文章编号:1004-0609(2016)-11-2256-11

A356铝合金自孕育流变压铸过程中的凝固行为

李 明1,李元东1, 2,邱 谨1,张继渊1,毕广利1, 2,马 颖1, 2

(1. 兰州理工大学 省部共建有色金属先进加工与再利用国家重点实验室,兰州 730050;

2. 兰州理工大学 有色金属合金及加工教育部重点实验室,兰州 730050)

摘 要:采用自孕育法制备A356铝合金半固态浆料,研究薄壁件流变压铸过程中的凝固行为。结果表明:在自孕育制浆过程中,等温保温过程对初生α(Al)颗粒的尺寸和形貌影响较大,而对后续薄壁件压铸过程中的二次凝固组织影响不是很大。当剩余液相充填型腔时,型腔提供的较大冷却速率使剩余液相爆发形核;晶核的生长分为稳定生长和失稳生长两个过程。爆发形核的核心先稳定生长成球状小颗粒,稳定生长的极限尺寸为6.5 μm。由于“成分过冷”等因素的存在,一次凝固(α1)颗粒和二次凝固(α2)颗粒最终均出现不稳定生长现象。由于α1颗粒的存在,剩余液相的成分与原始成分相比更接近共晶成分,导致α2颗粒中Si的含量较α1颗粒中的高。α2颗粒将共晶反应限制在许多晶间小区域内,在较高的局部冷却速率下,共晶硅最终长成细小纤维状或菊花状.

关键词:铝合金;半固态;自孕育;流变压铸;二次凝固;成分过冷;共晶硅

中图分类号:TG146.2 文献标志码:A

金属半固态成形自问世以来,广受国内外专家学者的关注,被誉为21世纪最有发展前景的现代加工新技术。在半固态成形时,浆料以非枝晶凝固方式开始结晶,合金中剩余液相能够互相连通,使凝固收缩得到有效补充,从而减少或消除缩松和热裂;同时,半固态浆料粘度较全液态的高,气体卷入较少。因此,半固态成形技术在理论上可以获得无孔洞类缺陷的产品[1-5]。经半个世纪的探索与研究,国内外学者相继开发出了半固态流变铸造法(Semi-solid rheocasting,SSR)[6]、连续流变转换法(Continuous rheoconversion process,CRP)[7]、新流变铸造法(New rheocasting process,NRC)[8]、涡流热焓平衡工艺(Swirled enthalpy equilibration device,SEED)[9]等半固态组织的制备工艺。在低温浇注、液-液混合法、固-液混合法、悬浮铸造及斜板冷却等现有细化工艺特点的基础上,一种新型凝固组织控制方法被提出,即自孕育法(Self-inoculation method,SIM)[10],就是将两个一定成分、质量和温度的合金混合,之后通过倾斜一定角度的导流器浇注,利用两个合金液(体)的温度、表面张力等不同性质,混合后使合金熔体中瞬间形成大量晶核(一次自孕育),同时通过导流器产生熔体冷却和对流效应,促进晶粒增殖,加强自孕育效果(二次自孕育),抑制晶粒生长,最终消除铸件中的粗大树枝晶,获得细小等轴晶组织。

所谓半固态金属流变成形是指利用混合浆料直接进行成形的方法。其中初生固相颗粒从液态合金中析出,进而制备出固液混合的半固态浆料的过程称为一次凝固过程;浆料的后续成形过程(即剩余液相的凝固过程)称为二次凝固过程。近年来,国内外学者对于半固态流变成形的研究大都集中于一次凝固过程,而对二次凝固过程的研究并不是太多。英国FAN团队[11]研究双螺杆的剪切作用对A357合金半固态浆料剩余液相的凝固特性的影响,发现高剪切作用和持续剪切相结合会促进二次凝固组织的细小化和球状化。李元东等[12]研究了AZ91D镁合金在半固态触变成形过程中的组织特征与二次凝固行为,提出二次凝固过程包括初生α-Mg相生长阶段,液相内部重新形核并生长成细小的等轴晶阶段和剩余的液相发生共晶反应形成共晶体三个阶段。CHEN等[13]研究AA8006铝合金在吸铸过程中的二次凝固行为,分析得出冷却速率不仅影响一次α(Al)枝晶的凝固,而且影响剩余液相的凝固。

鉴于此,本文作者在前期研究[14-17]的基础上选用A356亚共晶铸造铝合金为研究对象,利用其优良的铸造性能,采用自孕育法制备半固态浆料,结合传统高压压铸成形A356铝合金薄壁圆盘,研究制浆过程中的保温时间对压铸薄壁件最终凝固组织(一次凝固和二次凝固)的影响,并通过对元素、成分及共晶硅片层间距的定量分析系统地阐述流变压铸过程中剩余液相的凝固行为。

1 实验

1) 自孕育剂制备。将商用A356合金(成分见表1)在井式坩埚电阻炉中熔炼,待合金完全熔化后,开始测温。当熔体温度达到720~730 ℃时,用C2Cl6(合金质量的1%(质量分数))进行除气除渣,然后进行扒渣与静置,并对熔体温度进行测定。当熔体温度降至700 ℃时,浇注成d15 mm×150 mm的金属型棒料,加工成5 mm×5 mm×5 mm的小颗粒状的孕育剂,将其表面进行清洗,烘干作为自孕育剂待用。

