文章编号:1004-0609(2015)06-1441-09

挤压铸造Al-5.0Cu-0.6Mn-1.0Fe-1.0Ni合金的高温力学性能

娄照辉,张卫文,罗 执,郑成坤,孟凡生

(华南理工大学 机械与汽车工程学院,广州 510640)

摘 要:采用拉伸性能测试、光学显微镜、扫描电镜、透射电镜、电子探针、X射线衍射等研究了T7热处理态的挤压铸造Al-5.0Cu-0.6Mn-1.0Fe-1.0Ni合金的显微组织及力学性能,重点研究了挤压压力对合金高温力学性能的影响。结果表明:当挤压压力从0 MPa增加到75 MPa时,合金的高温力学性能明显提高,但抗拉强度和屈服强度的增加值随温度升高而逐渐减小。挤压压力可以消除合金中的缩松,抑制合金中针状Al7Cu2Fe相的形成,使块状Al7Cu2Fe相及Al9FeNi相分布更为弥散,并形成联通的骨骼状结构。但是,挤压压力也使合金晶间热稳定性好的富铁相数量减少,同时,细化合金晶粒及二次枝晶,增加晶界数量。

关键词:铝铜合金;挤压铸造;高温;力学性能

中图分类号:TG249.9;TG146.2 文献标志码:A

Mechanical properties of squeeze cast Al-5.0Cu-0.6Mn-1.0Fe-1.0Ni alloy at elevated temperatures

LOU Zhao-hui, ZHANG Wei-wen, LUO Zhi, ZHENG Cheng-kun, MENG Fan-sheng

(School of Mechanical and Automotive Engineering, South China University of Technology, Guangzhou 510640, China)

Abstract: The microstructures and mechanical properties of the T7 heat-treated Al-5.0Cu-0.6Mn-1.0Fe-1.0Ni alloy prepared by squeeze casting were studied by tensile test, optical microscopy (OM), scanning electron microscopy (SEM), transmission electron microscopy (TEM), electron probe micro analysis (EPMA), X-ray diffraction analysis (XRD). The effect of applied pressure on the elevated temperature mechanical properties of the alloy was investigated mainly. The results show that the mechanical properties of the alloy at elevated temperatures are improved significantly when the applied pressure increases from 0 to 75 MPa. However, the increments of the ultimate tensile strength and yield strength decrease with the increase of the temperature. The applied pressure can eliminate the porosity and suppress the formation of needle-like Al7Cu2Fe phase. Meanwhile, the block-like Al7Cu2Fe and Al9FeNi phases become smaller and more dispersive and form the interconnected bone-like structure. Unfortunately, the applied pressure reduces the volume fraction of the thermo-stable iron-rich phases and it also refines the grain size and secondary dendrite arm space of the alloy, which leads to the increase of grain boundary.

Key words: aluminum-copper alloy; squeeze casting; elevated temperature; mechanical property

铸造耐热铝合金具有导热性好和密度低等优点,广泛应用于航空及军工发动机零件、汽车耐热零部件等[1-3]。随着人们环保和资源意识的增强,以及发动机效率的不断提高,对铝合金的耐热性能提出了更高的要求[4-5]。合金化是提高铸造耐热铝合金性能最重要的手段之一[6]。这类合金中常常加入如Ni[7-8]、RE[9]、Zr[10]]等大量稀贵金属,它们一方面固溶于基体,增强原子间结合力,提高再结晶温度。另一方面形成热稳定性好的第二相,阻碍晶界滑动,提高高温力学性能。但添加稀贵合金元素往往导致合金成本的大幅度上升,不利于合金的推广应用。

