DOI:10.19476/j.ysxb.1004.0609.2019.02.01

固溶时间对ADC12铝合金挤压铸造组织及力学性能的影响

姜 博1,吉泽升1,胡茂良1,张永冰2,王云龙2,王绍著3

(1. 哈尔滨理工大学 材料科学与工程学院,哈尔滨 150040;

2. 哈尔滨吉星机械工程有限公司,哈尔滨 150069;

3. 临沂市科学技术合作与应用研究院,临沂 276000)

摘 要:研究了固溶时间对挤压铸造ADC12铝合金显微组织及力学性能的影响。结果表明:随着固溶时间的延长,显微组织中粗大片状共晶Si和针状Al5FeSi相均细化为细小颗粒状,长宽比(L/B)值由8.9降到2.0;合金的抗拉强度由挤压铸态的227 MPa增加到固溶时间为10 h的274 MPa;维氏硬度呈现先增加后降低的趋势,在固溶时间为4 h时达到最大值110HV,之后趋于稳定。ADC12铝合金断裂形式由准解理断裂向韧性断裂转变。

关键词: ADC12铝合金;间接挤压铸造;固溶时间;显微组织;力学性能

文章编号:1004-0609(2019)-02-0223-09 中图分类号:TG166. 3 文献标志码:A

间接挤压铸造是集铸造和锻造为一体的先进成型技术,间接挤压铸造所生产的零件具有尺寸精度高,组织致密,力学性能好,可热处理等优点[1-4]。ADC12铝合金作为近共晶铝合金具有优异的铸造性能,较高的抗腐蚀性,良好的耐磨性和较低的热膨胀系数等诸多优点[5-8]。热处理是铝合金强化的主要手段[9-11],采用固溶处理对间接挤压铸造进行强化,可使Al-Si合金的强度和耐磨性提高[12-14],李润霞等[15]对过共晶Al-Si合金热处理组织与力学性能进行了研究,热处理能显著改善原合金的组织形态及相分布,原合金中一些粗大相在固溶阶段溶解,时效阶段弥散析出,强化了基体。林高用等[16]对Al-Si-Cu-Mg合金通过固溶(495℃,90 min,WC)和时效(170 ℃,4 h,AC)处理,合金的硬度提高31.3%,强度提高3.3倍。本文对挤压铸造ADC12铝合金进行固溶处理,研究了固溶处理与组织及力学性能变化,得出固溶处理对 ADC12铝合金强化机制,为提高ADC12铝合金挤压铸造组织及性能提供依据。

1 实验

试验采用ADC12铝合金,其主要成分(质量分数)

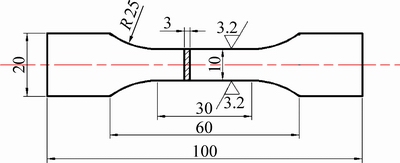

为11.3%Si、2.2%Cu、0.8%Fe、0.15%Mg、0.16%Mn和0.46%Zn,余量为Al。采用SCH-350A型号挤压铸造机进行试验,浇注温度为680 ℃,挤压压力为120 MPa。采用差示扫描量热法测定ADC12铝合金DSC曲线,根据DSC曲线选取固溶温度为500 ℃,固溶时间分别为2、4、6、8和10 h,出炉水冷,在180 ℃进行时效,时效时间为8 h。加工标准拉伸试样,试样尺寸如图1所示,在WDW-200万能拉伸试验机上进行拉伸试验测得抗拉强度值。利用维氏硬度计进行维氏硬测试,负荷为49 N。在断口附近截取试样进行抛光并用1%HF(体积分数)进行腐蚀,利用扫描电镜观察显微组织、拉伸断口形貌并进行能谱分析。

图1 拉伸试样

Fig. 1 Tensile specimen (Unit: mm)

2 实验结果

2.1 DSC分析

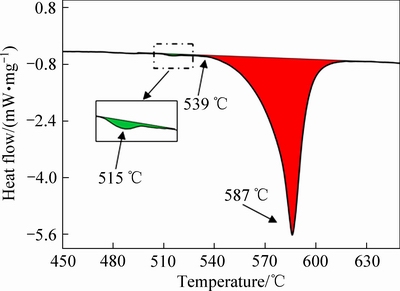

图2所示为ADC12铝合金DSC曲线。从图2可见,Al2Cu相的熔化温度为500 ℃,随着温度持续增加Al2Cu相逐渐转变为液相;在515 ℃时Al2Cu相熔化量达到了高峰,此时合金坯料的微观组织为“液相Al2Cu+α(Al)相+Si相”,即熔化的Al2Cu相浸润着α(Al)相和Si相。因此,热处理温度不能高于Al2Cu的熔化温度,所以固溶温度选在小于500 ℃。

