DOI:10.19476/j.ysxb.1004.0609.2018.03.10

热处理对流变压铸铝合金力学性能和显微组织的影响

陈正周1, 2,宋朝辉1, 2,罗文博3

(1. 慈溪汇丽机电有限公司,慈溪 315333;

2. 慈溪阿尔特新材料有限公司,慈溪 315301;

3. 北京科技大学 材料科学与工程学院,北京 100083)

摘 要:采用旋转永磁体搅拌工艺制备半固态A356铝合金浆料并进行流变压铸,研究热处理工艺对流变压铸样件本体力学性能的影响,并采用扫描电镜(SEM)和能谱分析仪(EDS)进行显微组织分析。结果表明:采用T51热处理时,当人工时效时间为3 h时,σb=290 MPa、δ=8.5%,此时δ达到最大值;延长人工时效时间,σb缓慢提高,但是δ下降;采用T6热处理时,当人工时效时间为1 h,σb=310 MPa、δ=16.5%;当人工时效时间4.5 h时,σb=335 MPa、δ=10.5%,此时σb达到最大值,δ达到最小值。T6热处理后,当人工时效时间为1 h,试样断口具有大量的撕裂棱和韧窝,在晶界处产生大量富Si的鹅卵石形状的强化相,当量直径小于4 μm。同时,在α(Al)基体内形成大量富Si和富Mg的GP区和亚稳相,还产生大量直径小于1 μm的Al、Si和Mg的氧化物,并钉扎在α(Al)基体内,与GP区和亚稳相共同对α(Al)基体起强化作用。

关键词:A356铝合金;力学性能;显微组织;热处理;流变压铸

文章编号:1004-0609(2018)-03-0518-10 中图分类号:TG146.2+1;TG249.9 文献标志码:A

半固态铝合金压铸件或挤压铸件组织比较致密、微观缩松少、尤其是含气量大幅降低,所以能够通过T6热处理来进一步提高力学性能[1-7]。然而,在铸态时,半固态铝合金压铸件与常规压铸的铝合金压铸件相比,力学性能(特别是强度)的提高并不很明显。铝合金用半固态浆料来压铸,一方面是改善显微组织,另一方面是降低铸件含气量,尤其是后者,从而可以使压铸件能够在接近熔点的温度下进行固溶处理。有关热处理对半固态铝合金铸件的力学性能和显微组织的影响,相关学者进行了研究。李伟东等[8]研究表明,半固态A356铝合金挤压铸件固溶处理后时效时间对抗拉强度和伸长率影响最大,并且随着时效时间延长力学性能先升后降。余忠土等[9]研究表明,固溶温度对半固态铝合金A356成形件力学性能的影响是原始强化相溶解与强化相析出的综合结果,并且后者在热处理中起主要作用。李元东等[10]研究了热处理对流变压铸2024变形铝合金组织及性能的影响。不同热处理方式对力学性能影响较大[11-16],同时热处理后的显微组织、断口形貌和强化模型相关文献[17-19]也进行了研究。然而,这些文献对力学性能和显微组织进行研究时,未能从量产的角度,而且研究对象大多采用标准压铸试棒或者实验室里试验样品模具。这些研究成果具有一定的学术价值,但从量产的角度,由于这些文献中所述的所谓最佳工艺参数没有得到量产验证,缺乏相关文献报道,所以对实际生产的参考意义并不大。

本文作者采用旋转永磁体搅拌工艺制备半固态A356铝合金浆料并进行流变压铸,研究热处理工艺对半固态流变压铸铝合金本体力学性能的影响,并采用扫描电镜(SEM)和能谱分析仪(EDS)对热处理后的显微组织进行分析,目的是从显微组织和断口形貌的角度分析T6热处理对半固态压铸铝合金力学性能的影响规律,为半固态压铸铝合金选择合理、经济的热处理工艺提供技术参考和理论依据。研究的样件已经量产,而且在汽车车身上正在应用。

1 实验

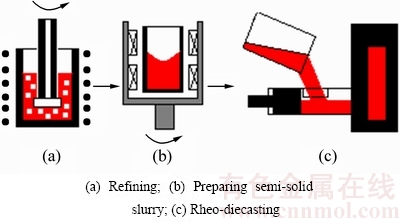

以商用A356铝合金为实验材料,其主要化学成分(质量分数)为Si 6.88%,Mg 0.41 %,Fe 0.15%,其余为Al和不可避免的微量元素。旋转永磁体搅拌工艺制备半固态A356铝合金浆料及流变压铸示意图如图1所示。在坩埚电阻炉内熔化铝锭,当铝液温度达到710 °C时,使用旋转式氮气除气机进行精炼,如图1(a)所示。精炼时加入0.2%(质量分数)的精炼剂,精炼后静止10 min再扒去熔渣,然后盖上炉盖冷却。永磁体采用钕铁硼材料,安装在转子内侧,转子在电机的驱动下产生旋转磁场,当铝液温度降至630 ℃时,用不锈钢坩埚舀取适量铝液置于转子内进行半固态浆料制备,如图1(b)所示。半固态浆料温度达到605 ℃时,将表面的氧化皮及浮渣清除干净,立即倒入压铸机料缸,料缸温度350 ℃,模具温度230 ℃,增压压力80 MPa。