Fe元素在铝合金中的溶解度非常小,常常与其他元素结合形成金属间化合物,即富铁相。Fe在铝合金中常常形成针状的β-Fe (Al5FeSi、Al7Cu2Fe),既硬又脆,对铝合金的延展性和铸造性能产生不利影响[11],因此,高强韧铸造铝合金对其中杂质Fe的含量要求很低。如在206合金系列中,为了确保合金的性能,合金中的最大含铁量一般控制在0.15%(质量分数)以 下[12]。但是,大部分富铁相具有很好的热稳定性,控制恰当能显著提高铝合金的高温性能。近年来,国内外学者针对Fe元素对铸造铝合金耐热性能影响方面开展了大量研究。ASGHAR等[13]研究了Al-Si合金中Fe、Ni同时加入对其性能的影响,发现Fe、Ni在AlSi12合金中会形成三维网络状化合物,能承载更多应力,提高合金的室温、高温强度及蠕变强度。LI等[9]研究了RE、Fe、Mn同时加入A390合金对其组织和性能的影响,发现RE、Fe、Mn加入到Al-Si合金中会形成α-Al(Mn,Fe)-Si等形貌良好分布弥散的复杂富铁相,使A390高温强度提升25%。武玉英等[14]研究了Al-Si-Fe-Cu-Mn-Ni合金中富铁相形貌对合金高温强度的影响,发现针片状富铁相对合金高温强度的提高较小,而鱼骨状和块状富铁相对合金高温强度提升明显。WANG等[15]也认为汉字状的富铁相将有利于Al-Si合金高温力学性能的提高。总之,关于富铁相对铝合金耐热性能的研究主要集中在重力铸造Al-Si合金。

挤压铸造作为一种较为先进的高效近净成形技术,融铸造和锻造的工艺特点为一体,使液态金属在高压作用下凝固成形,可使粗大相破碎,获得致密均匀的组织[16],目前已成为开发高性能铸造铝合金零件的一种重要手段。针对挤压铸造Al-Cu合金,目前的研究主要集中在常温组织与力学性能方面[17-19]。此外,压力下凝固可以改善合金中富铁相的形貌,在确保Al-Cu-Mn合金常温力学性能的基础上,可扩大铁元素的允许含量[20]。关于富铁相对铸造Al-Cu合金耐热性能影响的研究还很少,特别是通过特殊铸造工艺改变第二相形貌及分布来提高铸造Al-Cu合金耐热性能这方面的研究还鲜见报道。为充分发挥富铁相对合金耐热性的有利作用,本文作者以一种成分简单、具有较高Fe含量的Al-5.0Cu-0.6Mn合金为研究对象,重点研究了挤压压力对合金高温力学性能的影响,为进一步开发高Fe含量的挤压铸造耐热Al-Cu合金奠定基础。

1 实验

试验所用原材料为:纯度为99.8%的铝锭、Al-50Cu、Al-10Ni、Al-10Mn、Al-8.2Fe(质量分数)中间合金。在坩埚电阻炉中进行合金熔炼,采用商业固体精炼剂精炼,除气和除渣后,于710 ℃左右进行浇注。合金光谱分析后的主要化学成分如表1所列。

表1 合金的主要化学成分

Table 1 Chemical composition of alloy (mass fraction, %)

挤压铸造试验在1000 kN四柱液压机上进行直接挤压,模具材料为H13钢,采用石墨机油润滑,模具预热温度约250 ℃,挤压力分别为0、75 MPa,挤压速度为10~18 mm/s,保压时间30 s。获得的铸锭尺寸为d 68 mm×65 mm。T7热处理工艺为(530±5) ℃固溶5 h,升温至(540±5) ℃固溶7 h,90 ℃水淬,然后在(215±5) ℃时效16 h,空冷。在铸件同半径的周边截取d 5 mm的标准拉伸试样,在SANS CMT5105 微机控制万能材料试验机上进行拉伸力学性能测试,高温拉伸参照国标GB/T 4338—2006,拉伸速度为1 mm/min,每个测量结果为3个试样的平均值。在拉伸试样夹头部位末端的相同位置截取金相试样,抛光后采用的腐蚀剂为1 mL HF+16 mL HNO3+3 g CrO3+83 mL H2O 溶液,在LEICA/DMI 5000M 金相显微镜上进行微观组织观察,电解腐蚀采用的腐蚀剂为氟硼酸溶液(15 mL HBF3+200 mL H2O),电压为20 V,在LEICA/DMI 5000M 金相显微镜上观察合金晶粒大小。在显微硬度机上测量α(Al)基体的显微硬度,载荷为0.098 N,加载时间为15 s,每个测量结果是10个点的平均值。深腐蚀样品制备时,先将抛光后的金相样品倒置于含有碘的甲醇溶液中(0.1 g/mL),浸泡大约2~3 h后,取出后用清水冲掉表层,用超声波和酒精清洗。深腐蚀样品观察和拉伸断口分析在Nova Nano SEM 430 扫描电子显微镜上进行。在JEM-2010透射电镜下分析了α(Al)基体中的第二相。采用EPMA-1600波谱仪分析了不同挤压压力下铸态合金α(Al)基体中Fe、Ni、Mn和Cu 的成分。采用Bruker D8 ADVANCE X射线衍射仪对合金进行了相分析。