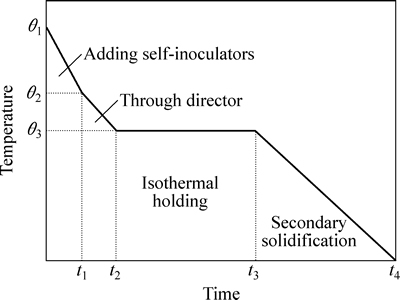

2) 浆料制备及压铸过程。图1为自孕育流变制浆工艺示意图,其中导流器参数为:长度为500 mm,角度为45°。将A356合金按照过程1)重新熔炼并精炼后,控制熔体温度达到680 ℃时,将孕育剂(合金质量的5%(质量分数))加入到A356铝合金熔体中并迅速搅拌,将混合后的熔体经过导流器后收集到浆料收集器,并将制备好的浆料在600 ℃下进行一定时间(0、3、5和10 min)的保温处理,然后用DAK 450-54型压铸机进行后续薄壁件流变压铸实验,压铸件实物图如图2所示。薄壁件圆盘的直径为200 mm,壁厚为2 mm。

3) 组织观察及定量分析。将压铸件进行取样(取样位置见图2),经预磨、抛光后用饱和NaOH溶液腐蚀,进行光学显微镜(MEF-3型)和扫描电镜(FEG450型)组织观察,并作成分分析。利用Image-Pro Plus 5.0软件对组织中的一次初生颗粒和二次颗粒的颗粒尺寸及其形状因子(圆整度)进行测定。利用Pandat软件计算初生颗粒与二次颗粒中的理论硅含量。

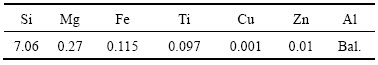

表1 商用A356铝合金成分

Table 1 Chemical composition of commercial A356 alloy (mass fraction, %)

图1 自孕育流变制浆工艺示意图

Fig. 1 Schematic diagram of slurry preparation by self-inoculation method (SIM)

图2 压铸薄壁件及取样位置

Fig. 2 Photo showing die casting component and sampling position

图3 自孕育半固态加工过程中的温度变化示意图

Fig. 3 Schematic diagram of temperature change in semi-solid process by SIM

图3所示为实验过程中温度变化的示意图。当熔体温度达到θ1时,加入孕育剂并进行搅拌,使温度降至θ2,接着过导流器,整个熔体温度降至θ3,在θ3温度下进行特定时间的保温,再进行后续成形(二次凝固)过程。经过多次实验测得,加入孕育剂后平均降温(θ2-θ1)约50 ℃,过导流器后平均降温(θ3-θ2)约30 ℃。

2 实验结果

2.1 A356合金不同成形方式的组织

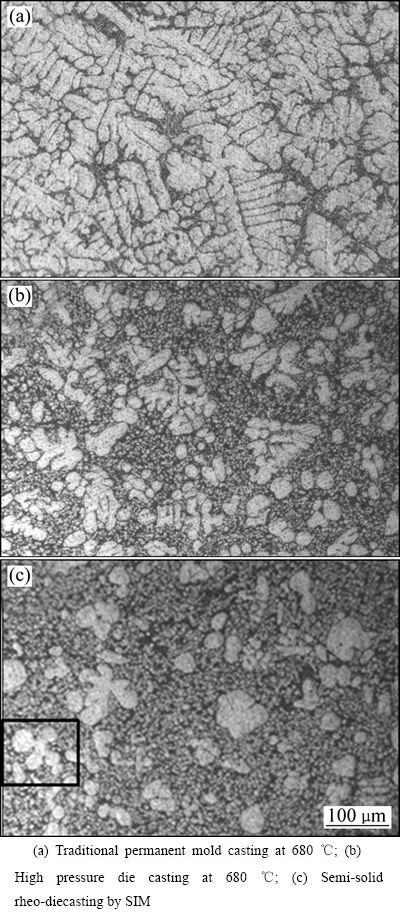

图4 A356铝合金不同成形方式的组织

Fig. 4 The microstructure of A356 alloy in different forming ways

图4所示为A356铝合金在不同成形方式下的组织。可见传统金属型组织多由粗大的树枝晶组成(见图4(a))。而液态压铸A356主要由树枝状初生α(Al)和细小α(Al)激冷晶组成(见图4(b))。液态压铸组织中前者是合金在进入压室时被冲头和压室内壁激冷而形成的,由于较快的冷却速率和不均匀的温度场而导致最终α(Al)长成了树枝晶。后者是充型过程中的液相整体过冷后爆发形核而形成的,冷却速率过快使晶核来不及长大而形成细小的激冷晶。自孕育流变压铸组织(见图4(c))由部分枝晶碎片、近球状晶以及细小的二次α(Al)组成,且枝晶较液态压铸的小,并出现明显的颈缩现象(结构见图4(c)中黑色方框),近一步证实自孕育过程中存在枝晶臂熔断并球化现象。