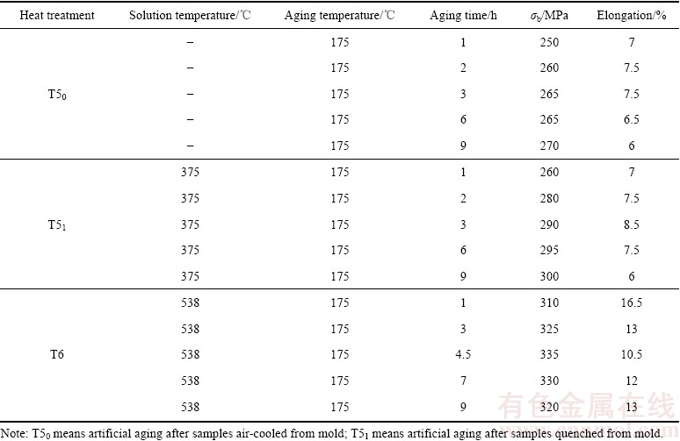

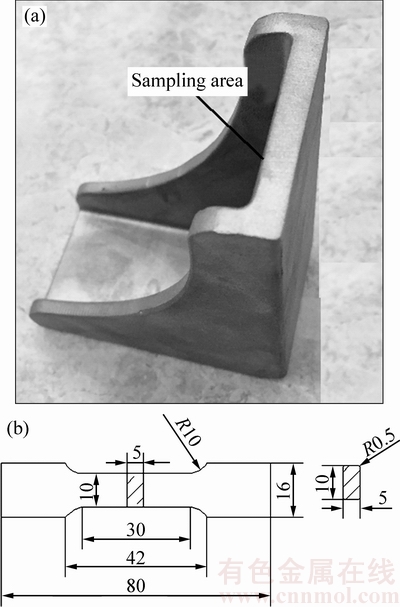

模具型腔采用一模两型,铸件单件质量220 g,壁厚6 mm,该铸件为汽车车身铆接接头。铸件采用T5和T6两种不同热处理工艺。采用T5热处理工艺时,一种工艺是将铸件出模后空冷,然后再进行人工时效;另一种工艺是将铸件出模(此时温度为375 ℃)后先置于室温水中淬火,然后再进行人工时效。T6热处理时,固溶温度为538 ℃,升温时间100 min,保温时间5 h,人工时效温度为175 ℃,升温时间60 min。热处理工艺参数见表1。热处理后在铸件的侧面截取本体试棒,铸件及本体试棒的尺寸如图2所示。取3件同一种热处理参数的本体试棒作为实验样品,拉伸测试后取其平均值。最后采用Neuphoto光学显微镜、扫描电镜(SEM)和能谱分析仪(EDS)对样品进行显微组织分析。

图1 旋转永磁体搅拌工艺制备半固态A356铝合金浆料及流变压铸示意图

Fig. 1 Schematic diagram of semisolid A356 aluminum alloy slurry prepared by rotating permanent magnet stirring process and rheo-diecasting

表1 热处理工艺参数

Table 1 Heat treatment process parameters

图2 流变压铸样品及其本体试棒尺寸

Fig. 2 Rheo-diecasting sample (a) and body test bar size (b) (Unit: mm)