2 实验结果

2.1 合金的力学性能

0和75 MPa挤压压力下T7处理态的合金在室温、200、250和300 ℃下的拉伸力学性能如图1所示。从图1中可以看出,重力铸造和挤压铸造条件下,合金的屈服强度、抗拉强度都随温度的升高而降低,而合金的伸长率随温度的升高而增加。同时,75 MPa压力下的合金相比于0 MPa压力的合金,每个温度下的屈服强度、抗拉强度、伸长率都有所提升,但屈服强度和抗拉强度的增加值随温度的升高而减少。如室温下合金的屈服强度增加值为22 MPa,抗拉强度的增加值约为30 MPa;200 ℃时,合金的屈服强度增加值约为18 MPa,抗拉强度的增加值约为9 MPa;250℃时,合金的屈服强度增加值约为10 MPa,抗拉强度的增加值约为8 MPa;300 ℃时,合金的屈服强度增加值约为4 MPa,抗拉强度的增加值约为5 MPa。75 MPa压力下合金的伸长率相比于0 MPa压力下合金的,不同温度下的合金伸长率增加值相差不大,为5.5%~ 7.5%。

图1 不同挤压压力下合金在不同温度下的力学性能

Fig. 1 Mechanical properties of alloys squeezed at different pressures and different temperatures

2.2 合金的显微组织

0和75 MPa挤压压力下铸态合金的显微组织如图2所示。从图2可以看到,铸态合金的显微组织主要由α(Al)枝晶及分布在枝晶之间的各种第二相组成。由图2(a)可以看出,0 MPa压力下,合金中有很多缩松。而75 MPa压力下,合金中的缩松基本消除,二次枝晶间距细化。从图2(c)和(d)的合金电解腐蚀形貌可以看出,75 MPa挤压压力的合金晶粒明显小于0 MPa挤压压力的合金。

图3所示为不同挤压压力下T7热处理态合金的第二相形貌。从图3(a)可以清楚地看出第二相的形貌特征,这些第二相包括白色的针状相A、白色块状相B及灰色块状相C。表2所列为这3个相的能谱分析结果,图4所示为图3(a)中合金的X射线衍射分析结果,结合相关文献可以判定白色的针状相A及白色块状相B均为Al7Cu2Fe[21],灰色块状相C相为Al9FeNi[22]。从图3(a)和(b)可以看出,0 MPa挤压压力的合金中,Al7Cu2Fe相呈粗大块状或针状分布,Al9FeNi相呈粗大块状分布。75 MPa挤压压力下,合金中的针状Al7Cu2Fe相大为减少,更多的变为短杆状,且块状的Al7Cu2Fe和Al9FeNi相更为细小弥散。图3(c)和(d)所示为合金深腐蚀后的富铁相立体形貌,从图中可以看出,0 MPa挤压压力时,合金中Al7Cu2Fe相实际上呈现粗大的板片状,Al9FeNi相呈三维联通的骨骼状;而75 MPa挤压压力下,合金中的板片状富铁相消失,所有的第二相皆为三维联通的骨骼状,且尺寸减小。

图2 不同挤压压力合金的铸态显微组织

Fig. 2 Microstructures of as-cast alloys squeezed at different applied pressures

图3 不同挤压压力下T7热处理态合金的第二相形貌

Fig. 3 Morphologies of T7 heat-treated alloys squeezed at different applied pressures