2.2 保温时间对自孕育流变压铸件初生α(Al)颗粒的影响

图5所示为不同保温时间下自孕育流变压铸组织。由图5可以看出,随着保温时间的延长,初生α-Al(α1)颗粒尺寸逐渐增大,且逐渐圆整化。对其平均晶粒尺寸和颗粒圆整度进行测量得(见图6(a)),在浆料未保温时,压铸件组织中α1颗粒的平均晶粒尺寸为35 μm,相应的颗粒圆整度为1.57;而在保温3 min和5 min时,α1颗粒的平均晶粒尺寸分别为66 μm和81 μm,相应的颗粒圆整度为1.25和1.34;当保温时间达到10 min时,α1颗粒的平均晶粒尺寸增大至104 μm,相应的颗粒圆整度为1.47。由图6(b)的拟合曲线可以看出,保温初期颗粒逐渐长大并圆整化,且其颗粒长大的速率符合Dt3-D03=Kt动力学方程[18](D0为保温初始时刻的初生固相颗粒直径,Dt为保温时间t后的平均颗粒尺寸)。过长的保温时间会使浆料中α1颗粒之间发生合并长大现象而恶化组织。综合分析,适合A356合金半固态流变成形的浆料保温时间为3 min。

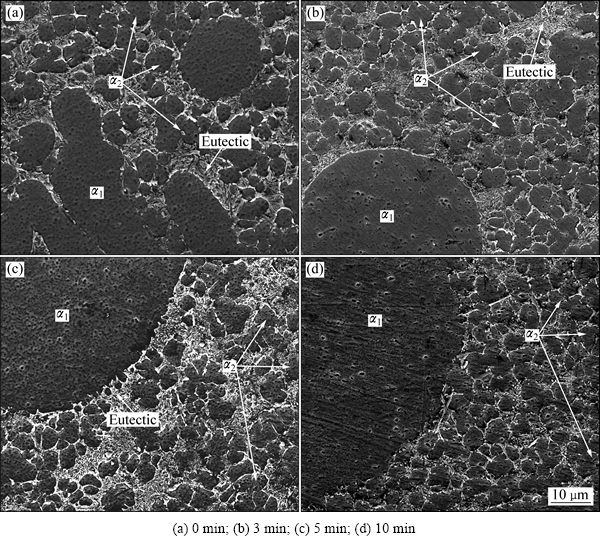

2.3 不同保温时间对二次凝固颗粒的影响

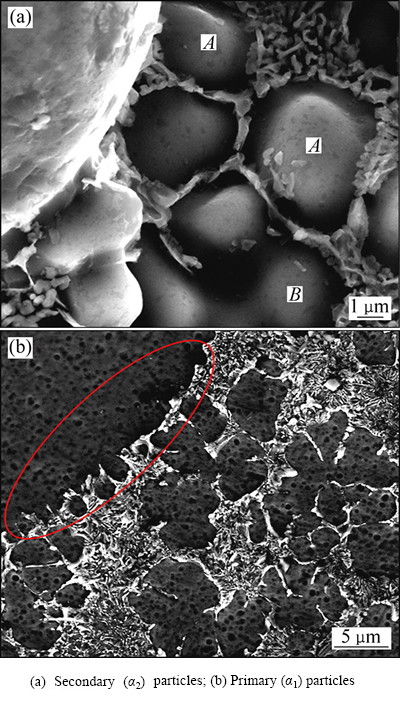

图7所示为不同保温时间后自孕育流变压铸的SEM像。通过观察发现,不同保温时间下α2颗粒的形状均为近球状晶或蔷薇状晶,也就是说,保温时间对压铸薄壁件的二次凝固组织影响不是很大。用Image-Pro Plus 5.0软件对α2颗粒的晶粒尺寸进行了测量(各取50个颗粒)。结果显示,保温0、3、5和10 min时α2颗粒的平均晶粒尺寸分别为6.5、7.0、6.7以及6.8 μm,各参数下二次颗粒的平均尺寸相差不大。对各个保温参数下的二次颗粒尺寸分布进行统计,如图8所示。结果表明,颗粒尺寸5~8 μm范围内的比例均大于50%。同时,从总分布图(见图8(e))也可以看出,二次颗粒的总体分布(200个颗粒)与各个参数下的尺寸分布范围及比例非常相似,尺寸在5~8 μm范围内的颗粒数目占总数的58%,进一步说明二次颗粒尺寸随保温时间的变化不大。对所取200个颗粒进行平均颗粒尺寸计算得,α2颗粒的平均晶粒尺寸为6.6 μm。

图5 不同保温时间下的自孕育流变压铸组织

Fig. 5 Microstructures of rheo-diecasting by SIM under different holding time

图6 初生颗粒尺寸及形状因子随保温时间的变化

Fig. 6 Changes of primary particle size and shape factor with holding time (a) and linear fitting curve (b)