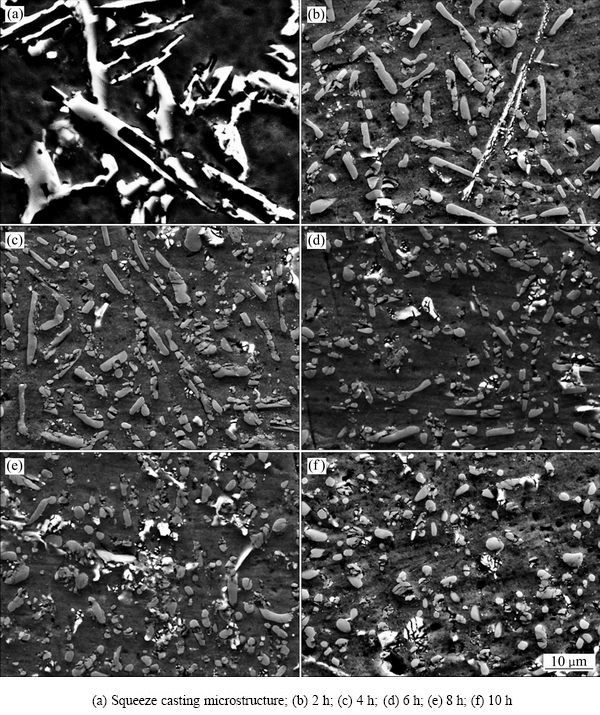

图3所示为挤压铸造态合金的显微组织。从图3可见,与压铸以及低压铸造等金属型铸造相比,由于金属液在高压作用下凝固结晶,挤压铸造的显微组织更为致密,少有铸造缩孔缩松类缺陷;显微组织中存在较多粗大针状Fe相和片状共晶Si相,其中共晶Si相主要分布在α相的晶界处,而有些Fe相则贯穿整个α晶粒。由于这些相的存在,增加了对基体组织的割裂作用,使材料的力学性能降低尤其对材料塑性降低更为明显。

图2 ADC12铝合金的DSC曲线

Fig. 2 DSC curve of ADC12 aluminum alloy

图3 挤压铸造态合金的显微组织

Fig. 3 Microstructure of squeeze casting alloy

2.2 固溶处理对显微组织影响

图4所示为不同固溶时间的合金显微组织。图4(a)所示为挤压铸造态显微组织,合金在压力作用下以较大冷却速率进行非平衡结晶,使得共晶相来不及长大,但显微组织中仍存在较多粗大片状共晶组织。由于ADC12铝合金是一种多元合金,含有较多的Cu和Fe,所以在显微组织中主要为Al5FeSi相,此外还存在Al2Cu相和一些Fe相。图4(b)~(f)所示分别为2、4、6、8和10 h固溶后的显微组织。由图4(b)~(f)可知,随着固溶时间的延长,显微组织中粗大共晶组织明显发生转变,粗大片状共晶组织逐渐锐化,降低了对基体组织的割裂作用,且粗大片状逐渐向颗粒状转变,在固溶时间为10h时共晶组织最为细小均匀;Fe相作为铝合金中的杂质相,对性能起着负面作用,经固溶处理后,挤压铸造组织中针状单斜晶系的Al5FeSi相在高温作用下向颗粒状转变;Al2Cu相是合金的主要强化相,随着固溶时间的增加Al2Cu逐渐溶入基体中,起到了固溶强化作用。

