文章编号:1004-0609(2007)04-0536-06

热处理对挤压铸造TiB2P/6061Al复合材料组织与性能的影响

赵 敏1, 2,姜龙涛1,武高辉1

(1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 中国石油独山子石化公司研究院,克拉玛依 833600)

摘 要:采用挤压铸造法制备了不同体积分数的TiB2P/6061Al复合材料,利用扫描电镜、透射电镜、硬度计、三点弯曲等手段对复合材料的组织与力学性能进行了研究,分析了热处理工艺对其组织性能的影响。结果表明:不同的热处理条件下TiB2P/6061Al复合材料的组织不同:退火态时观察到再结晶晶粒和少量位错;时效态时观察到大量的位错和析出相,界面产物尺寸比退火态时相对大些,且在界面附近的基体中存在明显的无析出区。热处理状态对弹性模量的影响不大,但对材料的硬度和抗弯强度影响较大。45%TiB2P/6061Al复合材料时效处理后硬度和抗弯强度分别比退火态时提高了40%和23%。

关键词:热处理;挤压铸造;TiB2P/6061Al复合材料;力学性能

中图分类号:TG 151 文献标识码:A

Effect of heat treatment on microstructure and properties of TiB2P/6061Al composites fabricated by squeeze casting

ZHAO Min1, 2, JIANG Long-tao1, WU Gao-hui1

(1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. Research Institute of Dushanzi Petrochemical Company, CNPC, Kelamayi 833600, China)

Abstract: TiB2P/6061Al composites with different volume fractions were fabricated by squeeze casting. The microstructure and mechanical properties of the composites were studied by means of scanning electron microscope, transmission electron microscope, hardness measurement and tensile test, and the effect of heat treatment on microstructure and properties of the composites was analyzed. The results show that the composites have different microstructure under different conditions of heat treatment. The recrystallized grains and some dislocations are observed in the composites after annealing treatment, while plenty of dislocations and precipitates are observed in the composites after aging treatment and the size of precipitates is bigger than that after annealing treatment. And in the composites after aging treatment, there exists obvious precipitate free zone in the matrix nearby the grain boundaries. The effect of heat treatment on elastic modulus is not evident, but it is much bigger on hardness and bending strength of the composites. After aging treatment, the hardness and bending strength of 45%TiB2P/6061Al composite are respectively 40% and 23% higher than those after annealing treatment.

Key words: heat treatment; squeeze casting; TiB2P/6061Al composites; mechanical properties

复合材料的性能除了取决于基体和增强体外,还与制备材料时所采用的工艺以及热处理状态有关系。相同的增强体和基体构成的复合材料因其制备工艺和热处理工艺不同,材料的力学性能也不同[1-4]。目前TiB2P/Al复合材料主要采用原位自生法制备[5-8],该方法中TiB2增强体通常以反应析出的方式生成,颗粒的尺寸和形状以及数量受控于形核和长大过程,这在很大程度上影响了材料性能的稳定性。另外,在反应生成TiB2增强相的同时,仍有其他夹杂物存在(如TiAl3等),它们常以针片状割裂基体,使材料力学性能下 降[9-10]。

本文作者采用挤压铸造专利技术[11]制备了不同体积分数的TiB2P/6061Al复合材料,利用扫描电镜(SEM)、透射电镜(TEM)、硬度计及三点弯曲等手段对复合材料的组织与力学性能进行了研究,分析了热处理工艺对复合材料组织性能的影响。

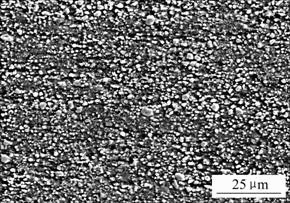

1 实验

采用平均粒径为1.3 μm的TiB2颗粒为增强相,选择东北轻合金厂生产的CZ态(淬火加自然时效)6061铝合金为基体,利用挤压铸造专利技术制备体积分数为30%和45%的TiB2P/6061Al复合材料,并利用Hitachi S-570扫描电镜对复合材料的微观组织进行观察(见图1)。由图可见,复合材料组织致密,无气孔、缩松、夹铝层等明显缺陷,颗粒均匀分布在铝基体中,不存在明显的颗粒偏聚区和贫化区。

