DOI:10.19476/j.ysxb.1004.0609.2019.01.007

高纯钽退火过程中储存能演变及其对再结晶行为的影响

祝佳林1,毛宇成2,刘施峰1,柳亚辉1,林男1,邓超1, 3

(1. 重庆大学 材料与科学工程学院,重庆 400044;

2. 北京航空航天大学 仪器科学与光电工程学院,北京 100191;

3. 重庆大学 电子显微镜中心,重庆 400044)

摘 要:将87%周向轧制钽板分别加热至700、800和900 ℃进行预回复处理,随后,将所有样品在1300℃保温30 min进行再结晶退火处理。应用X射线峰形分析(XLPA)定量计算经不同温度预回复处理后样品1/4厚度层的储存能。此外,利用电子背散射衍射(EBSD)和透射电子显微(TEM)技术表征了预回复和再结晶态样品的微观组织。结果表明:随着预回复温度的升高,一方面,亚晶数目逐渐增加;另一方面,{111}(111//ND(板法向))和{100}(100//ND)取向晶粒内部的储存能明显减小,且两者的比值也逐渐降低。因此,再结晶晶粒尺寸不断减小且晶粒形貌也趋近等轴状。但过高的预回复温度(900 ℃)使后续再结晶组织中出现了较强的{111}织构带,经过800℃预回复处理后的再结晶微观组织相对较为均匀,最有利于钽溅射靶材的应用。

关键词:高纯钽;周向轧制;预回复温度;储存能;微观组织

文章编号:1004-0609(2019)-01-0054-12 中图分类号:TG146.4 文献标志码:A

钽作为一种难熔过渡族稀贵金属,为体心立方(BCC)晶体结构,具有独特的物理与化学性质,如高熔点、高硬度、耐腐蚀以及良好的延展性等[1],因而被广泛地应用于钽电容和溅射靶材等电子工业领域 中[2-3]。在半导体集成电路产业中,为保证溅射薄膜的质量,要求钽靶材平均晶粒尺寸在100 μm以下,晶粒为等轴状且织构随机分布[4]。近年来,有人利用剧烈变形技术(如等径角挤压,高压扭转)对钽板引入整体的剪切应变而获得块体细晶组织[5-6],但此项技术受到样品尺寸的限制,目前,在工业中并不成熟且应用较窄[7]。因此,改善现有加工工艺,尤其是轧制技术及后续的退火制度来优化钽板的变形和再结晶组织和织构就显得尤为重要。

在轧制变形时,不同取向的晶粒由于施密特因子不同造成滑移系开动的难易程度各异,进而导致产生不同的形变亚结构及储存能[8-9]。早期通过对BCC钢铁材料的研究表明,变形储存能的取向相关性存在以下规律[10]:E{110}>E{111}>E{112}>E{100}。RAJMOHAN等[11]和BORBELY等[12]分别利用中子衍射和X射线衍射证实了上述结果。近来,FAN等[7]采用X射线峰形分析(XLPA)发现单轧钽板中心层{111}和{100}取向晶粒的储存能比值为3.1。这种取向相关性导致后续 退火时不同取向之间再结晶驱动力的差异,最终造成退火组织的不均匀。

对于高层错能金属(钽、铝等),位错容易发生攀移及交滑移,所以回复阶段释放了大部分的储存能,甚至高达70%[13-14]。因此,回复对高层错能金属再结晶行为影响较大。预回复处理是指加热温度在再结晶温度以下,它能够在一定程度上释放变形组织内部的储存能,由此,可以弱化这种取向相关性,缩小不同取向晶粒之间的储存能差值,所以理论上可以认为,预回复处理有助于后续获得更为均匀的再结晶微观组织。本文利用X射线峰形分析(XLPA)定量计算87%周向轧制钽板在不同温度预回复后的储存能,并利用电子背散射衍射技术(EBSD)对微观组织进行表征,着重研究预回复对后续钽板再结晶晶粒尺寸、形貌及晶体取向的影响,从而为制备出符合工业需求的高纯钽靶材提供技术指导和理论依据。

1 实验

本实验中所用原料为电子束熔炼法(EBM)制备的钽锭,纯度为99.95%(质量分数),具体化学成分见参考文献[15]。采用上下锻配合左右锻开坯处理后,对其进行真空退火得到完全再结晶组织。之后,将厚度为20 mm的高纯钽进行16道次周向轧制(后一道次轧向相对于前一道次轧向绕板法向逆时针旋转135°),轧制后的板材最终厚度为2.6 mm(压下量87%)。最后,从轧制钽板上切取长宽为12 mm×10 mm的试样(长边为轧制方向)。

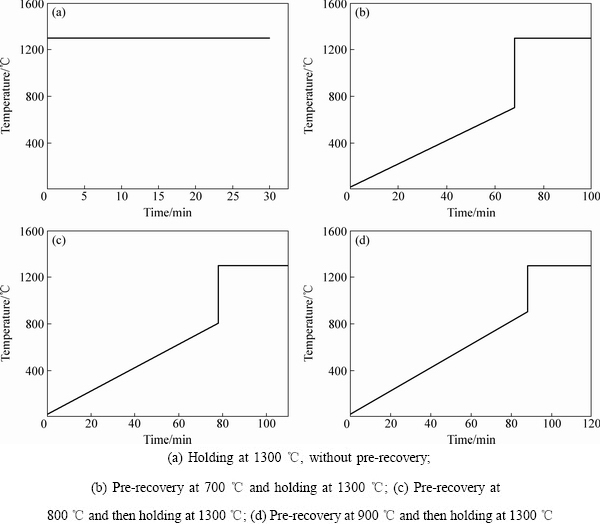

选用真空管式炉对试样进行退火处理,预回复温度设定为700、800和900 ℃,选择10 ℃/min的升温速率,退火过程中通入高纯氩气以防止高温氧化。室温时(20 ℃)将周向轧制87%的样品放入管式炉中,待升到预设定的温度后将样品迅速取出并放入冷水中淬火处理,最后将未经预回复处理以及经不同制度预回复处理后的样品在1300 ℃下保温30 min,得到完全再结晶组织,具体工艺见图1。