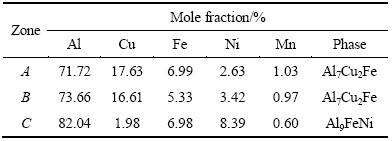

表2 第二相能谱平均成分

Table 2 Average composition of second phases

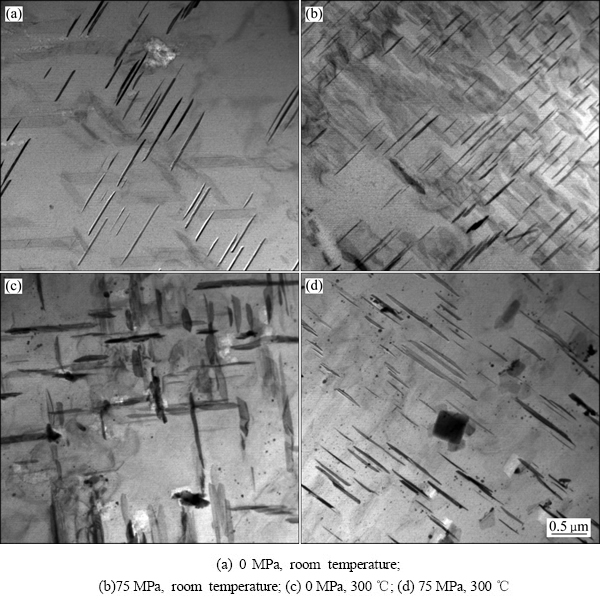

0 MPa及75 MPa挤压压力下,在室温及300 ℃拉伸后的合金基体TEM像如图5所示。从图5可见,在室温及300 ℃时,0 MPa挤压压力下合金基体中纳米沉淀相的数量都明显比75 MPa挤压压力下合金基体中少,且纳米沉淀相的尺寸较大。对于相同挤压压力下的合金,随着温度由室温升高到300 ℃时,基体内的纳米沉淀相数量显著减少,但纳米沉淀相的尺寸变得粗大,例如,当挤压压力为0 MPa时,室温组织中的纳米沉淀相尺寸约为500 nm,300 ℃组织中的纳米沉淀相尺寸约为1 μm,尺寸增大了约两倍。

图4 图3(a)中合金的XRD谱

Fig. 4 XRD patterns of alloys in Fig. 3(a)

2.3 合金的断口形貌

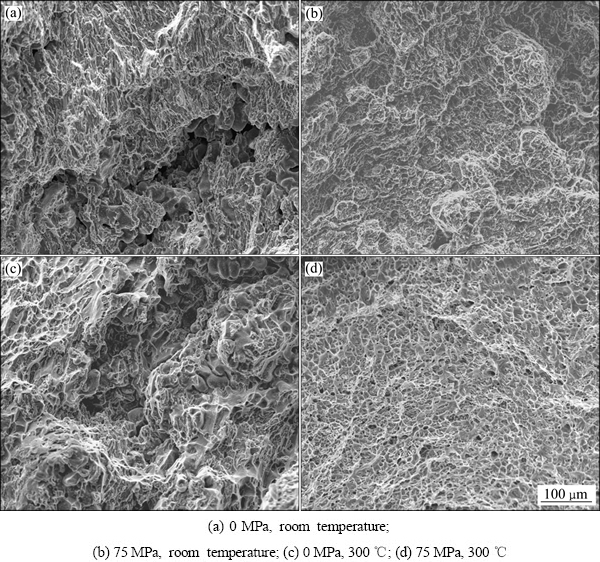

0 MPa及75 MPa挤压压力下,在室温及300 ℃拉伸后的合金断口形貌如图6所示。从图6(a)和(c)可看出,未施加挤压力的合金拉伸断口上可见明显缩松。不同挤压力合金的室温拉伸断口都可见撕裂棱,但75 MPa挤压力合金中的撕裂棱比0 MPa挤压力合金中的要多。0 MPa挤压压力合金的室温拉伸断口韧窝较少,而75 MPa挤压压力合金室温拉伸断口有一定数量大小不均匀的韧窝。从图6(b)和(d)中可以看出,不同挤压压力合金在300 ℃拉伸时的断口都可见大量韧窝,但75 MPa挤压力合金中的韧窝更加细小均匀。但随着温度的升高,拉伸断口中的韧窝数量显著增加,且韧窝变得更均匀,韧性断裂特征更加明显。

图5 不同挤压压力和温度下的合金基体的TEM像

Fig. 5 TEM images of alloy matrix squeezed at different applied pressures and temperatures

图6 不同挤压压力和温度下的合金拉伸断口形貌

Fig. 6 Fracture morphologies of alloys squeezed at different applied pressures and temperatures