2 结果与讨论

2.1 热处理后本体试棒的力学性能

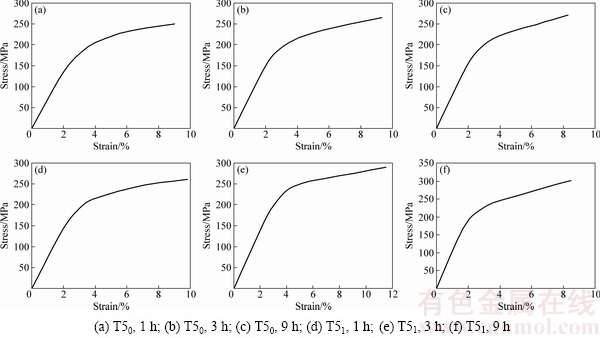

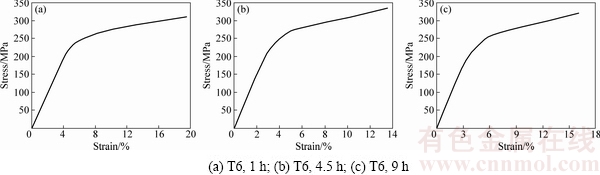

流变压铸A356铝合金样品的本体试棒铸态σb为240 MPa,δ为7.5%,比常规压铸样品的本体试棒σb提高约10%,δ提高了约一倍。采用T50热处理工艺, 当人工时效时间分别为1、3和9 h时,σb分别为250、265和270 MPa,δ分别为7%、7.5%和6%。采用T51热处理工艺,当人工时效时间分别为1、3和9 h时,σb分别为260、290和300 MPa,δ分别为7%、8.5%和6%。T5热处理试棒的拉伸曲线如图3所示。采用T6热处理工艺, 当人工时效时间分别为1、4.5和9 h时,σb分别为310、335和320 MPa,δ分别为16.5%、10.5%和13%。T6热处理试棒的拉伸曲线如图4所示。

2.2 热处理参数对本体试棒力学性能的影响

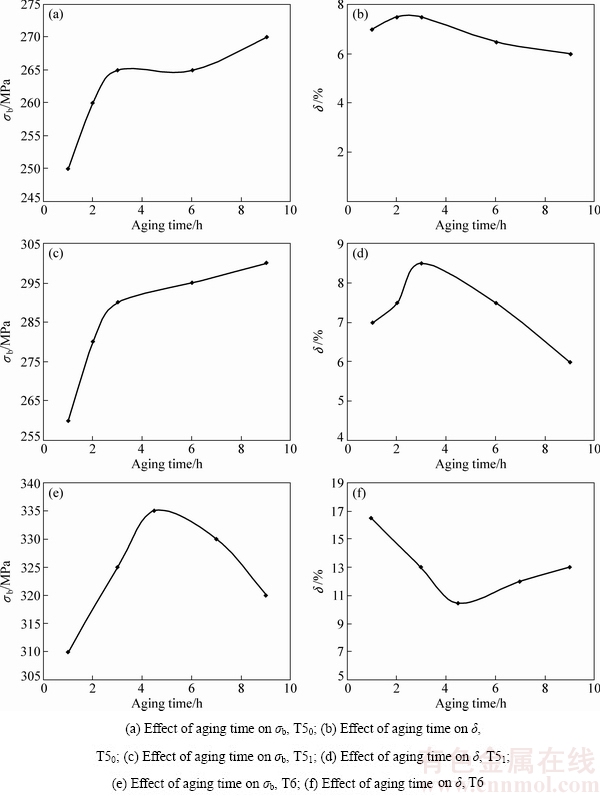

根据表1,不同热处理工艺对半固态A356铝合金流变压铸件本体力学性能的影响很大。图5所示为热处理工艺对力学性能的影响。铸件出模空冷后进行人工时效,当人工时效时间1 h,σb提高了4%左右,人工时效时间延长至3 h,σb提高了10%左右,而δ变化很小。如果人工时效时间继续延长至9 h,σb提高了12.5%,但是δ略有下降。从图5(a)看到,人工时效时间在3 h之内,σb提高较快,超过3 h,σb变化比较缓慢。从图5(b)看到,δ的变化总体较小。由此可以得出:铸件出模空冷后进行人工时效,σb的提高有限,而且δ得不到有效提升。

图3 T5热处理后的本体试棒拉伸应力-应变曲线

Fig. 3 Tensile stress-strain curves (σ-ε) of body test bar after T5 heat treatment

图4 T6热处理后本体试棒的拉伸应力-应变曲线

Fig. 4 Tensile stress-strain curves (σ-ε) of body test bar after T6 heat treatment

图5 热处理工艺对力学性能的影响

Fig. 5 Effect of heat treatment processes on mechanical properties

铸件出模后,借助铸件余温(此时温度为375 ℃) 进行淬火然后再人工时效,当人工时效时间1 h,σb提高了8%左右,人工时效时间延长至3 h,σb提高了20%左右,而δ也略微有所提高。如果人工时效时间延长至9 h,σb提高了25%,但是δ略有下降。比较图5(a)和(c),在人工时效时间3 h之内,σb都得到提高,但是T51工艺条件下的σb提高更明显。比较图5(b)和 (d),人工时效时间超过3 h之后,δ都缓慢下降。因此可以得出:借助铸件出模时的余温进行淬火,铸件起到一定的固溶效果,再经过人工时效,σb的提高明显一些,但是δ的改善不太明显。同时还可以看到,在人工时效9 h之内,铸件没有出现过时效现象。采用T51热处理工艺,铸件不经过高温固溶处理,其内部的微小气孔不会膨胀鼓泡,但是力学性能仍然有所提升。