利用EBSD技术对轧制、预回复及再结晶样品的微观组织进行了表征,测试在配有EBSD探头的TESCAN MIRA3场发射扫描电镜上进行。观察面为样品侧面(TD面),检测区域靠近1/4厚度区域。用于EBSD测试的样品按以下方法进行处理:对样品表面进行电解抛光处理,抛光液为浓硫酸和氢氟酸的混合溶液 (其体积比9:1),钽和石墨片分别为电解材料的阳极和阴极,电流控制在0.1 A/cm2附近。

X射线峰形分析在Rigaku D/max 2500PC型衍射仪上执行,工作电压和电流分别为40 kV和150 mA。检测面为轧面(ND面)并靠近样品1/4厚度区域。采用步进扫描记录(200)和(222)晶面衍射峰,步长为0.01°,每步停留1 s,通过JADE 7.0将所得衍射峰进行背底和仪器校正,获得衍射峰宽化数据,在此基础上对不同取向晶粒的储存能进行了分析。

图1 87%周向轧制钽板的预回复及再结晶退火工艺制度图

Fig. 1 Sketch maps of pre-recovery and recrystallization annealing processes for clock-rolled tantalum plate of 87% thickness reduction

利用TEM表征轧制及预回复样品的亚结构,检测面为样品侧面(RD-ND面),双喷液为体积比94:5:1的甲醇、硫酸和氢氟酸混合液,电解电压为20kV,温度为-30 ℃。实验在JEOL JEM-2100型透射电镜上进行,操作电压为200 kV。

2 实验结果

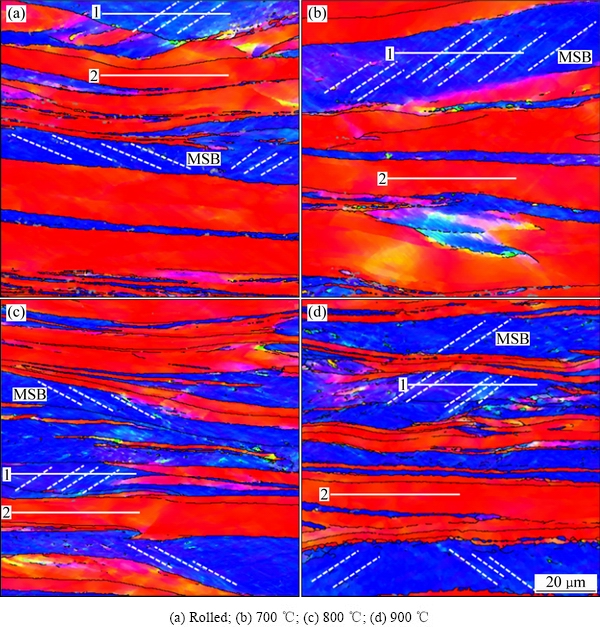

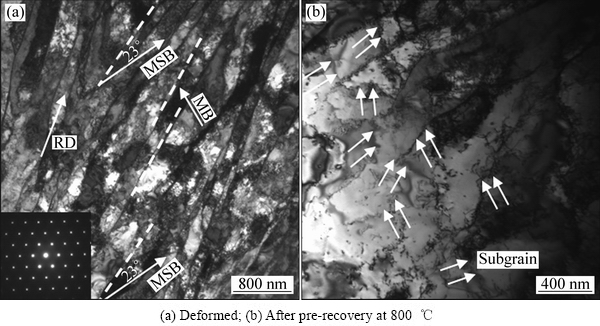

图2(a)所示为周向轧制87%形变量钽板的微观组织图,图2(b)~(d)所示分别为其在室温下随炉升温至700、800和900 ℃后的取向成像图。可以看出,经过不同温度预回复后的微观组织在微米尺度并没有发生明显的变化,仍然由{111}和{100}取向纤维组成,同时晶粒沿轧制方向拉长,而并没有看到明显的再结晶晶核。可以看出,{111}取向(蓝色)变形晶粒内部存在大量平行排列的微剪切带(MSB,图中白色虚线标记),与RD方向大致成23°夹角,微剪切带趋向于{110}取向(110//ND);而{100}取向(红色)晶粒内部未出现微剪切带。{111}取向变形晶粒内部的微剪切带是由于{111}晶粒的严重变形而导致,而{100}晶粒变形相对较难,未出现这种局部的严重变形组织。这主要是由于{100}取向晶粒具有较低且均匀的施密特因子,不利于单系滑移的开动[16]。早期SANDIM等[17-18]对粗晶钽的EBSD表征发现{100}取向的晶粒为稳定取向,在轧制变形中主要产生小角晶界的等轴位错胞结构。因此,这种变形行为的取向相关性将导致{111}和{100}变形晶粒内部显著的储存能差异,这在后续的结果中得到了证实。