3 分析与讨论

试验结果表明,对于同一挤压压力的合金,随着温度升高,合金抗拉强度及屈服强度都降低,而伸长率增加。这是由于随着拉伸试验温度的升高,位错运动更容易,合金中纳米沉淀相(见图5)会长大变粗,粗大的纳米沉淀相对合金中位错运动的阻碍作用减弱,从而使得合金强度下降[23]。另一方面,随着温度升高,原子扩散能力增强,界面滑动能力加强,在第二相处萌生裂纹源的机会减少,从而导致伸长率随着温度升高而显著提高[24-26]。

随着挤压压力的增大,合金的室温力学性能和高温力学性能都得到了不同程度的提升。这主要与挤压压力下合金中的缩松减少、晶粒及二次枝晶细化以及压力下富铁相形貌、分布发生了变化有关。合金在压力下凝固,有利于减小熔体凝固的形核功,增加参与结晶形核原子团的数量,提高形核率。另外,在压力作用下,固液区易于发生强制性补缩。所以挤压铸造可以细化晶粒及二次枝晶,使组织中孔洞或缩松减 少[16]。在挤压铸造过程中,压力的作用消除了铸件与模具之间的气隙,提高界面传热系数,使合金的冷却速度加快。冷却速度越快,合金越接近非平衡凝固,Fe 原子越来不及扩散析出,而针片状Al7Cu2Fe具有小平面择优生长趋势(在单一方向有特殊的生长优势),在较高的冷却速度下,Fe原子越不容易聚集,因此,增大冷却速度可以抑制针状Al7Cu2Fe相的形成,使Al7Cu2Fe相更多地转变为短杆状,同时能抑制Al9FeNi相的长大,形成更为细小弥散的块状甚至骨骼状的Al9FeNi相[27-30]。可见,挤压压力可以改善合金中金属间化合物的形态和分布。Al7Cu2Fe相[31]和Al9FeNi相[22]热稳定性非常好,但是合金的耐热性能不仅与第二相的性质有关,而且与第二相的形貌及分布有很大的关系[32]。当Al7Cu2Fe相呈粗大针状时,对基体有割裂作用,会降低合金力学性能。而当热稳定性好的第二相沿晶界弥散分布时则能提高合金耐热性能,特别是当其形成封闭的网状或骨骼状时,对合金热强性最有利。所以挤压铸造不仅能提高合金室温力学性能,同时也对合金高温下的力学性能有不同程度的改善。

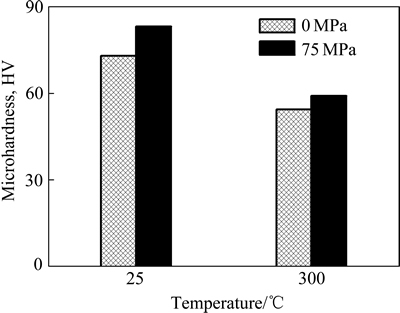

前期研究工作[27, 33]发现,挤压铸造能使Al-Cu- Mn-Fe合金中的溶质原子更多地固溶于α(Al)基体,而使得晶间富铁相数量减少。表3所列为铸态合金中α(Al)基体的化学成分,由表3和图5可知,挤压铸造也能使Al-5.0Cu-0.6Mn-1.0Fe-1.0Ni合金中的溶质元素更多地固溶于α(Al)基体中,使晶界第二相数量减少,而热处理后沉淀析出更多纳米相,图7的合金基体显微硬度值的差异也可以说明这一点。铝合金的高温力学性能取决于α(Al)基体中第二相的固溶和沉淀强化,以及晶界的第二相强化。然而在高温下,原子热振动振幅增大,原子间结合力下降,导致如溶质原子、晶界、相界、位错交互作用等这些在室温下的位错阻碍作用大大减轻,位错不仅易于滑移而且容易发生攀移,使得基体的力学性能下降,因此,固溶强化和沉淀强化在高温下的作用减弱,第二相强化是铝合金在高温下最有效的强化机制[34]。由于挤压铸造使合金中的α(Al)枝晶间距减少,晶界增多。而高温下晶界的不稳定性往往增加,使高温下晶界成为合金的弱化区[35]。因此,随着温度升高,晶界强度不断降低。挤压铸造使得合金晶界富铁相减少,同时,使得合金晶界增多,这将不利于合金高温力学性能的改善。