采用T6热处理工艺,当人工时效时间1 h,σb提高了30%左右,δ剧烈上升并且提高了120%。比较图5(a)、(c)和(e),铸件经过完全固溶后,经过1 h的人工时效,σb和δ就急剧上升,比T5工艺条件下的σb和δ显著提高。在T5工艺条件下,人工时效3 h,σb快速上升,然后上升变得很缓慢,然而,铸件经过完全固溶后,人工时效3 h后σb仍然会继续上升,直到4.5 h时,σb才达到最大值,然后σb开始缓慢下降,而δ开始上升。这说明,铸件经过充分固溶后再人工时效,σb大幅提高,而且强度达到最高值的人工时效时间大大缩短。从图5(e)和(f)看出,人工时效超过4.5 h后,铸件逐渐出现过时效现象。

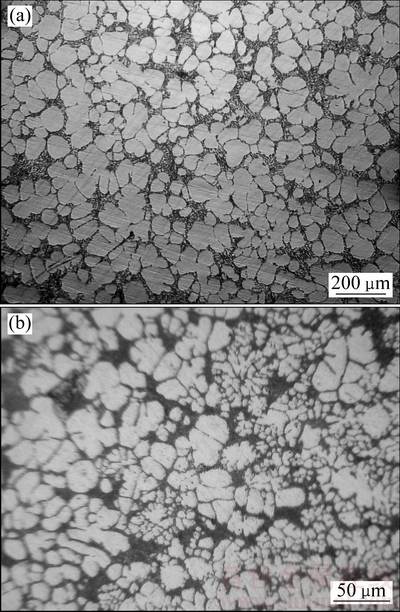

2.3 半固态浆料和本体试棒的显微组织

图6所示为半固态浆料及铸态样品的显微组织。图6(a)所示为半固态浆料在605 ℃时的水淬组织,初生α(Al) 中大部分为球状和近球状,少量为蔷薇状,其平均当量直径80 μm,形状因子0.78。图6(b)所示为流变压铸样品的铸态组织,初生α1(Al) 大部分为近球状和蔷薇状,其平均当量直径40 μm,形状因子0.75。初生α2(Al) 大部分为颗粒状和蔷薇状,其平均当量直径7 μm,形状因子0.76。