图9所示为α2颗粒在不同尺寸范围内的平均形状因子。由图9可看出,随着α2颗粒尺寸的增大,平均形状因子也增大,说明α2颗粒以稳定的球状生长开始。随着凝固过程的进行,颗粒尺寸增大,失稳现象逐渐显现出来。当α2颗粒尺寸在3~7 μm时,平均形状因子在1.1~1.2范围内,当尺寸大于7 μm时,形状因子大于1.25。为了更清楚地理解凝固过程中二次颗粒的稳定性与形状因子的关系,对图9作平均形状因子对颗粒平均尺寸的微分处理(见图9中曲线所示)。从其微分曲线可以看出,当二次颗粒尺寸小于7 μm时,形状因子变化趋势较缓慢;当二次颗粒尺寸达到8 μm时,形状因子急剧增大,在6~7 μm范围内出现了由缓到陡的转折点。在8 μm以后出现下降趋势是由于较大颗粒的突起在其原有基础上继续长大的速率较慢。由此可知,二次颗粒稳定生长的极限尺寸范围为6~7 μm,对应的形状因子为1.25。

2.4 元素分布

为了进一步说明一次颗粒与二次颗粒的差别,对α1颗粒、α2颗粒以及最终共晶组织进行了成分分析。

图7 不同保温时间下自孕育流变压铸的SEM像

Fig. 7 SEM images of rheo-diecasting by SIM under different holding time

点扫描结果如表2所列(α1、α2的点扫描位置均在颗粒的中心处)。无论保温与否,α1颗粒中的Si含量均为1.1%~1.2%,其余均为Al,而Mg、Cu、Zn的含量均为0。这样的现象同样发生在α2颗粒中,α2颗粒中除了约1.7%的Si外,其余的全是Al。Mg、Cu、Zn元素均分布在最终的共晶组织中。共晶组织中成分的偏差说明溶质元素的分布不均匀,出现偏析。

从图10所示的面分布图中可以看出硅主要分布在晶间白色共晶区域,其余部分分布在α1颗粒和α2颗粒中。镁含量较少,除了在晶内弥散分布外,在晶界附近的共晶区域镁明显富集。而铜与锌由于含量过少而未能检测出来。这与表2所示的点扫描成分相吻合。值得注意的是,α1颗粒和α2颗粒的边缘区域均有溶质元素的富集,而且富集层较为明显。由此可知,剩余液相在凝固过程中α1和α2是同时长大的。对比发现图10(a)中的α1颗粒边缘平滑,无明显的凸起,说明在此条件下α1颗粒凝固时的固液界面是相对稳定的。图10(b)中α1颗粒的边缘有明显的“齿状”(见图10(b)中区域B)和“胞状”(见图10(b)中区域A)凸起,说明该条件下α1颗粒凝固时的固液界面处于失稳状态,在界面前沿出现了“成分过冷”。凸起形貌和尺寸的差异也可说明成分过冷的倾向不同,倾向较大的区域凸起较大(如胞状),倾向较小的区域凸起较小(如齿状)。

2.5 液态压铸与自孕育流变压铸成形件共晶组织

凝固过程中最后发生的是剩余液相中的共晶反应。该反应发生于晶间共晶硅相。由于不规则α-Al-Si共晶体系由小晶面组成,共晶硅通常显示了很强的小晶面行为,使其长成了不规则的薄片状。然而扫描电镜组织显示,液态压铸的共晶硅相为块状(见图11(a));相比之下,自孕育流变压铸的共晶硅相呈发散的纤维状或菊花状(见图11(b))。

3 讨论

3.1 保温过程对α1颗粒的影响

图8 薄壁压铸件α2颗粒尺寸分布图

Fig. 8 Distribution of secondary particle size in thin-walled die-casting

表2 α1颗粒、α2颗粒及共晶组织中的元素含量

Table 2 Element content in α1 and α2 particles and eutectic structure

自孕育流变压铸是自孕育制浆与高压压铸相结合的新型成形方式,而制备出优良的半固态浆料是保证后续压铸过程中得到高质量、高完整性的压铸件的前提。浆料未保温时,熔体内部大多为枝晶碎片和依附高熔点质点长大的颗粒,浆料汇合流入导流器后存在对流,会使枝晶碎片尖角钝化。在保温过程中,对流减弱,熔体成分逐渐均匀。但由于枝晶碎片的存在使界面能增加,在界面能减小的驱动力影响下不规则的枝晶碎片逐渐圆整化,并作为基底吸附更多来自液相的溶质原子。于是随着保温时间的延长,α1颗粒增大,且逐渐圆整(见图5(b))。由于原始枝晶碎片尺寸有大有小,且生长速率不同,导致α1颗粒大小各异。尺寸较小的α1颗粒周围液相溶质浓度较低,而尺寸较大颗粒周围液相溶质浓度较高。随保温时间的进一步延长,Si元素将不断从大颗粒向小颗粒扩散,而Al元素则呈相反的扩散路径。其结果是大颗粒不断长大,小颗粒不断变小,甚至熔化消失,即发生所谓的Ostwald熟化[19]。保温10 min时,出现大量“8”字状或“梭”状初生颗粒的合并组织(见图5(d)),是由于保温后期颗粒与颗粒之间合并长大现象加剧而形成的。当两个尺寸相差较大的颗粒通过合并方式形成新颗粒时,在界面能减少的驱动力下,新颗粒最终会球化;但是当两个尺寸相差不大的颗粒合并成新颗粒时,新颗粒粒很难球化,最终长成“8”字状或“梭”状团簇。根据前期实验研究发现,适合A356铝合金自孕育流变成形的浆料保温时间为3 min,此时α1颗粒尺寸不是很大,圆整度最好。