合金的耐热性能与多种因素有关,且各种因素相互联系、相互制约[36]。挤压铸造能改善合金中热稳定性良好的第二相的分布及形貌,消除合金中的孔洞或缩松等铸造缺陷,有利于提升合金高温力学性能。但同时挤压铸造也使得热稳定性好的晶界第二相数量减少、α(Al)枝晶间距减少、晶界增多。综上所述,挤压力显著改善合金的高温强度,但随着温度的升高,强度的增加值逐渐减小。

表3 铸态合金中α(Al)基体化学成分

Table 3 Chemical composition of α(Al) matrix in as-cast alloys

图7 T7热处理态合金α(Al)基体的显微硬度

Fig. 7 Microhardness of α(Al) matrix in T7 heat-treated alloys

4 结论

1) 在25~300 ℃温度范围内,75 MPa压力下挤压铸造Al-5.0Cu-0.6Mn-1.0Fe-1.0Ni合金的力学性能较0 MPa时均得到了明显提高;但随温度的升高,强度的增加值逐渐减小,而伸长率的增加值变化不大。200 ℃时,75 MPa挤压压力的合金σ0.2为185 MPa、σb为220 MPa、δ为11.8%,较0 MPa时分别提升了18 MPa、9 MPa、6.4%;300 ℃时,75 MPa挤压压力的合金σ0.2为130 MPa、σb为143 MPa、δ为15.2%,较0 MPa时仅提升了4 MPa、5 MPa和5.8%。

2) 在Al-5.0Cu-0.6Mn-1.0Fe-1.0Ni合金中,挤压压力可以消除合金中的缩松等铸造缺陷。同时,抑制合金中晶界处针状的Al7Cu2Fe相形成,使块状使Al7Cu2Fe相及Al9FeNi相分布更为弥散,并形成联通的骨骼状结构,有利于提升合金的高温力学性能。

3) 在Al-5.0Cu-0.6Mn-1.0Fe-1.0Ni合金中,挤压压力也使合金晶间热稳定性好的富铁相数量减少,同时细化合金晶粒及二次枝晶,增加晶界数量,不利于合金高温力学性能的提升。

REFERENCES

[1] BELOV N A, ESKIN D G, AVXENTIEVA N N. Constituent phase diagrams of the Al-Cu-Fe-Mg-Ni-Si system and their application to the analysis of aluminium piston alloys[J]. Acta Materialia, 2005, 53: 4709-4722.

[2] 杨长贺, 舒 震, 赵九夷, 曾纪德, 周光核. 铸造手册: 铸造非铁合金[M]. 北京: 机械工业出版社, 1993: 110-112.

YANG Chang-he, SHU Zhen, ZHAO Jiu-yi, ZENG Ji-de, ZHOU Guang-he. Foundry manual: Nonferrous casting alloys[M]. Beijing: Mechanical Industry Press, 1993: 110-112.

[3] MAREK B, PETR L, MICHAL C, JAROSLAV B. Influence of remelting repeated on the mechanical properties and structure of alloys RR.350[J]. Metal, 2012(5): 23-25.

[4] JOYCE M R, STYLES C M, REED P A S. Elevated temperature short crack fatigue behavior in near eutectic Al-Si alloys[J]. International Journal of Fatigue, 2003, 5: 863-869.

[5] QIAN Zhao, LIU Xiang-fa, ZHAO De-gang, ZHANG Guo-hua. Effects of trace Mn addition on the elevated temperature tensile strength and microstructure of a low-iron Al-Si piston alloy[J]. Materials Letter, 2008, 62: 2146-2149.

[6] LI Yun-guo, YANG Yang, WU Yu-ying, WEI Zuo-shan, LIU Xiang-fa. Supportive strengthening role of Cr-rich phase on Al-Si multicomponent piston alloy at elevated temperature[J]. Materials Science and Engineering A, 2011, 528: 4427-4430.

[7] LI Yun-guo, YANG Yang, WU Yu-ying, WANG Li-yan, LIU Xiang-fa. Quantitative comparison of three Ni-containing phases to the elevated-temperature properties of Al-Si piston alloys[J]. Materials Science and Engineering A, 2010, 527: 7132-7137.

[8] ASGHAR Z, REQUENA G, DEGISCHER H P, CLOETENS P. Three-dimensional study of Ni aluminides in an AlSi12 alloy by means of light optical and synchrotron microtomography[J]. Acta Materialia, 2009, 57: 4125-4132.