图1 TiB2P/6061Al复合材料的扫描电镜照片

Fig.1 SEM image of TiB2P/6061Al composites

采用退火和时效两种工艺对复合材料进行热处理。其中,退火处理工艺为在空气炉于(415±5) ℃保温3 h;时效处理工艺(T6)为在KNO3盐浴炉于530 ℃保温1 h,水淬,然后在恒温烘箱于160 ℃保温10 h后空冷。采用HBV-30A型硬度计测试复合材料的布氏硬度,所加载荷为294.2 N,加载时间为30 s。三点弯曲实验在Instron5569万能电子拉伸实验机上进行,试样尺寸为36 mm×4 mm×3 mm,跨距为30 mm。应变片选用BJ120-3AA型电阻应变片。

采用Gatan-600离子减薄仪制备复合材料的透射电镜样品。减薄条件为:电压5 kV,电流1 mA;减薄时试样的掠射角7?~15?。利用Philips CM-12 和JEOL 200CX 电镜对复合材料的显微组织进行观察与分析,加速电压分别为120 kV和200 kV。

2 结果与讨论

2.1 热处理对TiB2P/6061Al复合材料基体的影响

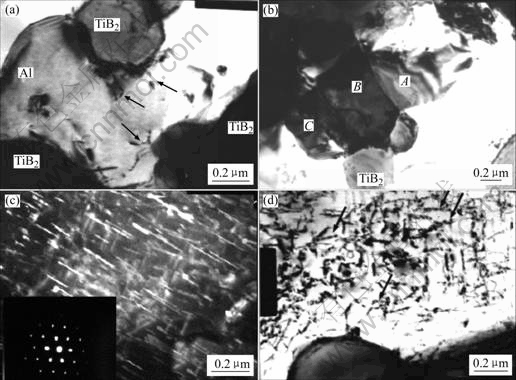

图2所示为30%TiB2P/6061Al复合材料退火态和峰时效态的TEM照片。由图2(a)可见,退火处理后复合材料基体中的位错密度较低。由于复合材料中颗粒与基体的热膨胀系数存在差异,且挤压铸造温度较高、冷却速率较快,复合材料中的内应力较大,通过退火处理,可以均匀复合材料的化学成分及组织,细化晶粒,调整硬度,消除材料内应力。因此,在退火态TiB2P/6061Al 复合材料基体中并未发现大量位错,只是在颗粒附近存在少量线性位错。与王秀芳[12]观察到的SiCP/2024Al复合材料退火后基体内仍存有大量位错缠结的TEM显微组织不同,这种位错形态差异与增强体的形态密切相关。本研究所用的TiB2颗粒没有明显的尖角,不易产生热应力集中,退火处理容易消除存在的内应力,使基体内的位错水平下降。但由于TiB2周围基体中的初始内应力较大,所采用的退火处理工艺仅能将部分内应力去除,因此形成少部分线性位错,未发现位错缠结的现象。

图2 退火态和峰时效态30%TiB2P/6061Al 复合材料TEM照片

Fig.2 TEM images of 30%TiB2P/6061Al composites in annealed and peak-aged state: (a) Dislocations in annealed composites; (b) Crystal grains in composites; (c) Precipitates in bright field; (d) Dislocations in aged composites

退火态TiB2P/6061Al复合材料显微组织的另一主要特征为再结晶。铝合金的再结晶过程与许多因素有关,如合金成分、变形量、退火时间以及退火加热速度等,均会改变再结晶温度和再结晶后的晶粒尺寸。图2(b)所示为TiB2P/6061Al 复合材料铝基体再结晶形态。从图中可以观察到复合材料中铝合金的再结晶晶粒,A、B和C处分别代表不同的铝合金晶粒,晶粒大小为0.2~0.7 μm。这说明退火处理使得复合材料基体合金中的晶粒明显细化。