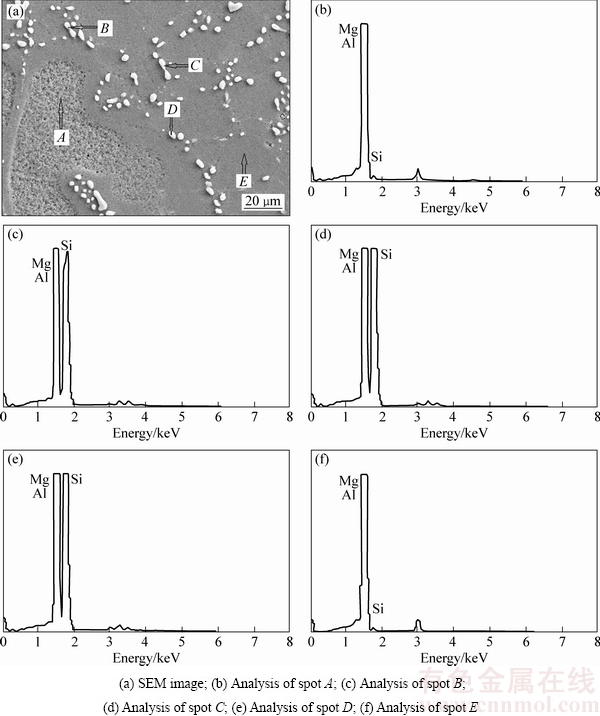

2.4 T6热处理后本体试棒的显微组织

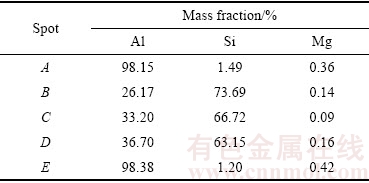

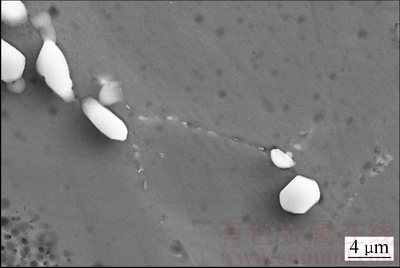

T6热处理(人工时效1 h)后显微组织如图7(a)所示,初生α2(Al)和共晶组织完全消失,整个组织由基体α(Al)和白色颗粒状组织组成。对A、B、C、D和E点处进行能谱分析,如图7(b)~(f)所示,分析结果如表2所示。结果表明在A和E点处Al的含量超过98%以上,即为α(Al)基体组织,而在A周围有明显的微观缩松。B、C和D点处的白色颗粒中Si含量超过60%,Al含量超过25%,说明这些白色颗粒为富Si的强化相。为了进一步确定白色颗粒的微观形貌,将7(a)局部在高分辨率下进行分析,如图8所示,白色颗粒的当量直径小于4 μm,长宽比小于2,形状如鹅卵石,主要沿着晶界分布,在基体内部也有少量存在。这个结果表明,经过T6热处理后,共晶组织中的Si形成新的强化相,并且其形貌从端部呈尖角的片状转变为鹅卵石形状。

图6 半固态浆料及铸态样品的显微组织

Fig. 6 Microstructures of semisolid slurry (a) and as-cast sample (b)

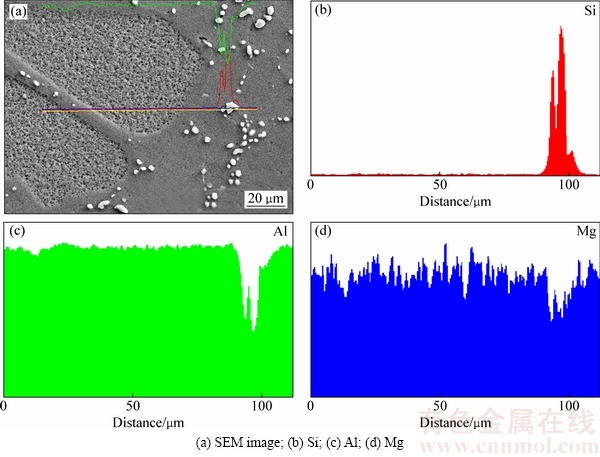

为了进一步分析T6热处理后化学元素在正常基体、缩松区域和强化相的分布,对样品进行线能谱分析,如图9(a)所示。比较正常基体和缩松区域的Al和Si,含量基本相等,Mg发生小幅波动,如图9(b)~ (d)所示。从表2中看到,在缩松区域,Si含量1.49%、Mg含量0.36%,在正常基体区域,Si含量1.20%、Mg含量0.42%,但是这仅仅是一个点的化学成分。缩松区域是半固态浆料最后凝固的地方,与先期凝固的正常基体区域的化学成分变化规律基本一致,说明经过旋转永磁体搅拌后,整个半固态浆料的化学成分比较均匀。同时,由于半固态浆料是在高压下凝固,凝固时间为毫秒级,所以成分偏析非常小。

经过高温固溶处理,Mg和部分Si溶解到基体α(Al)中并形成过饱和固溶体。经过人工时效,虽有部分Si和Mg从基体α(Al)中分解析出,但是仍有部分Si和Mg溶解在基体α(Al)中,见表2中A和E点化学成分。从图9(d)中看到,Mg在基体α(Al)中的不同位置处产生小幅波动,可以解释为:人工时效1 h为不完全人工时效,部分Mg溶解在基体α(Al)中形成GP区,一个波峰即为一个富Mg的GP区。