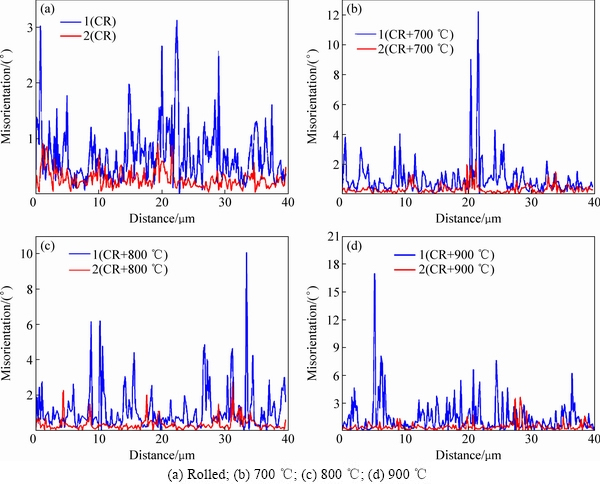

图3所示分别为{111}和{100}取向晶粒内部的相邻取向差(p-p)分布图,其中数字1和2分别代表{111}和{100}取向晶粒。从图3中p-p曲线可以看出{111}取向晶粒内部的分裂程度明显要大于{100}的;其次,对经过不同预回复程度的{111}和{100}晶粒内部取向差统计发现,未经过和经过700、800和900 ℃预回复处理后的{100}晶粒内部的平均取向差分别为0.274°、0.349°、0.407°和0.488°;而{111}晶粒内部的平均取向差分别为0.703°、0.989°、1.272°和1.409°,由于预回复时间有限导致回复程度并不均匀,某些局部区域依然呈现不规律性。

图2 87%变形量周向轧制钽板不同温度预回复后的取向成像图

Fig. 2 Orientation distribution maps of 87% clock-rolled tantalum plate after pre-recovery at different temperatures

图3 {111}和{100}取向晶粒经不同温度预回复后的线扫描相邻点之间的取向差(p-p)分布图

Fig. 3 Misorientation profiles of point-to-point (p-p) of different orientation grains along scanning lines after pre-recovery at different temperatures

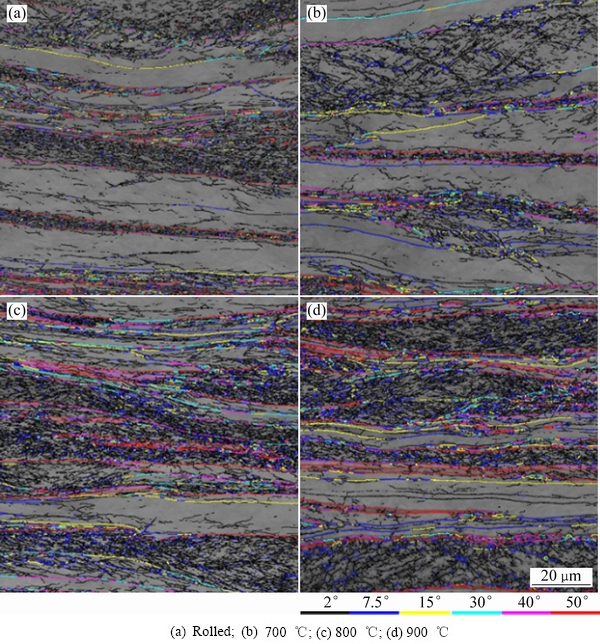

图4 不同温度预回复后的晶界演变图

Fig. 4 Grain-boundary evolutions maps of specimens after pre-recovery at different temperatures

图4所示分别为轧制态、700、800和900 ℃预回复后的晶界演变图。定义取向差大于2°、小于7.5°的为亚晶界,用黑色标记;取向差大于7.5°、小于15°的为亚晶粗化,用蓝色标记;取向差大于15°的是大角度晶界。其中大角度晶界又分为4个等级,如图4中颜色标尺所示。随着预回复温度的升高,晶粒内部的亚晶界明显增多且亚晶粗化程度也越加明显,即蓝色晶界逐渐增加。同时,随着预回复的进行,小角度晶界也逐渐向大角度晶界演变且大于15°的大角度晶界随着预回复温度的升高也有所增加,如图4所示。

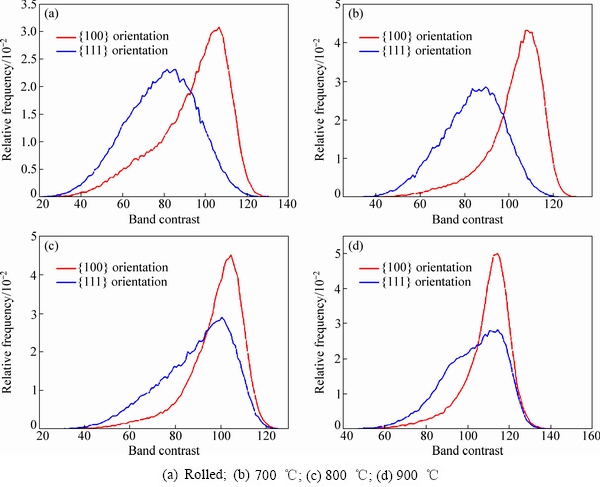

图5所示分别为轧制态、700、800和900 ℃预回复后的{111}和{100}晶粒的衬度分布图。由于花样质量与晶格畸变的数量密切相关,而晶格畸变反应了材料内部位错和内应力的情况。当材料应变越小时,位错密度越低,晶格畸变数量越少时,样品的EBSD花样质量越高[16]。即储存能(ES)与花样质量具有反比关系,利用式(1)可以对不同取向的储存能进行半定量分析[20]:

(1)

(1)

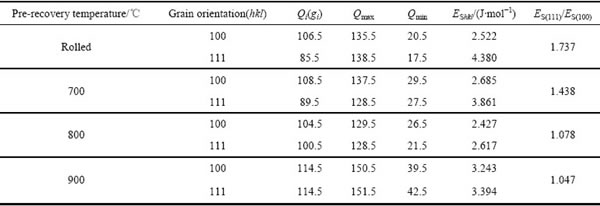

式中:Qi为扫描位置i取向的花样质量;Qmax和Qmin分别为扫描区域内花样质量的最大值和最小值,计算结果见表1。

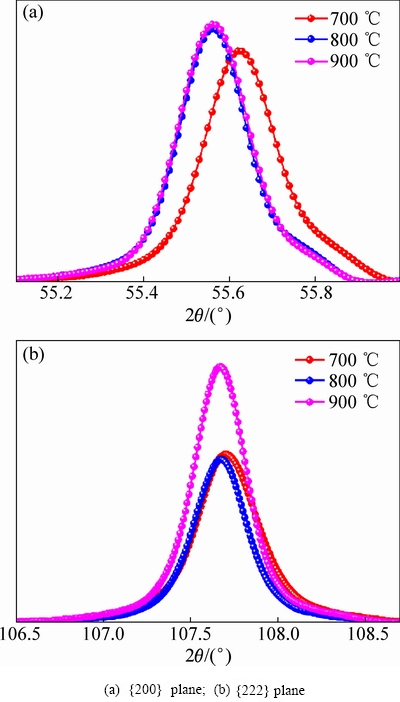

图6(a)和(b)所示分别为在不同温度预回复下钽板{200}和{222}晶面的XRD谱。700和800 ℃预回复后的{200}和{222}衍射峰都向右发生了一定程度的偏移,其中700 ℃预回复下的{200}衍射峰向右偏移的最为剧烈,这主要是由钽板中的残余应力所导致的。近年来,人们通过X射线峰形分析(XLPA)定量评估不同取向晶粒的储存能。例如,RAJMOHAN等[11]利用Stibitz公式估算了冷轧钢中取向相关的储存能(EShkl):

(2)

(2)

式中:θ为衍射面对应的布拉格角;Yhkl和Vhkl分别为沿(hkl)晶向的弹性模量和泊松比;Br和Ba分别为变形和完全退火样品的X射线衍射峰半高宽值。

图5 不同温度预回复后的{111}与{100}取向晶粒的衬度分布图

Fig. 5 Band contrast distribution maps of {111} and {100} orientation grain after pre-recovery at different temperature

表1 通过花样质量评估87%周向轧制钽板在经过不同预回复温度后的储存能

Table 1 Orientation-related stored energy by band contrast after 87% clock-rolled tantalum plate at different pre-recovery temperatures

图6 不同温度预回复后测定的(200)和(222)衍射峰

Fig. 6 Fitted (200) and (222) diffraction peaks after pre-recovery at different temperatures

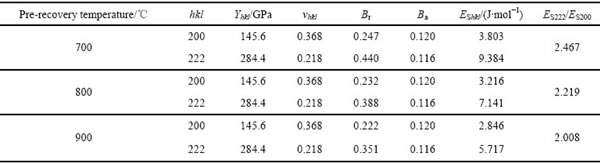

类似地,采用上述方法定量计算不同温度(700、800和900 ℃)预回复处理后高纯钽中{111}和{100}取向晶粒的储存能,计算结果如表2所示。从表2可以看出,经900 ℃预回复处理后的{111}和{100}取向晶粒的储存能最小,分别为5.717和2.846 J/mol,两者的比值也达到最小值。需要注意的是,XRD和EBSD测得的储存能在数值上存在一些偏差,这主要是由于XRD定量的反映宏观储存能,而EBSD则半定量的反映微观储存能的大小(此处“宏观”代表XRD检测的整个样品轧面,“微观”则代表EBSD检测的特定区域)。

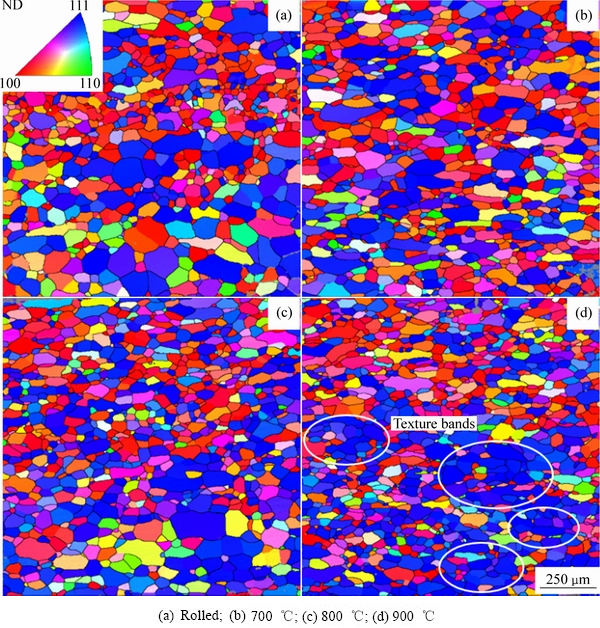

图7所示分别为轧制态以及700、800和900 ℃预回复后在1300 ℃退火30 min完全再结晶样品的取向成像图(OIM)。由图7可以发现,未经预回复处理样品的再结晶晶粒尺寸并不均匀,且{111}取向晶粒尺寸明显大于{100}取向晶粒,而经过不同温度预回复后的再结晶晶粒尺寸更加细小、均匀。值得注意的是,经900 ℃预回复处理样品完全再结晶后形成了明显的{111}织构带(织构带是指局部区域相同取向的晶粒发生了聚集,如图7(d)中白色椭圆区域,多个{111}取向晶粒在局部区域聚集,即形成了{111}织构带)。而经800 ℃预回复处理后,其晶粒取向及尺寸分布相对较为均匀。