图2(c)和(d)所示为30%TiB2P/6061Al复合材料经时效处理后基体的TEM显微组织,与退火组织存在明显区别。从图2(c)中可以看出,复合材料基体中有一些呈杆状的细小析出物,数量较多,且形态较为细密,长轴尺寸在50~200 nm之间。6061Al 为Al-Mg-Si 系合金,其时效脱溶过程[13]为:球状GP区→针状GP区→杆状β′相→片状β相(Mg2Si),由此可以判断图中析出物为β′相。另外,时效处理后复合材料中的位错数量明显增加,如图2(d)所示,高密度位错的存在,一方面可以为依赖于位错等缺陷形核的β′相提供非均匀形核的有利场所(见图2(d)中箭头所指处),缩短形核孕育期,加速析出相的形核,使析出相的形核密度增加,尺寸减小,促进时效析出;另一方面,还能够促进溶质原子Mg、Si等的扩散,降低β′相的热扩散激活能,促进其沉淀析出[14]。另外,TiB2颗粒的加入为复合材料引入了大量的界面,这些界面的存在也为β′相的析出形核提供了有利场所,促进了β′相的析出。

2.2 热处理对TiB2P/6061Al复合材料界面的影响

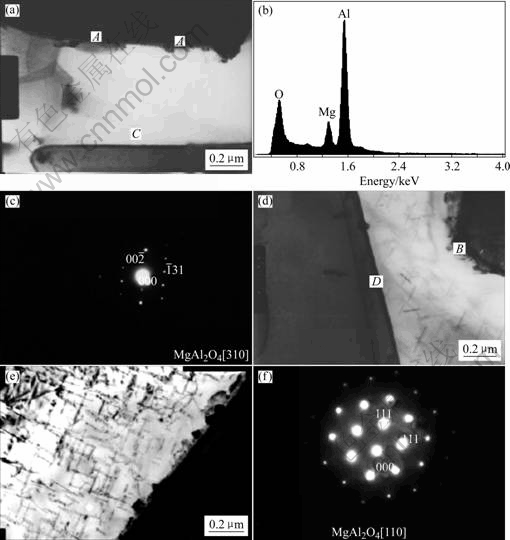

图3所示为退火态和峰时效态30%TiB2P/6061Al复合材料的显微组织。图3(a)所示为退火态复合材料颗粒与界面间的结合情况,A处颗粒与基体的界面十分干净,没有在界面上观察到有空洞或界面开裂的情况,而C处的界面上则发现沿着界面分布的块状物质,大小约为50 nm。图3(b)和(c)所示为退火态复合材料界面处块状析出物的能谱和相应的电子衍射花样(SADP)。能谱分析的结果表明,界面反应物的主要成分为Mg、Al和O,选区电子衍射花样标定的结果与立方晶系的MgAl2O4[310]晶体结构一致,因此确定该物相为MgAl2O4。

图3 退火态和峰时效态30%TiB2P/6061Al复合材料的显微组织

Fig.3 Microstructures of 30%TiB2P/6061Al composites in annealed and peak-aged state: (a) Interfaces in annealed composites; (b) Spectrum obtained via electron diffraction pattern; (c) SADP of MgAl2O4[310]; (d) Interfaces in aged composites; (e) Other interfaces in aged composites; (f) SADP of MgAl2O4[110]

峰时效态和退火态复合材料中界面的状态相似,如图3(d)中D处为无明显的界面产物,而B处界面上存在着细小的块状反应物。如图3(e)中所示,界面反应产物不连续地分布在界面上,厚度从10 nm到40 nm,长度为30 nm到60 nm,而且其周围似乎有层膜存在。对界面块状物质进行了电子衍射花样的标定,如图3(f)所示,界面物质的衍射斑点可以确定界面反应物为MgAl2O4,与退火态时的界面产物种类是一样的。但时效处理后,随着热处理保温过程中元素界面偏聚的程度增加,合金元素的原子进一步向界面扩散。因此,界面反应物比退火态时的尺寸相对要大些。另外由图3(d)和(e)还可以看出,在界面附近的基体中,存在明显的无析出区。这可能是由于溶质原子Mg 在界面上的偏聚,并且生成界面反应物MgAl2O4,使得界面附近的溶质原子贫化,所以界面附近基体的时效析出变得困难。