图5所示为挤压铸造态和固溶处理10 h的ADC12铝合金XRD谱。从图5可见,ADC12主要由初生α相、共晶硅、Al2Cu和Al5FeSi相组成,这些相在热处理前后未发生明显改变。挤压铸造后共晶硅的衍射峰较高,强度较大,说明共晶硅尺寸较大;而经固溶处理后共晶硅衍射峰强度降低,说明共晶硅在经过热处理后得到了显著的细化。而Al2Cu在热处理前较为明显,固溶处理后得到弱化,这主要是一部分Al2Cu溶入到α基体中,降低了衍射峰强度,一部分的Al2Cu经固溶时效后析出分布在晶界处,也使得衍射峰降低。同样,Al5FeSi相的衍射峰强度也显著降低,说明Al5FeSi相的尺寸也在减小。这说明XRD谱分析结果与挤压铸造后经固溶处理的显微组织相符,即固溶处理后能够使共晶硅及Al5FeSi相细化,由粗大片状和针状逐渐向颗粒状转变。

图6所示为挤压铸造固溶处理6 h后的能谱分析结果,图6(b)、(c)、(d)所示分别为图6(a)中A、B、C三个位置的能谱图。由图6可知,A处显微组织中白色物质含有较多的Al、Fe、Si元素,结合XRD可知这种物质为Al5FeSi相;B处为基体组织,此处主要为Al和Cu,Cu主要以固溶体的形式固溶在基体中,起到强化效果,时效后一部分Cu以Al2Cu的形式分布在晶界上也起到强化作用;C处是共晶硅,能谱成分测得此处Si含量较高,但同时又有一部分Al,可以判定这种组织为共晶硅而不是初晶硅。

图4 不同固溶时间后ADC12铝合金的显微组织

Fig. 4 Microstructures of ADC12 aluminum alloy after different solution time

图5 挤压铸造态和固溶处理10 h 后ADC12铝合金的XRD谱

Fig. 5 XRD patterns of ADC12 aluminum alloy for squeeze casting(a) and solution treatment at 500 ℃ for 10 h(b)

图6 固溶处理6 h后试样的SEM像及EDS谱

Fig. 6 SEM image and EDS spectra of samples after solution treatment for 6 h

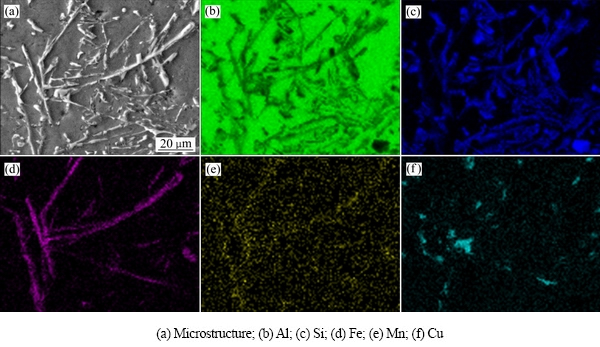

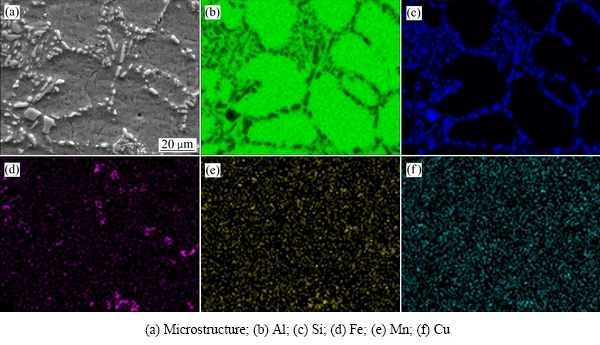

图7和8所示分别为挤压铸造态及热处理态合金中元素分布情况,图7(a)所示为挤压铸造态显微组织,图8(a)所示为热处理态显微组织,图7和8中(b)、(c)、(d)、(e)和(f)分别为Al、Si、Fe、Mn和Cu五种元素在显微组织中的分布情况。从图7可见,Si主要以粗大片状形式存在;针状组织为Fe相,Mn的分布相对较为均匀,但仍然可以看出少量Mn元素依附于Fe相;Cu元素与Al元素形成Al2Cu相,在铸造组织中主要分布在α相晶界处。从图8可见,与铸造组织元素分布对比可发现,固溶10 h后热处理使共晶硅发生熔断,共晶硅以颗粒状形态存在于组织中,粗大针状Fe相也发生熔断,使Fe相形态发生改变,降低了对基体α相的割裂作用。Mn元素和Cu元素由于固溶作用而溶入到α基体中,使元素分布更加均匀。