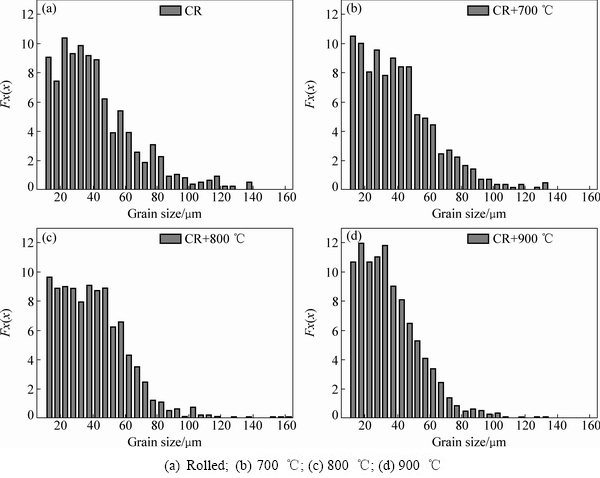

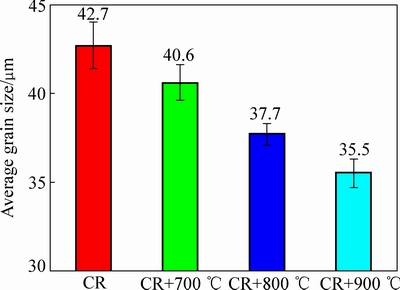

图8所示为经过不同温度预回复后在1300 ℃退火30min的晶粒尺寸分布图,图9所示为相对应的平均晶粒尺寸分布图。可以看出,直接在1300 ℃退火30 min后的再结晶晶粒尺寸分布较不均匀,存在较多的粗大晶粒,100 μm以上的晶粒所占比例达3.7%,而经过不同温度预回复后的晶粒尺寸分布较为均一,100 μm以上的晶粒尺寸数目相对较少。进一步统计表明未经预回复而直接在1300 ℃退火30 min的平均晶粒尺寸最大,为42.7 μm,而经700、800和900 ℃预回复处理后的平均再结晶晶粒尺寸分别为40.6、37.7和35.5 μm。可见,随着预回复温度的升高,再结晶晶粒尺寸逐渐减小。

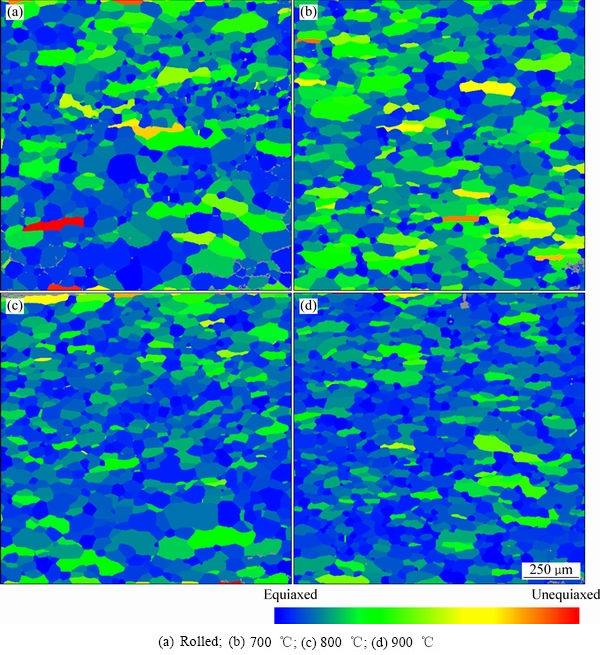

图10(a)~(d)分别为轧制态,700、800和900 ℃预回复后在1300 ℃退火30 min后的晶粒形状因子分布图。需要注意的是,由于这些晶粒形貌的不完整,上图边沿部分并没有纳入统计。进一步统计表明未经预回复和经700、800和900 ℃预回复处理后平均晶粒形状因子分别为2.15、2.02、1.67和1.61。当晶粒形状因子越接近1时,晶粒的等轴性越好,因此,未经预回复处理和只经700 ℃预回复处理后的再结晶晶粒的等轴性较差,而经800 ℃和900 ℃预回复后的晶粒形貌基本呈等轴状。

图7 不同温度预回复后在1300 ℃退火30 min的完全再结晶取向分布图

Fig. 7 Fully recrystallized orientation distribution maps at 1300 ℃ for 30 min with different pre-recovery temperatures

表2 XLPA定量计算87%周向轧制钽板在不同预回复温度后的储存能

Table 2 Orientation-related stored energy by XLPA after 87% clock-rolled tantalum plate at different pre-recovery temperatures

图11(a)和(b)所示分别为87%周向轧制钽板变形态及经800 ℃预回复处理后的显微结构。从图中可以看出,{111}变形晶粒内部存在大量的微带(MB)及微剪带(MSB),和轧制方向大致成23°夹角,与图2基本吻合。经过800 ℃预回复后,位错通过滑移和攀移而发生湮灭,如图11(b)白色箭头所示,导致位错密度不断降低,最终形成清晰的亚晶界和形貌规整的亚晶。