[9] LI Yun-guo, WU Yu-ying, QIAN Zhao, LIU Xiang-fa. Effect of co-addition of RE, Fe and Mn on the microstructure and performance of A390 alloy[J]. Materials Science and Engineering A, 2009, 527: 146-149.

[10] GAO Tong, ZHU Xiang-zhen, SUN Qian-qian, LIU Xiang-fa. Morphological evolution of ZrAlSi phase and its impact on the elevated-temperature properties of Al-Si piston alloy[J]. Journal of Alloys and Compounds 2013, 567: 82-88.

[11] TAYLOR J A. The effect of iron in Al-Si casting alloys[C]// 35th Australian Foundry Institute National Conference. Adelaide, Australia, 2004: 148-157.

[12] LIU K, CAO X, CHEN X G. Solidification of iron-rich intermetallic phases in Al-4.5Cu-0.3Fe cast alloy[J]. Metallurgical and Materials Transactions A, 2010, 42(7): 2004-2016.

[13] ASGHAR Z, REQUENA G, KUBEL F. The role of Ni and Fe aluminides on the elevated temperature strength of an AlSi12 alloy[J]. Materials Science and Engineering A, 2010, 527: 5691-5698.

[14] 武玉英, 刘相法, 姜炳刚, 边秀房. Al-Si-Fe-Cu-Mg-Ni合金中复合Fe-Si相的研究[J]. 铸造, 2006, 54(10): 959-962.

WU Yu-yin, LIU Xiang-fa, JIANG Bing-gang, BIAN Xiu-fang. Study of the complex Fe-Si phase in the Al-Si-Cu-Mg-Ni alloys[J]. Foundry, 2006, 54(10): 959-962.

[15] WANG E R, HUI X D, CHEN G L. Eutectic Al-Si-Cu-Fe-Mn alloys with enhanced mechanical properties at room and elevated temperature[J]. Materials & Design, 2011, 32(8): 4333-4340.

[16] GHOMASHCHI M R, VIKHROV A. Squeeze casting: An overview[J]. Journal of Materials Processing technology, 2000, 101: 1-9.

[17] GALLERNEAULT M, DURRANT G, CANTOR B. Eutectic channeling in a squeeze cast Al-4.5wt% Cu alloy[J]. Scripta Metallurgica et Materialia, 1995, 32(10): 1553-1557.

[18] GALLERNEAULT M, DURRANT G, CANTOR B. The squeeze casting of hypoeutectic binary Al-Cu[J]. Metallurgical and Materials Transactions A, 1996, 27(12): 4121-4132.

[19] ZHANG Wei-wen, Lin Bo, Cheng Pei, ZHANG Da-tong, LI Yuan-yuan. Effects of Mn content on microstructures and mechanical properties of Al-5.0Cu-0.5Fe alloys prepared by squeeze casting[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(6): 1525-1531.

[20] LIN Bo, ZHANG Wei-wen, LOU Zhao-hui, ZHANG Da-tong, LI Yuan-yuan. Comparative study on microstructures and mechanical properties of the heat-treated Al-5.0Cu-0.6Mn-xFe alloys prepared by gravity die casting and squeeze casting[J]. Materials & Design, 2014, 59: 10-18.

[21] WANG Feng, XIONG Bai-qing, ZHANG Yong-an, LI Zhi-hui, LI Pei-yue. Microstructural characterization of an Al-Cu-Mg alloy containing Fe and Ni[J]. Journal of Alloys and Compounds, 2009, 487: 445-449.

[22] CHEN C L, THOMSON R C. The combined use of EBSD and EDX analyses for the identification of complex intermetallic phases in multicomponent Al-Si piston alloys[J]. Journal of Alloys and Compounds, 2010, 490: 293-300.

[23] 崔忠圻, 覃耀春. 金属学与热处理[M]. 北京: 机械工业出版社, 2007: 385-386.

CUI Zhong-qi, TAN Yao-chun. Metallography and heat treatment[M]. Beijing: Mechanical Industry Press, 2007: 385-386.

[24] 张新明, 刘 波, 刘 瑛, 李慧中, 李惠杰. 温度与保温时间对2519A铝合金高温力学性能的影响[J]. 中国有色金属学报, 2007, 17(10): 1561-1566.

ZHANG Xin-ming, LIU Bo, LIU Ying, LI Hui-zhong, LI Hui-jie. Effects of temperature and holding time on elevated-temperature mechanical properties of aluminum alloy 2519A[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(10): 1561-1566.