图7 T6热处理后的SEM像及EDS分析结果

Fig. 7 SEM image and EDS analysis results after T6 heat treatment

表2 EDS分析元素分析结果

Table 2 EDS analysis results of elements shown in Fig. 7

2.5 T6热处理后的断口形貌

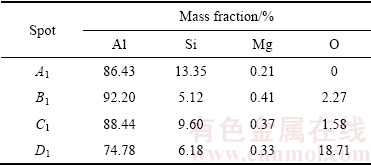

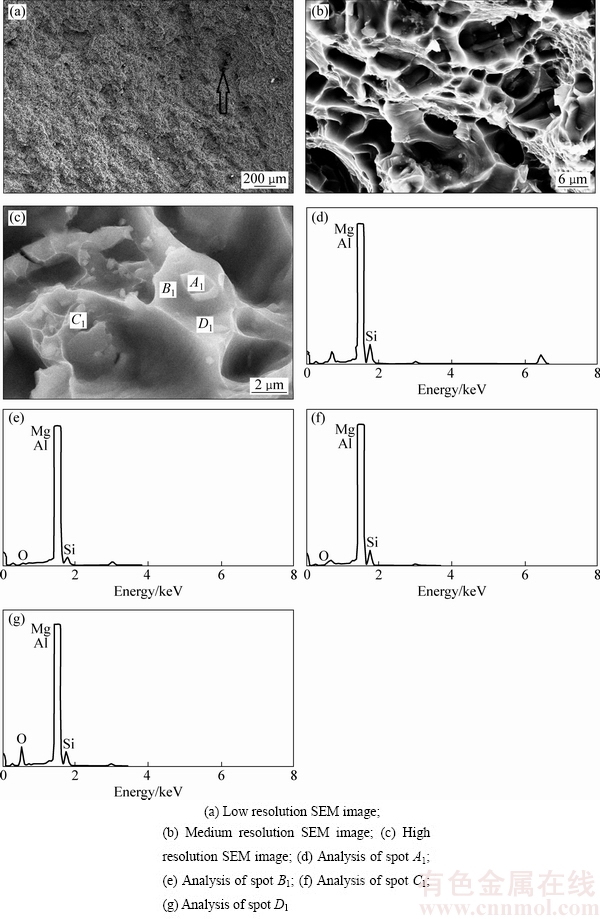

为了从断口特征分析T6热处理对力学性能影响,对T6热处理(人工时效1 h)的断口进行电镜扫描和能谱分析。图10(a)所示为低分辨率的断口SEM像,具有明显的微观孔洞类缺陷,如箭头所示。图10(b)所示为较高分辨率的断口SEM像,具有大量的撕裂棱和韧窝,说明试样具有较高的断裂韧性。图10(c)是高分辨率的断口SEM像,在撕裂棱和韧窝处发现大量颗粒状物质。对这些颗粒、撕裂棱进行EDS能谱分析,如图10(d)~(g)所示,分析结果见表3。

图8 白色颗粒的显微形貌

Fig. 8 Micro-morphology of white particles

图9 本体试棒心部区域表面化学元素线扫貌分析结果

Fig. 9 Line scanning analysis results of elements of body test bar heart area

表3 本体试棒断口的EDS分析结果

Table 3 EDS analysis results of spots shown in Fig. 10

图10(c)中灰色颗粒A1的Al含量86.43%,Si含量13.35%,当量直径1.5 μm左右,为Si溶解于α(Al)中形成的过饱和相,处于韧窝中间。这种含Si的过饱和α(Al)相与图7(a)中富Si强化相有着明显区别,图7(a)中富Si强化相含Si超过60%,属于第二相强化,而图10(c)中灰色颗粒A1为Si在α(Al)中的偏聚形成的GP区,属于GP区强化。结合图9(d)的分析结果,人工时效时间1 h,在α(Al)中既有Mg偏聚形成的GP区,又有Si偏聚形成的GP区,进一步说明人工时效时间1 h为不完全时效。大量GP区的存在,使试样既具有较高的强度,也具有很高的塑性。人工时效时间继续延长时,这些GP区将逐渐形成亚稳相,强度进一步提高,而塑性逐渐降低。当亚稳相形成第二相时,强度逐渐降低,而塑性又逐渐提高。本实验数据说明,在人工时效时间4.5 h时,GP区和亚稳相的比例组合使试样强度达到最大值。

图10(c)中与灰色颗粒A1同处一个韧窝内的D1点,其主要化学成分为Al 74.78%、Si 6.18%、Mg 0.33%、O 18.71%,说明D1点灰色颗粒为Al 、Si和Mg的氧化物,其当量直径为1 μm左右。在其它韧窝内也发现许多直径小于1 μm的Al 、Si和Mg的氧化物,这些氧化物钉扎在α(Al)基体内,起到强化效果。

图10(c)中B1和C1点分别是相邻两个撕裂棱,除了Al 、Si和Mg外,都含有O,见表3中B1和C1点成分。B1和C1点处O含量较低,未与其他元素形成第二相,而是固溶于α(Al)基体中。撕裂棱为α(Al)晶粒断裂的边缘,也就是晶粒表面,而O更容易富集于此。

图10 断口扫貌SEM像和EDS分析结果

Fig. 10 SEM image of fracture and EDS analysis results

3 结论

1) 半固态A356铝合金浆料经过流变压铸,采用T51热处理,当人工时效时间3 h时,σb=290 MPa、δ=8.5%,此时δ达到最大值。延长人工时效时间,σb缓慢提高,但是δ下降。采用T6热处理,当人工时效时间1 h,σb=310 MPa,δ=16.5%。当人工时效时间4.5 h时,σb=335 MPa,δ=10.5%,此时σb达到最大值,δ达到最小值。继续延长人工时效时间,σb开始下降,但是δ略有升高。

2) 采用T6热处理,当人工时效时间1 h,断口具有大量的撕裂棱和韧窝,此时材料具有较高的强度和断裂韧性。

3) T6热处理后,晶界处产生大量富Si的鹅卵石形状的强化相,当量直径小于4 μm,长宽比小于2。在α(Al)基体内形成大量富Si和富Mg的GP区和亚稳相,同时还产生大量直径小于1 μm的Al 、Si和Mg的氧化物,这些氧化物钉扎在α(Al)基体内,与GP区和亚稳相共同起到强化作用。

REFERENCES

[1] BAI Y F, ZHAO H D. Tensile properties and fracture behavior of partial squeeze added slow shot die-cast A356 aluminum alloy[J]. Materials and Design, 2010, 31(9): 4237-4243.

