载荷为300 MPa时,稳态蠕变阶段变得很短或几乎没有而直接进入加速阶段。

图1 2种制度热处理后Ti-600合金典型的蠕变曲线

Fig.1 Typical creep curves of Ti-600 alloy during α+β and β heat-treatment: (a) Samples solution-treated at 1 000 ℃; (b) Samples solution-treateded at 1 020 ℃

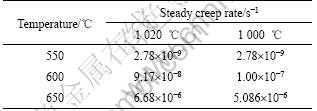

根据蠕变理论,稳态蠕变速率即最小蠕变速率是反映材料蠕变行为的特征量。根据图1所示的蠕变曲线的斜率和试样的标距长度可以计算出Ti-600合金在不同温度下的稳态蠕变速率。表1所示为Ti-600合金在300 MPa和不同温度下的稳态蠕变速率。从表1可以看出:Ti-600合金高温下的稳态蠕变速率较低;在蠕变应力为300 MPa、温度为600 ℃时蠕变,β处理的合金的稳态蠕变速率为9.17?10-8 /s;而α+β处理的合金的稳态蠕变速率也仅为1.00?10-7 /s。这表明合金具有较好的抗蠕变性能。此外,随着温度的升高,原子和空位移动速度加快,因而出现了稳态蠕变速率随着温度的升高而增加,而稳态蠕变时间缩短的趋势。

表1 蠕变应力为300 MPa时,不同温度下经2种制度处理的Ti-600合金的稳态蠕变速率

Table 1 Steady creep rates of Ti-600 alloys after treated at different temperatures with stress of 300 MPa

2.2 蠕变应力指数和蠕变激活能

大多数金属或合金的稳态蠕变速率可由下式表 示[7-8]:

(1)

(1)

式中:es为稳态蠕变速率;A为材料常数;σ为外加蠕变应力;QAPP为名义蠕变激活能;R为摩尔气体常数(R=8.314 J/(mol?K);T为热力学温度;n为应力指数。

当应力不变时,对方程(1)微分可得出名义蠕变激活能的表达式:

(2)

(2)

在稳态蠕变过程中表现出的蠕变激活能是反映合金蠕变机制的重要参数。根据表1中的数据,绘出lnes—1/T关系曲线,如图2所示。由图2可以计算出经β处理和α+β处理的Ti-600合金的蠕变激活能分别为490.1 kJ/mol和473.5 kJ/mol。

图2 Ti-600合金的lnes—1/T曲线

Fig.2 Arrhenius plots for determination of activation energy: (a) β heat treatment; (b) α+β heat treatment

2.3 蠕变前、后的显微组织

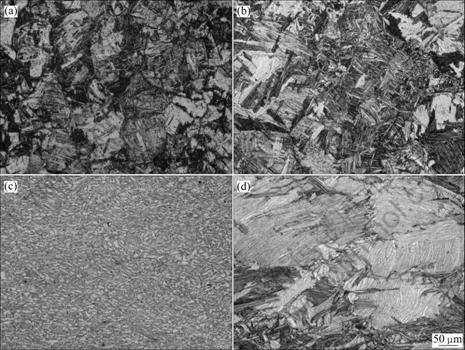

图3所示为Ti-600合金蠕变前、后的金相组织照片。从图3可以看出:经α+β处理的Ti-600合金组织

图3 蠕变前、后Ti-600合金的金相组织

Fig.3 Optical microstructures of Ti-600 alloy before creep ((a), (b)) and after creep at 650 ℃ with stress of 300 MPa ((c), (d)): (a), (c) Samples with α+β heat treatment, solution-treated at 1 000 ℃; (b), (d) Samples with β heat treatment, solution-treated at 1 020 ℃

是由5%左右的等轴或初生α+转变β构成的网篮状组织,析出的初生α较细小,其晶粒尺寸仅1~3 μm;转变β的晶粒尺寸为50~250 μm,转变β中细小的二次α片层的体积分数可达40%。而经β处理后,合金组织特征为片层状β转变组织,基本没有等轴α出现,合金由交替编织排列的片层状α和残余β相构成,晶粒尺寸大于100 μm,是典型的网篮状组织。β处理的片层状β转变组织比α+β处理的粗大,如图3(b)所示。这是由于前者热处理温度较高(1 020 ℃),其原始β晶粒尺寸比后者的大所致。蠕变实验后(见图3(c)和(d)),合金片层状组织特点更加明显,转变β晶粒发生扭曲变形,其晶粒尺寸明显增大,转变β内α和β片层明显拉长,这些都是蠕变变形的结果。β处理试样的组织变形比α+β处理的组织变形严重。蠕变实验后Ti-600合金的TEM像如图4所示。

图4 蠕变实验后Ti-600合金的TEM像

Fig.4 TEM image of Ti-600 alloy crept

2.4 蠕变机制

蠕变变形机制有2种:一种是位错蠕变机制,另一种是扩散蠕变机制[8-10]。材料在常温下的变形可通过位错的滑动产生滑移和孪晶2种变形形式。而位错的攀移则是高温的主要变形形式。位错通过攀移,使位错遇到障碍时作垂直于滑移面的运动,这样,位错便不会阻塞在障碍面前,而使得变形能继续下去。