图8 不同温度预回复后在1300 ℃退火30 min晶粒尺寸分布图

Fig. 8 Grain size distribution maps annealed at 1300 ℃ for 30 min with different pre-recovery temperatures

图9 经过不同温度预回复后在1300 ℃退火30 min后的平均晶粒尺寸分布图

Fig. 9 Average grain size profiles annealed at 1300 ℃ for 30 min with different pre-recovery temperatures

3 讨论

3.1 预回复对纯钽形核机制的影响

亚晶形核和大角度晶界迁移形核机制是退火过程中主要发生的两种形核机制。低温退火时,大角度晶界不容易开动,此时亚晶形核机制发挥着主要作用。亚晶形核又可以分成亚晶界迁移形核和亚晶合并形核,亚晶界迁移形核是通过某些局部密度很高的亚晶界的迁移、吞并相邻的变形基体而成为再结晶晶核,而亚晶合并形核主要是指相邻的不同取向的两个亚晶粒在退火过程中取向逐步偏转,最后趋于一致形成一个大晶粒的过程。大角度晶界形核主要是通过大角度晶界的迁移弓出形成新的无畸变的晶粒,高温时,大角度晶界运动速度快,迅速吞并形变亚结构而形成新晶粒。早期通过DSC测试发现87%周向轧制钽板的回复温度在900 ℃以下[13]。图2中并没有出现再结晶晶核,仍然由长条的形变组织构成,可见900℃尚未达到再结晶温度,依然处于回复状态。通过线扫描发现晶粒内部平均取向差角随着预回复温度的升高而增大,这主要是随着退火温度升高,位错运动迁移的能力不断提高并且亚晶通过各种作用合并、长大,导致亚晶界位相差的增大,最终构成大角度晶界。即图5中蓝色晶界(7.5°~15°)随着预回复温度的升高而逐渐增加,同时大角度晶界(>15°)的比例也在一定程度上有所提高。预回复过程中一方面位错通过滑移和攀移生成了亚晶(见图11(b)),进而导致后续再结晶由亚晶形核机制主导;另一方面,{111}和{100}取向晶粒的储存能差异也逐渐减小,使得后续的再结晶晶粒尺寸均匀性较好。然而,不经预回复处理时,大角度晶界形核机制发挥主要作用。后续晶核的生成速度与周围变形基体的取向密切相关,晶核向具有高储存能的{111}变形晶粒内生长较快,而向{100}变形晶粒内生长较慢,因而导致最终再结晶晶粒的均匀性及等轴性较差。

图10 不同预回复温度后在1300 ℃退火30 min晶粒形状因子分布图

Fig. 10 Maps of aspect ratio of grain annealed at 1300℃ for 30 min with different pre-recovery temperatures

图11 87%周向轧制钽板(a)变形态及(b)经800 ℃预回复处理后的显微结构

Fig. 11 Microstructures of 87% clock rolled tantalum plate

3.2 预回复对储存能的影响

回复过程中点缺陷不断减少,位错通过滑移和攀移发生湮灭及重组。回复和再结晶的驱动力是形变金属内部储存能的释放。对铜、铁等金属研究发现,退火时,储存能的释放主要由再结晶完成,而钽的层错能较高(220 mJ/m2)[21],其扩展位错宽度小,位错容易进行攀移,因此回复释放出绝大多数的储存能[1, 22]。DENG等[13]对87%形变钽板的DSC曲线计算发现,其回复过程中释放的储存能占了总量的70%。通过对比不同回复程度下{111}和{100}取向晶粒的花样质量分布图,发现随着预回复温度的升高,两者储存能的比值逐渐减小。这主要是回复阶段所释放的储存能与晶体取向密切相关,早期通过对体心立方结构的低碳钢研究发现,储存能较大的区域在回复阶段将以较快的速度释放储存能[23-24]。SRINIVASAN等[25]发现{111}和{100}取向单晶铌经历充分回复后,它们之间的硬度差由回复前的40%缩小到20%,而硬度值与储存能具有正比关系。因此,随着回复的进行,{111}取向晶粒必然比{100}取向晶粒释放出更多的储存能,从而导致两者的储存能逐渐接近。结合表2中X射线峰形分析可看出,随着预回复温度的升高,一方面,晶粒内部的储存能得到不断的释放;另一方面,{111}和{100}取向晶粒之间储存能的差别也逐渐减小。

3.3 预回复对再结晶晶粒尺寸及形貌的影响

3.3.1 预回复对晶粒尺寸的影响

低温退火时,亚晶形核扮演着主要作用。随着预回复温度的升高,亚晶粒数目逐渐增加并且先形成的亚晶继续长大成为有效晶核。经预回复处理后的形变钽板释放出大量的储存能,{111}与{100}变形晶粒内的储存能差异显著减小,当后续在1300 ℃退火时,晶核向周围形变基体生长的速度也较为均匀,使得最终的再结晶晶粒尺寸也更为均匀。同时,储存能的释放使得晶粒长大的驱动力逐渐减小,这有效地降低了晶粒的长大速率,导致再结晶晶粒尺寸随着预回复温度的升高而逐渐减小。而未经预回复处理的形变钽板内部储存能含量高,大角度晶界有足够的动力产生迁移。由于退火温度高,大角度晶界迁移速度较快,晶粒生长较快,进而形成尺寸较大的晶粒。值得注意的是,900 ℃预回复温度相对较高且时间较长,{111}基体内部中形成了大量的{111}亚晶,所以在高温退火时容易形成{111}晶粒的聚集,即{111}织构带,如图7(d)所示。