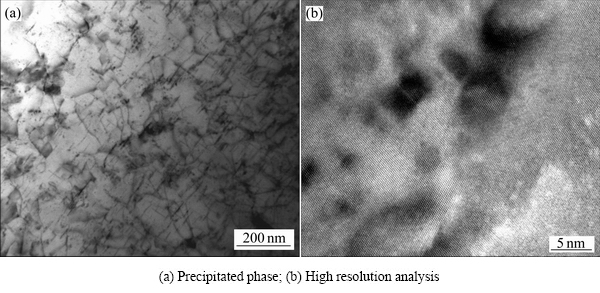

图9(a)和(b)所示为经固溶处理后析出相的TEM像。从图9可见,显微组织中存在较多的析出相,且析出相与母相之间存在一定共格关系,这是析出相强化的主要原因;同时还有些析出相分布在晶界处,对晶界起到钉扎作用,当位错线切割析出相粒子时,使临界切分应力增大,从而提高了材料的力学性能。

2.3 固溶处理对力学性能及断口形貌的影响

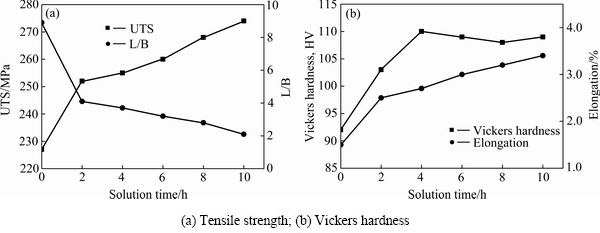

图10所示为在500 ℃下不同固溶时间合金的力学性能。图10(a)所示为不同固溶时间合金的抗拉强度变化情况,随着固溶时间的增加,铸件的抗拉强度逐渐增加,由挤压铸造态的227 MPa增加到固溶10 h后的274 MPa。L/B为共晶硅的长宽比,利用ImagePlus6.0软件测得不同固溶时间的长宽比,结果表明,未进行热处理时L/B为8.9;随着固溶时间的延长,L/B在固溶10 h时达到最小值2.0;结合力学性能分析可发现,抗拉强度随着L/B的降低而增加。这主要是由于共晶硅和Al5FeSi相的锐化降低了对基体组织的割裂作用,同时,Al2Cu的固溶作用对力学性能的提高也有一定的贡献。

图7 挤压铸造态ADC12铝合金的元素面分布

Fig. 7 Element mapping distributions of queeze casting ADC12 aluminum alloy

图8 固溶10 h后ADC12铝合金的元素面分布

Fig. 8 Element mapping distributions of ADC12 aluminum alloy after 10 h solution treatment

图10(b)所示为不同固溶时间合金的维氏硬度变化情况。从图10可见,挤压铸造态合金的维氏硬度较低,为92HV;在500 ℃进行固溶和时效后,合金的维氏硬度增加,且在固溶4 h时硬度达到最大值110HV;此后随着固溶时间的增加,合金的维氏硬度值略有下降,在固溶6 h到10 h的过程中,合金的维氏硬度变化不大,并趋于稳定。合金的硬度与基体的饱和程度、第二项形态及分布、第二相数量等因素有关。图10(b)中合金的维氏硬度呈现的规律主要有以下两个方面:一方面,Cu元素的固溶作用使基体的饱和度增加从而使晶内硬度升高;另一方面,共晶硅的细化对硬度也有一定的贡献,共晶硅细小可以使硬度提高。固溶4h时Cu元素的固溶作用和共晶硅的细化作用共同使维氏硬度达到最高;在固溶4 h后,晶粒进一步粗化并且伴随着Al2Cu的析出使基体的饱和度降低,从而使硬度略有下降,但由于共晶硅的细化,使维氏硬度值基本趋于稳定。

图9 ADC12铝合金的TEM像

Fig. 9 TEM images of ADC12 aluminum alloy

图10 固溶时间与力学性能关系

Fig. 10 Relationship between solution treatment time and mechanical properties

图11 不同固溶时间后ADC12铝合金的断口形貌

Fig. 11 Fracture morphologies of ADC12 aluminum alloys after different solution time