Al是一种较为活泼的金属,可以还原大部分的氧化物和碳化物。因此,它会与绝大部分增强体反应,如在Al-SiC系中,可能会有Al4C3和Si形成,从而降低材料的性能;而在Al-TiB2 系中,TiB2颗粒增强体与Al基本不反应,但是在复合材料的高温制备过程中Al合金和TiB2表面有可能发生氧化反应,生成Al2O3和TiO2。有学者研究了Al2O3颗粒在含Mg铝合金中的稳定性,表明在1 000 K时,铝合金中Mg的质量分数达到0.03%就会有镁铝尖晶石产生[13]。而本研究中选用的6061铝合金中Mg的质量分数远高于0.03%,因此,在TiB2P/6061Al复合材料的TiB2颗粒与铝基体的界面上生成有界面反应物MgAl2O4。MgAl2O4颗粒的周围似乎有层膜存在,但是由于界面的膜状物质较薄,无法在透射电镜上获得准确的能谱成分以及相应的电子衍射斑点,因此,膜状物质有待进一步利用高分辨电镜进行观察。

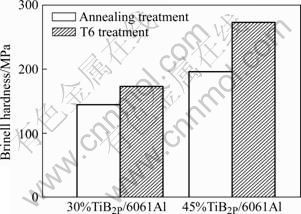

2.3 热处理对复合材料性能的影响

图4所示为TiB2P/6061Al复合材料的布氏硬度。由图可见,当增强相体积分数相同时,热处理状态对复合材料硬度有一定影响。经过时效处理后,复合材料的硬度均有显著增加。30%TiB2P/6061Al复合材料的硬度由退火态时的144.92 MPa提高到峰时效态时的173.97 MPa,增加了20%;而45%TiB2P/6061Al复合材料的硬度由退火态时的196.51 MPa提高到峰时效态时的274.26 MPa,增加了40%。这主要是由于时效处理使得基体合金的强度增加,从而使得复合材料整体硬度提高。

图4 TiB2P/6061Al复合材料的硬度

Fig.4 Hardness of TiB2P/6061Al composites

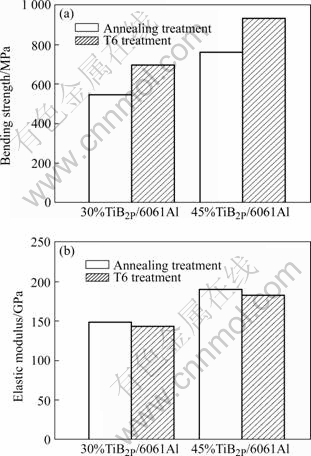

图5(a)所示为热处理状态对TiB2P/6061Al复合材料力学性能的影响。由图可见,与退火态的材料相比,两种复合材料经时效处理后抗弯强度都有明显提高。30%TiB2P/6061Al复合材料时效处理后抗弯强度比退火态的提高了28%,达到697 MPa。而45%TiB2P/ 6061Al复合材料时效处理后抗弯强度比退火态的提高了23%,达到934 MPa。这主要是由于TiB2颗粒的加入使得热错配应力之间的相互作用增大,位错密度增加。位错密度以及析出相数量的增加对提高复合材料的力学性能有一定的贡献。

图5 TiB2P/6061Al复合材料的抗弯强度(a)和弹性模量(b)

Fig.5 Bending strength (a) and elastic modulus (b) of TiB2P/6061Al composites

弹性模量是复合材料的一个重要力学性能指标。由于增强相的加入,复合材料的弹性模量通常较基体材料的有很大提高。由图5(b)可以看出,TiB2P/6061Al复合材料在退火态和时效态下的弹性模量相差不大。对于30%TiB2P/6061Al复合材料,退火态时的弹性模量比时效态的高了5 GPa,基本上可以认为热处理状态对材料的弹性模量没有明显的影响。对于45%TiB2P/6061Al复合材料而言,退火态时的弹性模量比时效态的高了7.3 GPa,基本上也可以认为热处理并没有改变材料的弹性模量。这是由于影响复合材料弹性模量的因素主要有增强体种类、含量和基体合金种类等。一般认为弹性模量是材料的本征特性,不随热处理状态而变化。

3 结论

1) 不同的热处理条件下,TiB2P/6061Al复合材料的组织特征不同。退火态时可以观察到有再结晶晶粒,而时效态时可以观察到大量的位错和析出相。

2) 不同的热处理条件下,挤压铸造TiB2P/6061Al铝基复合材料的布氏硬度、抗弯强度和弹性模量不同。45%TiB2P/6061Al复合材料时效处理后硬度和抗弯强度分别比退火态时提高了40%和23%,而弹性模量受热处理状态的影响不大。

REFERENCES

[1] Tee K L, Lu L, Lai M O. Mechanical properties of Al-TiB2 composite by the stir-casting technique[J]. Mater Sci Technol, 2001, 17(2): 201-206.