3.3.2 预回复对晶粒形貌的影响

形状因子定义为能够最好拟合某晶粒形貌的椭圆长轴与短轴之比;当晶粒形状越等轴,其相应的形状因子越接近于1。实验和模拟结果均表明[26-27],如果两相邻两晶粒的储存能差别较大时,其晶界处的晶核容易长成长条状。FAN等[28]近来研究发现,形变钽板在长时间的低温退火后有利于等轴晶粒的形成。从图2中可以看出,周轧87%钽板{111}和{100}取向晶粒交替分布,而储存能具有明显的取向相关性,预回复有效地降低了这两者取向之间的储存能差,使得储存能分布更加均匀,因此再结晶晶粒更趋近于等轴状。同时,前期预回复处理引入的亚晶对后续等轴状晶粒的生成也有一定的作用。

4 结论

1) 周向轧制87%钽板中{111}取向变形晶粒内部存在较多的微剪切带,而{100}晶粒内部并未出现这种局部的严重变形组织。这种变形行为的取向相关性导致{111}和{100}变形晶粒内部显著的储存能差异。

2) 经预回复处理后,形变基体内生成了大量的亚晶,进而导致后续的再结晶由亚晶形核机制主导,这有利于最终再结晶晶粒尺寸更为均匀。

3) X射线峰形分析及EBSD花样衬度图结果表明,{111}与{100}取向晶粒内部的储存能差异随着预回复温度的升高明显减小,这有效地降低了后续晶粒长大驱动力,同时由于回复有助于亚晶的生成,随着预回复温度的升高,亚晶数目逐渐增加,因此,再结晶晶粒尺寸逐渐减小。

4) 经过800 ℃预回复处理后的再结晶晶粒较为均匀且无明显的{111}织构带的生成,同时晶粒形貌也较为均衡,主要呈等轴状。

REFERENCES

[1] 张行健, 姜国圣, 王志法. 钽的加工硬化速率及其显微组织[J]. 中国有色金属学报, 2006, 16(3): 442-446.

ZHANG Xing jian, JIANG Guo sheng, WANG Zhi fa. Work hardening rate and microstructure of tantalum[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(3): 442-446.

[2] MICHALUK C A. Correlating discrete orientation and grain size to the sputter deposition properties of tantalum[J]. Journal of Electronic Materials, 2002, 31(1): 2-9.

[3] 何季麟. 钽铌电子材料新进展(Ⅱ)[J]. 中国有色金属学报, 2004, 14(S1): 291-300.

HE Ji-lin. New development of tantalum and niobium electronic materials[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(S1): 291-300.

[4] LI Zhao-bo, ZHANG Chun-heng, LI Gui-peng, Tong Lei. Research on grain size controlling process of niobium target used for sputtering and coating[J]. Development & Application of Materials, 2010.

[5] MATHAUDHU S N, HARTWIG K T. Grain refinement and recrystallization of heavily worked tantalum[J]. Materials Science and Engineering A, 2006, 426(1): 128-142.

[6] MATHAUDHU S N, BARBER R E, HARTWIG K T. Microstructural refinement of tantalum for Nb/sub 3/Sn superconductor diffusion barriers[J]. IEEE Transactions on Applied Superconductivity, 2005, 15(2): 3434-3437.

[7] FAN Hai-yang, LIU Shi-feng, LI Li-juan, DENG Chao, LIU Qing. Largely alleviating the orientation dependence by sequentially changing strain paths[J]. Materials & Design, 2016, 97: 464-472.

[8] HUANG X, HANSEN N. Grain orientation dependence of microstructure in aluminium deformed in tension[J]. Scripta Materialia, 1997, 37(1): 1-7.

[9] PEETERS B, BACROIX B, TEODOSIU C, HOUTTE P V, AERNOUDT E. Work-hardening/softening behavior of b.c.c. polycrystals during changing strain[J]. Acta Materialia, 2001, 49(9): 1621-1632.

[10] SEVILLANO J G, HOUTTE P V, AERNOUDT E. Inhomogeneity in the stored energy of deformed BCC-metals[J]. Scripta Metallurgica, 1976, 10(8): 775-778.

[11] RAJMOHAN N, HAYAKAWA Y, SZPUNAR J A, ROOT J H. Neutron diffraction method for stored energy measurement in interstitial free steel[J]. Acta Materialia, 1997, 45(6): 2485-2494.

[12] BORéBLY A, DRIVER J H. X-ray diffraction analysis of intergranular strains in cold-rolled ultra high purity iron[J]. Materials Science and Engineering A, 2004, 387(1): 231-234.

[13] DENG Chao, LIU Shi-feng, HAO Xiao-bo, JI Jing-li, ZHANG Zhi-qing, LIU Qing. Orientation dependence of stored energy release and microstructure evolution in cold rolled tantalum[J]. International Journal of Refractory Metals & Hard Materials, 2014, 46(3): 24-29.

[14] 张新明, 袁 韧, 周卓平. 硅元素对钽丝再结晶行为的影响[J]. 中国有色金属学报, 2002, 12(6): 1104-1108.

ZHANG Xin-ming, YUAN Ren, ZHOU Zhuo-ping. Effects of silicon on recrystallization behavior of tantalum wires during annealing[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1104-1108.