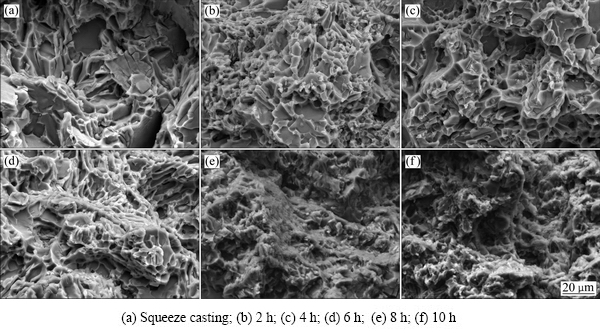

图11所示为挤压铸造态和不同时间固溶态合金后的断口形貌。图11(a)所示为挤压铸造态合金的拉伸断口形貌,其断口中存在较多解理面,并且存在一定数量的撕裂棱和少量韧窝,为介于韧性断裂和脆性断裂之间的混合断裂形式;固溶态合金的拉伸断口形貌发生明显变化,随着固溶时间的延长,其拉伸断口中解理面数量变少且逐渐细化,韧窝数量逐渐增多,且韧窝深度也加大,逐渐向韧性断裂转变。这说明经不同时间固溶处理后,材料力学性能得到提高,与材料的宏观性能变化一致。挤压铸造态合金由于存在较多粗大共晶组织,对显微组织的割裂作用严重,当有外力作用时,会使铸件内部产生较强的应力集中,从而形成脆性断裂。但铸件经过固溶处理后,共晶硅的锐化降低了其对基体组织的割裂作用,并且Cu元素的固溶强化作用和析出强化对晶界起到钉扎作用,使力学性能得到提高;当有外力作用时,由于钉扎作用,晶界结合较为牢固,此时容易在相界面形成微裂纹而使裂纹扩展形成撕裂棱,晶界断裂处出现韧窝。

3 讨论

挤压铸造态ADC12铝合金经固溶处理后,显微组织发生改变,从而使力学性能得到了提升。而固溶处理主要对挤压铸造显微组织有以下两点影响。

3.1 固溶处理对共晶相的影响

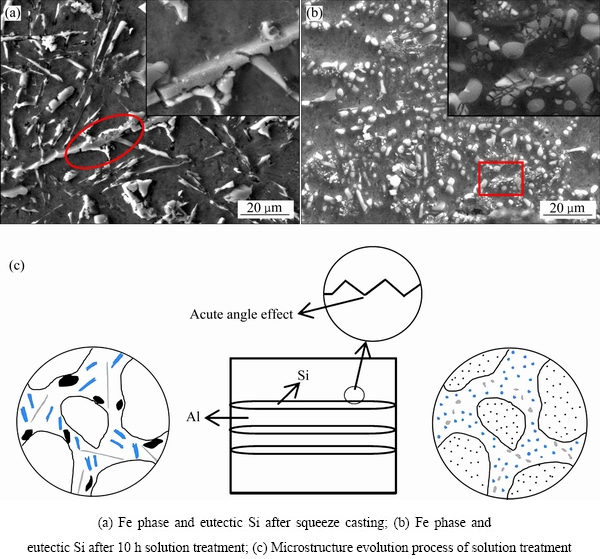

固溶时间的改变直接影响共晶相的形貌及尺寸。随着固溶时间延长,共晶相出现锐化,这一现象可以用热学中的尖角效应来解释。

如图12所示,挤压铸造合金中存在较多共晶硅和Fe相,这些共晶硅和Al5FeSi相在显微组织中都以粗大片状形态存在。而在微观尺度上来讲,共晶硅并非以光滑平面形态存在,而是近似于锯齿状;在受热状态下,尖角处由于尖角效应的作用温度较高,从而使共晶硅发生熔断并出现锐化,降低了对基体α相的割裂作用,使合金的力学性能得到提升。同样,显微组织中的Al5FeSi相原为单斜晶系的针状组织,也是由于尖角效应的作用使之得到细化。

3.2 对Al2Cu相的影响

Cu是铝合金的主要强化元素,固溶时间的变化直接影响着Cu的固溶与析出。在较短时间内,Cu主要以固溶体形式存在于基体α相中,起到固溶强化作用,但随着时间延长又会以Al2Cu析出,分布在晶界处,对晶界起到钉扎作用,从而提高了材料的力学性能。