图9 不同晶粒尺寸对应的平均形状因子

Fig. 9 Average shape factor in different range of grain sizes

图10 A356铝合金压铸组织的元素分布

Fig. 10 Elements distribution diagram of A356 alloy by RDC

图11 共晶组织形貌

Fig. 11 Morphologies of eutectic phase

3.2 薄壁件压铸过程中的二次凝固行为

根据WATERLOO G[20]所述,冷却速率R满足式(1):

(1)

(1)

式中:h为热传导系数;T为熔体浇注温度;T0为模具温度;c为比热容;ρ为密度;z为试样厚度。根据文献[21]所述,铝合金薄壁压铸过程中h可达1.5×104 W·m-2·K-1。而实验中所设模具温度为200 ℃,A356合金密度取2700 kg/m3,比热容为900 J/(kg·K),试样厚度为2 mm,代入式(1)可得冷却速率R达到1×103 K/s。

图12 颗粒的不稳定生长

Fig. 12 Unstable growth of particles

二次凝固开始于浆料移出等温保温炉之后。当浆料倒入压室时,由于压室温度较低(400 ℃),在浆料与压室内壁接触的地方会产生异质形核并迅速长成枝晶。之后浆料射入型腔,在通过内浇口时,枝晶被挤碎,即图5(b)、(c)、(d)中所看到部分枝晶碎片。当剩余液相充填型腔时,其结晶可以分为形核和长大两个过程。在接近α1的地方,液相中析出的Al原子会依附于α1颗粒直接生长。同时,型腔提供的较大的冷却速率(1×103 K/s)使剩余液相中爆发形核,在较大冷却速率下这些核心均能存活下来。随着凝固过程的进行,一次颗粒(α1)和二次颗粒(α2)逐渐长大;α1颗粒作为基底接纳由液相中析出的Al原子继续长大,而爆发形核的核心会稳定生长成球状小颗粒,即为稳定生长过程。随凝固的继续,α2颗粒达到其稳定生长的极限尺寸而失稳生长,加之凝固区域的限制,最终长成近球状颗粒(见图12(a)中A)或合并的“8”字状颗粒(见图12(a)中B);在α2颗粒生长的同时,α1周围的依附生长仍在继续,使界面前沿存在温度的波动,进而使生长中的晶体前沿受到扰动。且随凝固的进行,界面前沿的液相内将形成稳定的溶质富集层,并在晶体前沿造成“成分过冷”区,此时该区域的液相是准稳定态,也就存在着使固液界面扰动得以发展的驱动力。这样,在固液界面凸入液相内的尖端处,液相内的温度梯度会增加,同时,在尖端处合金液相内的溶质浓度梯度也会增加,从而使液相线的梯度也增加,最终使“成分过冷”区得以保存,使最终凝固后α1周围的扰动逐渐长成“胞状”或“齿状”凸起(见图12(b))。但过快的冷却速率使“胞状”或“齿状”凸起未充分长大而保留。尺寸不会超过二次颗粒尺寸。

根据M-S稳定性判据[22],当颗粒尺寸超过了临界值Rc时,熔体中球状晶的生长为不稳定生长,即

(2)

(2)

式中:Tm为熔点;T∞为熔体温度;ΔT为颗粒的过冷度;Ks和Kl分别为液相和固相α(Al)在熔点温度的导热系数;γsl是固液界面能;LV为固体单位体积的熔化潜热。将纯铝的热物理值[11]代入到式(2)中可得

(3)

(3)

可以看出,颗粒保持稳定球状生长的临界半径Rc受凝固过程中过冷度ΔT的影响。根据已有研究[23-24],假设过冷度为1~2 K,在二次凝固中,根据M-S理论,α(Al)球状晶将会稳定生长至直径为5.12~10.24 μm。而本次研究对α2颗粒尺寸和形状因子进行统计的过程中发现,α2颗粒的形状因子小于1.25时对应的颗粒尺寸最大为6.5 μm,表明α2颗粒保持稳态球状生长时的最小过冷度为1.58 K。由图9微分曲线表明,α2颗粒保持稳态球状生长时的临界形状因子为1.25。综合分析可得,α2颗粒保持稳定生长的极限尺寸为6.5 μm,接近实验所测得的α2颗粒平均尺寸(6.6 μm),且该尺寸在图9所得出的二次颗粒稳定生长的极限尺寸范围(6~7 μm)内。由此可以得出,α2颗粒保持稳定生长的极限尺寸为6.5 μm。