[2] 韩延峰,刘湘法,边秀房. 原位生成TiB2/Al-Si-Mg复合材料的组织与性能[J]. 中国有色金属学报, 2001, 11(5): 840-845.

HAN Yan-feng, LIU Xiang-fa, BIAN Xiu-fang. Microstructures and mechanical properties of in-situ TiB2/Al-Si-Mg composites [J]. The Chinese Journal of Nonferrous Metals, 2001, 11(5): 840-845.

[3] 陈子勇,陈玉勇,舒 群,孙剑飞,安阁英,李 东,刘羽寅. 铸态TiB2/Al-4.5Cu复合材料组织和性能的研究[J]. 复合材料学报, 2000, 17(1): 76-80

CHEN Zi-yong, CHEN Yu-yong, SHU Qun, SUN Jian-fei, AN Ge-ying, LI Dong, LIU Yu-yin. Microstructure and properties of as-cast Al-4.5Cu/TiB2 composite[J]. Acta Materiae Composite Sinica, 2000, 17(1): 76-80.

[4] 梁艳峰,董晟全,杨 通. 原位增强TiB2/Al-4.5Cu复合材料的组织与力学性能[J]. 铸造技术, 2004, 25(2): 125-127.

LIANG Yan-feng, DONG Sheng-quan, YANG Tong. Dry wear behavior of in-situ reinforced cast Al-4.5Cu alloy at a high temperature[J]. Foundry Technology, 2004, 25(2): 125-127.

[5] HAN Yan-feng, LIU Xiang-fa, BIAN Xiu-fang. In situ TiB2 particulate reinforced near eutectic Al-Si alloy composites[J]. Composite: Part A, 2002, 33(3): 439-444.

[6] Lu L, Lai M O, Su Y, Teo H L, Feng C F. In situ TiB2 reinforced Al alloy composites[J]. Scripta Mater, 2001, 45(9): 1017-1023.

[7] Tee K L, Lu L, Lai M O. In situ processing of Al-TiB2 composite by the stir-casting technique[J]. Journal of Materials Technology, 1999, 89/90: 513-519.

[8] Feng C F, Froyen L. On the reaction mechanism of an Al-TiO2-B system for producing in-situ (Al2O3-TiB2)/Al composites[J]. Scripta Mater, 1998, 39(1):109-118.

[9] Tee K L, Lu L, Lai M O. Improvement in mechanical properties of in-situ Al-TiB2 composite by incorporation of carbon[J]. Materials Science and Engineering A, 2003, 339: 227-231.

[10] Welham N J. Mechanical enhancement of the carbothermic formation of TiB2[J]. Metallurgical and Materials Transactions A, 2000, 31(1): 283-289.

[11] 武高辉. 一种亚微米陶瓷颗粒与铝合金的复合工艺:中国,94117266. X [P]. 1994-10-14.

WU Gao-hui. A combination technology for sub-micro ceramic particle and aluminum alloy: China, 94117266. X[P]. 1994-10-14.

[12] 王秀芳. SiCP/2024Al复合材料的尺寸稳定性研究[D]. 哈尔滨:哈尔滨工业大学, 2003: 56-59.

WANG Xiu-fang. Study on Dimensional Stability of SiCP/2024Al Composite[D]. Harbin: Harbin Institute of Technology, 2003: 56-59.

[13] 姜龙涛. 亚微米Al2O3颗粒增强铝基复合材料近界面区的显微结构特征[D]. 哈尔滨:哈尔滨工业大学, 2001: 55-100.

JIANG Long-tao. Study on Microstructure of Near-interfacial Areas in Sub-micron Al2O3 Particles Reinforced Al Matrix Composites[D]. Harbin: Harbin Institute of Technology, 2001: 55-100.

[14] Bartels C, Raabe D, Gottstein G, Huber U. Investigation of the precipitation kinetics in an Al6061/TiB2 metal matrix composite[J]. Material Science and Engineering A, 1997, 237: 12-23.

收稿日期:2006-10-17;修订日期:2007-01-08

通讯作者:赵 敏,工程师,博士;电话:0992-3863146;E-mail: yjy_zm@petrochina.com.cn

(编辑 杨幼平)