[2] CHEN Zheng-zhou, MAO Wei-min, WU Zong-chuang. Mechanical properties and microstructures of Al alloy tensile samples produced by serpentine channel pouring rheo-diecasting process[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(7): 1473-1479.

[3] 赵君文, 戴光泽, 吴树森, 黄兴民, 韩 靖. 浆料浇注温度对流变压铸件组织和力学性能的影响[J]. 中国有色金属学报, 2012, 22(10): 2777-2782.

ZHAO Jun-wen, DAI Guang-ze, WU Shu-sen, HUANG Xing-min, HAN Jing. Effect of slurry pouring temperature on microstructure and mechanical properties of rheo-diecasting[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(10): 2777-2782.

[4] DAI W, WU S S, LU S L, LIN C. Effect of rheo-squeeze casting parameters on microstructure and mechanical properties of AlCuMnTi alloy[J]. Materials Science and Engineering A, 2012, 538: 320-326.

[5] 王绍著, 赵 密, 胡茂良, 吉泽升, 李 欣, 王云龙, Sumio SUGIYAMA, Jun YANAGIMOTO. 近液相线挤压铸造工艺对ADC12铝合金支架显微组织和力学性能的影响[J]. 中国有色金属学报, 2015, 25(6): 1428-1434.

WANG Shao-zhu, ZHAO Mi, HU Mao-liang, JI Ze-sheng, LI Xin, WANG Yun-long, Sumio SUGIYAMA, Jun YANAGIMOTO. Effect of near-liquidus squeeze casting process on microstructure and mechanical property of ADC12 aluminium alloy differential support[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1428-1434.

[6] 祁明凡, 康永林, 周 冰, 张欢欢, 朱国明. 流变压铸A380铝合金的显微组织与力学性能[J]. 中国有色金属学报, 2015, 25(8): 2029-2039.

QI Ming-fan, KANG Yong-lin, ZHOU Bing, ZHANG Huan-huan, ZHU Guo-ming. Microstructures and mechanical properties of A380 aluminum alloy produced by rheo-diecasting process[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(8): 2029-2039.

[7] KHALIFA W, EL-HADAD S, TSUNEKAWA Y. Microstructure characteristics and tensile property of ultrasonic treated-thixocast A356 alloy[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(10): 3173-3180.

[8] 李伟东, 陈和兴, 王顺成, 郑开宏, 戚文军. 热处理对半固态A356铝合金挤压铸件组织与性能的影响[J]. 铸造, 2012, 61(8): 229-932.

LI Wei-dong, CHEN He-xing, WANG Shun-cheng, ZHENG Kai-hong, QI Wen-jun. Effect of heat treatment on microstructure and properties of squeeze casting of semi-solid A356 aluminum alloy[J]. Foundry, 2012, 61(8): 929-932.

[9] 余忠土, 张恒华, 邵光杰, 许珞萍, 方妍妍. 热处理对铝合金半固态成形件组织与性能的影响[J]. 理化检验物理分册, 2002, 38(11): 489-495.

YU Zhong-tu, ZHANG Heng-hua, SHAO Guang-jie, XU Luo-ping, FANG Yan-yan. Effect of the heat treatment on the microstructure and mechanical properties of the product of A356 aluminum alloy through semi-solid casting[J]. Ptca (Part A: Physical Testing, 2002, 38(11): 489-495.

[10] 李元东, 索江龙, 毕广利, 陈体军, 马 颖. 热处理对流变压铸2024变形铝合金组织及性能的影响[J]. 中国有色金属学报, 2014, 24(4): 894-904.

LI Yuan-dong, SUO Jiang-long, BI Guang-li, CHEN Ti-jun, MA Ying. Effects of heat treatment on microstructure and mechanical properties of rheo-diecasting 2024 wrought aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4): 894-904.

[11] 田 哲, 易丹青, 刘会群, 王 斌, 涂晓萱, 江 勇, 唐 聪. 固溶处理对Al-5.8Cu-0.6Mg-0.6Ag-0.3Nd合金组织和力学性能的影响[J]. 中国有色金属学报, 2015, 25(9): 2326-2334.

TIAN Zhe, YI Dan-qing, LIU Hui-qun, WANG Bin, TU Xiao-xuan, JIANG Yong, TANG Cong. Effects of solution treatment on microstructures and mechanical properties of Al-5.8Cu-0.6Mg-0.6Ag-0.3Nd aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(9): 2326-2334.