图12 共晶Si与Fe相熔断机制

Fig. 12 Fusing mechanisms of eutectic Si and Fe phases

4 结论

1) 根据DSC曲线,确定固溶温度为500 ℃,随着固溶时间的延长,挤压铸造显微组织中粗大共晶Si和针状Al5FeSi相得到细化呈现细小颗粒状,L/B值由8.9降到2.0。Al2Cu相固溶后析出在晶界处。

2) 经固溶处理后,材料的抗拉强度提高由挤压铸造态的227 MPa增加到固溶时间为10 h的274 MPa;维氏硬度呈现先增加后降低的趋势,在固溶时间为4 h时达到最大值110HV。

3) ADC12铝合金挤压铸件的断裂形式为准解理断裂;经固溶处理后,断口中的解理面减少,且逐渐细小化,并出现大量韧窝和撕裂棱,逐渐由准解理断裂向韧性断裂转变,与材料的宏观力学性能基本一致。

REFERENCES

[1] MI G B, LI P J, WANG J. Formation and evolution of nondendrite microstructure of Al-Si alloy slurry fabricated by near liquidus casting[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(3): 560-569.

[2] 齐丕骧. 国内外挤压铸造技术发展概况[J]. 特种铸造及有色合金, 2002(2): 20-23.

QI Pi-xiang. Squeeze casting technology at home and abroad[J]. Special Casting & Nonferrous Alloys, 2002(2): 20-23.

[3] 张卫文, 赵海东, 张大童, 游东东, 邵 明, 李元元. 金属材料挤压铸造成形技术的研究进展[J]. 中国材料进展, 2011, 30(7): 25-30.

ZHANG Wei-wen, ZHAO Hai-dong, ZHANG Da-tong, YOU Dong-dong, SHAO Ming, LI Yuan-yuan. Progress in technology of squeeze casting for metal materials[J]. Material China, 2011, 30(7): 25-30.

[4] 林 波, 张卫文, 程 佩, 汪先送, 李元元. 挤压铸造Al-5.0Cu-0.6Mn-0.5Fe合金的显微组织和力学性能[J]. 中国有色金属学报, 2013, 23(5): 1195-1201.

LIN Bo, ZHANG Wei-wen, CHENG Pei, WANG Xian-song, LI Yuan-yuan. Microstructure and mechanical properties of Al-5.0Cu-0.6Mn-0.5Fe alloy prepared by squeeze casting[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1195-1201.

[5] EIDHED W. Effects of solution treatment time and Sr-modification on microstructure and mechanical property of Al-Si piston alloy[J]. Journal of Material Science & Technology, 2008, 24(1): 29-32.

[6] ZHANG Ming, ZHANG Wei-wen, ZHAO Hai-dong, ZHANG Da-tong, LI Yuan-yuan. Effect of pressure on microstructures and mechanical properties of Al-Cu-based alloy prepared by squeeze casting[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(3): 496-501.

[7] BOOTH C, ATTWOOD D. Solution treatment effects on microstructure and mechanical properties of Al-(1 to 13pct)Si-Mg cast alloys[J]. Macromolecular Rapid Communications, 2011, 42(1): 171-180.

[8] MOUSTAFA M A, SAMUEL F H, DOTY H W. Effect of solution heat treatment and additives on the microstructure of Al-Si (A413.1) automotive alloys[J]. Journal of Materials Science, 2003, 38(22): 4507-4522.

[9] LI Rong-de, LI Run-xia, YU Li, HU Zhuang-qi. Effect of Cd and Sn addition on the microstructure and mechanical properties of Al-Si-Cu-Mg cast alloy[J]. Transactions of Materials & Heat Treatment, 2004, 25(5): 113-116.

[10] 李飞龙, 黄晓珍, 苏广才, 李飞庆, 刘俊生, 汤胜博, 江鸿杰, 谢尚昇. 固溶处理工艺对改良铸造铝硅合金组织和性能的影响[J]. 铝加工, 2015(1): 24-29.

LI Fei-long, HUANG Xiao-zhen, SU Guang-cai, LI Fei-qing, LIU Jun-sheng, TANG Sheng-bo, JIANG Hong-jie, XIE Shang-sheng. Effect of solution treatment process on the microstructure and property of modified aluminum silicon casting alloy[J]. Aluminium Fabrication, 2015(1): 24-29.