名义蠕变激活能可以反映不同温度和应力下合金的蠕变机制[7-9]。有研究表明:β处理和α+β处理的IMI834合金的蠕变激活能分别为414 kJ/mol和345 kJ/mol,其蠕变机制为位错攀移机制[9]。如前所述,在实验应力和温度范围内,Ti-600合金具有较大的蠕变激活能,因而其蠕变变形是由位错攀移控制的,蠕变速率受控于攀移控制的位错的消亡(湮没)速率。在刚开始蠕变变形时,位错可自由运动并易增殖,故蠕变第一阶段的变形速率较快。随着变形的继续发展,当转入蠕变第二阶段时,位错的组态发生变化,位错由原来任意分布的状态转变成完整的位错胞状结构,如图4所示。位错的胞壁是由位错攀移构成的小角度晶界。胞内滑动的位错分布和胞壁攀移的位错分布,构成一长程内应力场。当位错发生攀移造成异号位错消毁或在晶界处湮没时,打破了原来的内应力场平衡状态,胞内又有新的可动位错产生,使变形又继续下去。因此,第二阶段的蠕变速率由位错的攀移速率所控制。

α+β处理比β处理试样具有较低的蠕变激活能,其原因可能是:α+β处理后,合金内含有3种不同类型的界面[7],即原始β或β集束界面、等轴α与转变β间的界面、α/β板条或α/α片层间界面。钛合金中,初始β晶粒/集束边界、等轴α/β相界是大角度晶界,能提供大量的易扩散路径。在等轴的α+β两相组织中,前2种界面数量居多,合金内原子扩散加速,从而使得蠕变激活能较低。反之,β处理后,合金相界面主要是由共格的或半共格的α/α或α/β板条界面构成,前2种界面的数量较少,扩散路径较少,扩散不易进行,因而合金的蠕变激活能较高。硅化物对高温钛合金蠕变性能也有较大的影响。

3 结论

1) 当蠕变应力为300 MPa时,Ti-600合金的蠕变激活能Q较高,经β和α+β处理后,合金的Q分别为490.1 kJ/mol和473.5 kJ/mol。

2) 实验温度升高,原子和空位移动速度加快,Ti-600合金的稳态蠕变速率增加,而其稳态蠕变时间缩短。

3) 蠕变后,Ti-600合金转变β晶粒扭曲长大,其内α和β片层拉长。β处理的组织变形比α+β处理的组织变形严重。

4) Ti-600合金蠕变变形以位错攀移为主。

REFERENCES

[1] WILLIAMS J C, STARKE E A Jr. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51(19): 5775-5799.

[2] CHANDER H. Heat treatment’s guide: practices and procedures for nonferrous alloys[M]. ASM International, 1996.

[3] BANIA P J. An advanced alloys for elevated temperature[J]. Journal of Metals, 1988, 3: 20-22.

[4] ZENG L Y, HONG Q, YANG G J, ZHAO Y Q, QI Y L, GUO P. Tensile and creep properties of Ti-600 alloy[J]. Trans Nonferrous Met Soc China, 2007, 17(Special 1): s522-s525.

[5] CUI W F, LIU C M, ZHOU L, et al. Characteristics of microstructures and second-phase particles in Y-bearing Ti-1100 alloy[J]. Mater Sci Eng A, 2002, 323: 192-197.

[6] 蔡建明, 马济民, 黄 旭, 曹春晓. 高温钛合金中杂质元素Fe的扩散行为及其对蠕变抗力的损害作用[J]. 材料工程, 2009, 325(8): 84-88.

CAI Jian-ming, MA Ji-min, HUANG Xu, CAO Chun-xiao. Diffusion behavior of impurity iron in high temperature titanium alloys and its detrimental effect on creep resistance[J]. Journal of Materials Engineering, 2009, 325(8): 84-88.

[7] BARBOZA M J R, PEREZ E A C, MEDEIROS M M, REIS D A P, NONO M C A, NETO F P, SILVA C R M. Creep behavior of Ti-6Al-4V and a comparison with titanium matrix composites[J]. Mater Sci Eng A, 2006, 428: 319-326.

[8] REIS D A P, NETO C M, SILVA C R M, BARBOZA M J R, NETO F P. Effect of coating on the creep behavior of the Ti6Al4V alloy[J]. Mater Sci Eng A, 2008, 486(1/2): 421-426.

[9] MISHRA H, SATYANARAYANA D V V, NANDY T K, SAGAR P K. Effect of trace impurities on the creep behavior of a near α titanium alloy[J]. Scripta Materialia, 2008, 59(6): 591-594.

[10] HAYES R W, VISWANATHAN G B, MILLS M J. Creep behaviour of Ti-6Al-2Sn-4Zr-2Mo: I. The effect of nickel on creep deformation and microstructure[J]. Acta Mater, 2002, 50(20): 4953-4963.

(编辑 陈灿华)

基金项目:国家重点基础研究发展计划资助项目(2007CB613807);国家科技支撑计划资助项目(2007BAE07B01)

通信作者:曾立英;电话:029-86231078;E-mail: ZENG-ly@163.com