[25] UNLU N, GABLE B M, STARKE E A. The effect of cold work on the precipitation of Ω and θ′ in a ternary Al-Cu-Mg alloy[J]. Metallurgical and Materials Transactions A, 2003, 34(12): 2757-2769.

[26] LIU Gang, DING Xiang-dong, SUN Jun, CHENG Kang-hua. The influences of multiscale-sized second-phase particles on ductility of aged aluminum alloys[J]. Metallurgical and Materials Transactions A, 2004, 35(6): 1725-1734.

[27] 林 波, 张卫文, 程 佩, 汪先送, 李元元. 挤压铸造Al-5.0Cu-0.6Mn-0.5Fe合金的显微组织和力学性能[J]. 中国有色金属学报, 2013, 23(5): 1195-1201.

LIN Bo, ZHANG Wei-wen, CHENG Pei, WANG Xian-song, LI Yuan-yuan. Microstructure and mechanical properties of Al-5.0Cu-0.6Mn-0.5Fe alloy prepared by squeeze casting[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1195-1201.

[28] DONG J X, KARNEZIS P A, DURRANT G, CANTOR B. The effect of Sr and Fe additions on the microstructure and mechanical properties of a direct squeeze cast Al-7Si-0.3Mg alloy[J]. Metallurgical and Materials Transactions A, 1999, 30: 1341-1356.

[29] MAENG D Y, LEE J H, WON C W. The effects of processing parameters on the microstructure and mechanical properties of modified B390 alloy in direct squeeze casting[J]. Journal of Materials Processing Technology, 2000, 105: 196-203.

[30] KAMGA H K, LAROUCHE D, BOURNANE M, RAHEM A. Solidification of aluminum-copper B206 alloys with iron and silicon additions[J]. Metallurgical and Materials Transactions A, 2010, 41: 2844-2855.

[31] 董天春, 周家样. RR350耐热铝合金热处理实践[J]. 兵器材料科学与工程, 1989, 5: 37-43.

DONG Chun-tian, ZHOU Jia-xiang. The practice of RR350 heat-resistant aluminum alloy[J]. Ordnance Material Science and Engineering, 1989, 5: 37-43.

[32] YANG Yang, YU Kui-long, LI Yun-guo, ZHAO De-gang, LIU Xiang-fa. Evolution of nickel-rich phases in Al-Si-Cu-Ni-Mg piston alloys with different Cu additions[J]. Materials and Design, 2012, 33: 220-225.

[33] ZHANG Wei-wen, LIN Bo, ZHANG Da-tong, LI Yuan-yuan. Microstructures and mechanical properties of squeeze cast Al-5.0Cu-0.6Mn alloys with different Fe content[J]. Materials and Design, 2013, 52: 225-233.

[34] 李云国. Al-Si-Cu-Ni-Mg系活塞合金高温强化相的研究[D]. 济南: 山东大学, 2011: 6-8.

LI Yun-guo. The study of elevated-temperature strengthening phase of Al-Si-Cu-Ni-Mg piston alloys[D]. Jinan: Shandong University, 2011: 6-8.

[35] 张新明, 王文韬, 刘 波, 陈明安, 刘 瑛, 高志国, 叶凌英, 贾寓真. Nd对2519铝合金组织与耐热性能的影响[J]. 中国有色金属学报, 2009, 19(1): 15-20.

ZHANG Xin-ming, WANG Wen-tao, LIU Bo, CHEN Ming-an, LIU Ying, GAO Zhi-guo, YE ling-ying, JIA Yu-zhen. Effect of Nd addition on microstructures and heat-resisting properties of 2519 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(1): 15-20.

[36] 王建华. 2618耐热铝合金的组织与力学性能的研究[D]. 长沙: 中南大学, 2003.

WANG Jian-hua. Study on microstructures and mechanical properties of heat resistance aluminum alloy 2618[D]. Changsha: Central South University, 2003.

(编辑 龙怀中)

基金项目:GD-NSFC联合基金资助项目(U1034001);国家自然科学基金资助项目(51374110);教育部博士点基金资助项目(20120172110045)

收稿日期:2014-02-28;修订日期:2014-12-20

通信作者:张卫文,教授,博士;电话:13642315239;E-mail: mewzhang@scut.edu.cn