[11] 何 亮, 黄天佑, 康进武. 余热热处理对Al-Si-Cu合金铸件组织和性能的影响[J]. 材料热处理学报, 2007, 28(4): 69-73.

HE Liang, HUANG Tian-you, KANG Jin-wu. Effect of heat treatment on microstructure and tensile properties of 319 aluminum alloy[J]. Transactions of Materials & Heat Treatment, 2007, 28(4): 69-73.

[12] DANG B, LI Y B, LIU F, ZUO Q, LIU M C. Effect of T4 heat treatment on microstructure and hardness of A356 alloy refined by Ga+In+Sn mixed alloy[J]. Materials & Design, 2014, 57(5):73-78.

[13] 洪 涛, 龚园平, 田 妮, 赵 刚, 于福晓, 左 良. 固溶温度对新型Al-12.7Si-0.7Mg合金挤压材组织性能的影响[J]. 稀有金属, 2012, 36(3): 368-372.

HONG Tao, GONG Yuan-ping, TIAN Ni, ZHAO Gang, YU Fu-xiao, ZUO Liang. Effect of solution temperature on microstructure and properties of Al-12.7Si-0.7Mg aluminum alloy extrusion[J]. Chinese Journal of Rare Metals, 2012, 36(3): 368-372.

[14] 李润霞, 于洪江, 袁晓光, 李荣德. 热处理对过共晶Al-Si合金组织与性能的影响[J]. 热加工工艺, 2009, 38(14): 121-123.

LI Run-xia, YU Hong-jiang, YUAN Xiao-guang, LI Rong-de. Effect of heat treatment on microstructure and properties of hyper-eutectic Al-Si-based alloy[J]. Hot Working Technology, 2009, 38(14): 121-123.

[15] 林高用, 雷玉霞, 郭道强, 许秀芝, 张宗鹏. 变形Al-Si-Cu-Mg合金热处理强化及其组织特征[J]. 中国有色金属学报, 2014, 24(3): 584-592.

LIN Gao-yong, LEI Yu-xia, GUO Dao-qiang, XU Xiu-zhi, ZHANG Zong-peng. Heat treatment strengthening and microstructure characteristics of wrought Al-Si-Cu-Mg alloy[J] . Transactions of Nonferrous Metals Society of China, 2014, 24(3): 584-592.

Effect of solution time on microstructure and mechanical properties of ADC12 aluminum alloy by squeeze casting

JIANG Bo1, JI Ze-sheng1, HU Mao-liang1, ZHANG Yong-bing2, WANG Yun-long2, WANG Shao-zhu3

(1. School of Material Science and Engineering, Harbin University of Science and Technology, Harbin 150040, China;

2. Harbin Jixing Mechanical Engineering Company Limited, Harbin 150069, China;

3. Linyi Academy of Technology Cooperation and Application, Linyi 276000, China)

Abstract: The microstructure and mechanical properties of ADC12 aluminum alloy with different solution time were studied. The results show that, with the increase of solution time, the coarse lamellar eutectic Si and the needle like Al5FeSi phase in the squeeze casting microstructure are fine granular, and the ratio of length to width(L/B value) decreases from 8.9 to 2. The tensile strength of the material increases from 227 MPa of the squeeze casting to 274 MPa after 10 h solution treatment; Vickers hardness exhibits reducing after the first increase trend in the solution time to reach maximum 110HV at 4 h, and then trends to stable. The fracture form of ADC12 casting aluminum alloy transforms from quasi cleavage fracture to ductile fracture after solution treatment.

Key words: ADC12 aluminum alloy; indirect squeeze casting; solution time; microstructure; mechanical property

Foundation item: Project(WB15C104) supported by the Heilongjiang International Science and Technology Cooperation Project, China; Project(2015AB4AG004) supported by the Harbin Science and Technology Research Project, China

Received date: 2017-12-03; Accepted date: 2018-01-24

Corresponding author: JI Ze-sheng; Tel: +86-451-86392557; E-mail: jizesheng@hrbust.edu.cn

(编辑 何学锋)

基金项目:黑龙江省国际科技合作项目(WB15C104);哈尔滨市科技攻关项目(2015AB4AG004)

收稿日期:2017-12-03;修订日期:2018-01-24

通信作者:吉泽升,教授;电话:0451-86392557;E-mail:jizesheng@hrbust.edu.cn