[12] 何 兵, 覃 铭, 兰 旅. 热处理对A356铝合金组织与性能的影响[J]. 长春工业大学学报, 2015, 36(6): 617-625.

HE Bing, QIN Ming, LAN Lü. Effects of heat treatment on the structure and property of A356 aluminum[J]. Journal of Changchun University of Technology, 2015, 36(6): 617-625.

[13] 谭建波, 侯文杰. 流变压铸AlSi9Mg合金的热处理工艺[J]. 材料热处理学报, 2010, 31(12): 43-46.

TAN Jian-bo, HOU Wen-jie. Heat treatment process of AlSi9Mg alloy produced by rheo-diecasting[J]. Transactions of Materials and Heat Treatment, 2010, 31(12): 43-46.

[14] 李红英, 刘蛟蛟, 余玮琛, 郝壮志. 固溶处理对7B04铝合金组织及性能的影响[J]. 中国有色金属学报, 2016, 26(2): 252-260.

LI Hong-ying, LIU Jiao-jiao, YU Wei-chen, HAO Zhuang-zhi. Effects of solution treatment on microstructures and properties of 7B04 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(2): 252-260.

[15] YANG Chang-lin, LI Yuan-bing, DANG Bo, Lü He-bin, LIU Feng. Effects of cooling rate on solution heat treatment of as-cast A356 alloy[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(10): 3189-3196.

[16] PENG Ji-hua, TANG Xiao-long, HE Jian-ting, XU De-ying. Effect of heat treatment on microstructure and tensile properties of A356 alloys[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(9): 1950-1956.

[17] JIANG Wen-ming, FAN Zi-tian, LIU De-jun. Microstructure, tensile properties and fractography of A356 alloy under as-cast and T6 obtained with expendable pattern shell casting process[J]. Transactions of Nonferrous Metals Society of China, 2012(22): s7-s13.

[18] KOLAR M, PEDERSEN K O, GULBRANDSEN-DAHL S, MARTHINSEN K . Combined effect of deformation and artificial aging on mechanical properties of Al-Mg-Si alloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(8): 1824-1830.

[19] 王小娜, 韩利战, 顾剑锋. 铝合金时效析出动力学及强化模型[J]. 中国有色金属学报, 2013, 23(10): 2754-2768.

WANG Xiao-na, HAN Li-zhan, GU Jian-feng. Aging precipitation kinetics and strengthening models for aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(10): 2754-2768.

Effect of heat treatment on mechanical properties and microstructure of rheo-diecasting aluminum alloy

CHEN Zheng-zhou1, 2, SONG Chao-hui1, 2, LUO Wen-bo3

(1. Cixi Huili Machinery and Electric Co., Ltd., Cixi 315333, China;

2. Cixi ALT advanced material Co., Ltd., Cixi 315301, China;

3. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Semisolid A356 aluminum alloy slurry was prepared and rheo-diecasted by rotating permanent magnet stirring process. The effect of heat treatment process on the mechanical properties of rheo-diecasting samples was studied, and microstructure of the samples was analyzed by scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS). The results show that when T51 heat treatment is used, after being artificially aged for 3 h, σb is 290 MPa, δ is 8.5%, at this time, δ value reaches the maximum. When artificial aging time is prolonged, σb value increases slowly, whereas δ value decreases. When T6 heat treatment is used, after being artificially aged for 1 h, σb=310 MPa, δ=16.5%. After being artificial aged for 4.5 h, σb=335 MPa, δ=10.5%, at this time, σb value reaches the maximum, whereas δ value reaches the minimum. After T6 heat treatment, and being artificially aged for 1 h, a large number of torn edges and dimples are produced on the sample fracture surface, and a large number of pebble-shape strengthening phases with rich Si are produced at the grain boundaries, whose equivalent diameter is within 4 μm. At the same time, substantial GP zones with rich Si and rich Mg and metastable phases form in α(Al) matrix, and a large number of Al, Si and Mg oxides with diameter less than 1 μm are produced and pinned in α(Al) matrix. These oxides play an important role in strengthening the α(Al) matrix with the GP zones and metastable phases.

Key words: A356 aluminum alloy; mechanical property; microstructure; heat treatment; rheo-diecasting

Received date: 2016-12-21; Accepted date: 2017-04-01

Corresponding author: CHEN Zheng-zhou; Tel: +86-15857447624; E-mail: chzz19710425@126.com

(编辑 龙怀中)

收稿日期:2016-12-21;修订日期:2017-04-01

通信作者:陈正周,高级工程师,博士;电话:15857447624;E-mail:chzz19710425@126.com