3.3 EDS分析

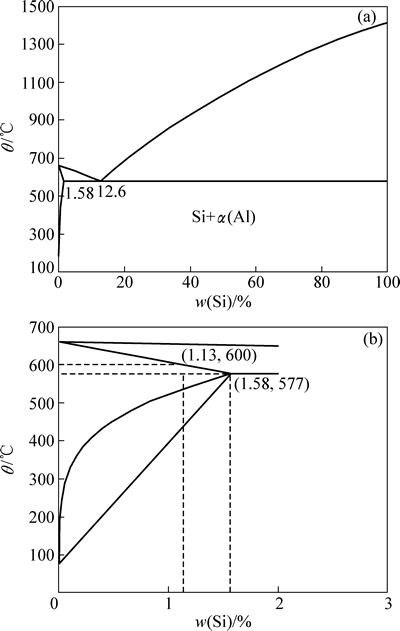

由表2及图10的EDS数据可知:在制浆和压铸成形过程中,只有少量Si固溶于一次颗粒与二次颗粒中,Mg、Cu、Zn元素均富集在共晶区域。由Pandat 热力学计算软件测得A356铝合金在600 ℃时的固相率约为40%。合金中Mg、Cu、Zn元素含量相对过少,可忽略不计。因此,合金中溶质元素为Si,且根据平衡相图及Pandat软件计算出一次颗粒中固溶的Si平均为1.13%(见图13)。则根据质量守恒[25],剩余液相的含量Cl可表示为

(4)

(4)

式中:c0为合金中初始Si含量;cs和f分别为已结晶固相的含量和体积分数。计算得剩余液相中Al含量为89.1%,Si含量为10.9%。也就是说剩余液相的成分靠近共晶成分(12.6%)。实验所得的α1与α2颗粒中Si含量的差别说明一次凝固是在A356合金原始成分中析出α(Al)颗粒的,所以颗粒中固溶的Si较少。而压铸过程中冷却速率较快(1×103 K/s),使界面前方所富集的Si原子由于扩散不及时而固溶于已结晶的二次颗粒中,所以其凝固时析出的二次α(Al)颗粒中的Si含量较一次颗粒中的高,约为1.7%。这一数值与理论计算的Si的饱和固溶度(1.58%)相差不大(见图13)。从图10(a)可以看出,一次颗粒尺寸较二次颗粒大很多,但其溶质富集层厚度相差不大,即可说明一次颗粒周围的溶质富集层是由浆料充型后的二次凝固过程所形成的。也就是说,剩余液相凝固时,依附于一次颗粒生长和液相中二次颗粒重新形核长大是同时进行的。另外,由于Mg、Cu、Zn元素本身含量较少,加之压铸时过快的冷却速率,导致二次颗粒的生长速率较大,剩余液相中析出的Al元素与已结晶的二次颗粒的结合优先于Mg、Cu、Zn元素,将Mg、Cu、Zn元素排挤至液相中。待凝固结束后,Mg、Cu、Zn元素只能在最后的共晶凝固过程中富集到共晶区域。

图13 Al-Si平衡相图中α1与α2颗粒理论Si含量

Fig. 13 Theoretical Si content of α1 and α2 particles in Al-Si equilibrium phase diagram

3.4 共晶硅相的形貌

共晶反应的结束标志着凝固过程完成。硅是小晶面相,Al-Si共晶通常被认为是不规则共晶。铸态组织中共晶硅呈粗大的针片状,会严重影响合金的性能,因此,需要获得细小的共晶硅组织以提高产品的力学性能。通常,将片状共晶硅转变为细小纤维状有两种不同方式:加入合适的元素(化学变质法)或加快冷却速率(物理方法)。本研究中发现,A356中的共晶硅经历了由HPDC试样中的块状到RDC试样中发散菊花状的转变。这种变化主要是由于较高的局部冷却速率所致。 RDC的二次凝固过程中,二次颗粒将剩余液相划分为许多晶间小区域。因此,包括共晶硅在内的共晶反应发生在很小的晶间区域。这时,较高的局部冷却速率能够促进硅形貌的转变。测得RDC中共晶硅相的平均共晶间距λ约为0.57 μm,HPDC中共晶硅间距为1.14 μm。根据Jackson-Hunt共晶生长理论[26],共晶间距λ与生长速度v有如下关系:

(5)

(5)

而在Al-6Si-Al-12Si合金中[27],测得常数为(25.2±3.2) μm2/3s-1/2。根据式(5),共晶硅间距为0.57和1.14分别对应的生长速率为1489 μm/s和372 μm/s。表明RDC局部共晶生长速度是HPDC的4倍,且这两个共晶生长速度远大于测得的发生形态变化的临界速度270 μm/s[28]。因此,共晶硅长成了块状(见图11(a))或菊花状(见图11(b)),而非不规则的针片状。

4 结论

1) 自孕育制浆过程中,保温过程只影响初生α(Al)颗粒,而对A356铝合金薄壁件压铸过程中剩余液相的凝固组织影响不是很大。适合A356铝合金自孕育流变成型的浆料保温时间为3 min。

2) 二次凝固开始于浆料移出等温保温炉之后。当剩余液相充填型腔时,型腔提供的较大的冷却速率使剩余液相中爆发形核,而在接近初生α(Al)的地方,剩余液相中析出的Al原子会依附于初生颗粒生长。

3) 晶核的生长分为稳定生长和失稳生长两个过程。爆发形核的核心先稳定生长成球状小颗粒,稳定生长的极限尺寸为6.5 μm。由于“成分过冷”等因素的存在,α1和α2颗粒最终均出现不稳定生长现象。

4) 由于α1颗粒的存在,剩余液相的成分与原始成分相比靠近共晶成分。同时较快的冷却速率(1×103 K/s)使界面前沿富集的Si原子扩散不及时而固溶于已结晶的二次颗粒中,导致α2颗粒中Si的含量较α1的多。

5) α2颗粒将剩余液相划分为许多晶间小区域,较高的局部冷却速率使共晶硅在较快的生长速率下凝固,并由此长成了细小纤维状或菊花状,而HPDC过程中形成的共晶硅是块状。

REFERENCES

[1] FLEMINGS M C. Behavior of metal alloys in the semi-solid state[J].Metall Trans A, 1991, 22: 957-981.