[15] LIU Shi-feng, FAN Hai-yang, DENG Chao, HAO Xiao-bo, GUO Yu, LIU Qing. Through-thickness texture in clock-rolled tantalum plate[J]. International Journal of Refractory Metals & Hard Materials, 2015, 48: 194-200.

[16] LIU Ya-hui, LIU Shi-feng, ZHU Jia-lin, DENG Chao, FAN Hai-yang, CAO Lin-fei, LIU Qing. Strain path dependence of microstructure and annealing behavior in high purity tantalum[J]. Materials Science & Engineering A, 2017: 707.

[17] SANDIM H R Z, MARTINS J P, PADILHA A F. Orientation effects during grain subdivision and subsequent annealing in coarse-grained tantalum[J]. Scripta Materialia, 2001, 45(6): 733-738.

[18] SANDIM H R Z, PADILHA A F, RANDLE V, BLUM W. Grain subdivision and recrystallization in oligocrystalline tantalum during cold swaging and subsequent annealing[J]. International Journal of Refractory Metals & Hard Materials, 1999, 17(6): 431-435.

[19] WILKINSON A J, DINGLEY D J. Quantitative deformation studies using electron back scatter patterns[J]. Acta Metallurgica Et Materialia, 1991, 39(12): 3047-3055.

[20] CHOI S H. Monte carlo technique for simulation of recrystallization texture in interstitial free steels[J]. Materials Science Forum, 2002, 408/412: 469-474.

[21] PEGEL B. Stacking faults on {110 planes in the B.C.C. lattice[J]. Physica Status Solidi, 1968, 28(2): 603-609.

[22] HUMPHREYS F J, HATHERLY M. Recrystallization and Related Annealing Phenomena[M]. 2nd ed. Netherlands: Elsevier, 2004: 219-224.

[23] EVERY R L, HATHERLY M. Oriented nucleation in low-carbon steels[J]. Texture, 1974, 1(3): 233-243.

[24] MARTiNEZ-DE-GUERENU A, ARIZTI F, DiAZ-FUENTES M, GUTIeRREZ I. Recovery during annealing in a cold rolled low carbon steel. Part I: Kinetics and microstructural characterization[J]. Acta Materialia, 2004, 52(12): 3657-3664.

[25] SRINIVASAN R, VISWANATHAN G B, LEVIT V I, FRASER H L. Orientation effect on recovery and recrystallization of cold rolled niobium single crystals[J]. Materials Science and Engineering A, 2009, 507(1/2): 179-189.

[26] OKUDA K, ROLLETT A D. Monte Carlo simulation of elongated recrystallized grains in steels[J]. Computational Materials Science, 2005, 34(3): 264-273.

[27] SINCLAIR C W, MITHIEUX J D, SCHMITT J H, BReCHET Y. Recrystallization of stabilized ferritic stainless steel sheet[J]. Metallurgical & Materials Transactions A, 2005, 36(11): 3205-3215.

[28] FAN Hai-yang, LIU Shi-feng, DENG Chao, WU Xue-dong, CAO Lin-fei, LIU qing. Quantitative analysis: How annealing temperature influences recrystallization texture and grain shape in tantalum[J]. International Journal of Refractory Metals & Hard Materials, 2018, 72: 244-252.

Stored energy evolution of high-purity tantalum during annealing and its effect on recrystallization behavior

ZHU Jia-lin1, MAO Yu-cheng2, LIU Shi-feng1, LIU Ya-hui1, LIN Nan1, DENG Chao1, 3

(1. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. School of Instrument Science and Opto-electronics, Beihang University, Beijing 100191, China;

3. Electron Microscopy Center of Chongqing University, Chongqing University, Chongqing 400044, China)

Abstract: High-purity tantalum plates were clock rolled to 87% reduction in thickness. Then, the samples were heated up to 700, 800 and 900 ℃ in the furnace, respectively, and were all annealed at 1300 ℃ for 30 min to get the recrystallization microstructure. X-ray line profile analysis (XLPA) was adopted to quantify the bulk stored energy of a quarter of the thickness of tantalum plates at different pre-recovery temperatures, combing with the electron back-scattered diffraction (EBSD) and transmission electron microscopy (TEM) to characterize the pre-recovery and recrystallization microstructure. The results show that the number of subgrains increases gradually with the increase of pre-recovery temperature and the stored energy gap of {111} ([111]//ND, ND is normal direction) and {100} ([100]//ND) orientation grain decreased obviously, which effectively reduces the subsequent driving force of recrystallization. Therefore, the recrystallization grain size gradually decreases and the grain morphology is close to be equiaxed. However, the high pre-recovery temperature (900 ℃) leads to a strong {111} texture bands in recrystallization microstructure, while the recrystallization microstructure is relatively uniform through pre-recovering of 800 ℃, which is beneficial to the application of tantalum sputtering target.

Key words: high-purity tantalum; clock rolled; pre-recovery temperature; stored energy; microstructure

Foundation item: Projects(51421001, 51701032) supported by the National Natural Science Foundation of China; Project(cstc2017jcyjAX0094) supported by Chongqing Research Program of Basic Research and Frontier Technology, China

Received date: 2018-05-30; Accepted date: 2018-08-28

Corresponding author: LIU Shi-feng; Tel: +86-13883433048; E-mail: liusf06@cqu.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51421001,51701032);重庆市基础科学与前沿技术研究项目(cstc2017jcyjAX0094)

收稿日期:2018-05-30;修订日期:2018-08-28

通信作者:刘施峰,副教授,博士;电话:13883433048,E-mail:liusf06@cqu.edu.cn