[2] 罗守靖, 姜永正, 李远发, 单巍巍. 重新认识半固态金属加工技术[J]. 特种铸造及有色合金, 2012, 32(7): 603-607.

LUO Shou-jing, JIANG Yong-zheng, LI Yuan-fa, SHAN Wei-wei. Recognition of semi-solid metal forming technologies[J]. Special Casting and Nonferrous Alloy, 2012, 32(7): 603-607.

[3] ESKIN D G, KATGERMAN S L. Mechanical properties in the semi-solid state and hot tearing of aluminum alloys[J]. Progress in Materials Science, 2004, 49(5): 629-711.

[4] 徐 骏, 张志峰. 半固态加工技术的最新进展[J]. 哈尔滨理工大学学报, 2013, 18(2): 1-6.

XU Jun, ZHANG Zhi-feng. Research progress of semisolid processing technology[J]. Journal of Harbin University of Science and Technology, 2013, 18(2): 1-6.

[5] ZHAO Jun-wen, WU Shu-seng. Microstructure and mechanical properties of rheo-diecasted A390 alloy[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S3): s754-s757.

[6] YUCK J A, MARTINEZ R A, FLEMINGS M C. Development of the semi-solid rheocasting (SSR) process[C]//Proceeding of 7th International Conferences on semi-solid Process of alloys and Composites. Tsukuba, 2002: 659-664.

[7] PAN Q Y, FINDON M, APELIAN D. The continuous rheoconversion process(CRP)[C]//8th International Conference on semi-solid Process of alloys and Composites, Limassol, Cyprus: Metallurgical Science and Technology, 2004: 9-18.

[8] KAUDMANN H, MUNDI A, POTZINGER R, UGGOWIRZER P J, ISHIBASHI N. An update on the new rheo-casting-development work for Al and Mg alloys[J]. Die Casting Engineer, 2002(4): 16-19.

[9] MIDSON S P. Rheocasting processes for semi-solid casting of aluminum alloy[J]. Die Casting Engineer, 2006, 50(1): 48-51.

[10] 李元东, 杨 健, 马 颖, 曲俊峰, 张 鹏. 浇注温度对自孕育铸造法制备 AM60 镁合金半固态浆料的影响(Ⅰ)[J]. 中国有色金属学报, 2010, 20(6): 1046-1052.

LI Yuan-dong, YANG Jian, MA Ying, QU Jun-feng, ZHANG Peng. Effect of pouring temperature on AM60 Mg alloy semi-solid slurry prepared by self-inoculation method (Ⅰ)[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1046-1052.

[11] HITCHCOCK M, WANG Y, FAN Z. Secondary solidification behaviour of the Al-Si-Mg alloy prepared by the rheo-diecasting process[J]. Acta Materialia, 2007, 55(5): 1589-1598.

[12] 李元东, 陈体军, 马 颖, 净峰云, 郝 远. 触变成形AZ91D 镁合金的组织与二次凝固行为[J]. 中国有色金属学报, 2008, 18(1): 18-23.

LI Yuan-dong, CHEN Ti-jun, MA Ying, YAN Feng-yun, HAO Yuan. Microstructural characteristic and secondary solidification behavior of AZ91D alloy prepared by thixoforming[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(1): 18-23.

[13] CHEN Zhong-wei, ZHANG Hai-fang, LEI Yi-min. Secondary solidification behaviour of AA8006 alloy prepared by suction casting[J]. Journal of Material Science and Technology, 2011, 27(9): 769-775.

[14] 李元东, 刘兴海, 李艳磊, 索江龙, 周宏伟, 张心龙. 2024变形铝合金半固态浆料在连续冷却和保温过程中的组织演变[J]. 中国有色金属学报, 2013, 35(1): 44-48.

LI Yuan-dong, LIU Xing-hai, LI Yan-lei, SUO Jiang-long, ZHOU Hong-wei, ZHANG Xin-long. Microstructure evolutions of semisolid slurry of 2024 wrought aluminum alloy during continuous cooling and isothermal holding[J]. The Chinese Journal of Nonferrous Metals, 2013, 35(1): 44-48.

[15] XING Bo, HAO Yuan, LI Yuan-dong, MA Ying, CHEN Ti-jun. Microstructure control of AZ31 alloy by self-inoculation method for semisolid rheocasting[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 567-575.

[16] 李元东, 邢 博, 马 颖, 郝 远. 导流器对自孕育铸造法制备 AM60 镁合金半固态浆料的影响(Ⅲ)[J]. 中国有色金属学报, 2012, 22(1): 22-32.

LI Yuan-dong, XING Bo, MA Ying, HAO Yuan. Effect of cooling channel on AM60 Mg alloy semi-solid slurry prepared by self-inoculation method (Ⅲ)[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(1): 22-32.

[17] LI Yan-lei, LI Yuan-dong, LI Chun, WU Hui-hui. Microstructure characteristics and solidification behavior of wrought aluminum alloy 2024 rheo-diecast with self-inoculation method[J]. China Foundary, 2012, 9(4): 328-336.

[18] MANSON-WHITTON E D, STONE I C, JONES J R, GRANT P S, CANTOR B. Isothermal grain coarsening of spray formed alloys in the semi-solid state[J]. Acta Materialia, 2002, 50: 2517-2535.

[19] VOORHEES P W, HARDY S C. Ostwald ripening in a system with a high volume fraction of coarsening phase[J]. Metallurgical Transactions A, 1988, 19(11): 2713-2721.

[20] WATERLOO G, JONES H. Microstructure and thermal stability of melt-spun A1-Nd and Al-Ce alloy ribbons[J]. Journal of Materials Science, 1996, 31: 2301-2310.

[21] 郭志鹏, 熊守美. 合金材料及工艺参数对压铸过程中铸件/铸型界面换热系数的影响[J]. 金属学报, 2008, 44(4): 433-439.

GUO Zhi-peng, XIONG Shou-mei. Effects of alloy materials and process parameters on the heat transfer coefficient at metal/die interface in high pressure die casting[J]. Acta Metallurgica Sinica, 2008, 44(4): 433-439.

[22] MULLINS W W, SEKERKA R F. Morphological stability of a particle growing by diffusion or heat flow[J]. Appl Phys, 1963, 34(2): 323-329.

[23] BURDEN M H, HUNT J D. Cellular and dendritic growth[J]. Cryst Growth, 1974, 22(2): 109-116.

[24] HUNT J D, LU S Z. Numerical modeling of cellular/dendritic array growth: spacing and structure predictions[J]. Metall Mater Trans A, 1996, 27: 611-623.

[25] YANG W, LIU F, WANG H F, LU B P, YANG G C. Non-equilibrium transformation kinetics and primary grain size distribution in the rapid solidification of Fe-B hypereutectic alloy[J]. Journal of Alloys and Compounds, 2011, 509: 2903-2908.

[26] JACKSON K A, HUNT J D. Lamellar and rod eutectic growth[J]. Transactions of the Metallurgical Society of American Institute of Mining, Metallurgical and Petroleum Engineers, 1966, 236(8): 1129-1142.

[27] GRUGEL R, KURZ W. Growth of interdendritic eutectic in directionally solidified Al-Si alloys[J]. Metall Trans A, 1987, 18: 1137-1142.

[28] BAYRAKTAR Y, LING D, JONES H. Formation and segregation of primary silicon in Bridgman solidified Al-18.3wt% Si alloy[J]. Materials Science, 1995, 30: 5939-5943.

Solidification behavior of A356 aluminum alloy during rheo-diecasting process with self-inoculation method

LI Ming1, LI Yuan-dong1, 2, QIU Jin1, ZHANG Ji-yuan1, BI Guang-li1, 2, MA Ying1, 2

(1. State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals,

Lanzhou University of Technology, Lanzhou 730050, China;

2. Key Laboratory of Non-ferrous Metal Alloys and Processing, Ministry of Education,

Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: The semisolid slurry of A356 aluminum alloy was prepared by self-inoculation method and the solidification behavior of thin-walled component produced by rheo-diecasting was investigated. The results indicate that the isothermal holding process during slurry preparation has great effect on primary α(Al) particles, but has little effect on the microstructure of secondary solidification in the process of thin-walled rheo-diecasting. When the remaining liquid fills die cavity, due to the large cooling rate provided by metallic dies, the nucleation is expected to take place throughout the entire remaining liquid. The growth of nucleus has two stages, nucleus will grow stably into globular particles with the limited grain size of 6.5 μm, then, as the exist of constitutional undercooling, both primary (α1) particles and secondary (α2) particles will appear unstable growth phenomenon. Compared with original composition of alloy, the remaining liquid closes to the eutectic composition due to the existence of α1 particles, which makes the content of Si in α2 particles higher than that in α1 particles. The eutectic reaction is confined to small intergranular areas due to the presence of fine α2 particles. With high local cooling rate, the eutectic silicon will solidify in fine fibrous or chrysanthemum morphology.

Key words: aluminum alloy; semi-solid forming; self-inoculation method; rheo-diecasting; secondary solidification; constitutional undercooling; eutectic silicon

Foundation item: Project(51464031) supported by the National Nature Science Foundation of China

Received date: 2015-09-12; Accepted date: 2016-02-26

Corresponding author: LI Yuan-dong; Tel: +86-931-2976795; E-mail: liyd_lut@163.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51464031)

收稿日期:2015-09-12;修订日期:2016-02-26

通信作者:李元东,教授;电话:0931-2976795;E-mail:liyd lut@163.com